ASTM A334 Grade 1 is a seamless and welded carbon steel pipe for low-temperature service.

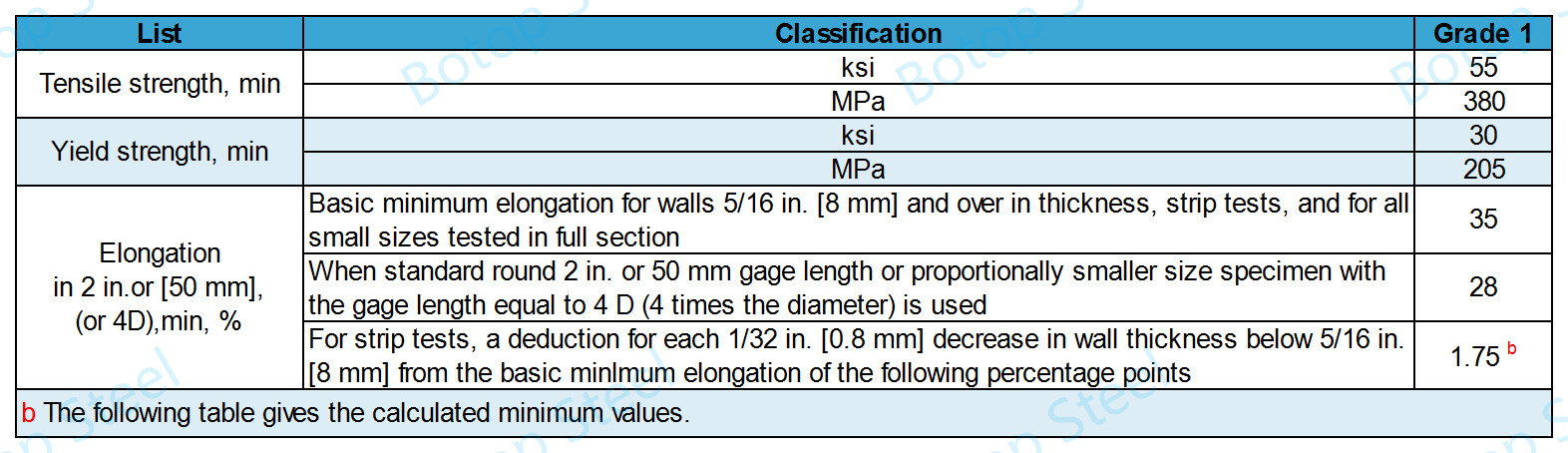

It has a maximum carbon content of 0.30%, a manganese content of 0.40-1.60%, a minimum tensile strength of 380Mpa (55ksi), and a yield strength of 205Mpa (30ksi).

It is mainly used for fluid transportation in low-temperature environments, refrigeration equipment, and other industrial applications that require low-temperature impact resistance.

ASTM A334 has several grades to deal with different low-temperature environments, namely: Grade 1, Grade 3, Grade 6, Grade 7, Grade 8, Grade 9, and Grade 11.

There are two types of steel, carbon steel and alloy steel.

Grade 1 and Grade 6 are both carbon steels.

They can be produced by seamless or welded processes.

In the production of seamless steel tubes, there are two production processes, Hot-finished or Cold-drawn.

The choice depends mainly on the end use of the pipe, the size of the pipe, and the specific requirements for material properties.

Below is a diagram of the hot-finished seamless production process.

The hot finish seamless pipe process involves heating a steel billet to a high temperature and then forming the pipe by rolling or extruding. This process takes place at high temperatures and helps to improve the microstructure of the material, thereby increasing its overall toughness and uniformity.

The hot finish process is particularly suited to the production of large-diameter and thick-walled tubes, commonly used in mass transportation pipelines and structural applications, and is suitable for high volume production due to its relatively low cost.

Cold-drawn seamless steel tubes are processed by stretching after the material has been completely cooled to achieve the precise size and shape required. This method significantly improves the dimensional accuracy and surface finish of the product, while the cold work-hardening effect also enhances the mechanical properties of the tube, such as strength and wear resistance.

The cold drawing process is particularly well suited to the manufacture of tubes with small diameters and thin wall thicknesses where high precision and excellent surface quality are required and is widely used in areas such as hydraulic systems, automotive components, and high-pressure equipment to meet specific high-performance needs, albeit at a higher cost.

Normalize by heating to a uniform temperature of not less than 1550 °F [845 °C] and cool in the air or in the cooling chamber of an atmosphere-controlled furnace.

If tempering is required, it will need to be negotiated.

For the above grades of seamless steel tubes only:

Reheat and control hot working and the temperature of the hot-finishing operation to a finishing temperature range from 1550 - 1750 °F [845 - 955℃] and cool in a controlled atmosphere furnace from an initial temperature of not less than 1550 °F [845 °C].

Grade 1 chemistry is designed to balance strength, hardness, and low-temperature toughness for applications in low-temperature environments.

| Grade | C (Carbon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| Grade 1 | max 0.30 % | 0.40-1.06 % | max 0.025 % | max 0.025 % |

| For each reduction of 0.01 % carbon below 0.30 %, an increase of 0.05 % manganese above 1.06 % will be permitted to a maximum of 1.35 % manganese. | ||||

Carbon is the main element that increases the strength and hardness of steel, but in low-temperature applications, high carbon content may reduce the toughness of the material.

Grade 1, with a maximum carbon content of 0.30%, is classified as low-carbon steel and is controlled at a low level to optimize its low-temperature toughness.

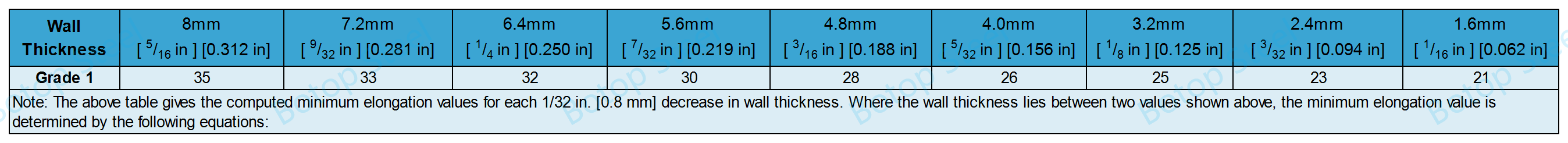

Computed minimum elongation values for each 1/32 in.[0.80 mm] decrease in wall thickness.

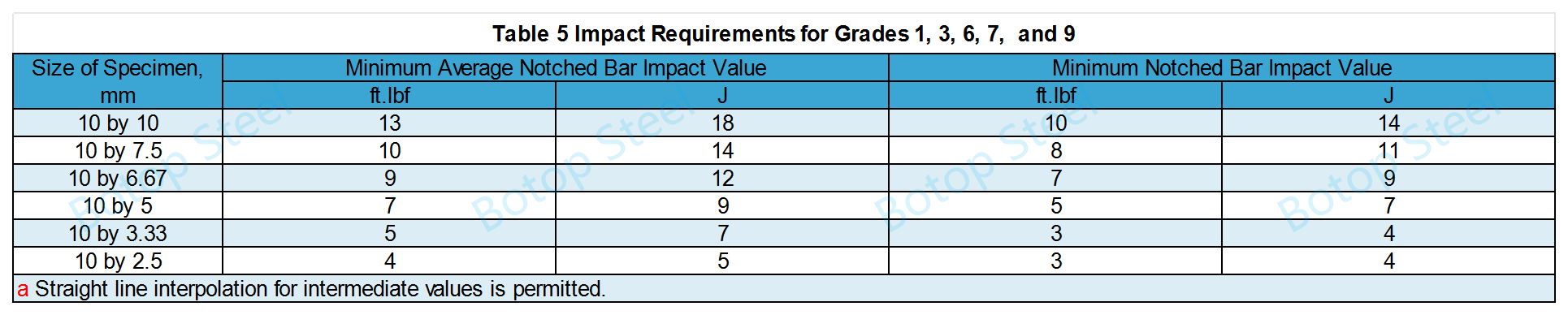

Impact experiments on Grade 1 steel tubing are conducted at -45°C [-50°F], which is designed to verify the toughness and impact resistance of the material in very low-temperature environments. The test is performed by selecting the appropriate impact energy based on the wall thickness of the steel pipe.

Notched-bar impact specimens shall be of the simple beam, Charpy-type, in accordance with Test Methods E23. Type A, with a V notch.

Two common methods of hardness measurement are the Rockwell and Brinell hardness tests.

| Grade | Rockwell | Brinell |

| ASTM A334 Grade 1 | B 85 | 163 |

Each pipe shall be non-destructively tested electrically or hydrostatically in accordance with STM A1016/A1016M. Unless otherwise specified in the purchase order, the type of test to be used shall be at the manufacturer's option.

In addition to the markings specified in Specification A1016/A1016M, the marking shall include hot finished, cold drawn, seamless, or welded, and the letters "LT" followed by the temperature at which the impact test was performed.

When the finished steel pipe is not of sufficient size to obtain a small impact specimen, the marking shall not include the letters LT and the indicated test temperature.

Widely used in a variety of industrial applications requiring low-temperature operation.

Cryogenic fluid transportation: Grade 1 steel pipe is widely used to transport cryogenic fluids such as liquefied natural gas (LNG), liquefied petroleum gas (LPG), and other cryogenic chemicals. These fluids often need to be transported safely at temperatures below ambient, and Grade 1 steel pipe maintains its physical properties and structural integrity at these low temperatures.

Refrigeration systems and equipment: Often used for coolant delivery piping in these systems.

Heat exchangers and condensers: Heat exchangers and condensers are critical components in the industrial and energy sectors, often using Grade 1 steel tubing as a building material. These devices require materials that maintain high strength and corrosion resistance at low temperatures to ensure long-term operational reliability and efficiency.

Cold storage and refrigeration facilities: In cold storage and other refrigeration facilities, piping systems must be adapted to extremely low temperatures. grade 1 steel pipe can be used to construct piping systems in these facilities because of its ability to continue to work in cold environments without failing.

1. EN 10216-4: P215NL, P255QL;

2. DIN 17173:TTSt35N;

3. JIS G3460:STPL 380;

4. GB/T 18984: 09Mn2V.

These standards and grades are designed to have similar or equivalent properties to ASTM A334 Grade 1, taking into account low-temperature properties and other relevant performance criteria.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions. The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.