API 5L X65 (L450) is an API 5L medium to high-grade carbon steel pipe, named for its minimum yield strength of 65,300 psi (450 MPa).

Often designed to cope with extreme pressures and harsh environments, X65 steel pipe is ideally suited for oil and gas pipelines where high durability and reliability are required. In addition, its excellent mechanical properties and corrosion resistance make it ideal for use in subsea pipelines and highly corrosive industrial environments.

Botop Steel is a professional manufacturer of thick-walled large-diameter double-sided submerged arc LSAW steel pipe located in China.

Location: Cangzhou City, Hebei Province, China;

Total Investment: 500 million RMB;

Factory area: 60,000 square meters;

Annual production capacity: 200,000 tons of JCOE LSAW steel pipes;

Equipment: Advanced production and testing equipment;

Specialization: LSAW steel pipe production;

Certification: API 5L certified.

API 5L X65 Classification

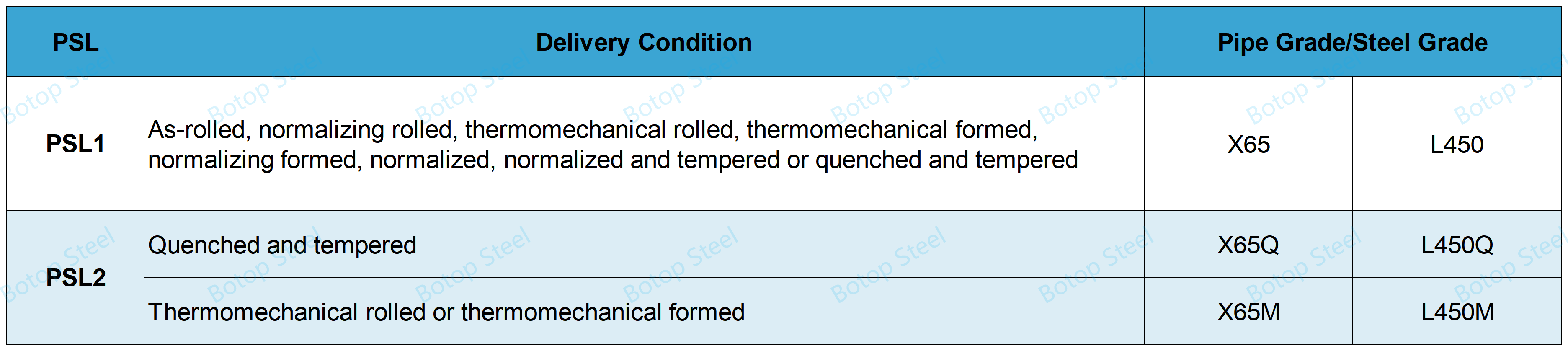

Depending on the PSL level and delivery condition, X65 can be categorized as follows:

PSL1: X65 (L450);

PSL2: X65Q (L450Q) and X65M (L450M);

In order to cope with the harsh conditions of offshore (O) and sour service environments (S), the API 5L PSL2 standard has special requirements for both environments. These requirements are indicated by the addition of a specific letter to the pipe grade.

Offshore services PSL2 pipe: X65QO (l450QO) or X65MO (L450MO);

Sour service PSL2 pipe: X65QS (L450QS) or X65MS (L450MS).

Delivery Conditions

Meaning of Q and M

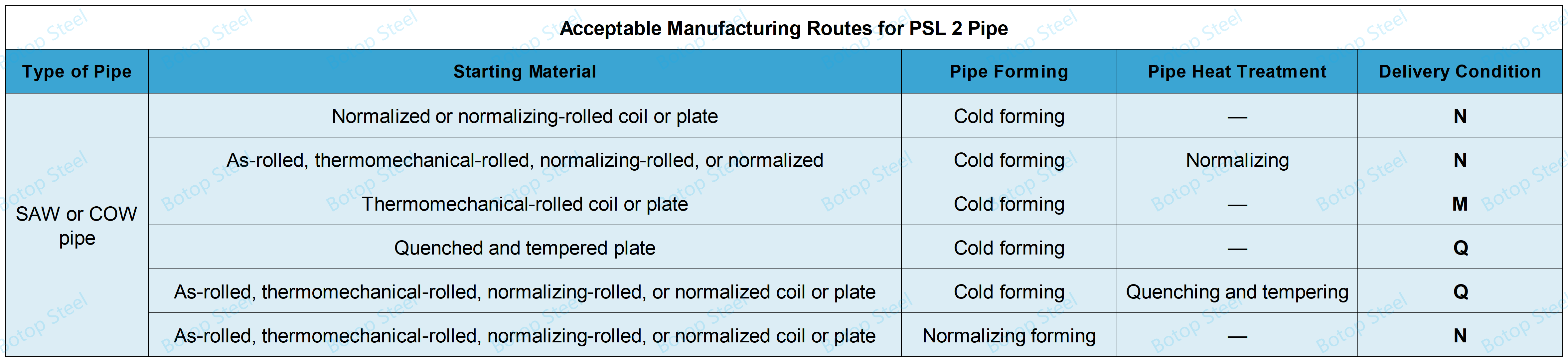

For SAW ( Submerged Arc Welded) or COW (Combination Welded Pipe), Q and M in the delivery status of API 5L PSL2 correspond to the following manufacturing processes respectively.

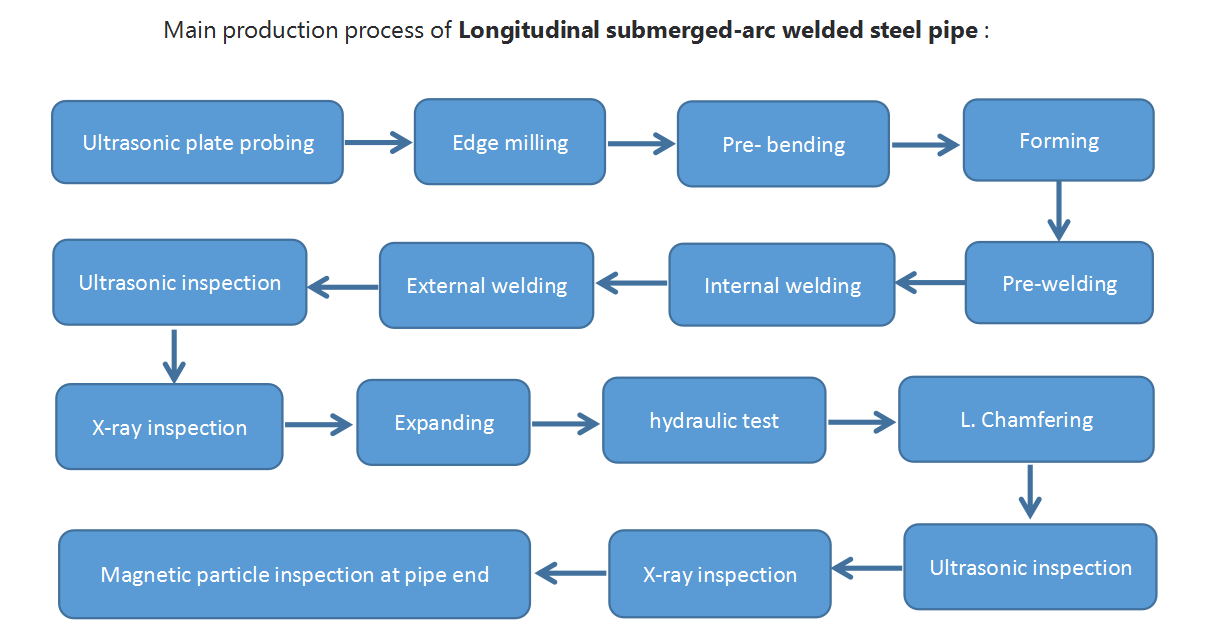

API 5L X65 Manufacturing Process

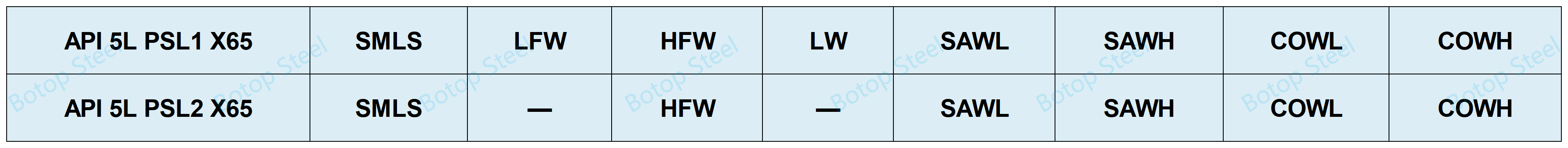

X65 pipes can be produced through a variety of manufacturing processes to suit a wide range of engineering applications.

SAWL (LSAW) is ideal for the production of large-diameter, thick-walled tubes with diameters in excess of 660 mm, especially at the price point where it offers a cost advantage over seamless tubes.

Pipe End Types for API 5L X65

PSL1 Steel Pipe End: Belled end or Plain end;

PSL2 Steel Pipe End: Plain end;

For plain pipe ends the following requirements should be followed:

The end faces of t ≤ 3.2 mm (0.125 in) plain end pipe shall be square cut.

Plain-end tubes with t > 3.2 mm (0.125 in) shall be beveled for welding. The bevel angle should be 30-35° and the width of the root face of the bevel should be 0.8 - 2.4 mm (0.031 - 0.093 in).

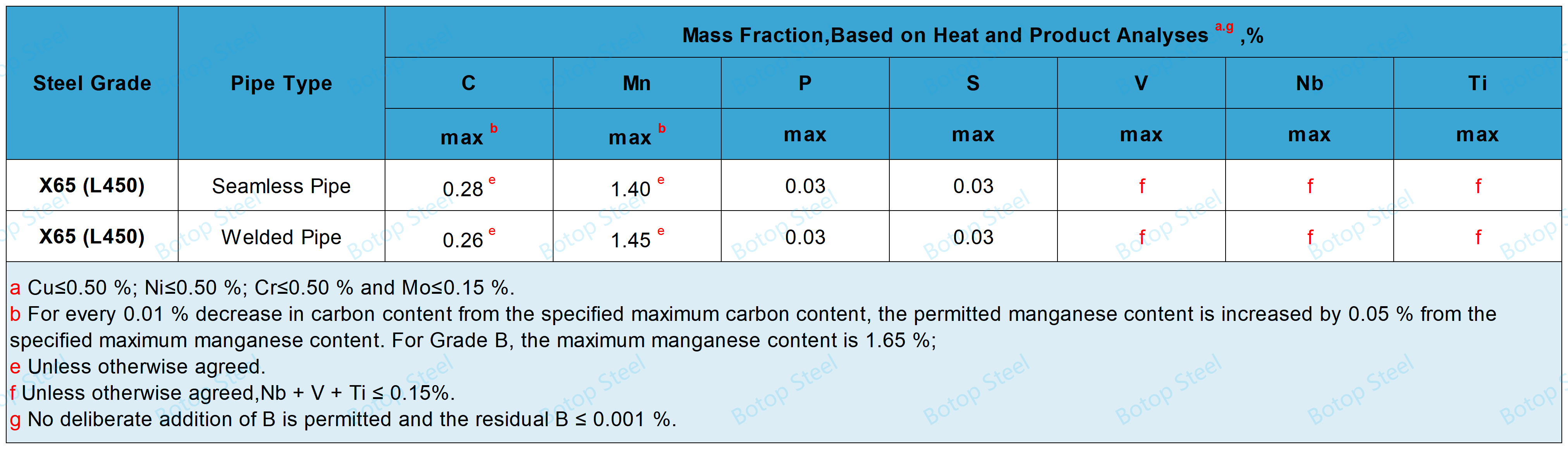

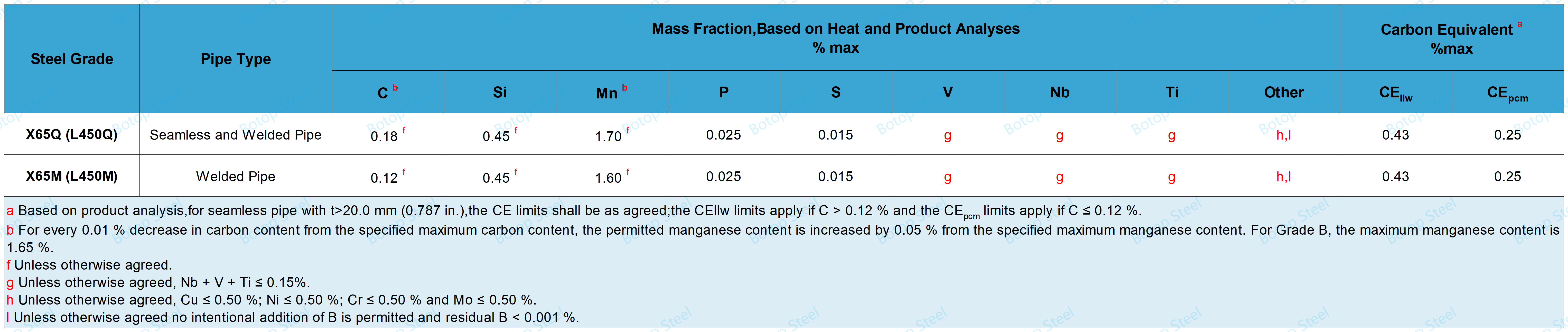

API 5L X65 Chemical Composition

The chemical composition of PSL1 and PSL2 steel pipe t > 25.0 mm (0.984 in) shall be determined by agreement.

Chemical Composition for PSL 1 Pipe with t ≤ 25.0 mm (0.984 in.)

Chemical Composition for PSL 2 Pipe with t ≤ 25.0 mm (0.984 in.)

For PSL2 steel pipe products analyzed with a carbon content of ≤0.12%, the carbon equivalent CEpcm can be calculated using the following formula:

CEpcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

For PSL2 steel pipe products analyzed with a carbon content > 0.12%, the carbon equivalent CEllw can be calculated using the formula below:

CEllw = C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

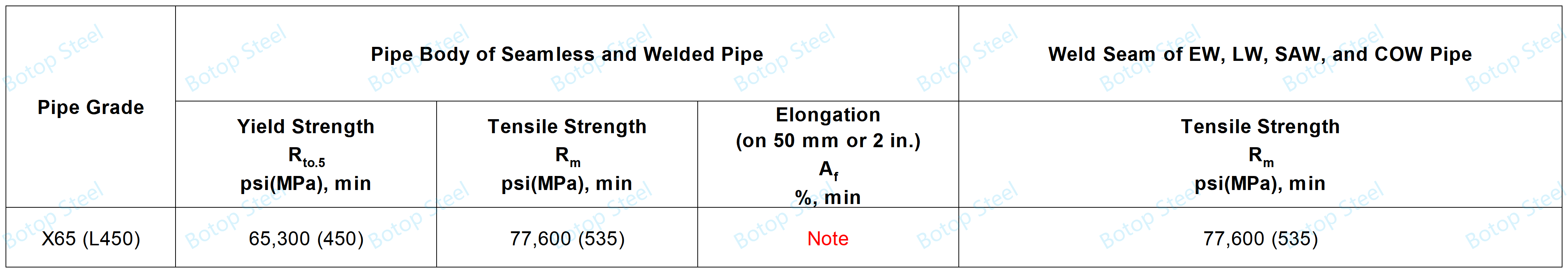

API 5L X65 Mechanical Properties

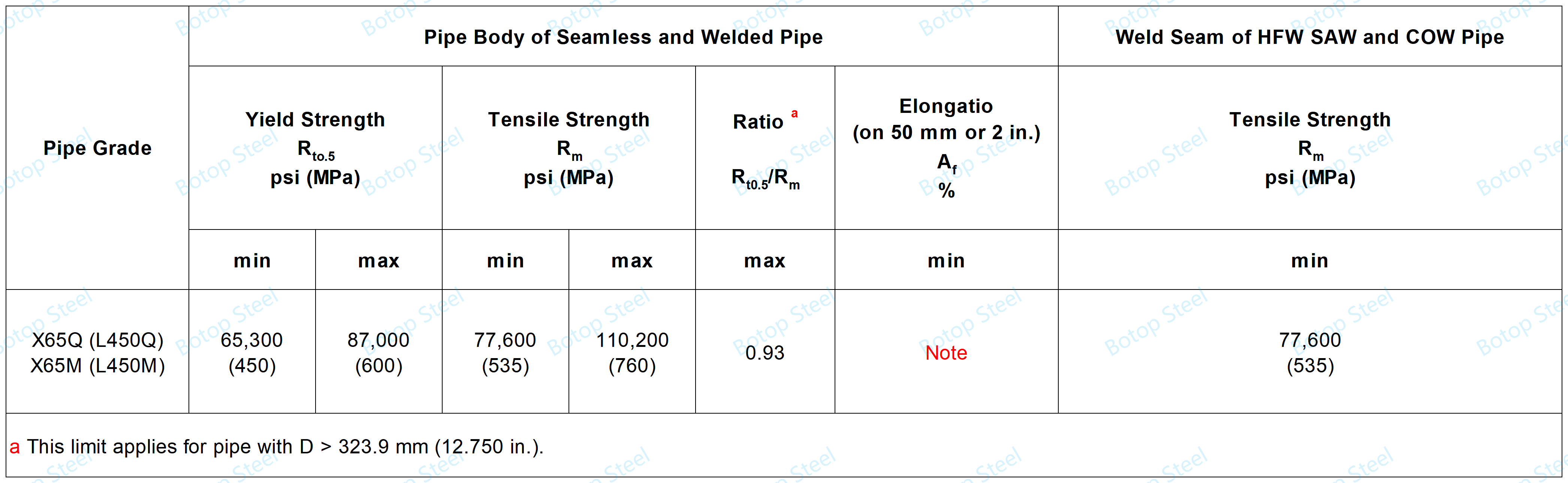

Tensile Properties

Tensile testing allows for the determination of key properties of X65 materials, including yield strength, tensile strength, and elongation.

PSL1 X65 Tensile Properties

PSL2 X65 Tensile Properties

Note: The requirements are detailed in API 5L X52, which can be viewed if needed.

Other Mechanical Experiments

The following test program applies to SAW pipe types. For other pipe types, see Tables 17 and 18 of API 5L.

Weld guide bending test;

Cold-formed welded pipe hardness test;

Macro inspection of the welded seam;

and only for PSL2 steel pipe: CVN impact test and DWT test.

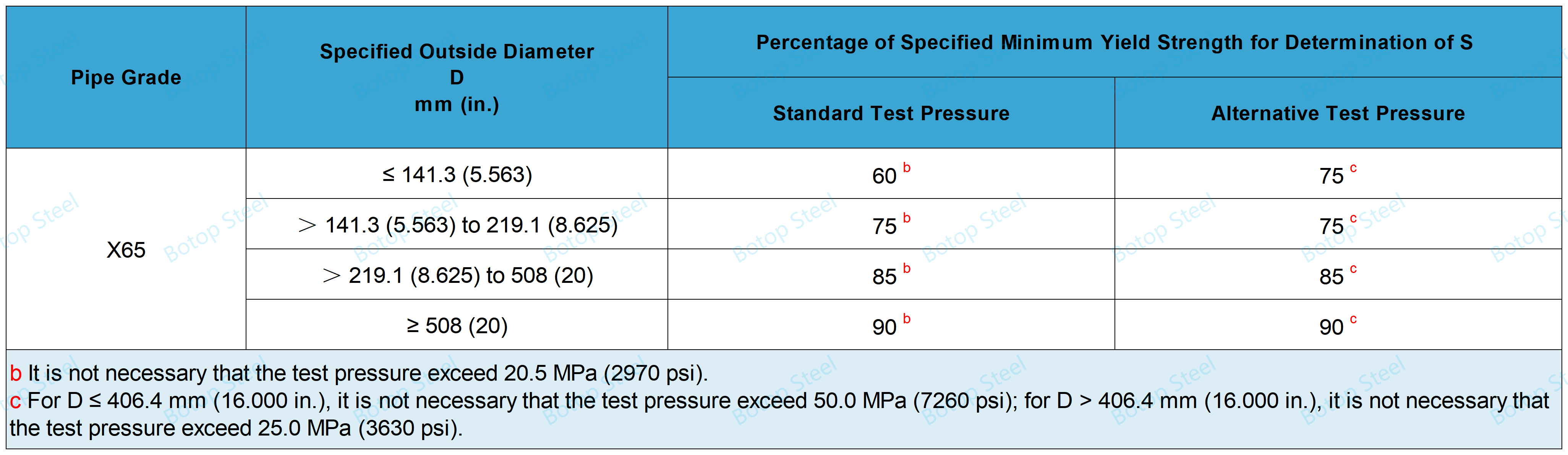

Hydrostatic Test

Test Time

All sizes of seamless and welded steel tubes with D ≤ 457 mm (18 in.): test time ≥ 5s;

Welded steel pipe D > 457 mm (18 in.): test time ≥ 10s.

Experimental Frequency

Each steel pipe.

Test pressures

The hydrostatic test pressure P of a plain-end steel pipe can be calculated by using the formula.

P = 2St/D

S is the hoop stress. the value is equal to the specified minimum yield strength of the steel pipe x a percentage, in MPa (psi);

t is the specified wall thickness, expressed in millimeters (inches);

D is the specified outside diameter, expressed in millimeters (inches).

Nondestructive Inspection

For SAW tubes, two methods, UT (ultrasonic testing) or RT (radiographic testing), are usually used.

ET (electromagnetic testing) is not applicable to SAW tubes.

Welded seams on welded pipes of grades ≥ L210/A and diameters ≥ 60.3 mm (2.375 in) shall be nondestructively inspected for full thickness and length (100 %) as specified.

UT non-destructive examination

RT non-destructive examination

API 5L Pipe Schedule Chart

API 5L pipes are categorized into different "Schedules" according to different wall thicknesses, such as Schedule 20, Schedule 40, Schedule 80, etc. These wall thicknesses correspond to different pressure ratings and application scenarios. These wall thicknesses correspond to different pressure ratings and application scenarios.

For ease of viewing and use, we have organized the relevant schedule PDF files. You can always download and view these documents if needed.

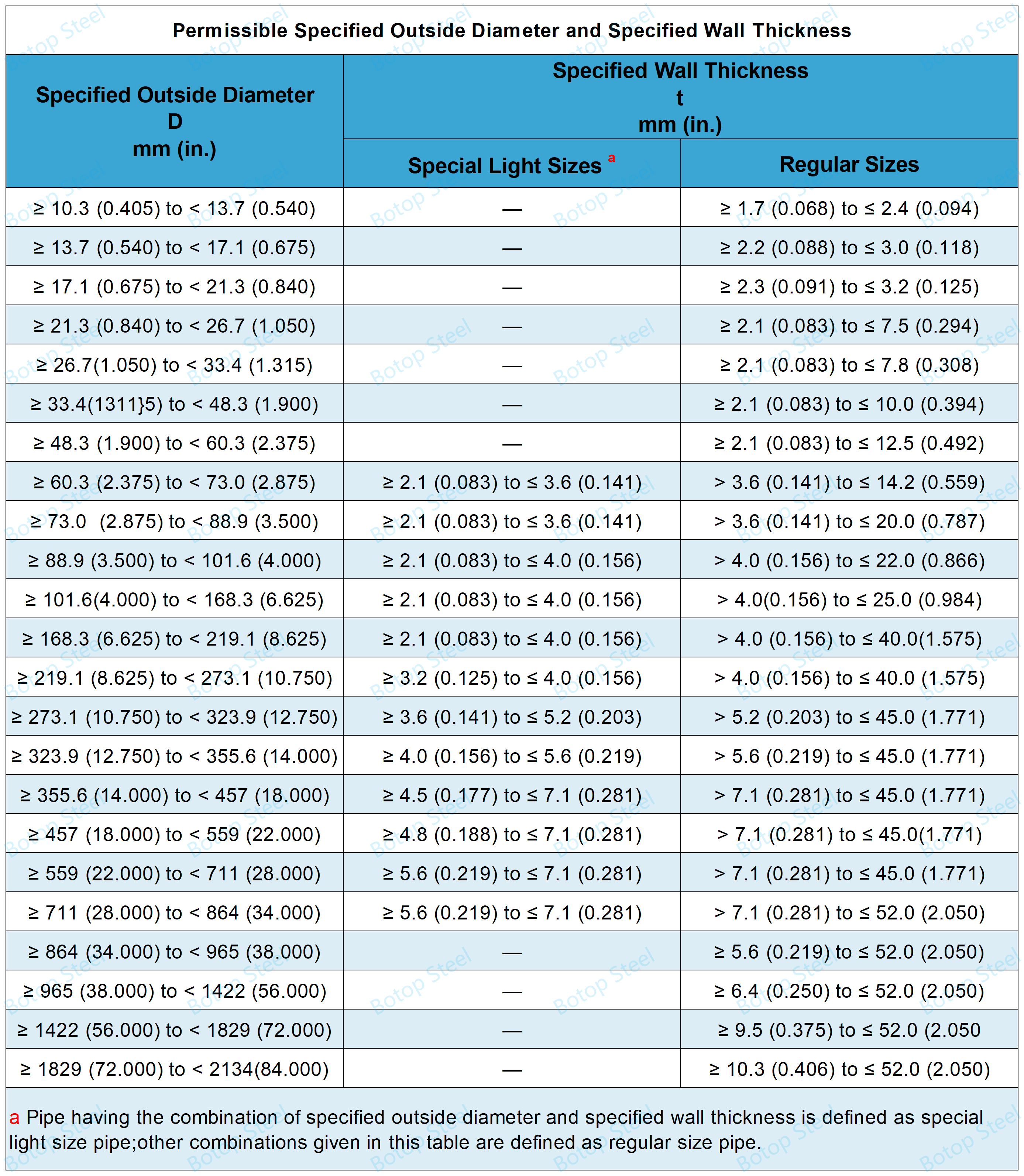

Specify Outside Diameter and Wall Thickness

Standardized values for specified outside diameters and specified wall thicknesses of steel pipe are given in ISO 4200 and ASME B36.10M.

Dimensional Tolerances

The API 5L requirements for dimensional tolerances are detailed in API 5L Grade B. To avoid repetition, you can click on the blue font to view the relevant details.

Applications

API 5L X65 steel pipe is a high-strength steel pipe used primarily in the oil and gas industry, especially in long-distance transmission pipelines and high-pressure applications.

Long-distance transportation pipelines: Commonly used for long-distance oil and gas transportation pipelines, these pipelines need to withstand high pressure and extreme environmental conditions.

Crossing pipelines: Where pipelines need to cross rivers, mountains, or other obstacles, the high strength properties of API 5L X65 steel pipe make it ideal.

Offshore platform: In offshore oil and gas extraction, used to connect a drilling platform to a land terminal or to transfer hydrocarbons between offshore facilities.

Industrial piping systems: Used in petrochemicals, refineries, and other industrial facilities to transport a variety of media, such as crude oil, natural gas, chemical raw materials, etc.

X65 Equivalent Material

API 5L X65 equivalents usually refer to steel pipe materials with similar chemical composition, mechanical properties, and applications, the following are some of the equivalent material standards and grades:

ISO 3183: L450;

EN 10208-2: L450MB;

JIS G3454: STPG450;

DNV OS-F101: S450;

Our Supply Range

Standard: API 5L or ISO 3183;

PSL1: X65 or L450;

PSL2: X65Q, X65M or L450Q, L450M;

Pipe Type: Welded Carbon Steel Pipe;

Manufacturing Process: LSAW, SAWL or DSAW;

Outer Diameter: 350 – 1500;

Wall Thickness: 8 - 80mm;

Length: Approximate lengths or random length;

Pipe Schedules: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 and SCH160.

Identification: STD, XS, XXS;

Coating: Paint, varnish, 3LPE, FBE, 3LPP, HDPE, galvanized, epoxy zinc-rich, cement weighted, etc.

Packing: Waterproof cloth, wooden case, steel belt or steel wire bundling, plastic or iron pipe end protector, etc. Customized.

Matching Products: Bends, flanges, pipe fittings, and other matching products are available.