AS/NZS 1163 is a standard developed by Standards Australia and Standards New Zealand.

The standard specifies requirements for the manufacture and supply of cold formed, Electric Resistance Welding(ERW), steel hollow sections for structural purposes. These hollow sections are commonly used in construction and engineering applications for a variety of structures such as buildings, bridges, and infrastructure.

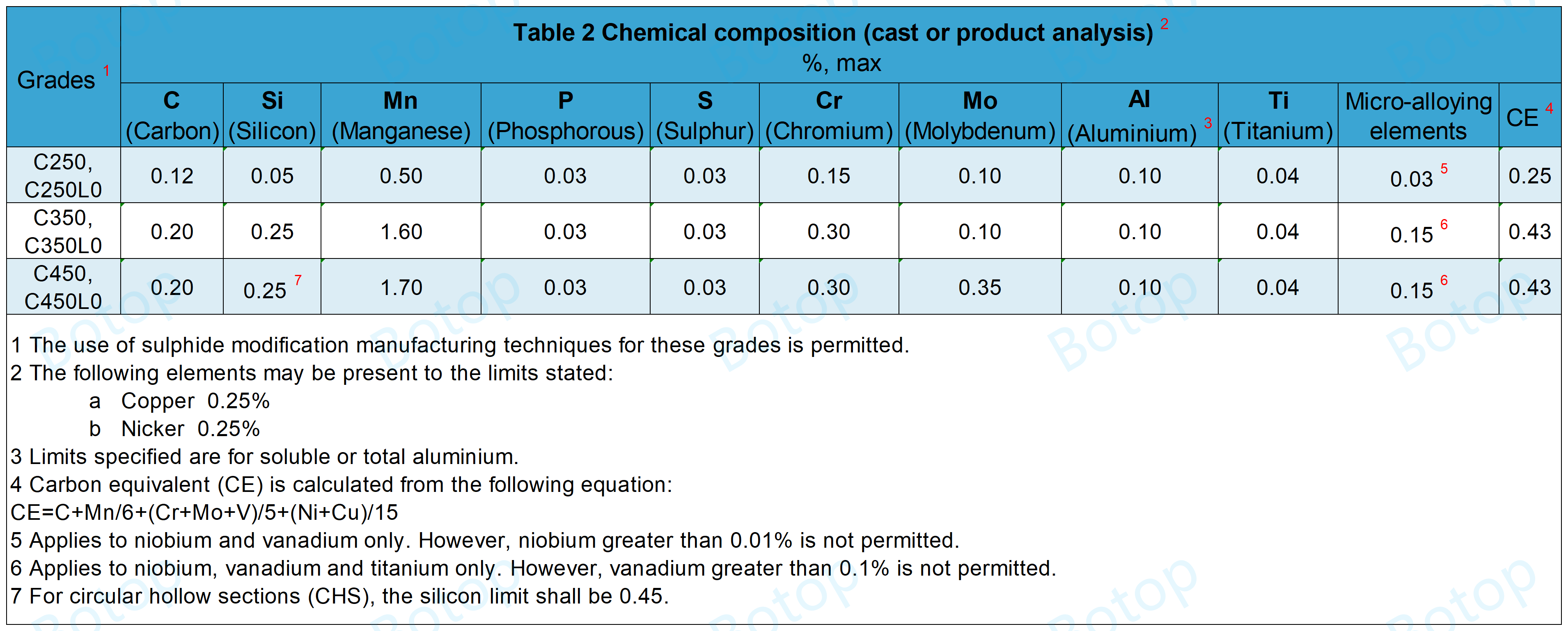

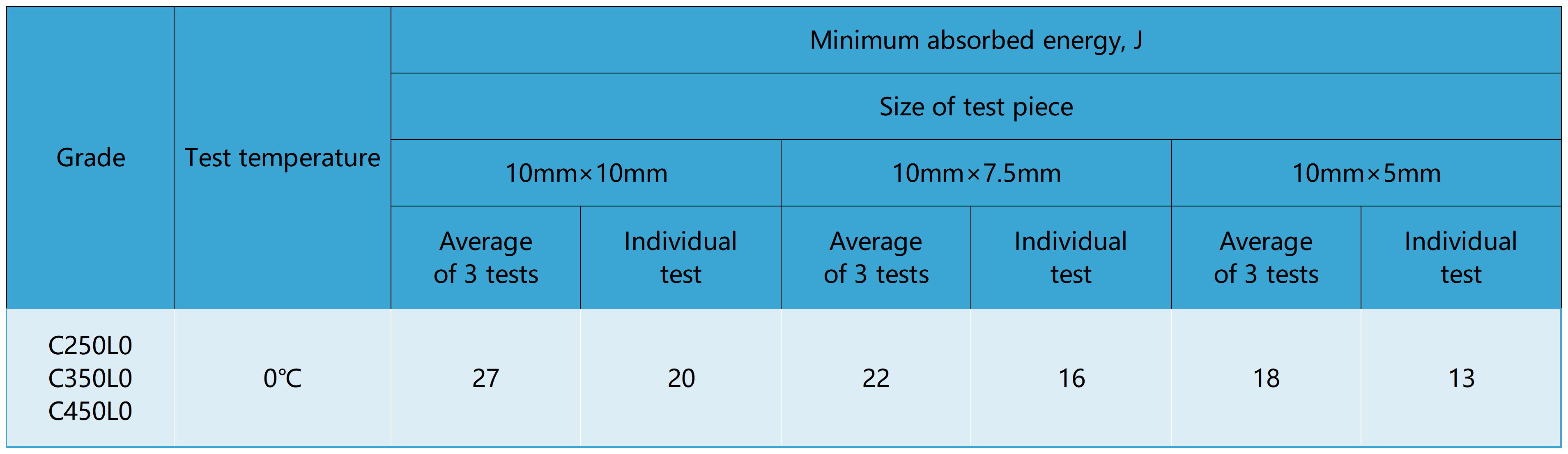

Three grades are classified in terms of minimum yield strength and fulfillment of 0°C impacts.

AS/NES 1163-C250/C250L0

AS/NES 1163-C350/C350L0

AS/NES 1163-C450/C450L0

hot-rolled coil or Cold-rolled coil.

Fine-grained steel is specified as the raw material for steel coils.

Finished hollow sections are manufactured using a cold-forming process and the edges of the steel strip are joined using electric resistance welding (ERW) technology.

And shall remove excess welds on the exterior; the interior may be left uncleaned.

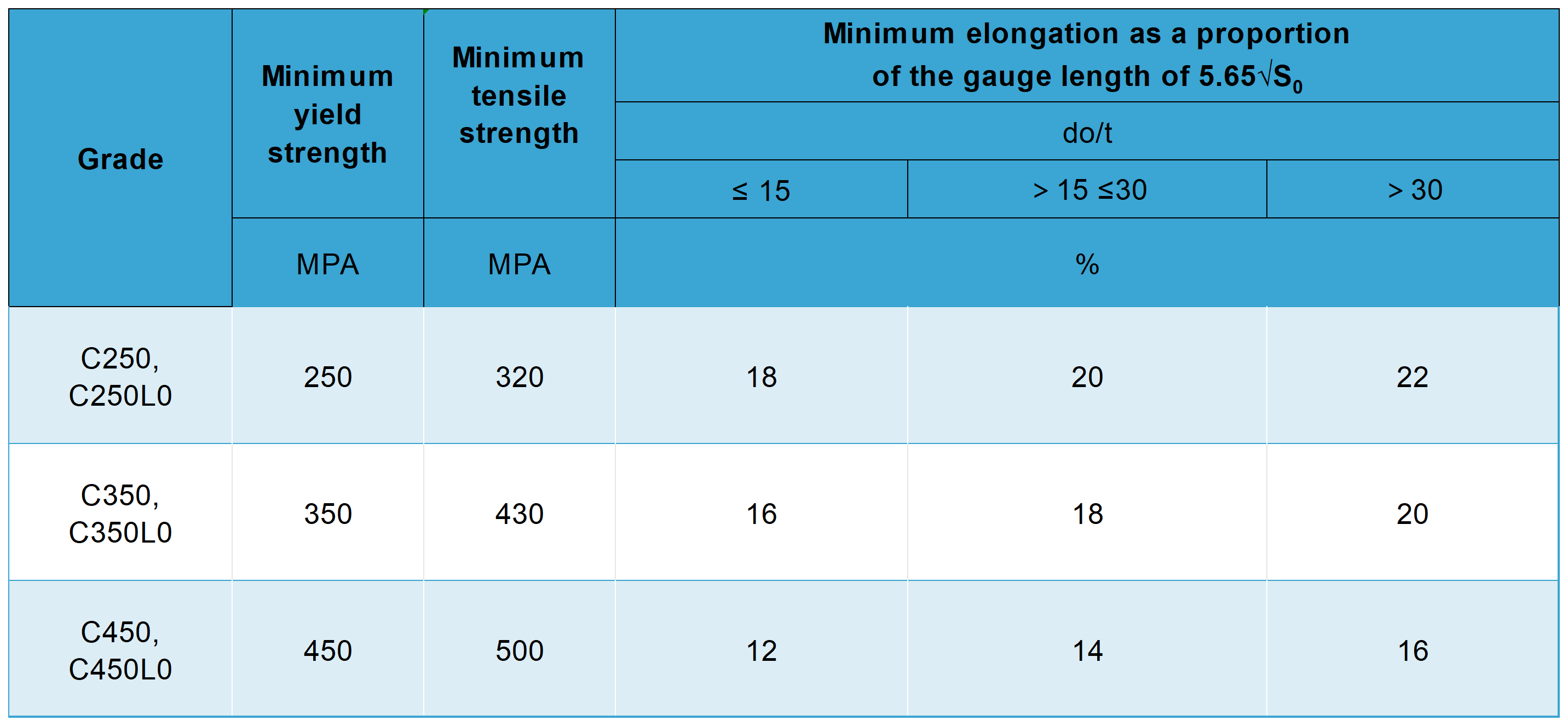

The provision of tensile properties is one of the important components of AS/NZS 1163, which covers the tensile strength, yield strength, elongation, and other key parameters of steel, providing basic data and reference standards for engineering design and structural analysis.

| Type | Range | Tolerance |

| Characteristic | — | Circular hollow sections |

| External dimensions(do) | — | ±1%, with a minimum of ±0.5 mm and a maximum of ±10 mm |

| Thickness (t) | do≤406,4 mm | 土10% |

| do>406.4 mm | ±10% with a max of ±2 mm | |

| Out-of-roundness (o) | Outer diameter(bo)/wall thickness(t)≤100 | ±2% |

| Straightness | total length | 0.20% |

| Mass (m) | specified weight | ≥96% |

| Type of length | Range m |

Tolerance |

| Random length | 4m to 16m with a range of 2m per order item |

10% of sections supplied may be below the minimum for the ordered range but not less than 75% of the minimum |

| unspecified length | ALL | 0-+100mm |

| Precision length | ≤ 6m | 0-+5mm |

| >6m ≤10m | 0-+15mm | |

| >10m | 0-+(5+1mm/m)mm |

The SSHS (Structural Steel Hollow Sections) list contains a table of pipe weights and cross-sectional characteristics, among other things.

C250 is used for general building structures and low-pressure fluid transfer pipelines.

C350 is used for building structures and bridges.

C450 is used for large bridges and high-pressure pipelines.

C350L0 and C250L0 are low-temperature toughness steels used for structures and pipelines in cold regions.

C450L0 is suitable for extreme environmental conditions such as offshore platforms and polar construction.

Appearance size inspection of steel pipe mainly includes the following items:

Diameter and wall thickness, length, straightness, ovality, and surface quality.

Steel pipe bevel angle

Pipe wall thickness

Outer diameter of steel pipe

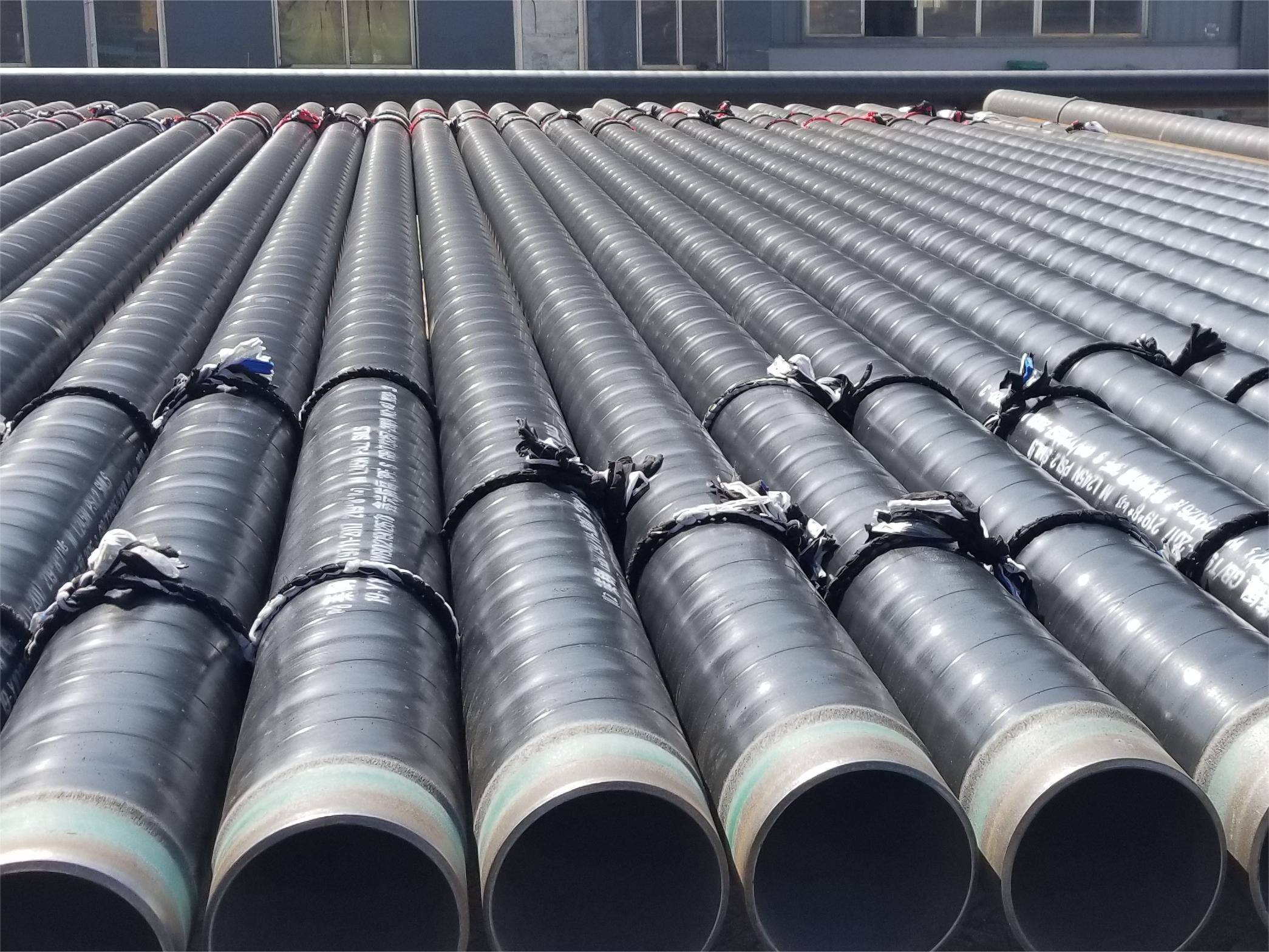

According to customers' requirements, the anti-corrosion treatment of steel pipe surfaces can be done in many different ways to enhance its corrosion resistance and prolong its service life.

Including varnish, paint, galvanization, 3PE, FBE, and other methods.

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions.

For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!