API 5L X42, also known as L290, is a type of line pipe used in the oil and gas industry.

Material properties are a minimum yield strength of 42,100 psi (290 MPa) and a minimum tensile strength of 60,200 psi (415 MPa). It is one grade higher than API 5L Grade B and is suitable for medium-strength applications.

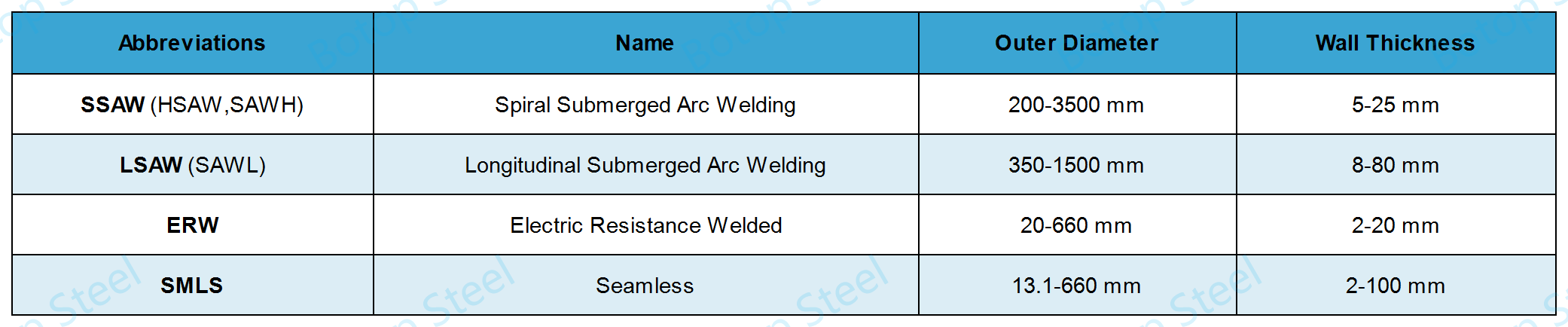

X42 is commonly manufactured in Seamless, SSAW, LSAW, and ERW. Coatings and finishes are available to meet specific application requirements.

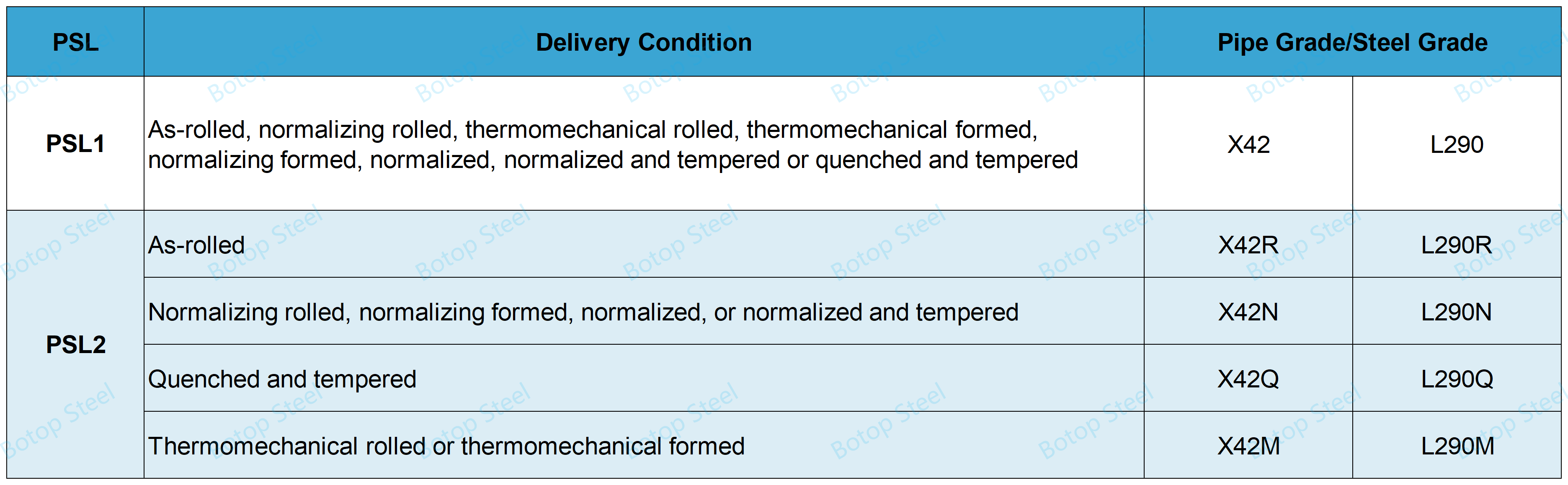

Delivery Conditions

Depending on the delivery conditions and PSL level, it can be categorized as follows:

PSL1: X42 or L290;

PSL2: X42R, X42N, X42Q, X42M or L290R, L290N, L290Q, L290M;

The letters of the PSL2 suffix each represent a different heat treatment.

R: Rolled;

N: Normalizing;

Q: Quenched and Tempered;

M: Thermo-mechanical treatment.

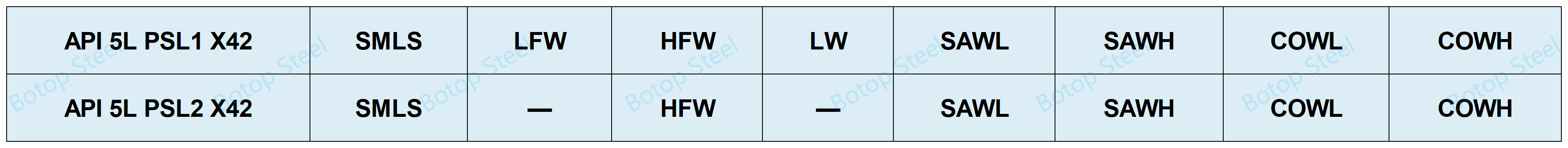

Manufacturing Process

X42 allows for the following manufacturing process:

If you find these abbreviations difficult to understand, check out our compilation of articles on common abbreviations for steel pipes.

Botop Steel can provide you with a range of pipe sizes as shown in the table below.

Our Supply Range

Standard: API 5L (ISO 3183);

PSL1: X42 or L290;

PSL2: X42R, X42N, X42Q, X42M or L290R, L290N, L290Q, L290M;

Welded steel pipe: LSAW (SAWL), SSAW (HSAW), DSAW, ERW;

Seamless steel pipe: SMLS;

Pipe Schedules: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 and SCH160.

Identification: STD (Standard), XS (Extra Strong), XXS (Double Extra Strong);

Coating: Paint, varnish, 3LPE, FBE, 3LPP, HDPE, galvanized, epoxy zinc-rich, cement weighted, etc.

Packing: Waterproof cloth, wooden case, steel belt or steel wire bundling, plastic or iron pipe end protector, etc. Customized.

Matching Products: Bends, flanges, pipe fittings, and other matching products are available.

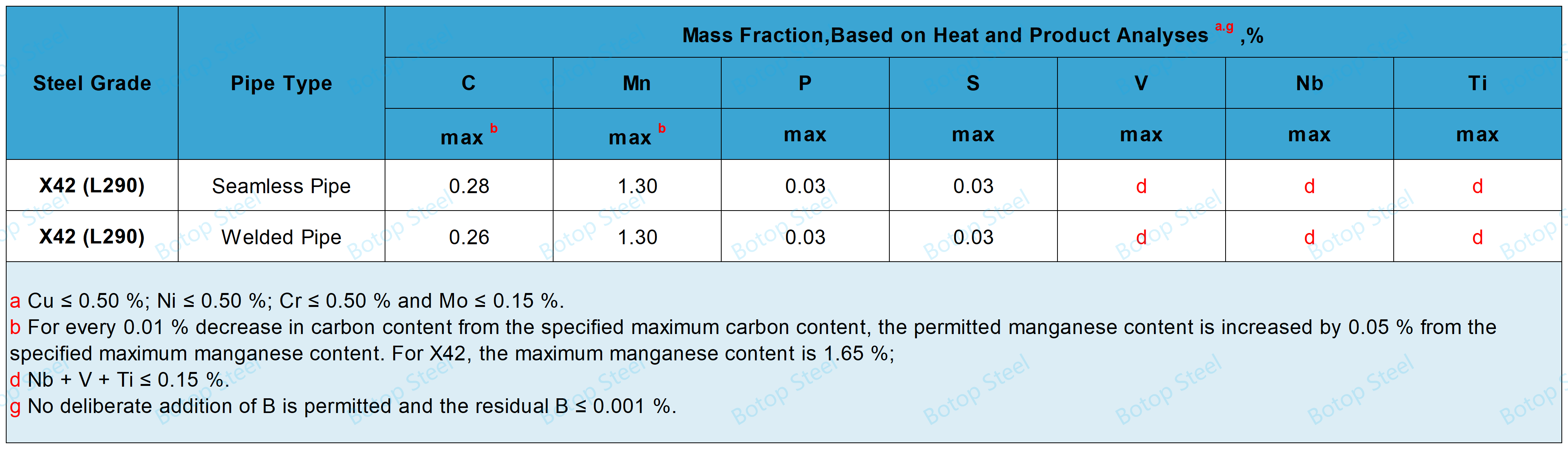

API 5L X42 Chemical Composition

Chemical Composition for PSL 1 Pipe with t ≤ 25.0 mm (0.984 in.)

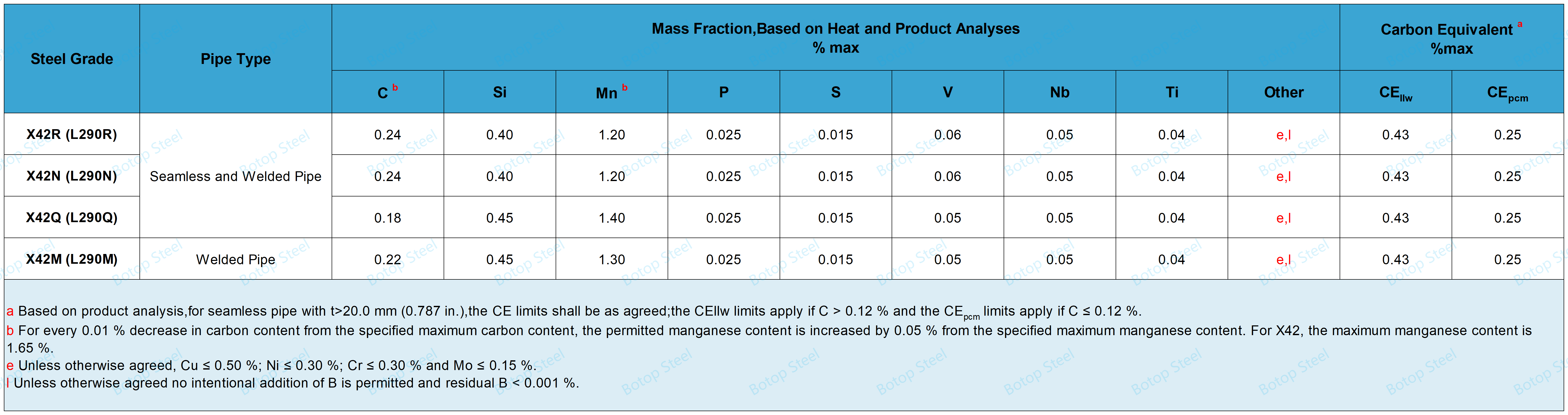

Chemical Composition for PSL 2 Pipe with t ≤ 25.0 mm (0.984 in.)

For PSL2 steel pipe products analyzed with a carbon content of ≤0.12%, the carbon equivalent CEpcm can be calculated using the following formula:

CEpcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

For PSL2 steel pipe products analyzed with a carbon content > 0.12%, the carbon equivalent CEllw can be calculated using the formula below:

CEllw = C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

Chemical Composition with t > 25.0 mm (0.984 in.)

This can be negotiated by referring to the chemical composition above.

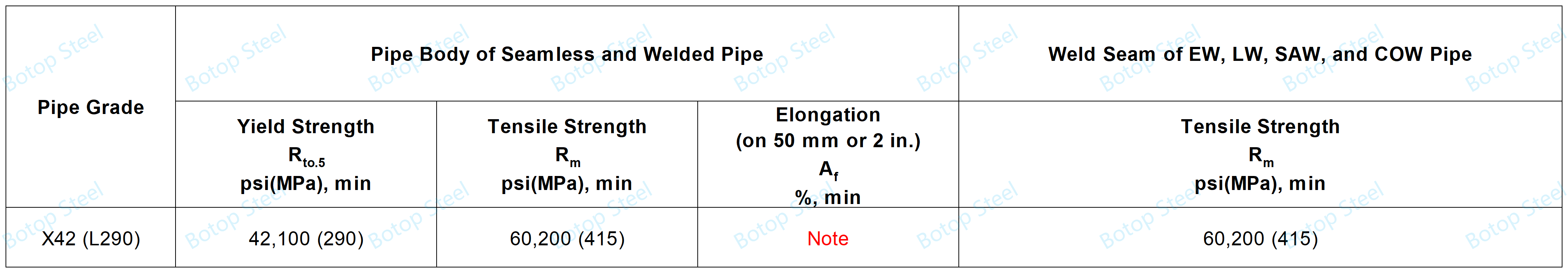

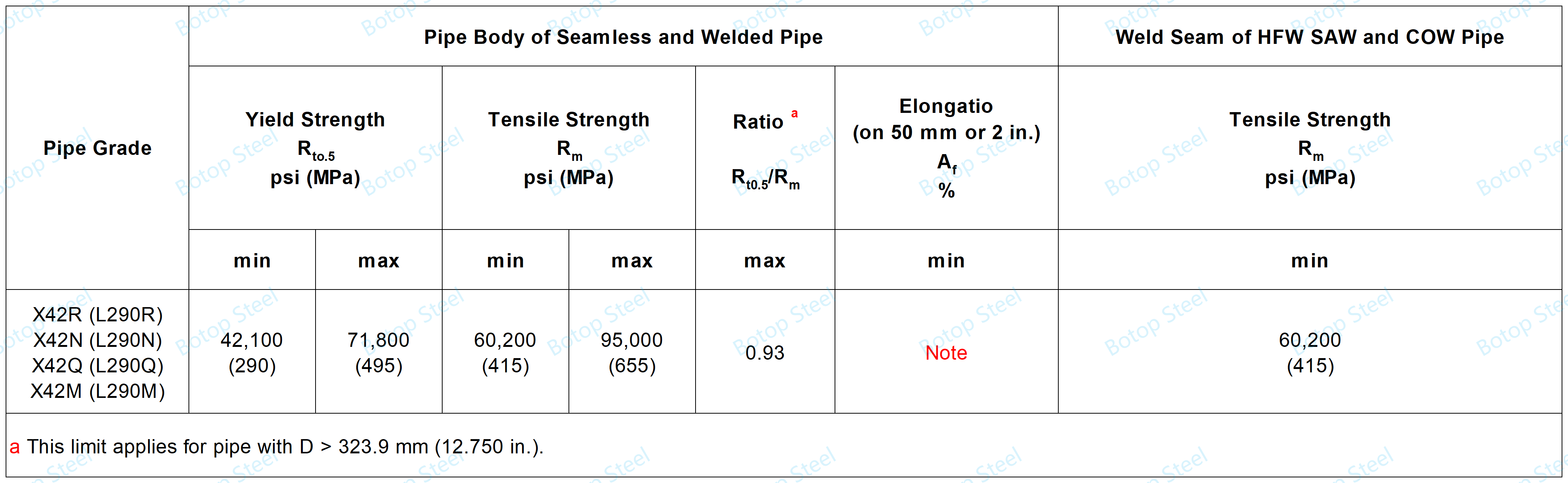

API 5L X42 Mechanical Properties

Tensile Properties

The tensile test is a key test for the mechanical properties of steel tubes, which is able to measure yield strength, tensile strength, and elongation important parameters.

X42 yield strength is 42,100 psi or 290 MPa.

X42 tensile strength is 60,200 psi or 415 MPa.

PSL1 X42 Tensile Properties

PSL2 X42 Tensile Properties

Note: The requirements are detailed in the Mechanical Properties section of API 5L X52, which can be viewed by clicking on the blue font if you are interested.

Other Mechanical Experiments

Bend Test

Flattening Test

Guided-bend Test

CVN Impact Test for PSL 2 Pipe

DWT Test for PSL 2 Welded Pipe

Of course, not all tubes need to be tested for a full set of mechanical properties, but rather the tests are selected according to the type of tube. Specific requirements can be found in Tables 17 and 18 of the API 5L standard.

You can also contact us for this information.

Hydrostatic Test

Test Time

All sizes of seamless and welded steel tubes with D ≤ 457 mm (18 in.): test time ≥ 5s;

Welded steel pipe D > 457 mm (18 in.): test time ≥ 10s.

Experimental Frequency

Each steel pipe and there shall be no leakage from the weld or pipe body during the test.

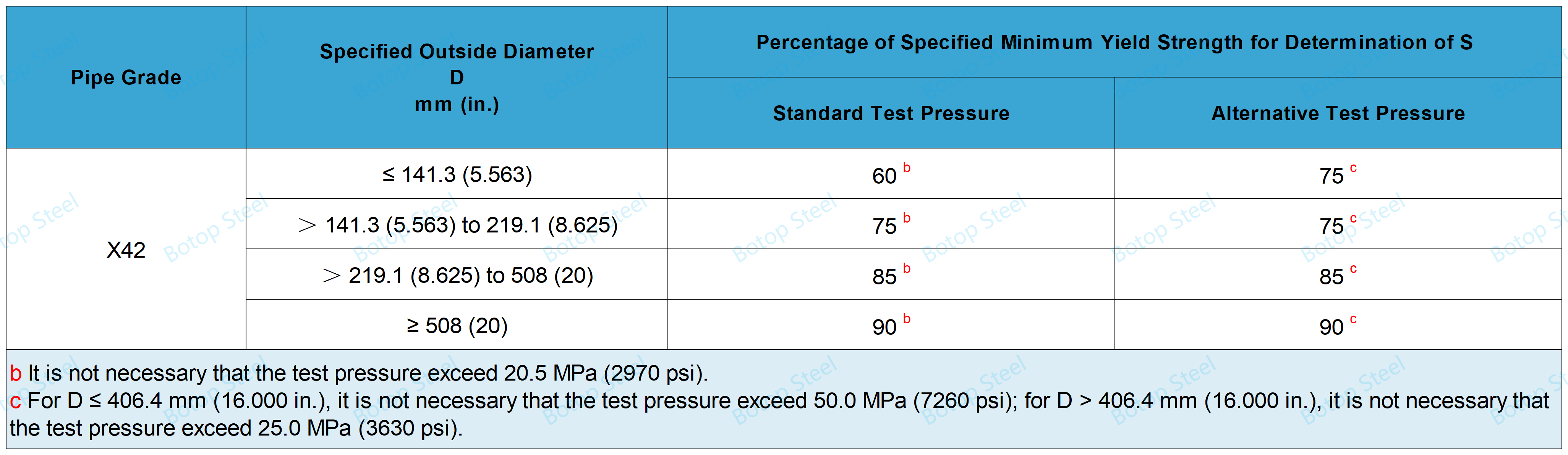

Test pressures

The hydrostatic test pressure P of a plain-end steel pipe can be calculated by using the formula.

P = 2St/D

S is the hoop stress. the value is equal to the specified minimum yield strength of the steel pipe x a percentage, in MPa (psi);

t is the specified wall thickness, expressed in millimeters (inches);

D is the specified outside diameter, expressed in millimeters (inches).

Nondestructive Inspection

For SAW tubes, two methods, UT (ultrasonic testing) or RT (radiographic testing), are usually used.

ET (electromagnetic testing) is not applicable to SAW tubes.

Welded seams on welded pipes of grades ≥ L210/A and diameters ≥ 60.3 mm (2.375 in) shall be nondestructively inspected for full thickness and length (100 %) as specified.

UT non-destructive examination

RT non-destructive examination

All seamless tubes of PSL 2, and quenched and tempered seamless tubes of PSL1 Grade B, shall be subjected to full-length (100 %) nondestructive testing.

One or a combination of ET (Electromagnetic Testing), UT (Ultrasonic Testing), and MT (Magnetic Particle Testing) can be used for NDT.

Dimensional Tolerances

The API 5L requirements for dimensional tolerances are detailed in API 5L Grade B. To avoid repetition, you can click on the blue font to view the relevant details.

API 5L Pipe Schedule Chart

For ease of viewing and use, we have organized the relevant schedule PDF files. You can always download and view these documents if needed.

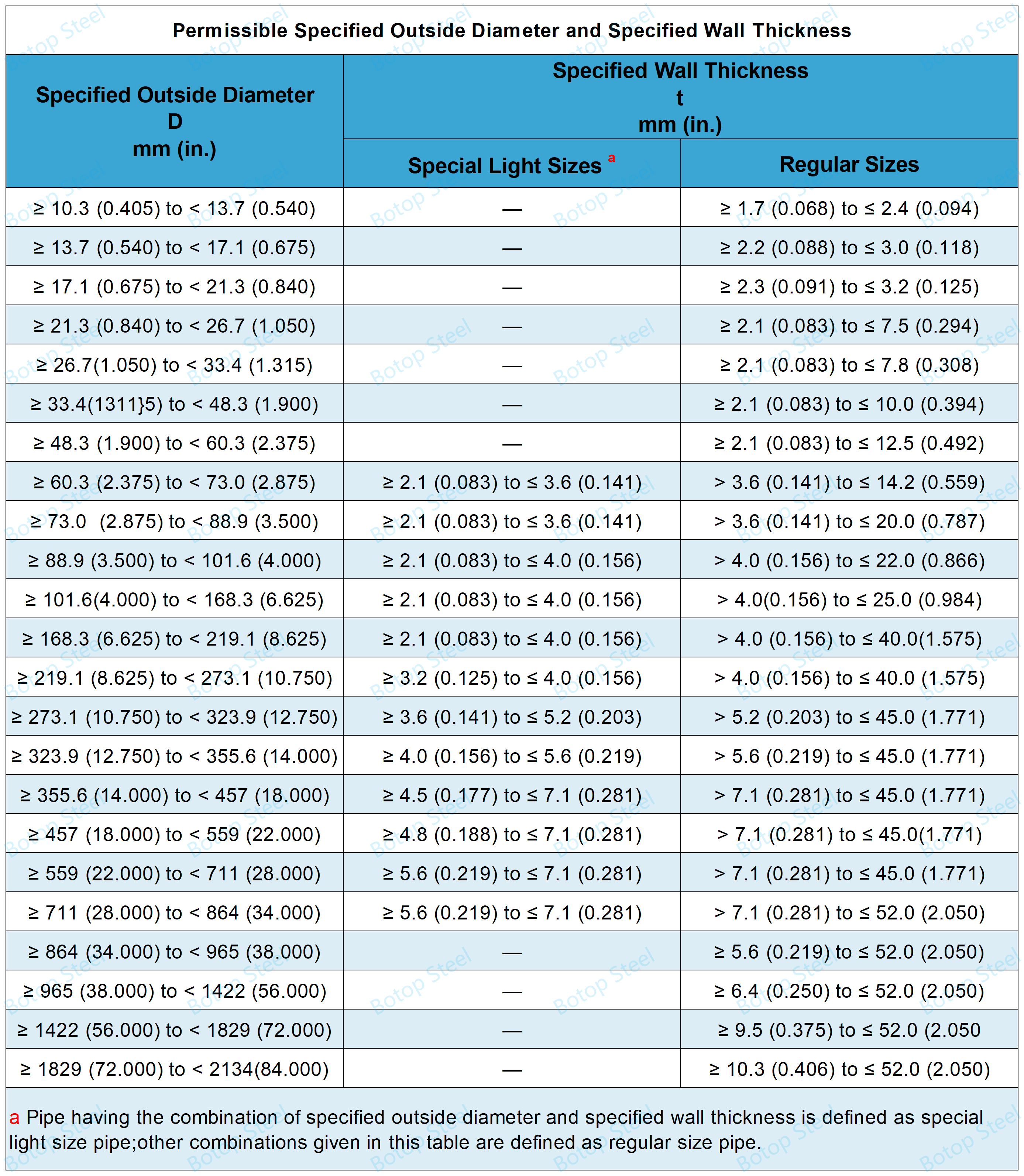

In addition, API 5L specifies the permissible specified outside diameter and specified wall thickness.

Dimensional Tolerances

The API 5L requirements for dimensional tolerances are detailed in API 5L Grade B. To avoid repetition, you can click on the blue font to view the relevant details.

Our Related Products

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.