API 5L X65 PSL1/PSL2 LSAW Carbon Steel Pipe is manufactured by forming the X65 steel plates into a round shape then welding the seam through automatically arc welding process. In the production of API 5L X65 PSL1&PSL2 LSAW Carbon Steel Pipe, plates of grade X65 are formed by the molding machine into round shape then welded through double-sided submerged arc welding.The production process of submerged arc welded straight seam steel pipe includes JCOE forming technology, coil forming submerged arc welding technology and UOE forming technology.

The process of manufacturing Longitudinal Submerged-arc Welded(LSAW) Pipe is as follows:

Ultrasonic plate probing → edge milling → pre-bending → forming → Pre-welding → Internal welding→ External welding → Ultrasonic inspection → X-ray inspection → Expanding → hydraulic test →l. Chamfering → Ultrasonic inspection → X-ray inspection → magnetic particle inspection at tube end

| Product Name | LSAW Steel Pipe |

| Process | LSAW-UO(UOE), RB (RBE),JCO(JCOE) |

| Standard | API 5L,API 5CT,ASTM 53,EN10219,GB/T3091,GB/T9711 |

| Certificate | ISO9001 ISO45001 IS014001 BV BC1 EN10219 EN10210 ASTM A500/501 JIS G3466 EPD PHD |

| Out Diameter | 406mm-1500mm |

| Wall Thickness | 8-50mm |

| Length | 1-12M or as request |

| Grade | API X42 X52 X60 X65 X70 GR.A GR.B GR.C,S275JOH,S355JR,S355JOH,S355J2H,S355 S235,S420,S460 |

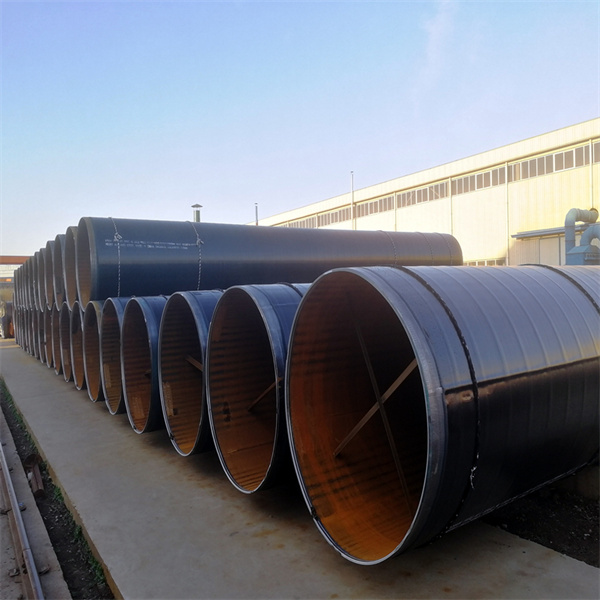

| Surface | Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer's requirement |

| Test | Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test. |

| MOQ | 5 Tons |

| END | Plain,Bevelled |

| Package | In bundles ,loose piece. |

API 5L X65 PSL1/PSL2 LSAW Carbon Steel Pipe is usually used in projects of oil and gas pipeline, submarine pipelines, and pipelines through high-altitude zones and dense urban areas.

Engineering Case of Hong Kong

Engineering Case of Qatar

Engineering Case of Iran

Mechanical Properties of API 5L GR.B X65 (PSL1) / API 5L X70 (PSL1):

|

Grade |

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

||

|

|

psi |

MPa |

psi |

MPa |

Elongation (Min ) |

|

X65 |

65,000 |

448 |

77,000 |

531 |

18 |

|

X70 |

70,000 |

483 |

82,000 |

565 |

18 |

Mechanical Properties of API 5L X65 PSL1/PSL 2 (PSL2) / API 5L Grade X70 (PSL 2):

|

Grade |

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

Impact (J) |

||

|

|

psi |

MPa |

psi |

MPa |

Elongation (Min ) |

Min |

|

X65 |

65,000 |

448 |

87,000 |

600 |

18 |

40 |

|

X70 |

70,000 |

483 |

90,000 |

621 |

18 |

40 |

RT Testing

Hydrostatic Testing

UT Testing

Grade and Chemical Composition (%) For API 5L X65 PSL1 / API 5L X70 PSL1

|

Standard |

Grade |

Chemical composition(%) |

|||

|

C |

Mn |

P |

S |

||

|

API 5L |

X65 |

≤0.26 |

≤1.45 |

≤0.030 |

≤0.030 |

|

API 5L |

X70 |

≤0.26 |

≤1.65 |

≤0.030 |

≤0.030 |

| Size |

Type of Pipe |

Tolerance1 (Percent of Specified Wall Thickness} |

|

|

Grade B or Lower |

Grade X42 or Higher |

||

|

<2 7/8 |

All |

+20.- 12.5 |

+ 15.0.-12.5 |

|

>2 7/8and<20 |

All |

+ 15,0,-12.5 |

+ 15-I2.5 |

|

>20 |

Welded |

+ 17.5.-12.5 |

+ 19.5.-8.0 |

|

>20 |

Seamless |

+ 15.0.-12.5 |

+ 17.5.-10,0 |

Where negative tolerances smaller than those listed are specified by the purchaser, the positive tolerance shall be increased to the applicable total tolerance range in percent less the wall thickness negative tolerance.

Black Painting

3LPE Coating

FBE Coating

API 5L X70 LSAW Steel Pipe

API 5L X65 LSAW Steel Pipe

LSAW Carbon Steel Pipe

LSAW STEEL PIPE WITH 3PE COATING

DN1400 LARGE DIAMETER LSAW STEEL PIPE