ASTM A252 Grade 3 is the most common material used as a cylindrical pile pipe.

Grade 3 steel pipe piles are not limited to a specific production process and can be manufactured using a variety of pipe fabrication methods, including SMLS (seamless), SAW (submerged arc welded), and EFW ( electro-fusion welded). This flexibility allows it to be adapted to different engineering needs and application scenarios.

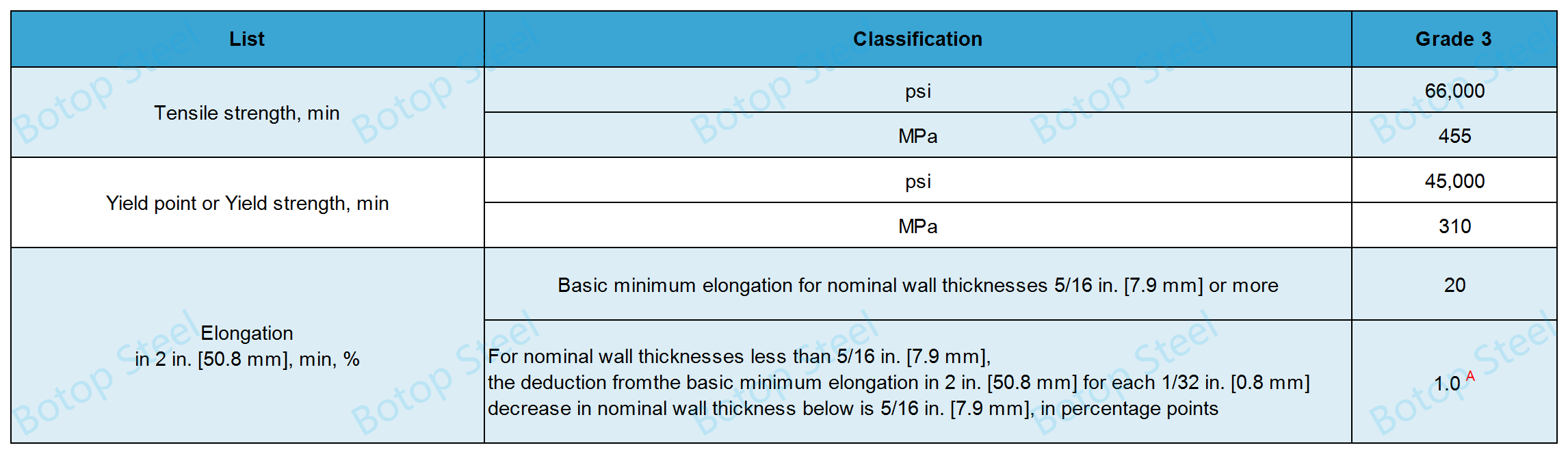

As the highest grade in the A52 standard, it has excellent mechanical properties with a minimum yield strength of 310 MPa and a minimum tensile strength of 455 MPa and can be used as a permanent load-bearing structural component or as a shell for cast-in-place concrete piles.

The ASTM A252 standard categorizes steel pipe piles into three grades to suit different application environments and loading requirements. The three grades are:

Grade 1, Grade 2, and Grade 3.

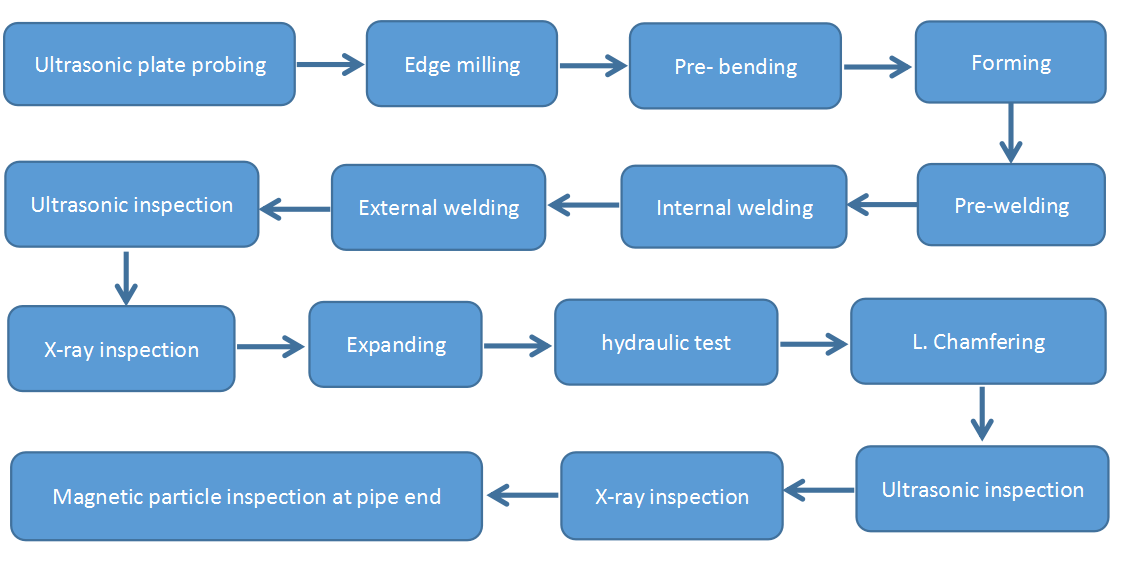

The company has introduced a complete set of advanced JCOE LSAW steel pipe production equipment and testing equipment, specializing in the production of thick-walled, large-diameter LSAW steel pipe with DSAW ( double-sided submerged arc welding).

The product specifications are:

Outer Diameter: DN 350 – 1500;

Wall Thickness: 8 – 80 mm;

Pipe piles shall be plain end.

The ends shall be flame-cut or machine-cut and deburred.

In the case of beveled ends, the angle of the beveled end should be 30 - 35°.

Botop Steel offers a wide range of high-quality ASTM A52 steel pipes. Please feel free to contact us for your requirements.

The steel shall be made by one or more of the following processes: open-hearth, basic-oxygen, or electric-furnace.

A252 shall be made by the seamless, electric resistance welded, flash welded, or fusion welded process.

The seams of welded pipe piles shall be longitudinal, helical-butt, or helical-lap.

To ensure the quality and performance of steel pipe piles, it is critical to select the correct production process.

The LSAW (SAWL) process is ideal for large-diameter, thick-walled steel pipe, especially in construction and infrastructure projects that require high load-bearing capacity and deep foundation construction. Due to its superior strength, load-carrying capacity, and depth adaptability, it is able to adapt to a wide range of complex geologic conditions while providing the benefits of quick installation and long-term durability.

JCOE is a common forming process in the production of LSAW steel pipe, which has the advantages of high efficiency, high quality, large diameter production capacity, dimensional accuracy, adaptability, and economy, which have made it the preferred pipe forming process in many large-scale engineering projects.

The steel shall contain no more than 0.050 % phosphorous.

Limiting the phosphorus content in steel is to ensure that the steel has good mechanical properties, especially when used for structural applications such as building piling.

This limitation helps to prevent the steel from becoming too brittle at low temperatures, thus ensuring its safety and reliability in use.

For other element contents, there are no requirements.

This is because the main focus of pipe pile tubes is to ensure that the tubes have adequate structural strength and toughness, which are critical properties for use in supporting structures.

For tubular pile tubes, more attention is paid to the mechanical properties of the tubes, such as yield strength, tensile strength, and toughness, as these properties are directly related to the load-carrying capacity and structural stability of the tubular piles in practical applications.

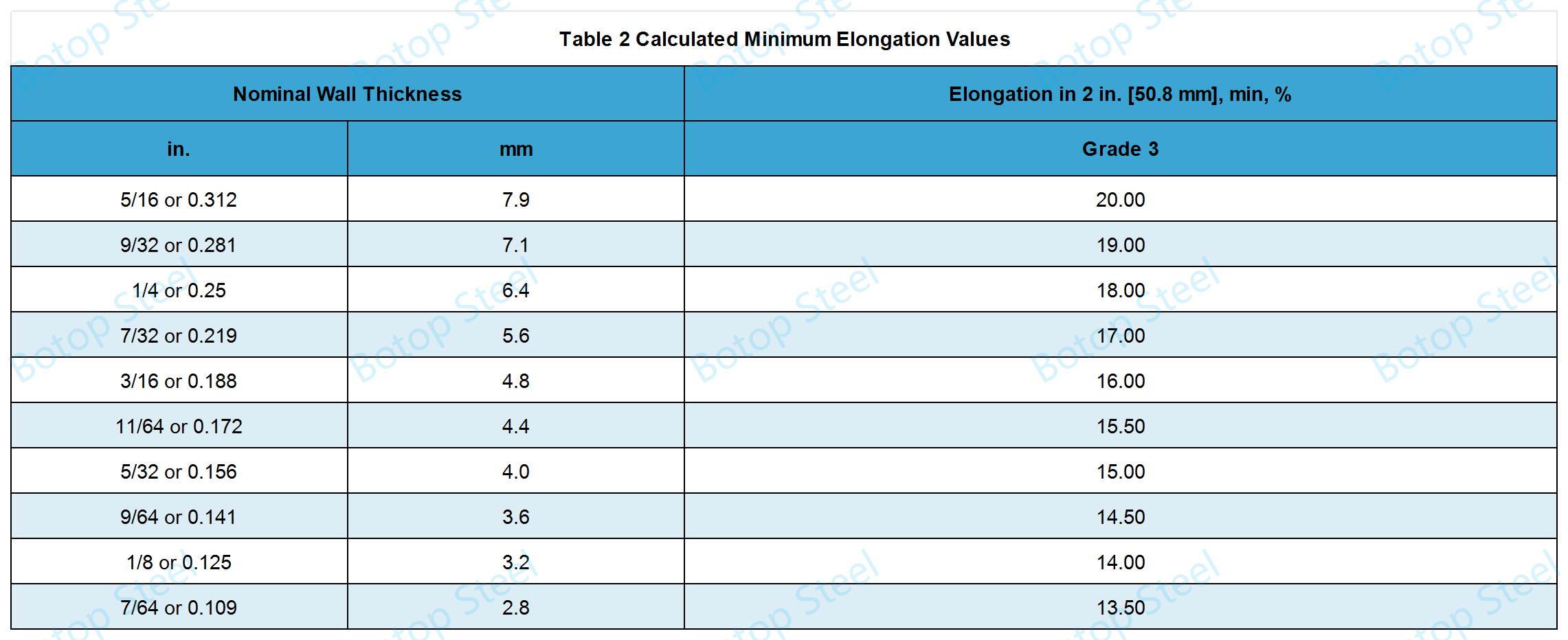

A Table 2 gives the computed minimum values:

Where the specified nominal wall thickness is intermediate to those shown above, the minimum elongation value shall be determined as follows:

Grade 3: E = 32t + 10.00 [E = 1.25t + 10.00]

E: elongation in 2 in. [50.8 mm], %;

t: specified nominal wall thickness, in. [mm].

The ASTM A252 Grade 3 standard ensures the safety and reliability of tubular piles in use by setting minimum requirements for these mechanical properties.

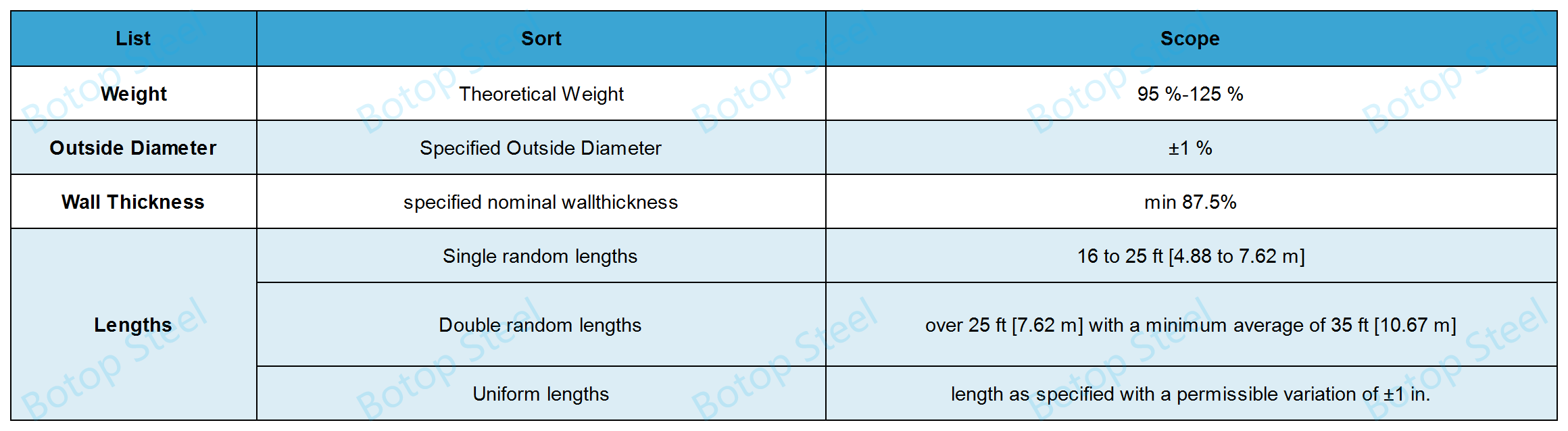

For pipe dimensions not listed in the pipe weight tables, the weight per unit length can be calculated using the formula.

w = C×(D-t)×t

w: weight per unit length, Ilb/ft [kg/m];

D: specified outside diameter, in. [mm];

t: specified nominal wall thickness, in. [mm];

C: 0.0246615 for calculations in SI units and 10.69 for calculations in USC units.

The above calculations are based on the assumption that the density of the steel pipe is 7.85 kg/dm³.

ASTM A252 Grade 3 has high strength and toughness for a variety of soils and load-bearing requirements. This steel pipe is commonly used in the following applications:

1. Building foundations: ASTM A252 Grade 3 steel pipe is used as pile foundations in foundation work for high-rise buildings, bridges, and other large structures to provide the necessary support and stability.

2. Ports and harbors: These steel pipes are used for piling in the construction of ports and harbors to ensure that the structure is able to withstand the impact of ships and the erosion of the marine environment. In order to increase the durability and resistance to corrosion of steel pipes, coatings are often applied to provide additional protection.

3. Waterworks: ASTM A252 Grade 3 steel pipe is used to reinforce river banks and provide flood protection in the construction of dams, locks, and other water facilities.

4. Energy projects: In wind power, oil rigs, and other energy infrastructure projects, these steel pipes are used as support structures to ensure the stable operation of the equipment.

5. Transportation facilities: ASTM A252 Grade 3 steel pipe is used for piling in the construction of railroads, highways, and airport runways to provide adequate load-carrying capacity and durability.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

Botop Steel offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

ASTM A252 GR.2 GR.3 Seamless Steel Piles Pipe

ASTM A252 GR.3 SSAW Steel Piles Pipe

AS 1579 SSAW Water Steel Pipe And Steel Pile

EN10219 S355J0H LSAW(JCOE) Steel Pipe Pile

EN 10219 S275J0H/S275J2H ERW Steel Pipe For Structural

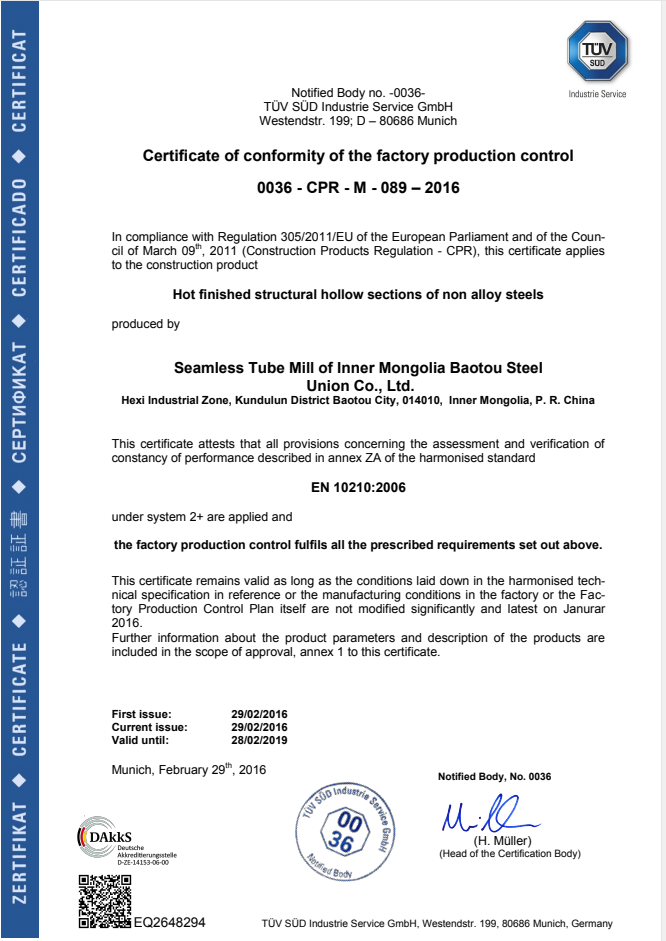

BS EN10210 S355J0H Carbon Seamless Steel Pipe

EN10210 S355J2H STRUCTURAL ERW STEEL PIPE

API 5L PSL1&PSL2 GR.B Longitudinal Submerged-Arc Welded Pipe

ASTM A501 Grade B LSAW Carbon Steel Structural Tubing

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe

ASTM A671/A671M LSAW Steel Pipe

ASTM A500 Grade C Seamless Steel Structural Tube