API 5L X70 (L485) is a type of steel pipe used in the oil and gas industry for pipeline transportation systems, named after its minimum yield strength of 70,300 psi (485 MPa), and consists of both seamless and welded pipe forms and is divided into two product specification levels, PSL1 and PSL2. In PSL1, X70 is the highest grade, while in PSL2 it is also one of the higher grades of steel pipe.

API 5L X70 steel pipe is particularly suited to the demands of long-distance, high-pressure transportation because of its high strength and pressure resistance. In order to withstand higher pressures, X70 steel pipe is often designed with thicker walls to ensure adequate strength and durability.

Botop Steel is a professional manufacturer of thick-walled large-diameter double-sided submerged arc LSAW steel pipe located in China.

Location: Cangzhou City, Hebei Province, China;

Total Investment: 500 million RMB;

Factory area: 60,000 square meters;

Annual production capacity: 200,000 tons of JCOE LSAW steel pipes;

Equipment: Advanced production and testing equipment;

Specialization: LSAW steel pipe production;

Certification: API 5L certified.

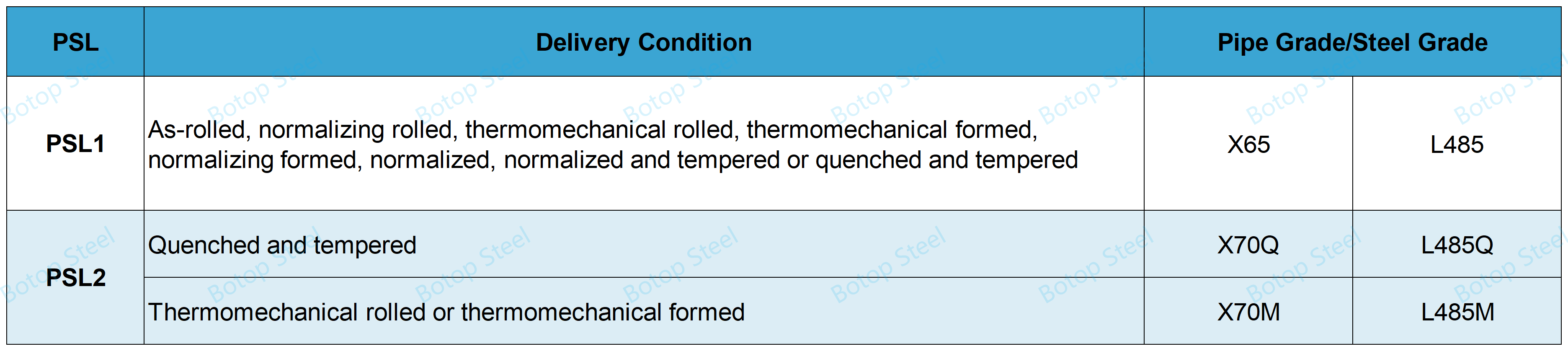

Delivery Conditions

Delivery condition is the heat-treated or processed state of a steel tube when it is ready to be delivered to the customer after manufacturing. Delivery condition is essential to ensure the tube has the required mechanical properties and structural integrity.

Depending on the PSL level and delivery condition, X70 can be categorized as follows:

PSL1: X70 (L485);

PSL2: X70Q (L485Q) and X70M (L485M);

PSL2 suffix letters Q and M stand for respectively:

Q: Quenched and tempered;

M: Thermomechanical rolled or thermomechanical formed;

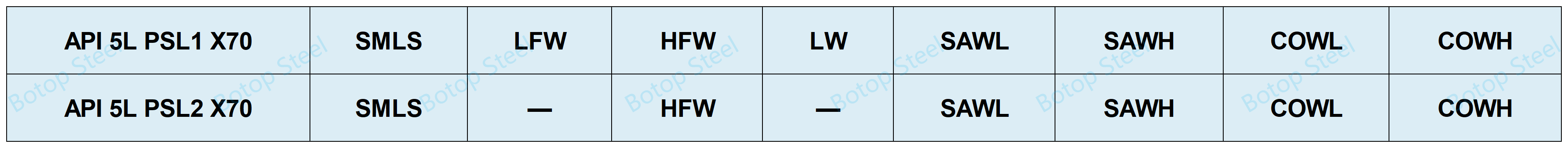

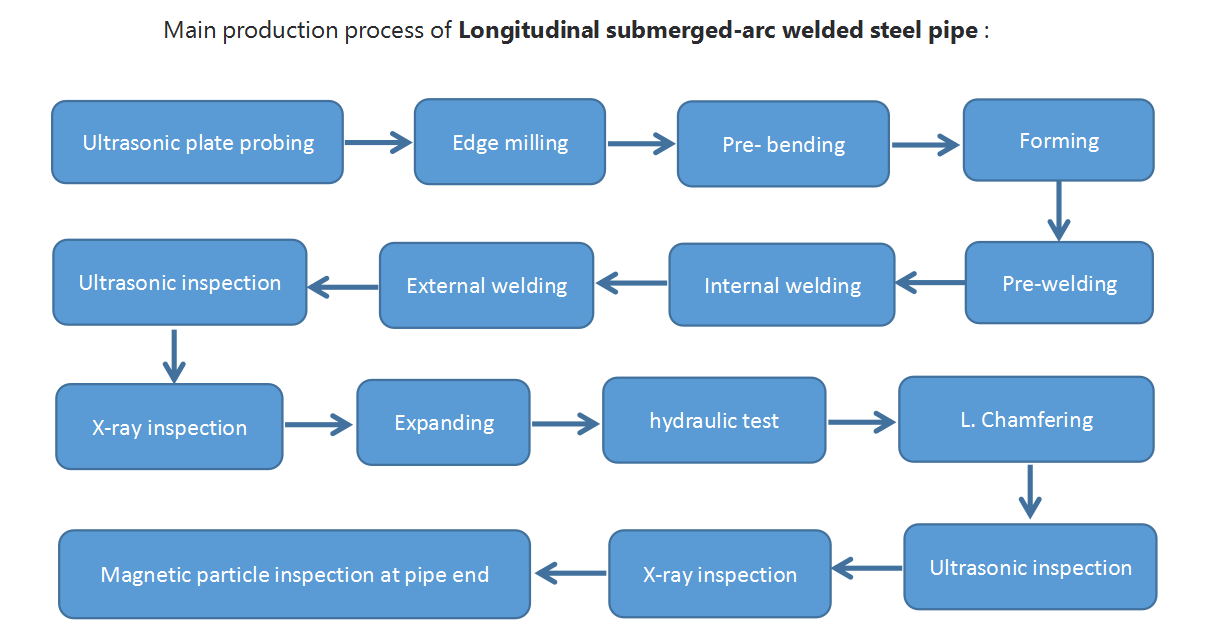

API 5L X70 Acceptable Process of Manufacture

The X70 manufacturing process includes both seamless and welded forms, which can be categorized as:

Of these, SAWL (LSAW) is the most common process used in the production of X70 welded processes and is advantageous in the production of large-diameter, thick-walled dimensional steel pipe.

Although seamless steel pipes are still considered the preferred choice due to their characteristics under certain extreme conditions, the maximum diameter of seamless steel pipes produced is usually limited to 660 mm. This size limitation can be problematic when faced with large long-distance transportation pipeline projects.

In contrast, the LSAW process is capable of producing tubes with diameters up to 1,500 mm and wall thicknesses up to 80 mm. And the price can be more cost-effective than seamless steel.

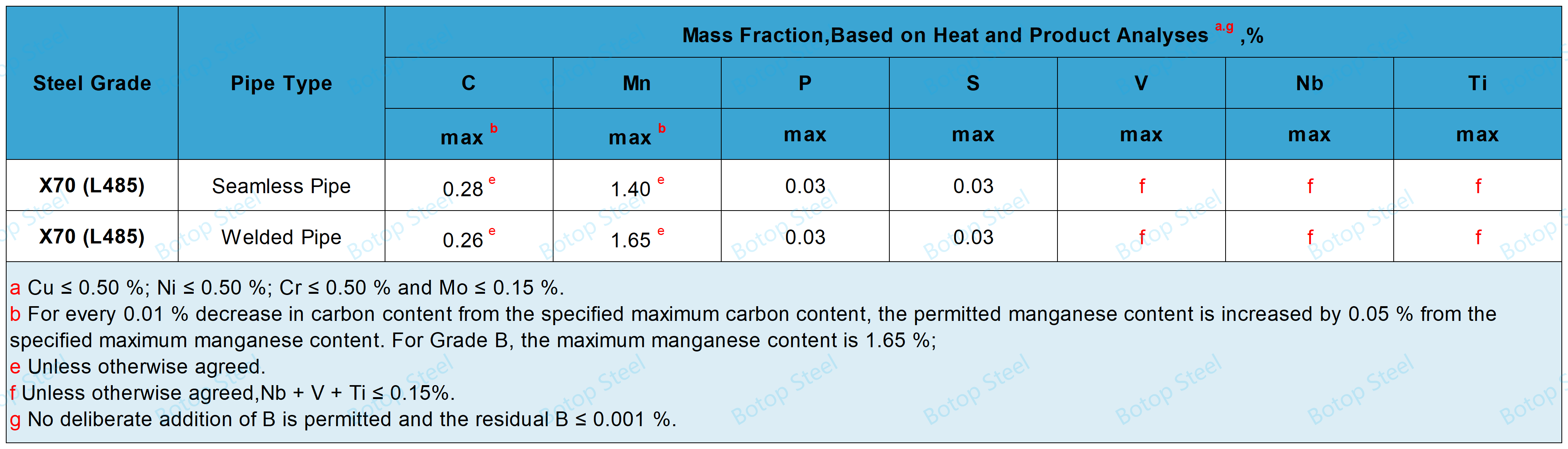

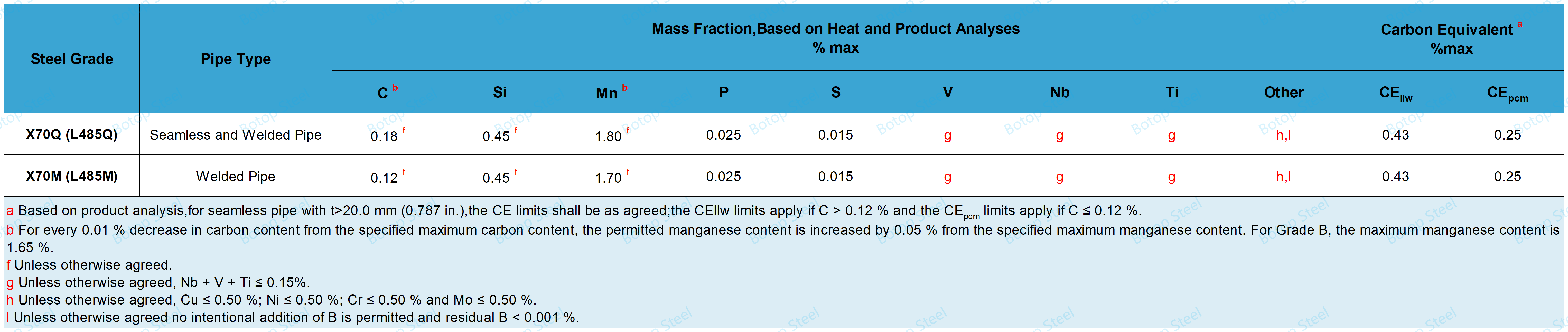

API 5L X70 Chemical Composition

Chemical Composition for PSL 1 Pipe with t ≤ 25.0 mm (0.984 in.)

Chemical Composition for PSL 2 Pipe with t ≤ 25.0 mm (0.984 in.)

For PSL2 steel pipe products analyzed with a carbon content of ≤0.12%, the carbon equivalent CEpcm can be calculated using the following formula:

CEpcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

For PSL2 steel pipe products analyzed with a carbon content > 0.12%, the carbon equivalent CEllw can be calculated using the formula below:

CEllw = C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

Chemical Composition with t > 25.0 mm (0.984 in.)

It shall be determined by negotiation and modified to a suitable composition based on the chemical composition requirements above.

API 5L X70 Mechanical Properties

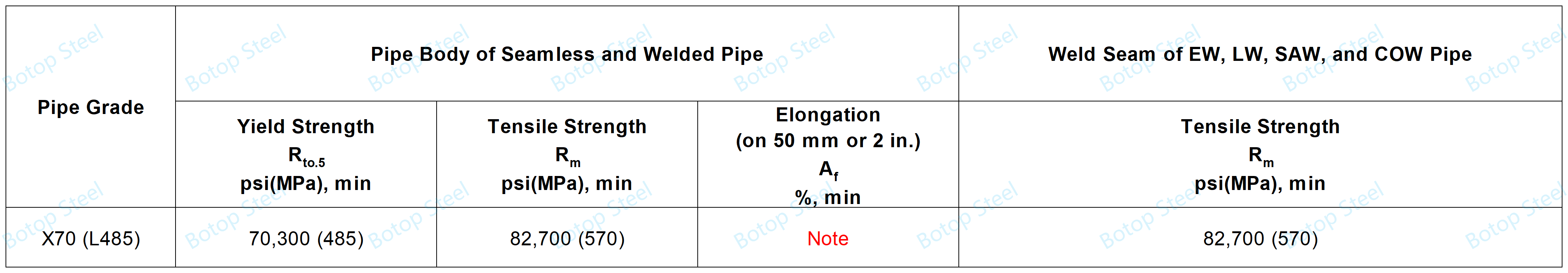

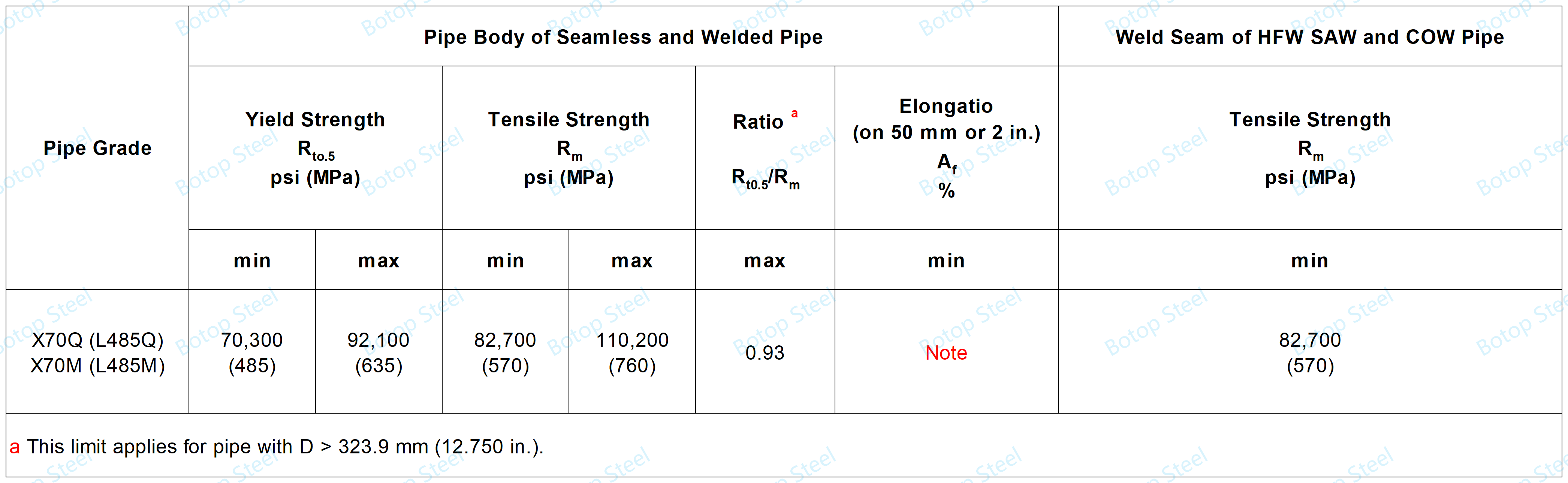

Tensile Properties

PSL1 X70 Tensile Properties

PSL2 X70 Tensile Properties

Note: The requirements are detailed in API 5L X52, which can be viewed if needed.

Other Mechanical Experiments

The following experimental program applies to SAW steel pipe types only.

Weld guide bending test;

Cold-formed welded pipe hardness test;

Macro inspection of welded seam;

and only for PSL2 steel pipe: CVN impact test and DWT test.

Test items and test frequencies for other pipe types can be found in Tables 17 and 18 of the API 5L standard.

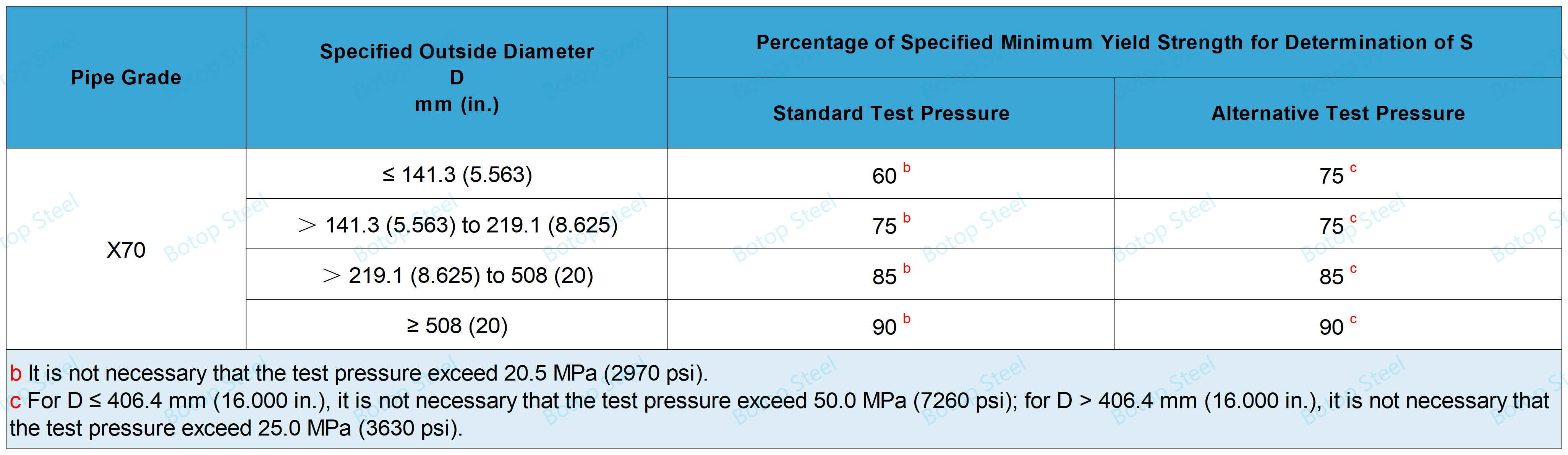

Hydrostatic Test

Test Time

All sizes of seamless and welded steel tubes with D ≤ 457 mm (18 in.): test time ≥ 5s;

Welded steel pipe D > 457 mm (18 in.): test time ≥ 10s.

Experimental Frequency

Each steel pipe and there shall be no leakage from the weld or pipe body during the test.

Test pressures

The hydrostatic test pressure P of a plain-end steel pipe can be calculated by using the formula.

P = 2St/D

S is the hoop stress. the value is equal to the specified minimum yield strength of the steel pipe x a percentage, in MPa (psi);

t is the specified wall thickness, expressed in millimeters (inches);

D is the specified outside diameter, expressed in millimeters (inches).

Nondestructive Inspection

For SAW tubes, two methods, UT (ultrasonic testing) or RT (radiographic testing), are usually used.

ET (electromagnetic testing) is not applicable to SAW tubes.

Welded seams on welded pipes of grades ≥ L210/A and diameters ≥ 60.3 mm (2.375 in) shall be nondestructively inspected for full thickness and length (100 %) as specified.

UT non-destructive examination

RT non-destructive examination

For SAW and COW pipe, the welds shall be inspected by radiographic inspection methods within a minimum of 200 mm (8.0 in) of each pipe end. in) of each pipe end shall be inspected by radiographic inspection.

API 5L Pipe Schedule Chart

For ease of viewing and use, we have organized the relevant schedule PDF files. You can always download and view these documents if needed.

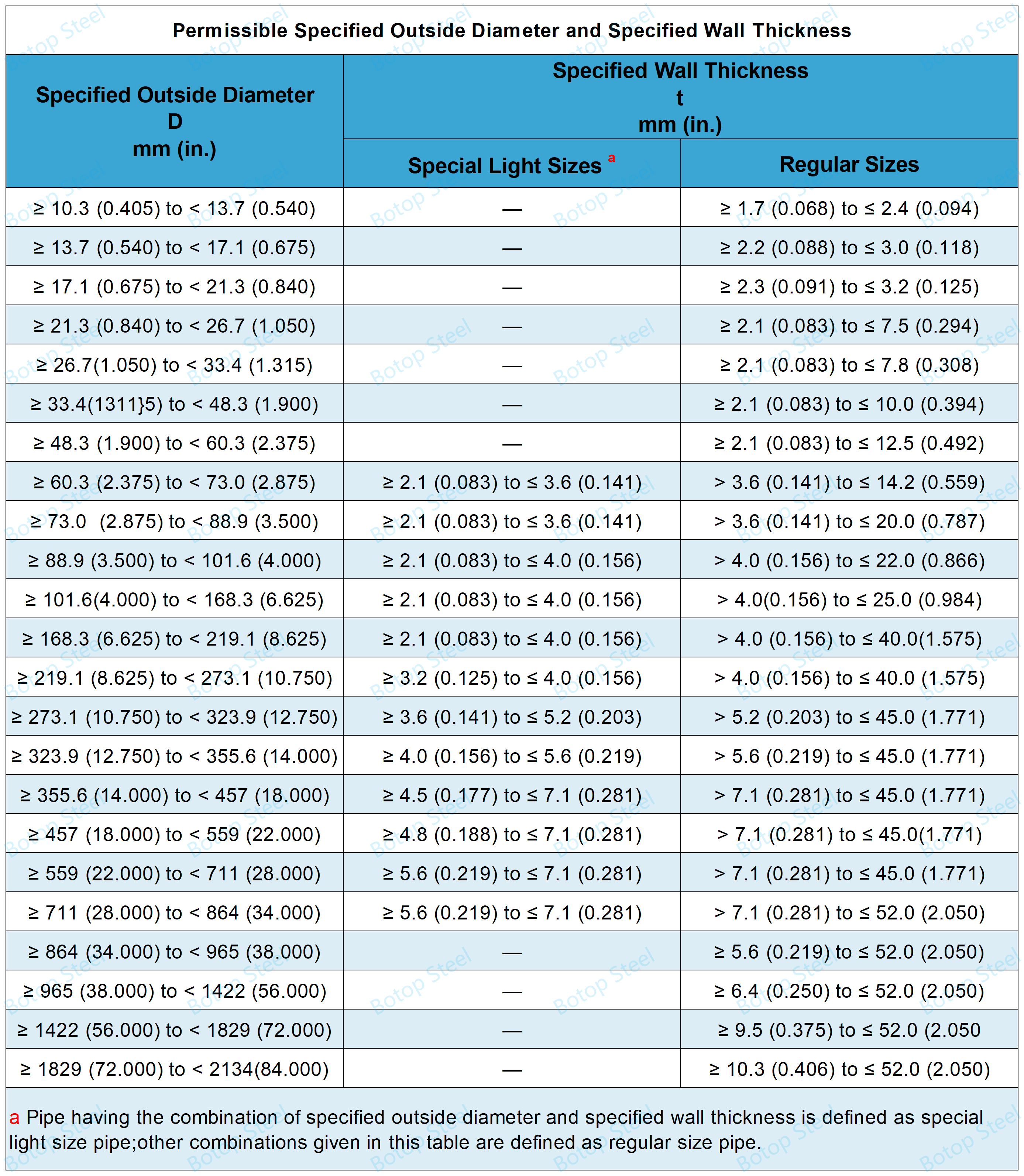

Specify Outside Diameter and Wall Thickness

Standardized values for specified outside diameters and specified wall thicknesses of steel pipe are given in ISO 4200 and ASME B36.10M.

Dimensional Tolerances

The API 5L requirements for dimensional tolerances are detailed in API 5L Grade B. To avoid repetition, you can click on the blue font to view the relevant details.

Common Defects and Repairs

For SAW tubes, the following defects are commonly found: nibbled edges, arc burns, delamination, geometric deviations, hard lumps, etc.

Deficiencies found by visual inspection shall be verified, categorized, and disposed of as follows.

a) Depth ≤ 0.125t, and does not affect the minimum allowable wall thickness of the defect shall be determined as acceptable defects and shall be disposed of in accordance with the provisions of C.1.

b) Defects >0.125t in depth that do not affect the minimum allowable wall thickness shall be judged to be defects and shall be removed by resharpening in accordance with C.2 or disposed of in accordance with C.3.

c) A defect affecting the minimum permissible wall thickness shall be recognized as a defect and shall be disposed of in accordance with C.3.

Color Identification

If requested, a color marking of approximately 50 mm (2 in.) in diameter can be painted on the inside surface of each steel pipe to allow for easy differentiation of the different materials.

| Pipe Grade | Paint Color |

| L320 or X46 | Black |

| L360 or X52 | Green |

| L390 or X56 | Blue |

| L415 or X60 | Red |

| L450 or X65 | White |

| L485 or X70 | Purple-violet |

| L555 or X80 | Yellow |

What is X70 Steel Equivalent to?

ISO 3183 - L485: This is a pipeline steel under international standards and is similar in properties to API 5L X70.

CSA Z245.1 - GR 485: This is a Canadian Standards Association steel grade for oil and gas pipelines.

EN 10208-2 - L485MB: This is a pipeline steel under the European Standard for the manufacture of pipelines for the transportation of oil and gas.

Coating

We not only provide our customers with high-quality X70 steel pipes but also offer many types of coating services to meet the specific needs of different projects.

Paint coatings: Traditional paint coatings provide basic protection against corrosion and are suitable for non-extreme environments or temporary protection.

FBE coating: Applied to the surface of steel pipe by electrostatic spraying process and then cured by heat. This coating has good chemical and abrasion resistance and is suitable for underground or underwater pipelines.

3LPE coating: Consisting of an epoxy coating, an adhesive layer, and a polyethylene layer, it provides excellent corrosion resistance and mechanical protection for a wide range of underground transportation piping systems.

3LPP coating: Similar to 3LPE, the 3LPP coating consists of three layers, but uses polypropylene as the outer layer. This coating has higher heat resistance and is suitable for piping in high-temperature environments.

Coatings can be selected based on the specific application environment and requirements of the pipeline to ensure the reliability and safety of API 5L X70 pipelines during service.

Reasons to Choose Us for X70 Steel Pipe

1. API 5L certified factories: Our factories hold API 5L certification, which ensures high-quality standards from source to finished product with a price advantage.

2. Multiple pipe types: We are not only a manufacturer of welded steel pipes but also a stockist of seamless steel pipes, and we can offer a wide range of pipe types that can meet the specific needs of different projects.

3. Complete supporting equipment: In addition to steel pipe, we can also provide flanges, elbows, and other supporting equipment, providing one-stop procurement solutions for your project.

4. Customized service: We are able to provide customized solutions according to customer's specific needs, including the production and processing of steel pipes with special specifications.

5. Specialized services: Since its establishment in 2014, the company has participated in a number of engineering projects and accumulated rich experience in the industry, enabling it to provide specialized services and support.

6. Rapid response and support: Our customer service team can provide rapid response and professional technical support to ensure that your problems and needs are resolved in a timely manner.