ASTM A334 Grade 6 is a high-strength, low-temperature carbon steel pipe with a maximum carbon content of 0.30%, a manganese content of 0.29-1.06%, a minimum tensile strength of 415Mpa (60ksi), and a yield strength of 240Mp (35ksi).

It is mainly used in the field of liquefied natural gas facilities, polar engineering, and refrigeration technology, adapting to extremely low-temperature environments.

ASTM A334 Grade 6 steel pipe can be produced by seamless or welded processes.

Welding processes include various methods such as electric resistance welding (ERW) and submerged arc welding (SAW).

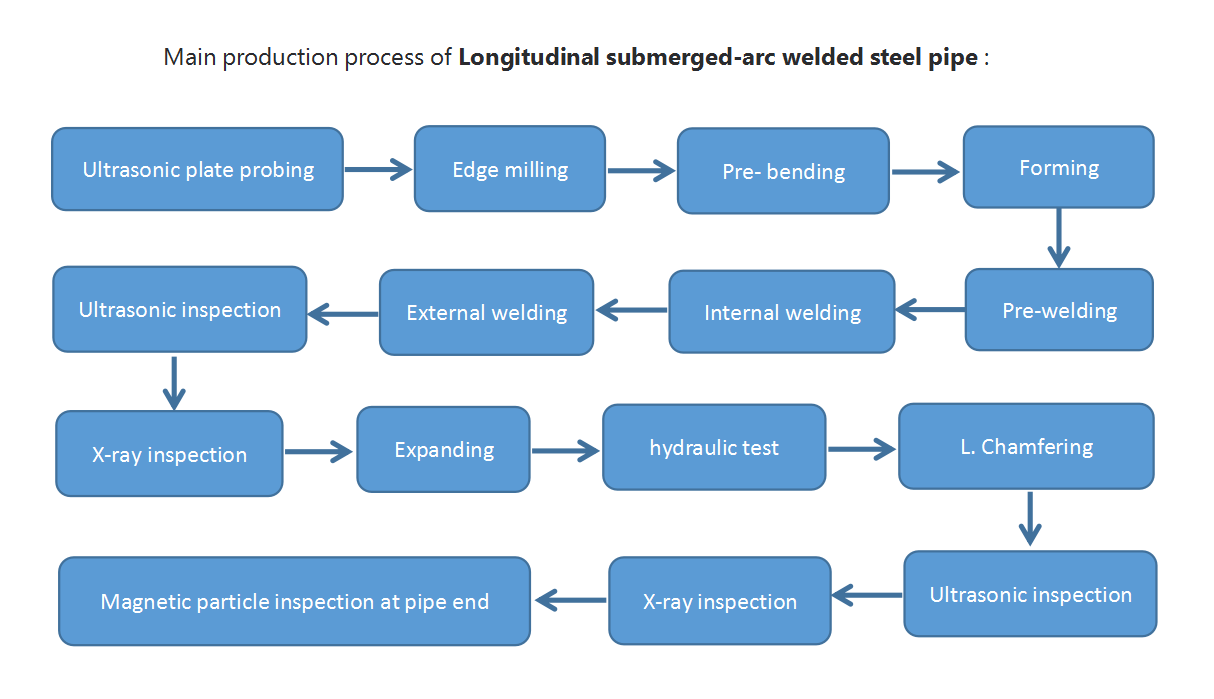

Below, is the production process for Longitudinal Submerged Arc Welding (LSAW).

As a manufacturer of welded steel tubes, we are able to meet the specific needs of our diverse customers, offering a diverse range of product options to ensure the best performance and quality for every application.

The one-piece weld of LSAW tubing significantly improves the overall strength of the tube, allowing it to withstand higher pressures.

In addition, it is ideally suited for the production of large-diameter and thick-walled steel pipe that meets the needs of ASTM A334 Grade 6 in large-scale industrial and energy delivery systems, such as in the construction of large liquefied natural gas (LNG) facilities.

At the same time, precise dimensional control ensures consistent pipe diameters and wall thicknesses for improved connection reliability and leakage prevention in piping systems.

Normalize by heating to a uniform temperature of not less than 1550 °F [845 °C] and cool in the air or in the cooling chamber of an atmosphere-controlled furnace.

If tempering is required, it will need to be negotiated.

The chemical composition of ASTM A334 Grade 6 steel pipe is designed to ensure good mechanical properties at low temperatures and sufficient toughness for reliable service under extreme conditions.

| Grade | C (Carbon) |

Mn (Manganese) |

P (Phosphorus) |

S (Sulfur) |

Si (Silicon) |

| Grade 6 | max 0.30 | 0.29-1.06 | max 0.025 | max 0.025 | min 0.10 |

| For each reduction of 0.01 % carbon below 0.30 %, an increase of 0.05 % manganese above 1.06 % will be permitted to a maximum of 1.35 % manganese. | |||||

For Grade 1 or Grade 6 steels, it is not permitted to provide alloying grades for any elements other than those expressly required. However, it is permitted to add elements necessary for the deoxidation of the steel.

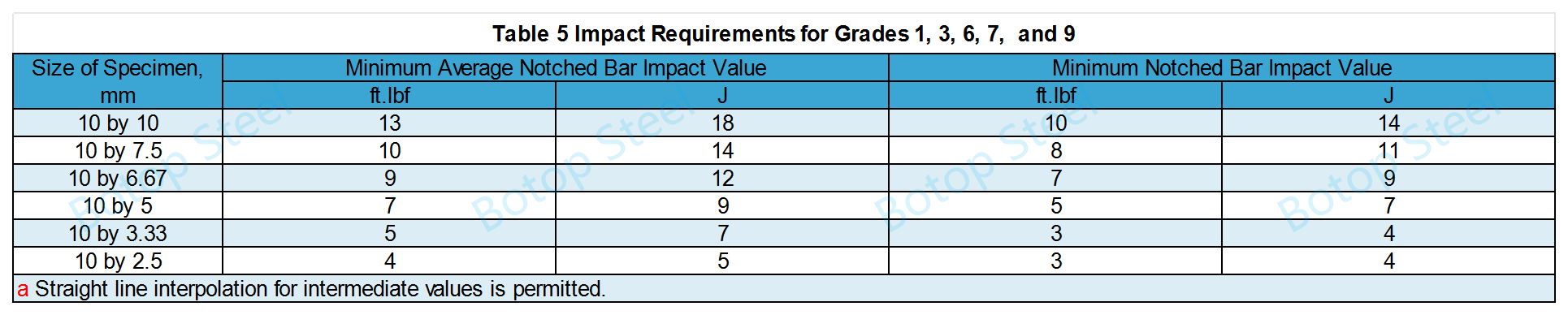

Impact experiments on Grade 6 steel pipe are conducted at -45°C [-50°F] as a means of verifying the toughness and impact resistance of the material in very low-temperature environments.

The test was conducted by selecting the appropriate impact energy based on the wall thickness of the steel pipe.

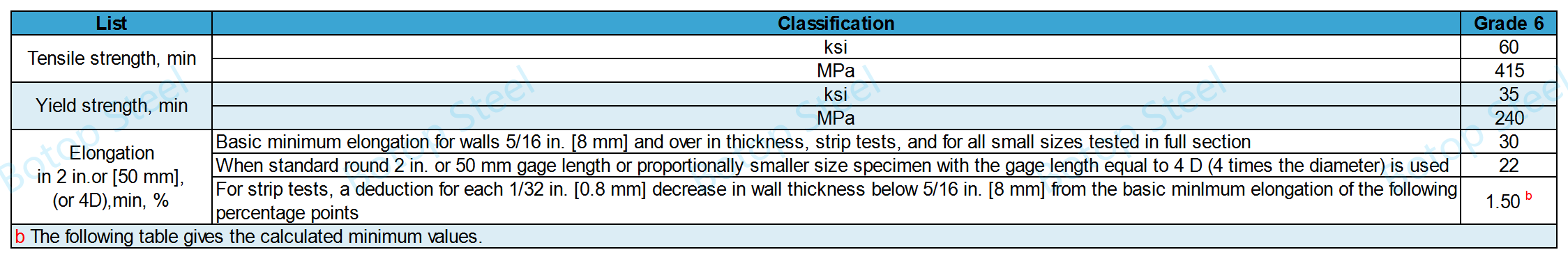

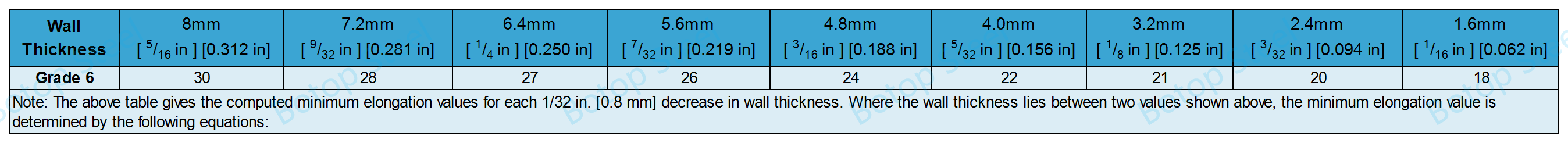

Computed minimum elongation values for each 1/32 in.[0.80 mm] decrease in wall thickness.

| Grade | Rockwell | Brinell |

| ASTM A334 Grade 6 | B 90 | 190 |

Each pipe shall be nondestructively tested electrically or hydrostatically in accordance with Specification A1016/A1016M.

Unless otherwise specified in the purchase order, the type of test to be used shall be at the manufacturer's option.

Flattening Test

Flare Test (Seamless Tubes)

Flange Test (Welded Tubes)

Reverse Flattening Test

1. Liquefied Natural Gas (LNG) facilities: Due to its excellent low temperature properties, Grade 6 steel pipe is widely used in LNG production, storage and transportation facilities. These facilities require materials that maintain high strength and good toughness at very low temperatures.

2. Oil and gas transportation systems: used to transport liquid or gaseous hydrocarbons, such as liquefied petroleum gas (LPG) and other low-temperature fluids in a low-temperature environment.

3. Refrigeration technology and cold storage facilities: This also applies to other areas of refrigeration technology, such as freezing and cold storage systems in food processing and other chemical processes that require low-temperature operation.

4. Polar engineering: In engineering projects in polar regions, such as scientific research stations in the Arctic or Antarctica, they are used to build stable and reliable conveyor systems and structures that must be able to withstand extreme cold temperatures and harsh environmental conditions.

5. Air-conditioning systems and heat exchangers: Also commonly used in large air-conditioning systems and heat exchangers, which need to operate efficiently at low temperatures to ensure system efficiency and safety.

6. Power engineering and power stations: In special power engineering projects, such as certain types of power stations, Grade 6 steel tubes may be used to handle fluids or gases at low temperatures to ensure the safe and efficient operation of the system.

EN 10216-4:P265NL: Mainly used for cryogenic pressure vessels and cryogenic piping systems, it has good toughness and strength and is suitable for use in cryogenic environments.

DIN 17173:TTSt41N: Designed for low-temperature applications, it provides excellent low-temperature performance and is commonly used in equipment and piping requiring extremely low-temperature operating environments.

JIS G3460:STPL46: Used for pipeline transportation systems in low-temperature environments, capable of withstanding certain low-temperature impacts and pressures.

GB/T 18984:09Mn2V: This material is specialized in the manufacture of seamless steel tubes for use in low-temperature environments, with good low-temperature toughness and crack resistance.

When selecting these equivalent materials, it is important to ensure that their chemical composition and mechanical properties meet the required application criteria and performance requirements.

These parameters should be compared in detail and additional testing and certification processes may be required to verify the suitability and performance of the material.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions. The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.