ASTM A333 Grade 6 is a carbon steel tubing material used in cryogenic and other applications requiring notched toughness. It is capable of being used in environments as low as -45°C (-50°F) and is available in both seamless and welded forms.

ASTM A333 can be used in a seamless or welded process.

The seamless steel pipe process is divided into hot finish and cold drawn. And it needs to be reflected above the marking.

Seamless steel tubes are the first choice for harsh environments, stressful conditions, and when exceptionally thick tubes are required.

ASTM A333 GR.6 needs to be treated according to one of the following methods to control its microstructure:

● Normalizing: Heat to a uniform temperature of at least 1500 °F [815 °C], then cool in the air or in the cooling chamber of an atmosphere-controlled furnace.

● Tempering after normalizing: After normalizing, it may be reheated to the proper tempering temperature at the manufacturer's discretion.

● For seamless processes, this can be accomplished by controlling the temperatures of the hot work and hot finishing operations so that the final temperatures range from 1550 to 1750 °F [845 to 945 °C] and then cooling in air or in an atmosphere-controlled furnace from an initial temperature of at least 1550 °F [845 °C].

● Tempering after controlled hot working and finishing heat treatment may be reheated to the proper tempering temperature at the manufacturer's discretion.

● Quenching and tempering: Instead of any of the above treatments, seamless tubes of Grades 1, 6, and 10 may be treated by heating to a uniform temperature of at least 1500 °F [815 °C], followed by quenching in water and reheating to the proper tempering temperature.

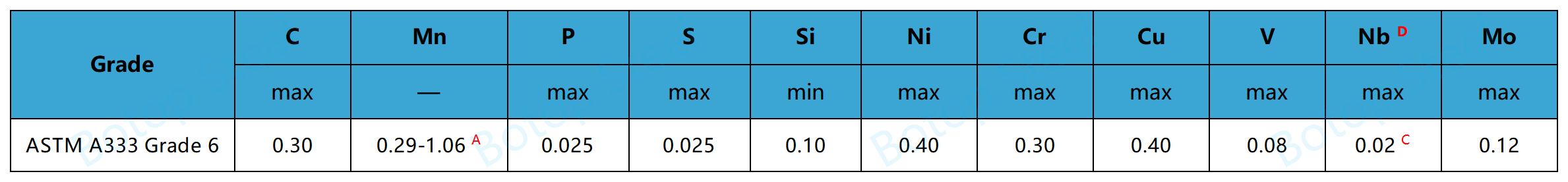

A For each reduction of 0.01% carbon below 0.30 %, an increase of 0.05% manganese above 1.06 % would be permitted to a maximum of 1.35 % manganese.

C By agreement between the manufacturer and the purchaser, the limit for niobium may be increased up to 0.05 % on heat analysis and 0.06 % on product analysis.

D The terms Niobium (Nb) and Columbium (Cb) are alternate names for the same element.

Tensile Property

| Grade | Tensile strength | Yielding strength | Elongation | |

| in 2 in. or 50 mm, min, % | ||||

| Longitudinal | Transverse | |||

| ASTM A333 Grade 6 | 415 MPa [60,000 psi] | 240 MPa [35,000 psi] | 30 | 16.5 |

The elongation here is just the basic minimum.

Other Tests

ASTM A333 has a flattening test, an impact test, in addition to a tensile test.

The following are the impact test temperatures for grade 6:

| Grade | Impact Temperature | |

| ℉ | ℃ | |

| ASTM A333 Grade 6 | - 50 | - 45 |

Each pipe shall be subjected to a non-destructive electrical or hydraulic test.

Hydrostatic test: ASTM A999 Section 21.2 shall be met;

Non-destructive electrical testing: shall conform to the requirements of ASTM A999, Division 21.3;

Standard: ASTM A333;

Grade: Grade 6 or GR 6

Pipe Type: Seamless or welded steel pipe;

SMLS SMLS dimensions: 10.5 - 660.4 mm;

Pipe Schedules: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 and SCH160.

Identification: STD, XS, XXS;

Coating: Paint, varnish, 3LPE, FBE, 3LPP, HDPE, galvanized, epoxy zinc-rich, cement weighted, etc.

Packing: Waterproof cloth, wooden case, steel belt or steel wire bundling, plastic or iron pipe end protector, etc. Customized.

Matching Products: Bends, flanges, pipe fittings, and other matching products are available.