API 5L X60 (L415) is a line pipe with a minimum yield strength of 60,200 (415 MPa) for use in pipeline transportation systems in the oil and gas industry.

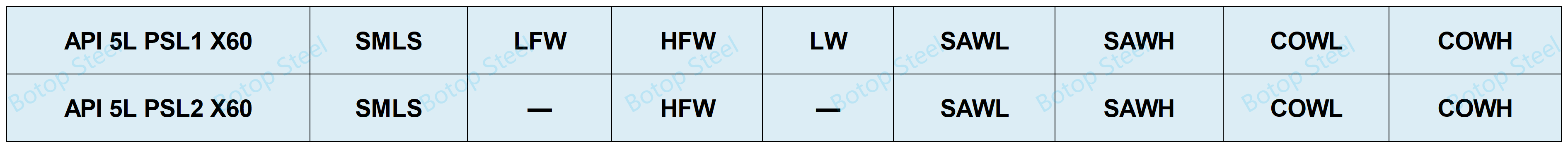

X60 can be seamless or many types of welded steel tubing, commonly LSAW (SAWL), SSAW (SAWH), and ERW.

Due to its high strength and durability, the X60 pipeline is often used for long-distance trans-regional pipelines or transportation tasks through complex terrains and other demanding environments.

Botop Steel is a professional manufacturer of thick-walled large-diameter double-sided submerged arc LSAW steel pipe located in China.

· Location: Cangzhou City, Hebei Province, China;

· Total Investment: 500 million RMB;

· Factory area: 60,000 square meters;

· Annual production capacity: 200,000 tons of JCOE LSAW steel pipes;

· Equipment: Advanced production and testing equipment;

· Specialization: LSAW steel pipe production;

· Certification: API 5L certified.

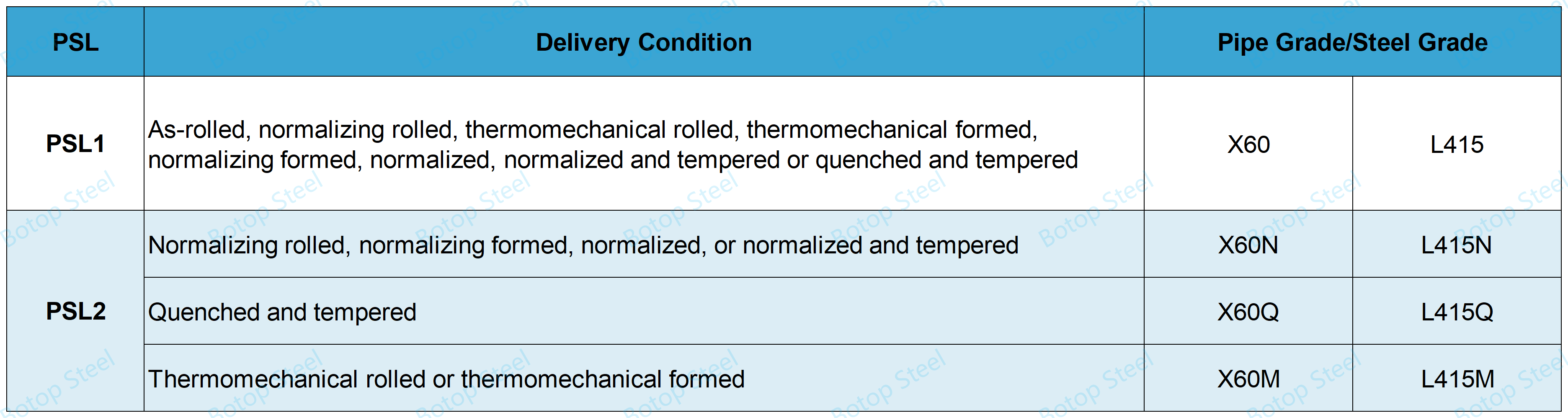

Delivery Conditions

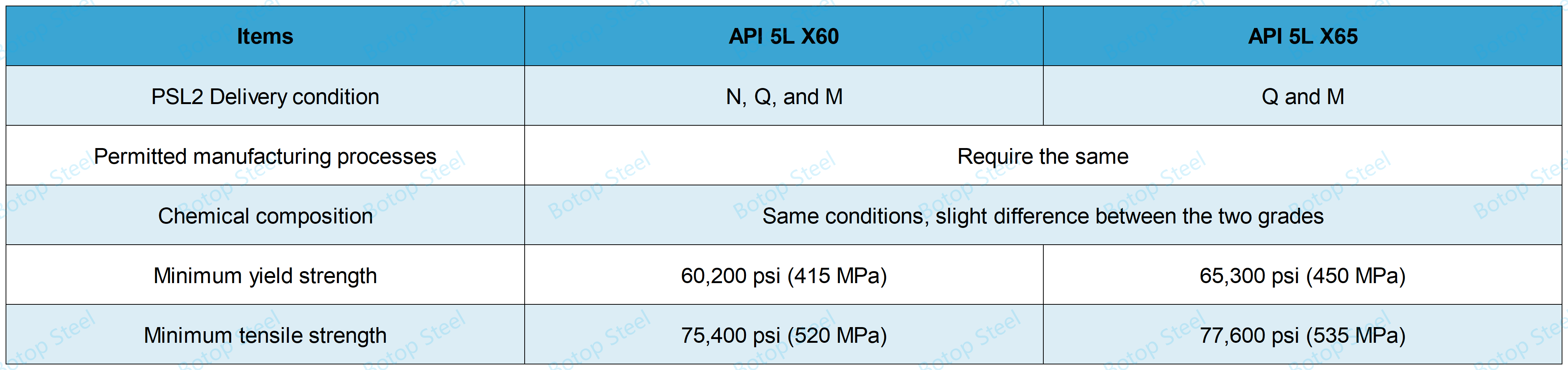

Depending on the delivery conditions and PSL level, the X60 can be categorized as follows:

PSL1: x60 or L415;

PSL2: X60N, X60Q, X60M or L415N, L415Q, L415M.

N: Indicates normalization of the material. By heating steel to a certain temperature followed by air cooling. To improve the microstructure and mechanical properties of steel and to increase its toughness and consistency.

Q: Stands for Quenching and Tempering. Tempering of steel by heating it to a certain temperature, cooling it rapidly, and then heating it again to a lower temperature. To obtain a balance of specific mechanical properties, such as high strength and toughness.

M: Indicates thermo-mechanical treatment. A combination of heat treatment and machining to optimize the microstructure and properties of steel. It is possible to increase the strength and toughness of the steel while maintaining good welding properties.

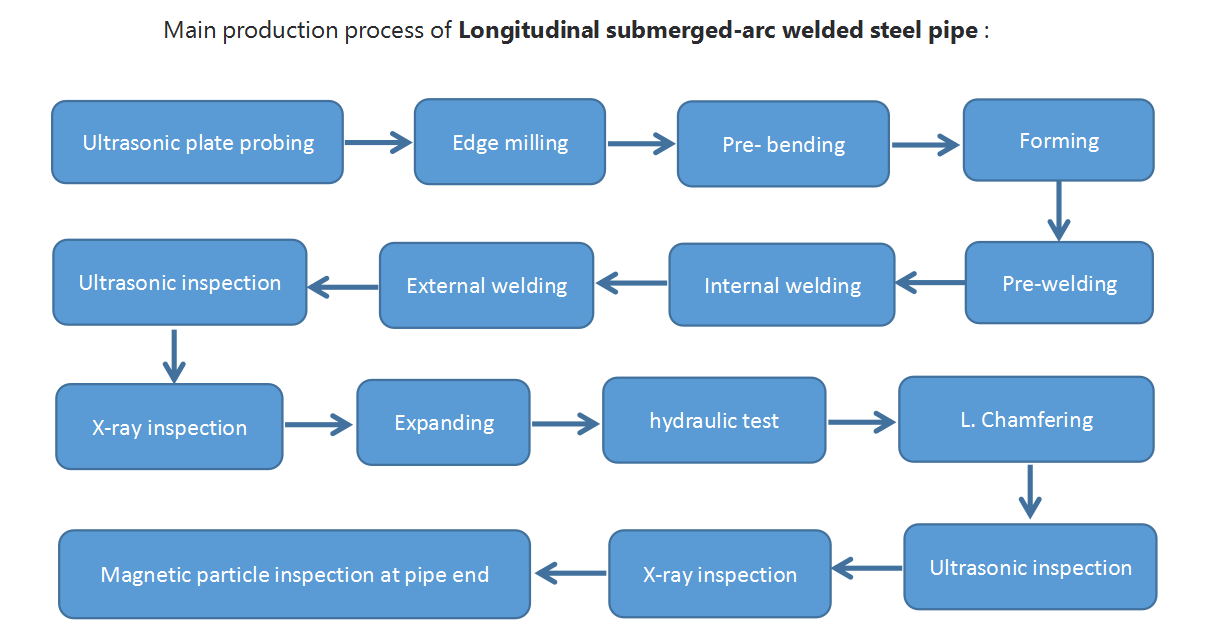

API 5L X60 Manufacturing Process

Acceptable steel tube manufacturing process for X60

If you find these abbreviations difficult to understand, check out our compilation of articles on common abbreviations for steel pipes.

Advantages of SAWL (LSAW)

If you need large diameter thick wall steel pipe, the first choice is SAWL (LSAW) steel pipe.LSAW steel pipe can be produced in sizes up to 1500mm in diameter and 80mm in wall thickness, which is fully capable of meeting the needs of long-distance pipelines for large-scale projects.

In addition, during the production process, LSAW steel pipe adopts double-sided submerged arc welding (DSAW) process, which ensures the quality of the weld seam.

API 5L X60 Chemical Composition

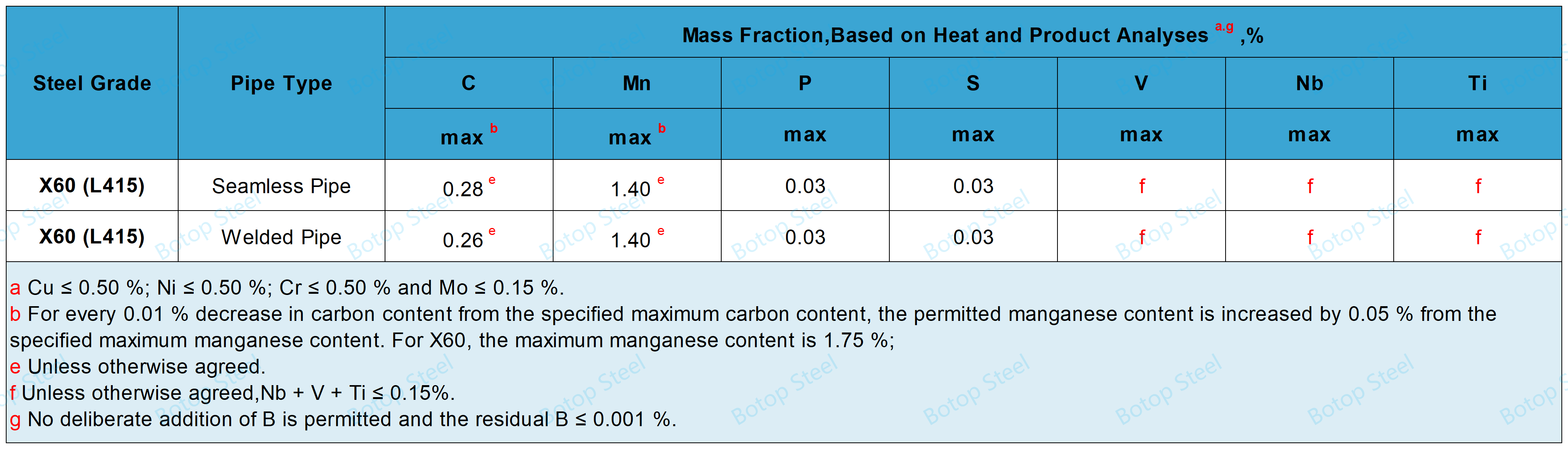

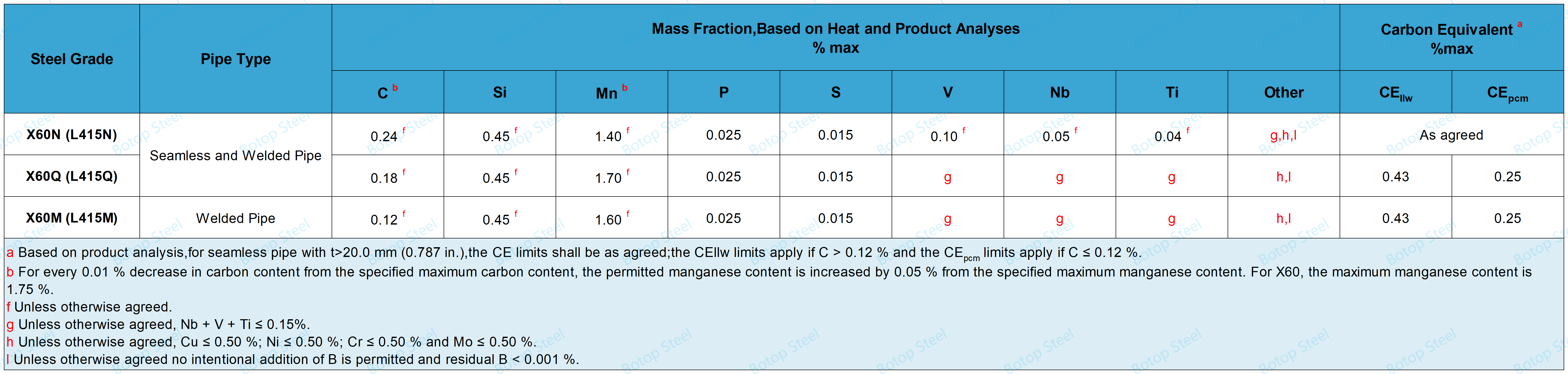

PSL1 is much simpler than PSL2 in terms of chemical composition, mechanical properties, and other requirements.

This is because PSL1 represents the standard level of quality for pipeline steel pipe, while PSL2 can be seen as an upgraded version of PSL1, which offers more advanced specifications and stricter quality control.

Chemical Composition for PSL 1 Pipe with t ≤ 25.0 mm (0.984 in.)

Chemical Composition for PSL 2 Pipe with t ≤ 25.0 mm (0.984 in.)

For PSL2 steel pipe products analyzed with a carbon content of ≤0.12%, the carbon equivalent CEpcm can be calculated using the following formula:

CEpcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

For PSL2 steel pipe products analyzed with a carbon content > 0.12%, the carbon equivalent CEllw can be calculated using the formula below:

CEllw = C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

Chemical Composition with t > 25.0 mm (0.984 in.)

It shall be determined by negotiation and modified to a suitable composition based on the chemical composition requirements above.

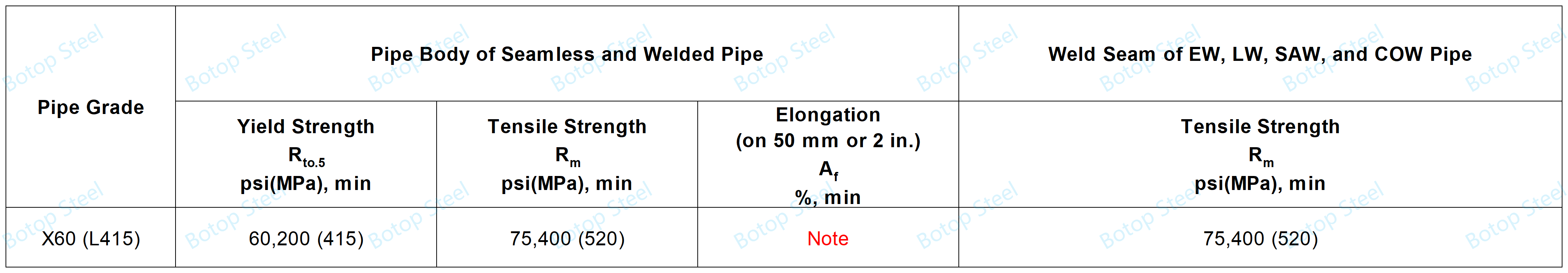

API 5L X60 Mechanical Properties

Tensile Properties

The tensile test is a key experimental program for evaluating the mechanical properties of steel tubes. This test allows the determination of important parameters of the material, including yield strength, tensile strength, and elongation.

PSL1 X60 Tensile Properties

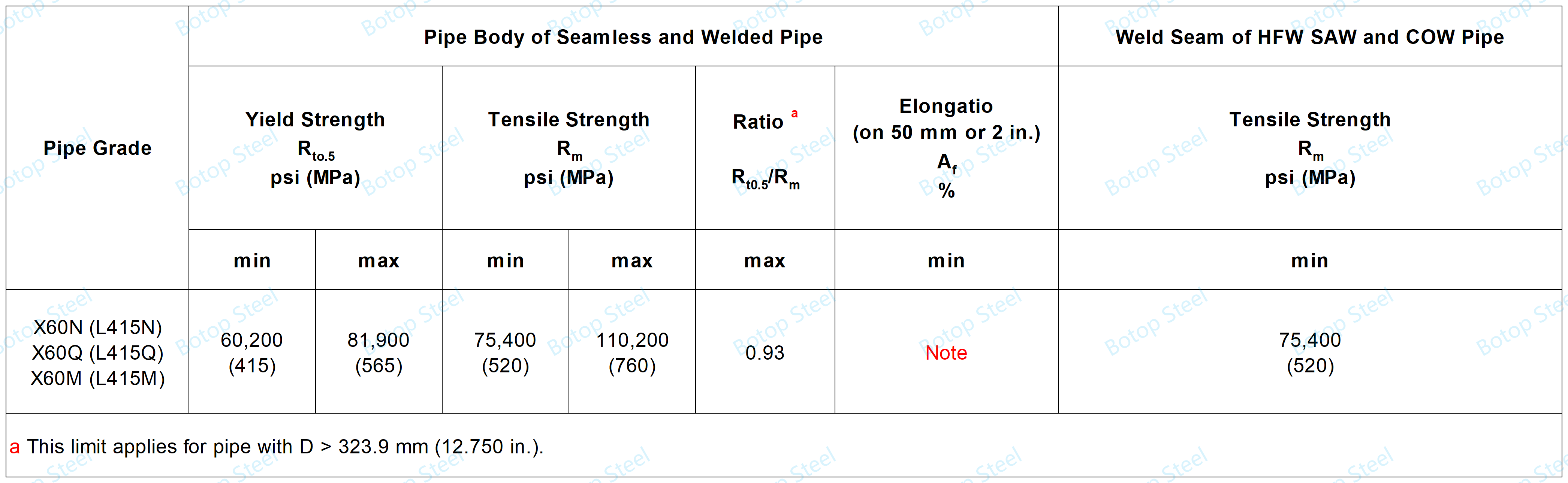

PSL2 X60 Tensile Properties

Note: The requirements are detailed in the Mechanical Properties section of API 5L X52, which can be viewed by clicking on the blue font if you are interested.

Other Mechanical Experiments

The following experimental program applies to SAW steel pipe types only.

Weld guide bending test;

Cold-formed welded pipe hardness test;

Macro inspection of welded seam;

and only for PSL2 steel pipe: CVN impact test and DWT test.

Test items and test frequencies for other pipe types can be found in Tables 17 and 18 of the API 5L standard.

Hydrostatic Test

Test Time

All sizes of seamless and welded steel tubes with D ≤ 457 mm (18 in.): test time ≥ 5s;

Welded steel pipe D > 457 mm (18 in.): test time ≥ 10s.

Experimental Frequency

Each steel pipe and there shall be no leakage from the weld or pipe body during the test.

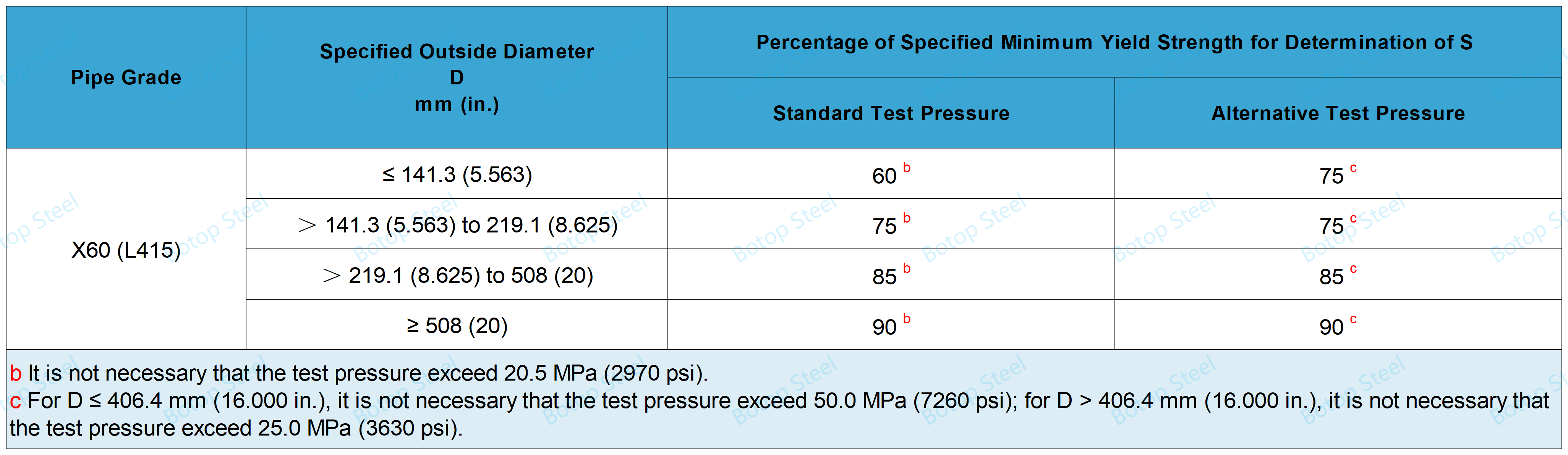

Test pressures

The hydrostatic test pressure P of a plain-end steel pipe can be calculated by using the formula.

P = 2St/D

S is the hoop stress. the value is equal to the specified minimum yield strength of the steel pipe x a percentage, in MPa (psi);

t is the specified wall thickness, expressed in millimeters (inches);

D is the specified outside diameter, expressed in millimeters (inches).

Nondestructive Inspection

For SAW tubes, two methods, UT (ultrasonic testing) or RT (radiographic testing), are usually used.

ET (electromagnetic testing) is not applicable to SAW tubes.

Welded seams on welded pipes of grades ≥ L210/A and diameters ≥ 60.3 mm (2.375 in) shall be nondestructively inspected for full thickness and length (100 %) as specified.

UT non-destructive examination

RT non-destructive examination

API 5L Pipe Schedule Chart

For ease of viewing and use, we have organized the relevant schedule PDF files. You can always download and view these documents if needed.

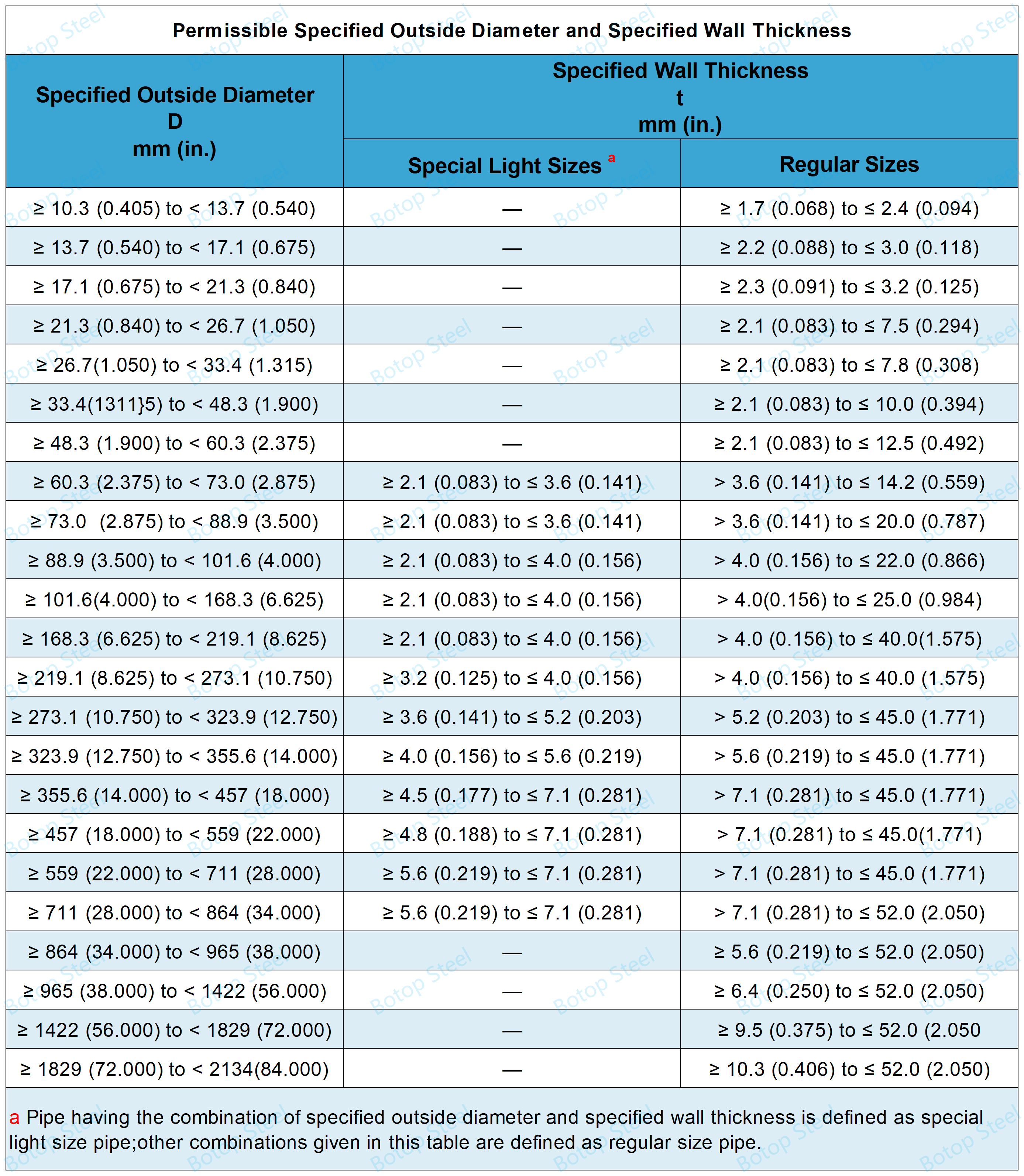

Specify Outside Diameter and Wall Thickness

Standardized values for specified outside diameters and specified wall thicknesses of steel pipe are given in ISO 4200 and ASME B36.10M.

Dimensional Tolerances

The API 5L requirements for dimensional tolerances are detailed in API 5L Grade B. To avoid repetition, you can click on the blue font to view the relevant details.

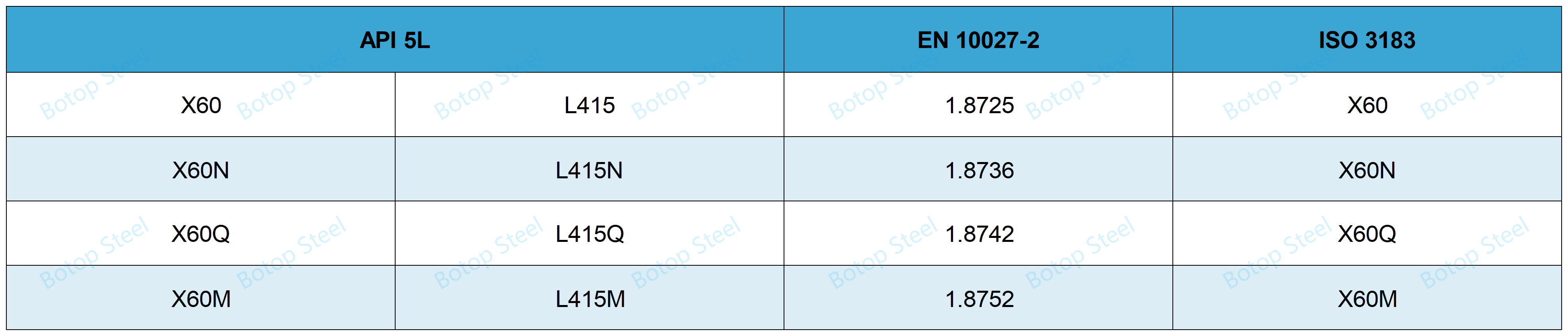

What is X60 Steel Equivalent to?

What is the Difference Between API 5L X60 and X65?