| Description | Standard | Grade |

| Carbon Steel Seamless Pipe/Alloy Steel Seamless Pipe | API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70,etc |

| ASTM A53 | GR.A ,GR.B | |

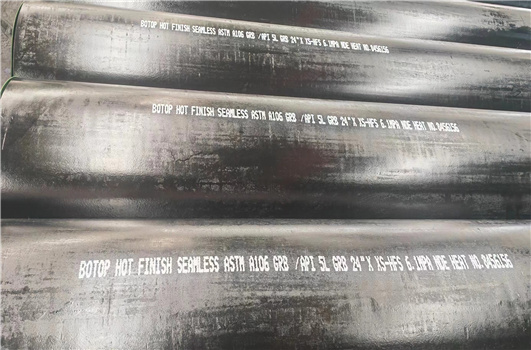

| ASTM A106 | GR.A ,GR.B,GR.C | |

| API 5CT | J55,K55,N80,L80,P110 ,etc | |

| ASTM A179 | A179 | |

| ASTM A192 | A192 | |

| ASTM A210/SA210 | GR.A-1,GR.C | |

| ASTM A252 | GR.1, GR.2,GR.3 | |

| BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H,etc | |

| JIS G3454 | STPG370,STPG410 | |

| DIN2391 | ST35,ST37,ST37.4,ST45,ST52,ST52.4 | |

| DIN1629 | ST37,ST44,ST52 | |

| JIS G3456 | STPG370,STPG410,STPG480 | |

| ASTM A213 | GR.T11 ,GR.T12,GR.T13 | |

| ASTM A519 | GR.1020,GR.1026,GR.1045,GR.4130,etc | |

| ASTM A335 | GR.P9,GR.P11,GR.P5,GR.P22,GR.P91,etc | |

| ASTM A333 | GR.1, GR.3,GR.4,GR.6,etc |

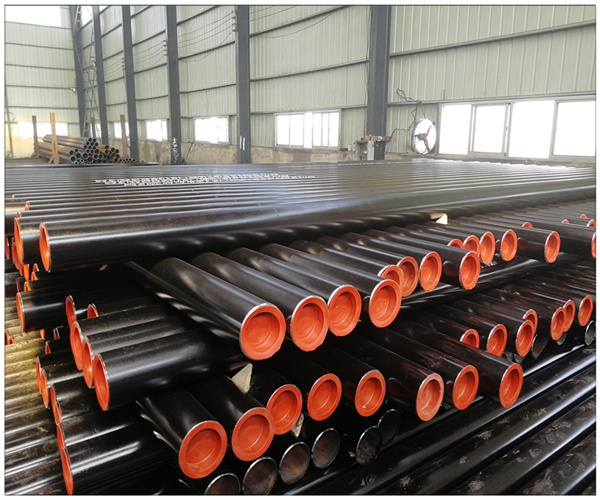

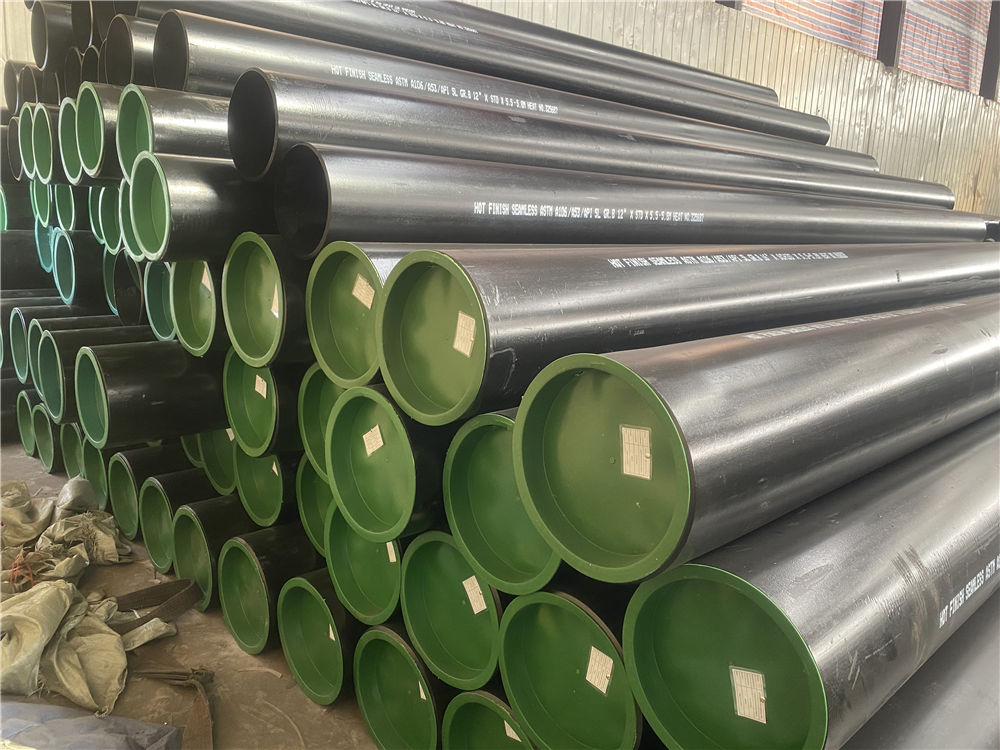

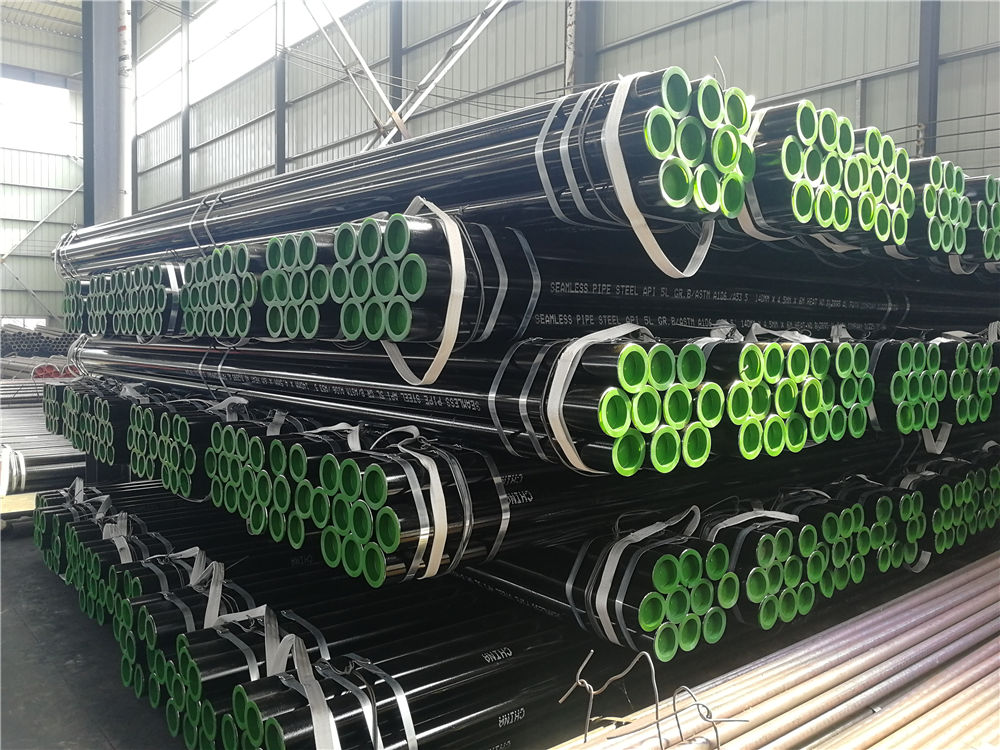

Botop Steel is the leading manufacturer and stockist of steel pipe and tubes in China, we stock and supply circular seamless carbon steel pipe for liquid and petroleum applications in size range of 10 OD to 660 OD in thickness range of 1mm to 100mm. We manufacture carbon LSAW steel pipes strictly according to international standard like ASTM,API &DIN. We owns more than 8000 tons seamless line pipe in stock monthly, generally we can be deliver the goods immediately. However in special cases, if stock of carbon steel pipes is not available we can deliver the goods with shortest delivery time through local mill sources or import

All our steel pipes and tube products are supplied with 3.1 specific test certificates, according to EN 10204. Certification according to 3.2 can be agreed at the time of ordering. Third party inspection is accepted(BV, SGS,etc)

A sufficient number of visual surface imperfections to

provide seasonable assurance is necessary.

The defect shall be removed or cut off within the

limits of requirements on length . The finished pipe

shall be reasonably straight.

Manufacturer’s name or mark

Specification number(year-date or required)

Size( OD, W.T, length)

Grade( A or B)

Type of pipe( F, E, or S)

Test pressure( seamless steel pipe only)

Heat Number

Any additional information specified in the purchase order.

Grade and Chemical Composition (%)

|

Grade |

C≤ |

Mn |

P≤ |

S≤ |

Si≥ |

Cr≤ |

Cu≤ |

Mo≤ |

Ni≤ |

V≤ |

|

A |

0.25 |

0.27-0.93 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

B |

0.30 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

C |

0.35 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

Mechanical Properties:

|

|

|

|

A% |

|

|

A |

≥330 |

≥205 |

20 |

Annealed |

|

B |

≥415 |

≥240 |

20 |

Annealed |

|

C |

≥485 |

≥275 |

20 |

Annealed |

Out Diameter Inspection

Wall Thickness Inspection

End Inspection

Straightness Inspection

UT Inspection

Appearance Inspection

Pipe End Beveling

Plastic Caps

Black Painting with Marking

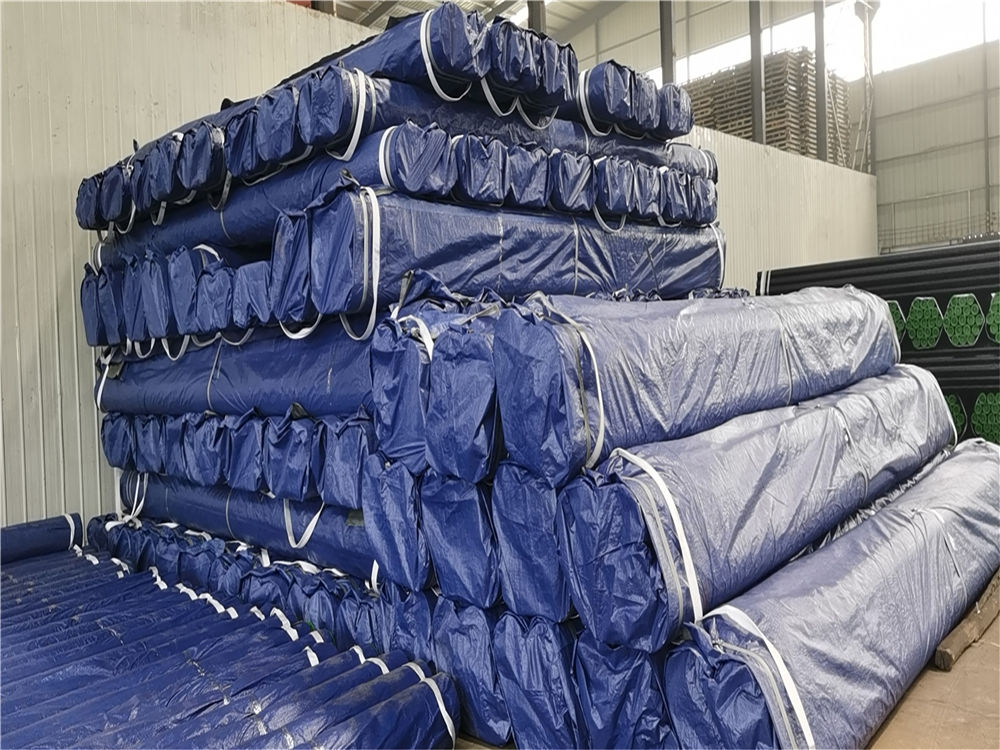

Wrapper

Bundling and Sling

Package Appearance

Seamless Pipe Ship to Qatar

Seamless Pipe ship to Pakistan

Seamless Pipe Ship to South Africa

Seamless Pipe ship to Ecuador