AS 1579 steel pipe is a butt weld arc welded steel pipe mainly used for the transportation of water and wastewater with an outside diameter of ≥ 114 mm and for pipe piles with a rated pressure not exceeding 6.8 MPa.

Pipe piles are circular structural members driven into the soil and are not used for internal pressure control.

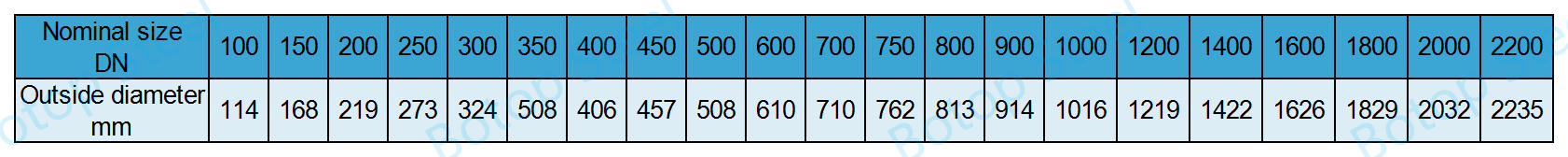

The minimum outside diameter is 114mm, although there is no specific limitation on the size of the pipe but preferred sizes are provided.

Shall be manufactured from analyzed or structural grades of hot rolled steel conforming to AS/NZS 1594 or AS/NZS 3678.

Depending on the end use it is still categorized as follows:

Hydrostatically tested pipes shall be manufactured from an analysis or structural grade of hot rolled steel complying with AS/NZS 1594 or AS/NZS 3678.

Piles and non-hydrostatically tested pipe shall be manufactured from a structural grade of steel complying with AS/NZS 1594 or AS/NZS 3678.

Alternatively, piles may be manufactured from an analysis grade complying with AS/NZS 1594., in which case the steel shall be mechanically tested in accordance with AS 1391 to demonstrate that it meets the tensile requirements specified by the purchaser.

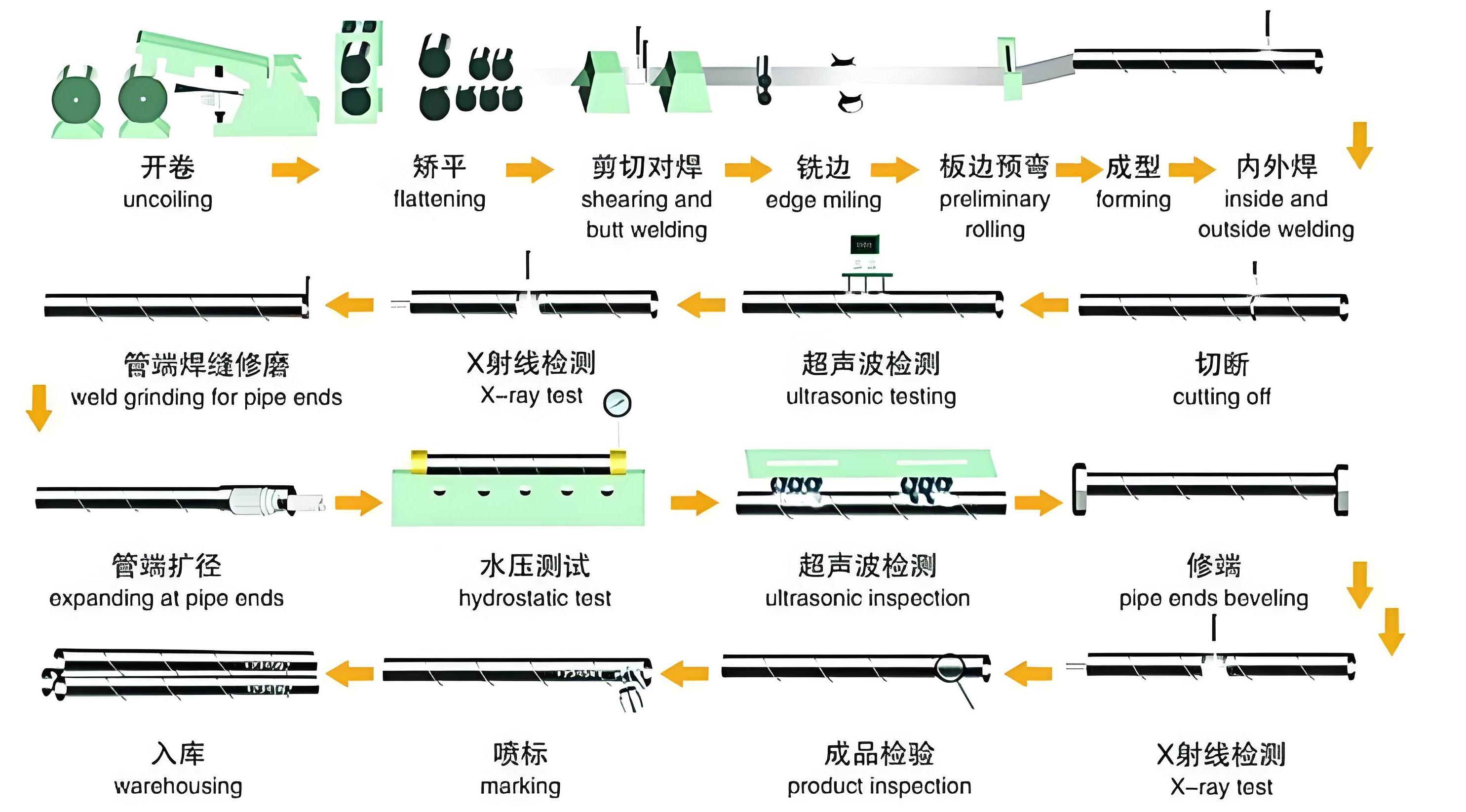

AS 1579 steel pipe is manufactured using arc welding.

All welds shall be fully penetrated butt welds.

Arc welding utilizes the heat of an electric arc to melt metal materials and form a welded joint between the metals to create a continuous steel pipe structure.

The commonly used arc welding manufacturing process is SAW (Submerged Arc Welding), also known as DSAW, which can be categorized into LSAW (SAWL) and SSAW (HSAW) according to the direction of the butt weld.

In addition to SAW, there are other types of arc welding such as GMAW, GTAW, FCAW, and SMAW. Various arc welding techniques have their own characteristics and application scenarios, and the selection of the appropriate welding method depends on the specifications of the steel pipe to be manufactured, the budget, and the quality requirements.

The standards themselves do not directly specify specific chemical compositions and mechanical properties, as this is often dependent on specific steel standards such as AS/NZS 1594 or AS/NZS 3678, which detail the chemical and mechanical property requirements of the steel used to make these tubes.

AS 1579 specifies only the carbon equivalent.

The carbon equivalent (CE) of the steel shall not exceed 0.40.

CE=Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

CE is an important parameter used to assess the weldability of steel. It helps to predict the hardening that may occur in steel after welding and thus assess its weldability.

Hydrostatic pressure testing is required for every water or wastewater steel pipe used for transportation.

Pipe piles are usually not required to be hydrostatically tested because they are primarily used to carry structural loads rather than internal pressures.

Experimental Principles

The pipe is sealed at each end and is pressurized hydrostatically.

It is checked for strength at a pressure that represents the design pressure of the pipe. It is tested for leak tightness at the rated pressure of the pipe.

Experimental Pressures

The maximum rated pressure of the steel pipe is 6.8 MPa.This maximum is dictated by a pressure test equipment limit of 8.5 MPa.

Pr = 0.72×(2×SMYS×t)/OD or Pr = 0.72×(2×NMYS×t)/OD

Pr: Rated pressure, in MPa;

SMYS: Specified minimum yield strength, in MPa;

NMYS: Nominal minimum yield strength, in MPa;

t: Wall thickness, in mm;

OD: Outside diameter, in mm.

In emergency situations, transient pressures may lead to an increase in pipe stress. Under these conditions, the maximum allowable combined stresses shall be determined by the designer, but shall not exceed 0.90 x SMYS.

Pt = 1.25Pr

After the strength test, there shall be no rupture or leakage in the test pipe.

90% of the specified minimum yield strength (SMYS) or the nominal minimum yield strength (NMYS) or 8.5 MPa, whichever is less.

Pl = Pr

A leak test shall be conducted on the pipe.

Upon leak testing, there shall be no leakage observable on the pipe surface.

All non-hydrostatic test pipes shall have a wall thickness of not less than 8.0 mm.

The pipe shall have 100% of its welds non-destructively tested by ultrasonic or radiographic methods in accordance with AS 1554.1 Category SP and conform to the specified acceptance criteria.

Non-destructive testing of partial pile welds for pipe piles. The test results shall comply with AS/NZS 1554.1 Class SP requirements. If the inspection reveals non-compliance with the labeling, the entire weld on that pipe pile shall be inspected.

Pipes and fittings used for the conveyance of water and sewage shall be protected from corrosion by the selection of a suitable coating The coating shall be applied in accordance with AS 1281 and AS 4321.

In the case of potable water, they should comply with AS/NZS 4020. The aim is to ensure that these products, when in contact with the water supply system, do not adversely affect the quality of the water, such as chemical contamination, microbiological contamination, or alteration of the taste and appearance of the water.

The outer surface of the tube, not more than 150 mm from the end, shall be clearly and permanently marked with the following information:

a) Unique serial number, i.e. tube number;

b) Place of manufacture;

c) Outside diameter and wall thickness;

d) Standard number, i.e. AS 1579;

e) Manufacturer's name or trademark;

f) Hydrostatic test pipe pressure rating (only for steel pipe subjected to hydrostatic testing);

g) Non-destructive testing marking (NDT) (only for steel pipe that has undergone non-destructive testing).

The manufacturer shall provide the Purchaser with a signed certificate stating that the pipe has been manufactured in accordance with the requirements of the Purchaser and this Standard.

ASTM A252: Designed for steel pipe piles and contains detailed mechanical properties and chemical composition specifications for three performance classes.

EN 10219: relates to cold-formed welded structural steel tubes for structural applications including pipe piles.

ISO 3183: Steel line pipe for the oil and gas industry, with quality and strength requirements that make it also suitable for carrying pipe piles.

API 5L: Mainly used for transportation pipelines in the oil and gas industry, the high-quality standards also make it suitable for making piles that are subject to high loads.

CSA Z245.1: Specifies steel pipes and fittings for the transportation of oil and gas, which are also suitable for pipe piles.

ASTM A690: Designed for steel pipe piles used in marine and similar environments, emphasizing corrosion resistance.

JIS A 5525: Japanese standard covering steel pipe for pipe piles, including material, fabrication, dimensional and performance requirements.

GOST 10704-91: Electrically welded straight seam steel pipe for use in building and engineering structures, including pipe piles.

GOST 20295-85: Details of electrically welded steel pipes for the transportation of oil and gas, showing their performance under high pressure and in harsh environments, applicable to pipe piles.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.