| Style | Technical | Material | Standard | Grade |

| Longitudinal Submerged-arc Welded Pipe | SAW | Carbon Steel | API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70 ,etc |

| ASTM A252 | GR.1,GR.2, GR.3 | |||

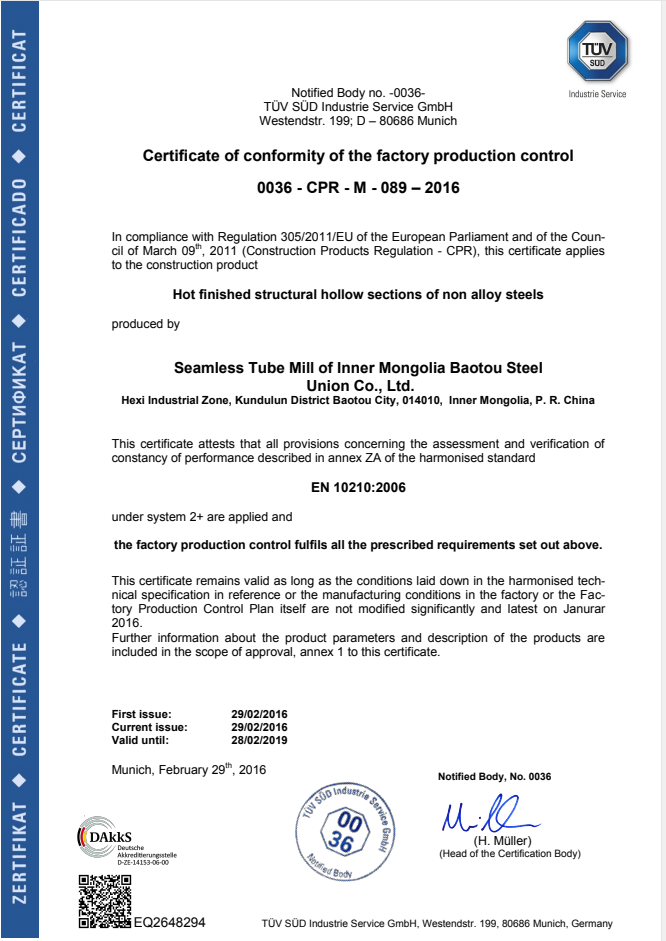

| BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H,etc | |||

| BS EN10219 | S275JRH,S275J0H,S355J0H,S355J2H,etc |

Engineering case of Hong Kong

Engineering case of Qatar

Engineering case of Turkey

Longitudinal Submerged-arc Welded(LSAW) Pipe adopts submerged arc welding technology, using filler welding, particle protection flux buried arc.

LSAW is the English abbreviation of submerged arc welded straight seam steel pipe. The production process of submerged arc welded straight seam steel pipe includes JCOE forming technology, coil forming submerged arc welding technology and UOE forming technology.

The process of manufacturing Longitudinal Submerged-arc Welded(LSAW) Pipe is as follows:

Ultrasonic plate probing → edge milling → pre-bending → forming → Pre-welding → Internal welding→ External welding → Ultrasonic inspection → X-ray inspection → Expanding → hydraulic test →l. Chamfering → Ultrasonic inspection → X-ray inspection → magnetic particle inspection at tube end

a.Quantity ( feet,meters,or number of lengths)

b.Name of material(carbon steel/alloy steel,etc)

c.Grade

d.Manufacture

e.Size (outside or inside diameter,normal wall thickness)

f.Special outside diameter tolerance pipe

g.Inside diameter tolerance pipe ,over 10 inch.

h.Length (specific or random)

i.Optional requirement.

j.NDT reports ,e.g

Bending Test— a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel.

Flattening test-although testing is not required ,pipe shall be capable of meeting the flattening test requirements.

Hydro-static test—except as allowed ,each length of pipe shall be subjected to the hydro-static test without leakage through the pipe wall.

Nondestructive electric test-as an alternative to the hydro-static test ,the full body of each pipe shall be tested with a nondestructive electric test . where nondestructive electric test is performed,the lengths shall be marked with the letters”NDE”

The ultrasonic testing

The eddy current examination

NDT Testing

Mechanical Testing

LSAW is manufactured by JCOE steel pipe forming which makes it have one weld and submerged arc welding process. When the diameter is large, two steel plates may be rolled, which will form a double weld phenomenon.There has double-wire submerged arc welding and there has multi-wire submerged arc welding.

A sufficient number of visual surface imperfections to provide seasonable assurance is necessary. The defect shall be removed or cut off within the limits of requirements on length . The finished pipe shall be reasonably straight.

Bare pipe, black coating ( customized);

6" and below sizes In bundles with two cotton slings, other sizes in loose;

Both ends with end protectors;

Plain end, bevel end;

Marking.