API 5L Grade B steel pipe is produced in accordance with the relevant requirements of API 5L and is widely used in pipeline transportation systems in the oil and gas industry.

Grade B may also be referred to as L245. The characteristic is that the minimum yield strength of the steel pipe is 245 MPa.

API 5L line pipe is available in two product specification grades: PSL1 is primarily used in standard transportation systems, while PSL2 is suitable for more severe conditions with higher mechanical strength and more stringent testing standards.

The manufacturing process can be seamless (SMLS), electric resistance welded (ERW), or submerged arc welded (SAW) to suit different installation and operational needs.

Botop Steel is a professional manufacturer of thick-walled large-diameter double-sided submerged arc LSAW steel pipe located in China.

Location: Cangzhou City, Hebei Province, China;

Total Investment: 500 million RMB;

Factory area: 60,000 square meters;

Annual production capacity: 200,000 tons of JCOE LSAW steel pipes;

Equipment: Advanced production and testing equipment;

Specialization: LSAW steel pipe production;

Certification: API 5L certified.

API 5L Grade B Classification

It is subdivided into several different types based on different Product Specification Levels (PSL) as well as delivery conditions.

This categorization makes the selection of the right line pipe more relevant to meet the needs of a specific project and the requirements of the working environment.

PSL1: B.

PSL2: BR; BN; BQ; BM.

Several special PSL 2 steel tubes are used for special service environments.

Sour service environments: BNS; BQS; BMS.

Offshore service environment: BNO; BQO; BMO.

Applications requiring longitudinal plastic strain capacity: BNP; BQP; BMP.

Delivery Conditions

| PSL | Delivery Condition | Pipe Grade/Steel Grade | |

| PSL1 | As-rolled, normalizing rolled, thermomechanical rolled, thermomechanical formed, normalizing formed, normalized, normalized and tempered; or, if agreed, quenched and tempered for SMLS pipe only |

B | L245 |

| PSL 2 | As-rolled | BR | L245R |

| Normalizing rolled, normalizing formed, normalized, or normalized and tempered | BN | L245N | |

| Quenched and tempered | BQ | L245Q | |

| Thermomechanical rolled or thermomechanical formed | BM | L245M | |

The delivery condition of the steel pipe mainly refers to the heat treatment or other treatments carried out at the end of the manufacturing process of the steel pipe, and these treatments have an important influence on the mechanical properties, corrosion resistance, and structural stability of the steel pipe.

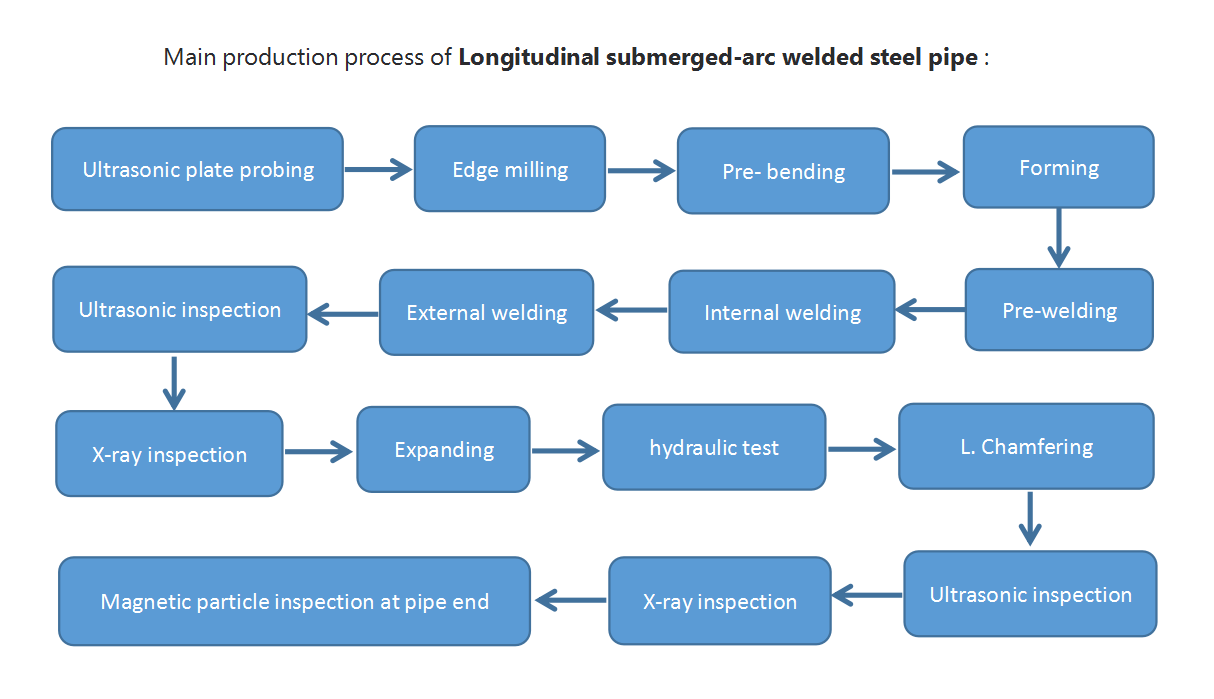

API 5L GR.B Steel Pipe Manufacturing Process

In the API 5L standard Grade B pipe can be produced using one of the production processes in the following table.

| API 5L PSL1 Grade B | SMLS | LFW | HFW | SAWL | SAWH | COWL | COWH |

| API 5L PSL2 Grade B | SMLS | — | HFW | SAWL | SAWH | COWL | COWH |

To find out more about the meaning of the acronym Manufacturing Process, click here.

LSAW is the optimum solution for large-diameter, thick-walled steel pipes.

The distinctive feature in appearance is the presence of a weld in the longitudinal direction of the pipe.

Pipe End Type

API 5L Grade B steel pipe end types may vary in PSL1 and PSL2.

PSL 1 Steel Pipe End

Belled end; Plain end; Plain end for special coupling; Threaded end.

Belled end: Limited to tubes with D ≤ 219.1 mm (8.625 in) and t ≤ 3.6 mm (0.141 in) at the socket end.

Threaded end: Threaded-end pipe is limited to SMLS and longitudinal seam welded pipe with D < 508 mm (20 in).

PSL 2 Steel Pipe End

Plain end.

For plain pipe ends the following requirements should be followed:

The end faces of t ≤ 3.2 mm (0.125 in) plain end pipe shall be square cut.

Plain-end tubes with t > 3.2 mm (0.125 in) shall be beveled for welding. The bevel angle should be 30-35° and the width of the root face of the bevel should be 0.8 - 2.4 mm (0.031 - 0.093 in).

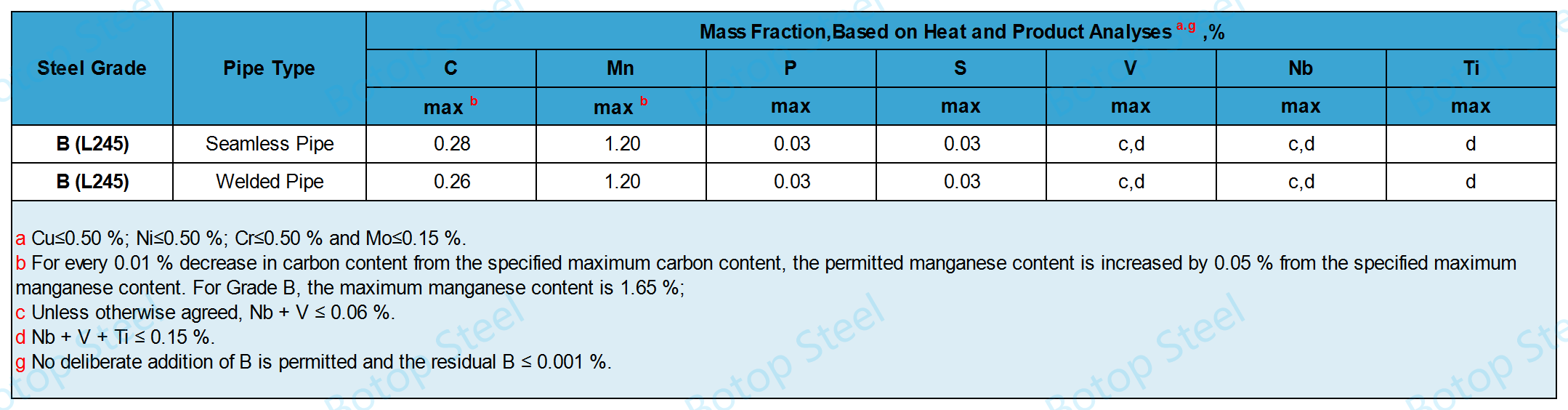

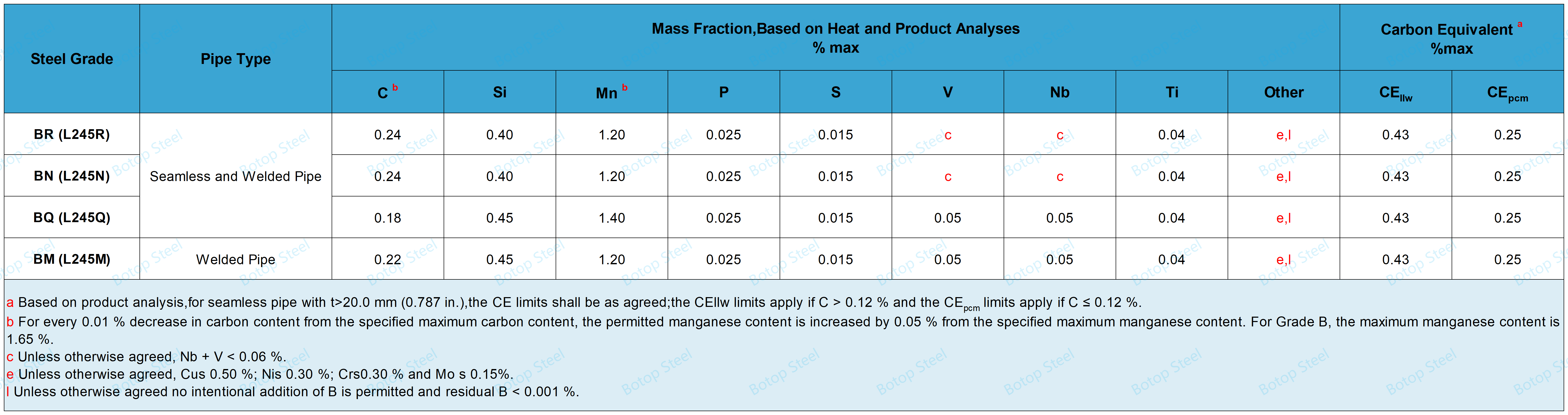

API 5L Grade B Chemical Composition

The chemical composition of PSL1 and PSL2 steel pipe t > 25.0 mm (0.984 in) shall be determined by agreement.

Chemical Composition for PSL 1 Pipe with t ≤ 25.0 mm (0.984 in.)

Chemical Composition for PSL 2 Pipe with t ≤ 25.0 mm (0.984 in.)

For PSL2 steel pipe products analyzed with a carbon content of ≤0.12%, the carbon equivalent CEpcm can be calculated using the following formula:

CEpcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

For PSL2 steel pipe products analyzed with a carbon content > 0.12%, the carbon equivalent CEllw can be calculated using the formula below:

CEllw = C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

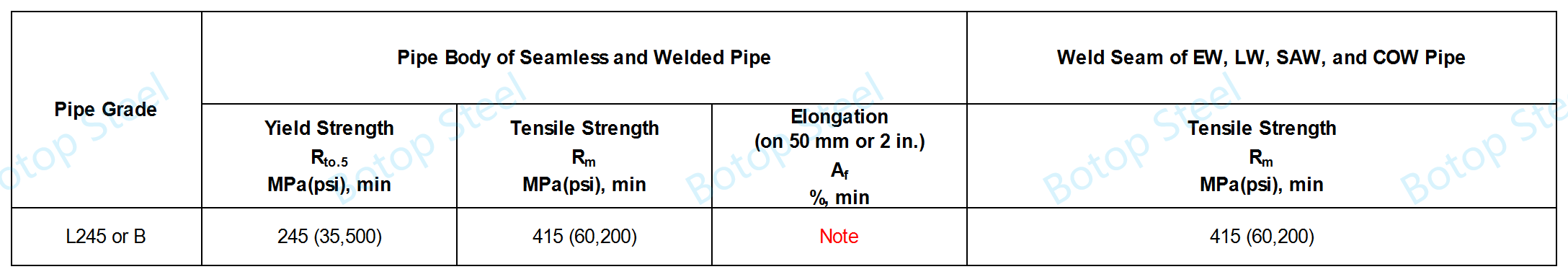

API 5L Grade B Mechanical Property

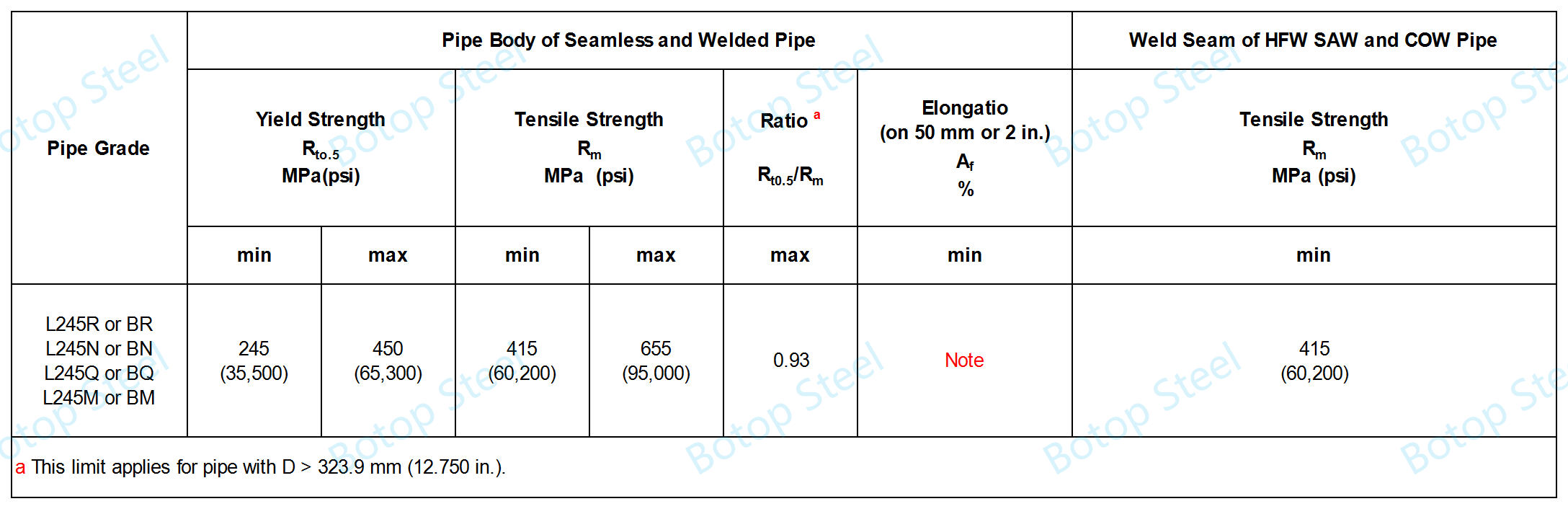

Tensile Property

PSL1 GR.B Tensile Properties

PSL2 GR.B Tensile Properties

Note: The specified minimum elongation, Af shall be as determined using the following equation:

Af = C × (Axc0.2/U0.9)

C is 1940 for calculations using SI units and 625,000 for calculations using USC units;

Axc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

1) for circular cross-section test pieces, 130 mm2 (0.20 in.2) for 12.7 mm (0.500 in.) and 8.9 mm (0.350 in.) diameter test pieces; 65 mm2(0.10 in.2) for 6.4 mm (0.250 in.) diameter test pieces;

2) for full-section test pieces, the lesser of a) 485 mm2 (0.75 in.2) and b) the cross-sectional area of the test piece, T derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in.2);

3) for strip test pieces, the lesser of a) 485 mm2 (0.75 in.2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in.2);

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

Bend Test

No part of the specimen shall be cracked and the weld shall not crack.

Flattening Test

Not applicable to LSAW steel pipe.

Suitable for EW, LW, and CW manufacturing types of tubes.

Guided-bend Test

Reveal any cracks or ruptures in the weld metal longer than 3.2 mm (0.125 in), regardless of depth.

Reveal any cracks or ruptures in the parent metal, HAZ, or fusion line longer than 3.2 mm (0.125 in) or deeper than 12.5 % of the specified wall thickness.

CVN Impact Test for PSL 2 Pipe

CVN (Charpy V-Notch) Impact test, a standardized test method for evaluating the toughness of materials when subjected to rapid impact loads.

The following requirements apply to grades ≤ X60 or L415.

| CVN Absorbed Energy Requirements for Pipe Body of PSL 2 Pipe | |

| Specified Outside Diameter D mm (in.) |

Full-size CVN Absorbed Energy min Kv J (ft.lbf) |

| ≤762 (30) | 27 (20) |

| >762 (30) to 2134 (84) | 40 (30) |

DWT Test for PSL 2 Welded Pipe

The average shear area per test shall be ≥ 85 % at 0 °C (32 °F) test temperature.

For tubes with wall thickness >25.4 mm (1 in.), the acceptance requirements for the DWT test shall be negotiated.

Hydrostatic Test

Test Time

All sizes of seamless and welded steel tubes with D ≤ 457 mm (18 in.): test time ≥ 5s;

Welded steel pipe D > 457 mm (18 in.): test time ≥ 10s.

Test Frequency

Each steel pipe.

Test pressures

The hydrostatic test pressure P of a plain-end steel pipe can be calculated by using the formula.

P = 2St/D

S is the hoop stress. the value is equal to the specified minimum yield strength of the steel pipe x a percentage, in MPa (psi);

For API 5L Grade B, the percentages are 60% for the standard test pressure and 70% for the optional test pressure.

For D <88.9 mm (3.500 in.), it is not necessary that the test pressure exceed 17.0 MPa (2470 psi);

For D > 88.9 mm (3.500 in.), it is not necessary that the test pressure exceed 19.0 MPa (2760 psi).

t is the specified wall thickness, expressed in millimeters (inches);

D is the specified outside diameter, expressed in millimeters (inches).

Nondestructive Inspection

For SAW tubes, two methods, UT (ultrasonic testing) or RT (radiographic testing), are usually used.

ET (electromagnetic testing) is not applicable to SAW tubes.

Welded seams on welded pipes of grades ≥ L210/A and diameters ≥ 60.3 mm (2.375 in) shall be nondestructively inspected for full thickness and length (100 %) as specified.

UT non-destructive examination

RT non-destructive examination

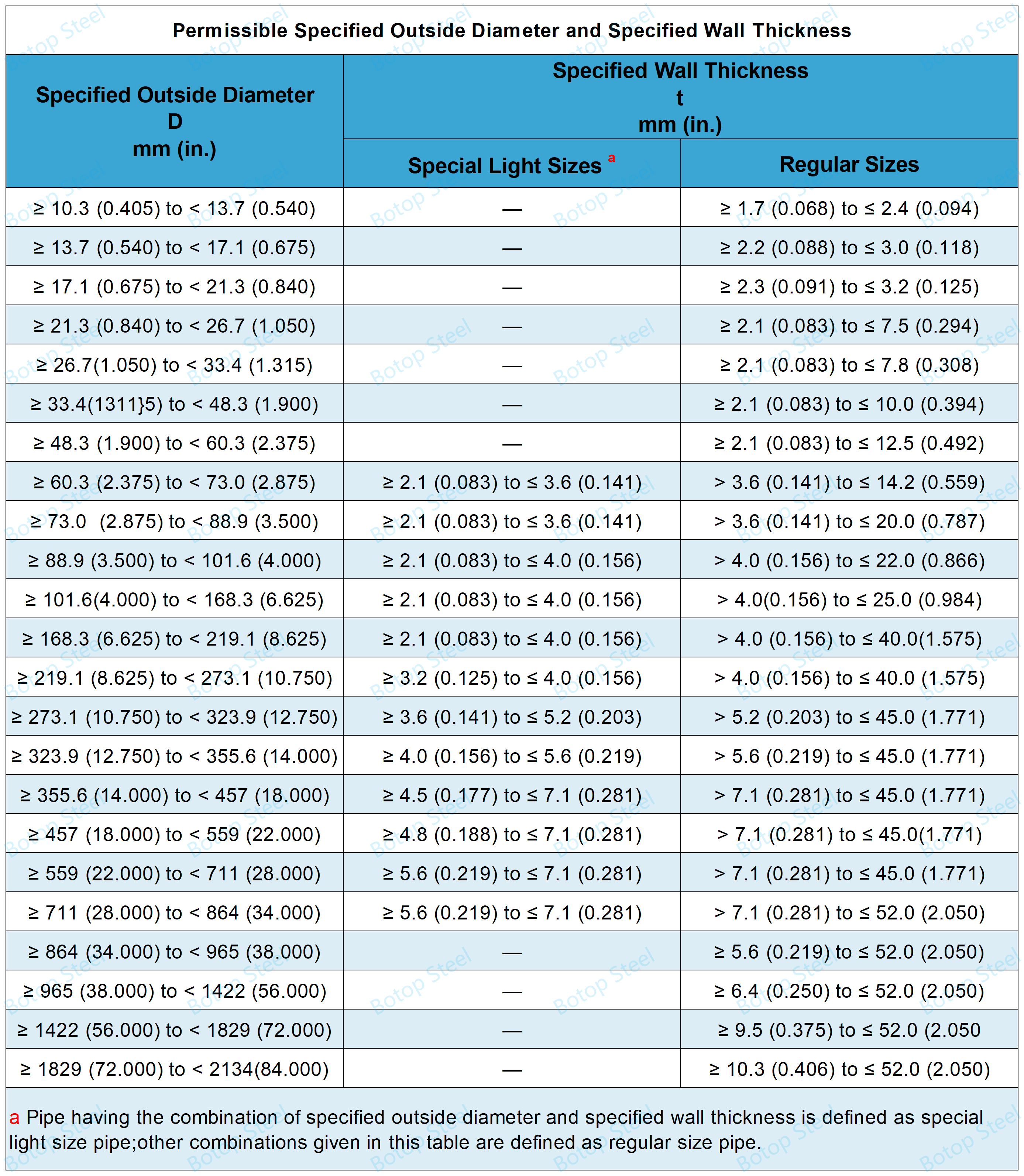

Specify Outside Diameter and Wall Thickness

Standardized values for specified outside diameters and specified wall thicknesses of steel pipe are given in ISO 4200 and ASME B36.10M.

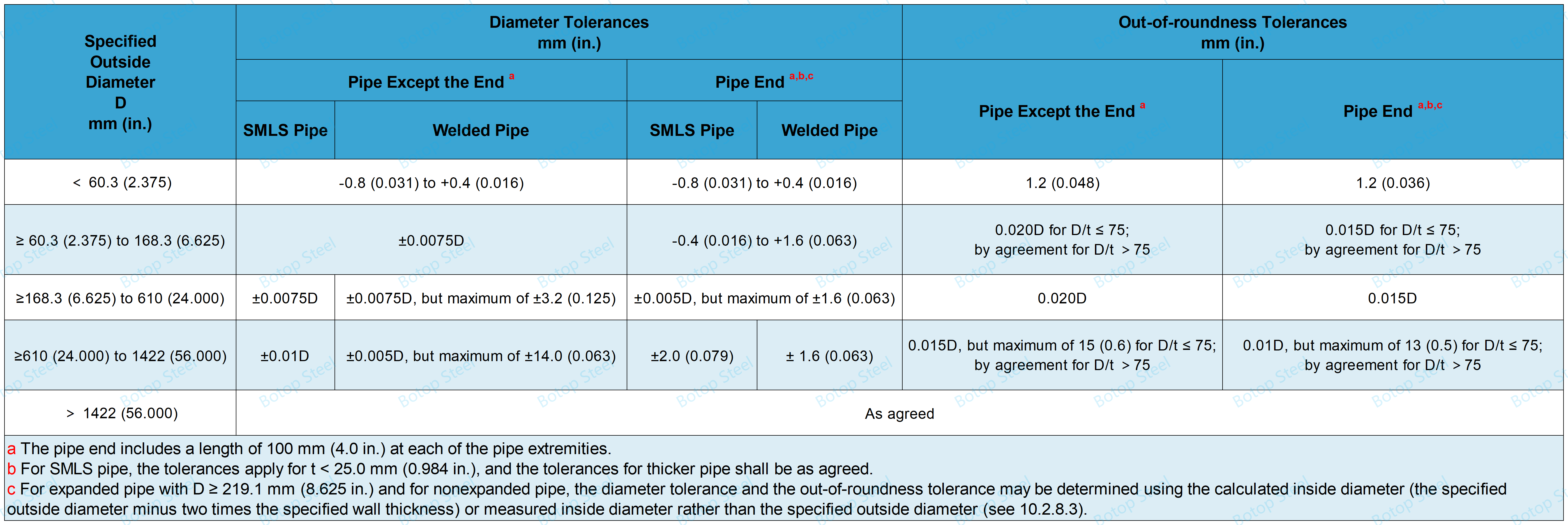

Dimensional Tolerances

Tolerances for Diameter and Out-of-roundness

The diameter of a steel pipe is defined as the circumference of the pipe in any circumferential plane divided by π.

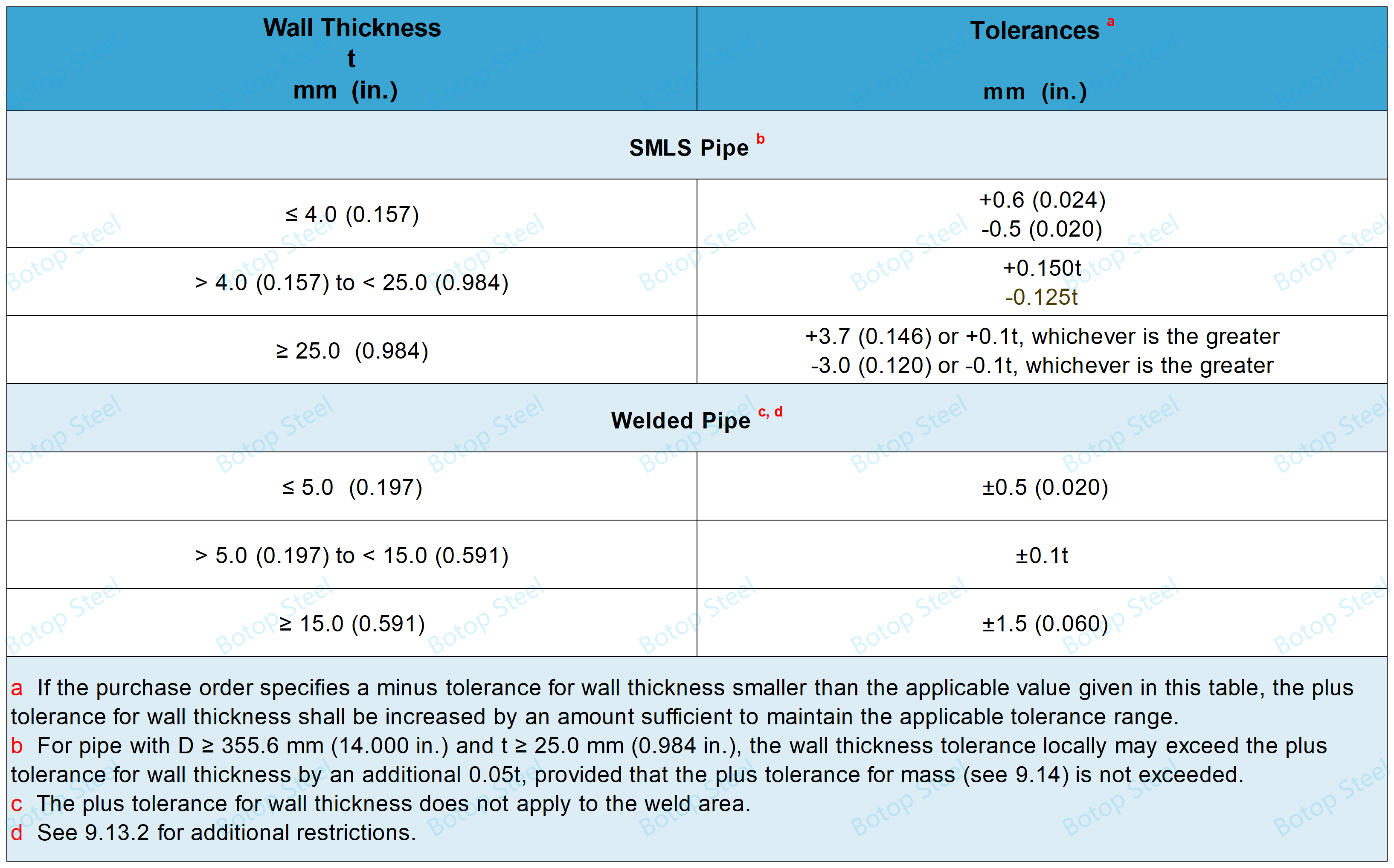

Tolerances for Wall Thickness

Tolerance for Length

Approximate lengths shall be delivered within a tolerance of ±500 mm (20 in.).

Tolerances for random length

| Random Length Designation m (ft) |

Minimum Length m (ft) |

Minimum Average Length for Each Order Item m (ft) |

Maximum Length m (ft) |

| Threaded-and-coupled Pipe | |||

| 6 (20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5) | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72 (45.0) |

| Plain-end Pipe | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5) | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0) | 10.67 (35.0) | 13.72 (45.0) |

| 15 (50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0) | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

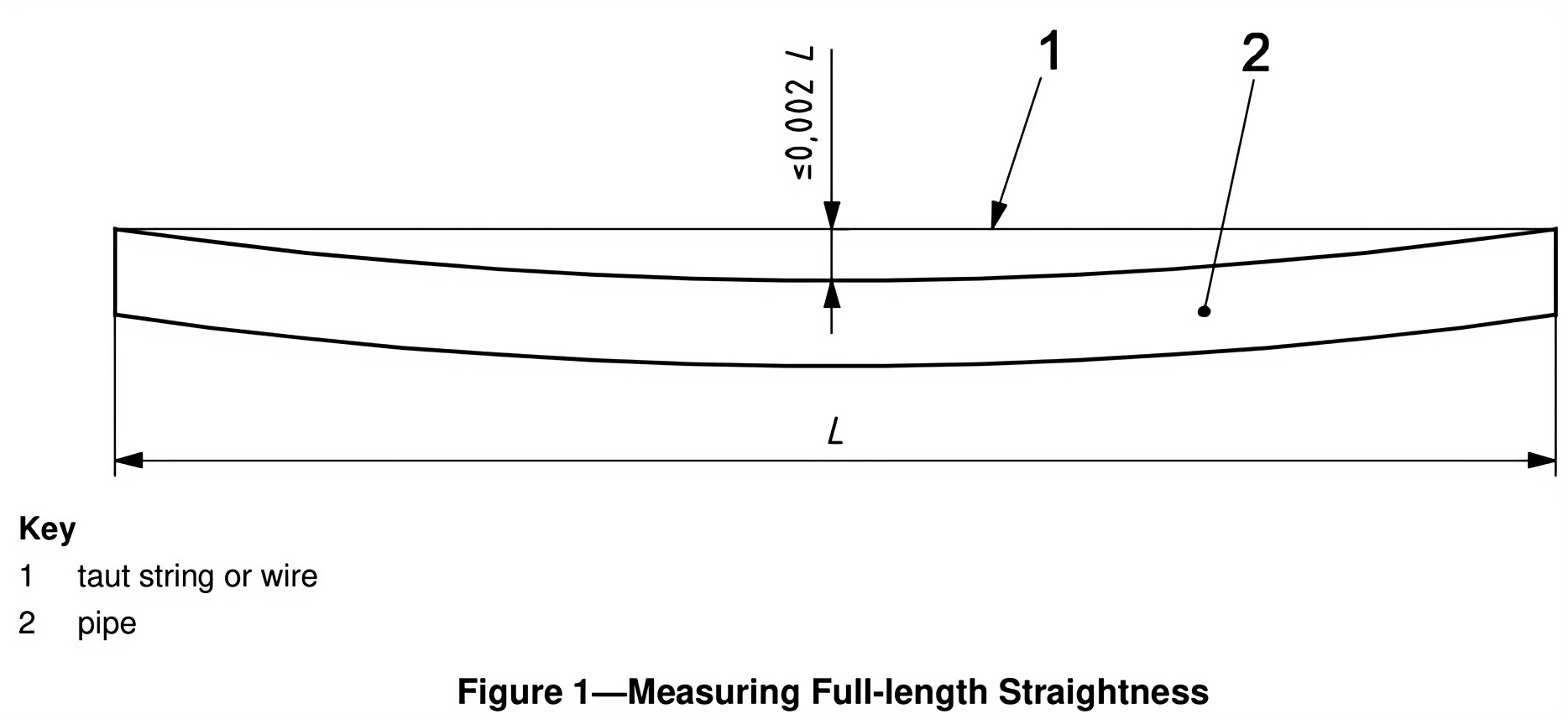

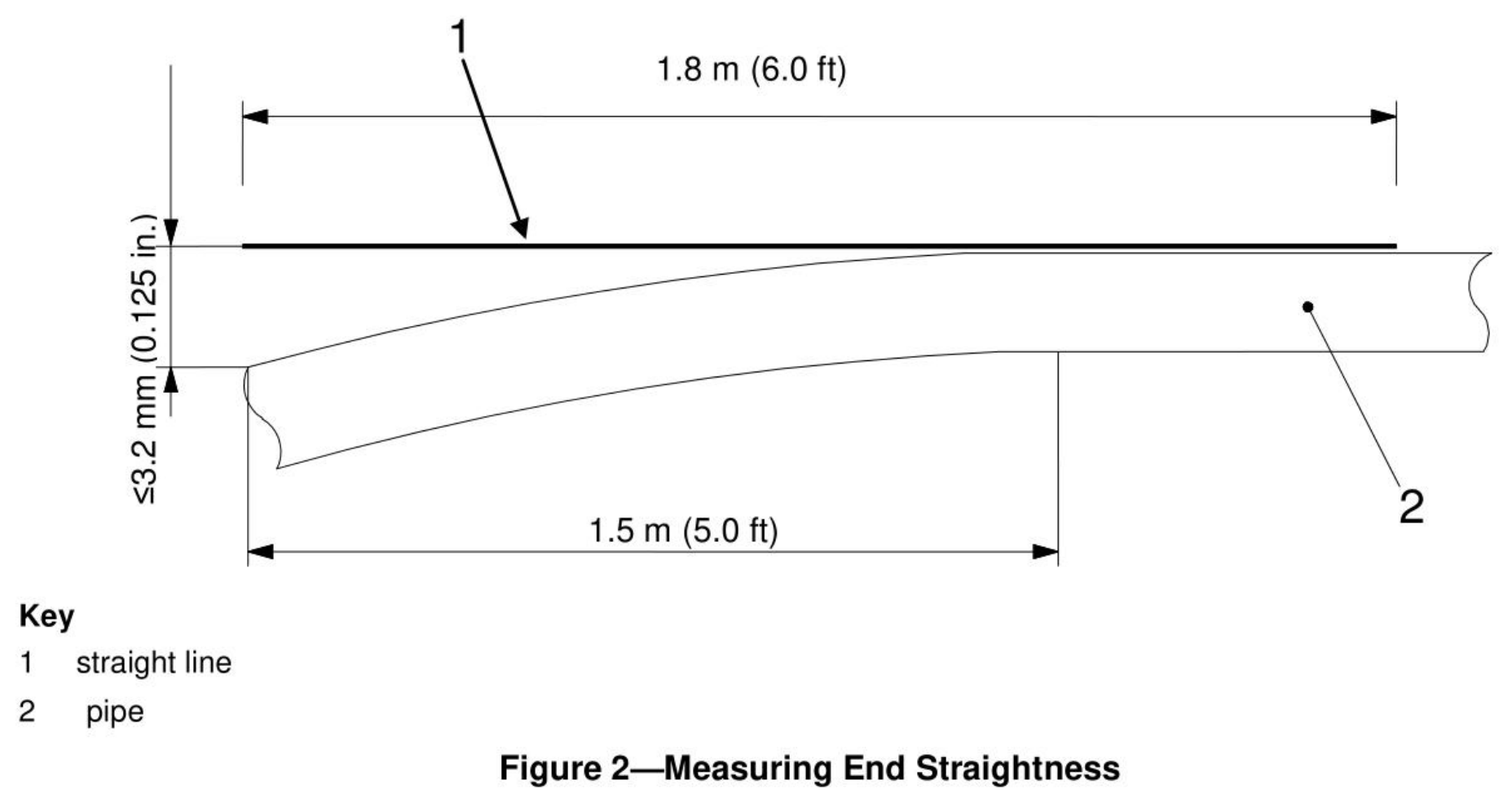

Tolerance for Straightness

Straightness deviation over the entire length of the tube: ≤ 0.200 L;

Straightness deviation of 1.5 m (5.0 ft) pipe end of steel pipe: ≤ 3.2mm (0.125 in.).

Tolerance for Straightness

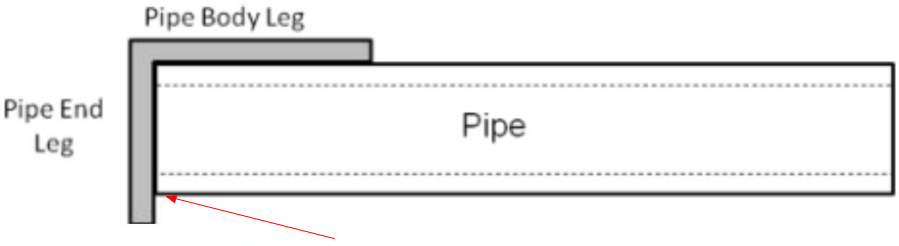

End squareness is defined as a square to the end of the pipe.

The out-of-squareness shall be < 1.6 mm (0.063 in.). The out-of-squareness is measured as the gap between the end of the pipe and the pipe end leg.

Tolerances for the Weld Seam

Maximum Permissible Radial Offset for SAW and COW Pipe.

| Specified Wall Thickness t mm (in.) |

Maximum Permissible Radial Offset amm (in.) |

| ≤ 15.0 (0.590) | 1.5 (0.060) |

| > 15.0 (0.590) to 25.0 (0.984) | 0.1t |

| > 25.0 (0.984) | 2.5 (0.098) |

| a These limits apply also to strip/plate end welds | |

Maximum Permissible Weld Bead Height for SAW and COW Pipe (Except at Pipe Ends).

| Specified Wall Thickness

mm (in.) |

Weld Bead Height mm (in.) maxim |

|

| Internal Bead | External Bead | |

| ≤13.0 (0.512) | 3.5 (0.138) | 3.5 (0.138) |

| >13.0 (0.512) | 3.5 (0.138) | 4.5 (0.177) |

The weld shall have a smooth transition to the surface of the adjacent steel pipe.

Pipe end welds are to be ground to a length of 100 mm (4.0 in.) with a residual weld height of ≤ 0.5 mm (0.020 in.).

Tolerances for Mass

Each steel pipe:

a) for special light size pipe: -5.0% - +10.0%;

b) for pipe in Grade L175, L175P, A25, and A25P: -5.0% - +10.0%;

c) for all other pipes: -3.5% - +10.0%.

Pipe per lot (≥ 18 tons (20 tons) for order lot):

a) for grades L175, L175P, A25, and A25P: -3.5 %;

b) for all other grades: -1.75 %.

API 5L GR.B Applications

API 5L Grade B steel pipe is a type of line pipe, mainly used to transport fluids such as oil, natural gas, and water, and is one of the commonly used materials in the oil and gas industry.

Oil and gas transmission systems: API 5L Grade B steel pipe is commonly used in oil and gas field extraction and processing facilities to transport crude oil and natural gas to gathering systems or processing facilities.

Water pipelines: Additional surface treatments, such as coatings or cladding, may be applied to improve their corrosion resistance for use in the conveyance of water, including water supply and irrigation systems.

Refineries: In refineries, API 5L Grade B steel pipe is used to transport a variety of chemicals and intermediates derived from the fractional distillation of crude oil.

Construction and infrastructure: In the construction industry, for building bridges, support structures, or other important infrastructure projects, especially where long-distance transportation of fluids is required.

API 5L Grade B Equivalent

ASTM A106 Grade B: Seamless carbon steel tubing typically used for high-temperature service, with chemical composition and mechanical properties very similar to API 5L Grade B. ASTM A106 Grade B is commonly used for the transport of high-temperature water vapor, chemicals, and petroleum products.

ASTM A53 Grade B: This is another type of carbon steel pipe, which can be welded or seamless, and is widely used in mechanical, construction, and other engineering applications. Although it is primarily used for low-pressure and temperature applications, some of its mechanical property parameters are similar to API 5L Grade B.

EN 10208-2 L245NB: Used for manufacturing pipelines for transporting flammable gases and other liquids. L245NB (1.0457) is a medium-strength pipeline steel with mechanical properties similar to API 5L Grade B.

ISO 3183 L245: Used in pipeline transportation systems in the oil and gas industry.L245 in ISO 3183 is very close in properties to API 5L Grade B and can often be used interchangeably.

Additional Services We Can Provide

Botop Steel not only provides high-quality API 5L Grade B steel pipe, but also offers you a series of supporting services, including a wide range of anti-corrosion coating options, personalized packaging solutions, and comprehensive logistics support to ensure that we can meet your various needs.

We are committed to creating a one-stop sourcing platform that allows you to conveniently access all the products and services you need. With our professional and reliable services, you can complete every step of your project efficiently and hassle-free, ensuring quality and progress. Our goal is to be your most trustworthy partner.

Anti-corrosion Coating

Botop Steel offers a wide range of corrosion protection coating options, including painted, galvanized, 3LPE (HDPE), 3LPP, FBE, and cementitious counterweights, to meet the various usage requirements of your project.

packaging

We offer a variety of packaging options, including bales, tarps, crates, and pipe caps, which can be customized to meet your specific needs.

Technical Support

Our company is committed to providing comprehensive technical support services covering all stages of a project. From pre-project tender preparation to mid-project procurement and transportation arrangements, to post-project maintenance and troubleshooting, our professional team can provide you with expert advice and support.

Our goal is to help you purchase high-quality and affordable products in China, ensuring that your project runs smoothly and cost-effectively. We look forward to working with you to create a win-win future.