ASTM A335 P91, also known as ASME SA335 P91, is a seamless ferritic alloy steel pipe for high-temperature service, UNS No. K91560.

It has a minimum tensile strength of 585 MPa (85 ksi) and a minimum yield strength of 415 MPa (60 ksi).

P91 mainly contains alloying elements such as chromium and molybdenum, and a variety of other alloying elements are added, belonging to the high-alloy steel, so it has super strength and excellent corrosion resistance.

In addition, P91 is available in two types, Type 1 and Type 2, and is commonly used in power plants, refineries, chemical facilities critical equipment, and piping in high-temperature and high-pressure environments.

P91 steel pipe is categorized into two types, Type 1 and Type 2.

Both types are the same in terms of mechanical properties and other requirements such as heat treatment, with minor differences in chemical composition and specific application focus.

Chemical composition: Compared to Type 1, the chemical composition of Type 2 is more stringent and contains more alloying elements to provide better heat and corrosion resistance.

Applications: Due to the optimized chemical composition, Type 2 is more suitable for extremely high temperatures or more corrosive environments, or in applications where higher strength and durability are required.

ASTM A335 steel pipe must be seamless.

The seamless manufacturing process is categorized into hot finish and cold drawn.

Below is a diagram of the hot finish process.

In particular, P91, a high-alloy steel pipe, which is often used in harsh environments subject to high temperatures and pressures, seamless steel pipe is uniformly stressed and can be made into thick-walled, thus ensuring higher safety and better cost-effectiveness.

P91 All pipes must be heat-treated to optimize the microstructure of the pipe, improve its mechanical properties, and enhance the resistance to high temperature and pressure.

| Grade | Heat Treat Type | Normalizing Temperature | Tempering Temperature |

| P91 Type 1 and Type 2 | normalize and temper or | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 ~ 1470 ℉ [730 - 800 ℃] |

| quench and temper | 1900 - 1975 ℉ [1040 - 1080 ℃] | 1350 - 1470 ℉ [730 - 800 ℃] |

P91 Type 1 Chemical Components

| Grade | Composition, % | ||||||

| P91 Type 1 | C | Mn | P | S | Si | Cr | Mo |

| 0.08 - 0.12 | 0.30 - 0.60 | 0.020 max | 0.010 max | 0.20 - 0.50 | 8.00 - 9.50 | 0.85 - 1.05 | |

| V | N | Ni | Al | Nb | Ti | Zr | |

| 0.18 - 0.25 | 0.030 - 0.070 | 0.40 max | 0.02 max | 0.06 - 0.10 | 0.01 max | 0.01 max | |

P91 Type 2 Chemical Components

| Grade | Composition, % | ||||||

| P91 Type 2 Product Chemical Components | C | Mn | P | S | Si | Cr | Mo |

| 0.07 - 0.13 | 0.30 - 0.50 | 0.020 max | 0.005 max | 0.20 - 0.40 | 8.00 - 9.50 | 0.80 - 1.05 | |

| V | Ni | Al | N | N/Al ratio | Nb | Ti | |

| 0.16 - 0.27 | 0.20 max | 0.02 max | 0.035 - 0.070 | ≥ 4.0 | 0.05 - 0.11 | 0.01 max | |

| Zr | Sn | Sb | As | B | W | Cu | |

| 0.01 max | 0.01 max | 0.003 max | 0.01 max | 0.001 max | 0.05 max | 0.10 max | |

With the two images above, it's easy to see the difference between Type 1 and Type 2 chemical elements and restrictions.

1. Tensile Property

The tensile test is commonly used to measure the yield strength, tensile strength, and elongation of the steel pipe experimental program, and is widely used in the material properties of the test.

| P91 Type 1 and Type 2 | |||

| Tensile strength | 85 ksi [585 MPa] min | ||

| Yield strength | 60 ksi [415 MPa] min | ||

| Elongation | Elongation Requirements | Longitudinal | Transverse |

| Elongation in 2 in. or 50 mm, (or 4D), min, %; Basic minimum elongation for wall 6 in. [8 mm] and over in thickness, strip tests, and for all small sizes tested in full section |

20 | — | |

| When standard round 2-in. or 50-mm gage length or proportionally smaller size specimen with the gage length equal to 4D (4 times the diameter) is used | 20 | 13 | |

| For strip tests a deduction for each 1/32 in. [0.8 mm] decrease in wall thickness below 5/16 in. [8 mm] from the basic minimum elongation of the following percentage points shall be made | 1 | — | |

2. Hardness

A variety of hardness testing methods can be used, including Vickers, Brinell, and Rockwell.

| Grade | Brinell | Vickers | Rockwell |

| P91 Type 1 and Type 2 | 190 - 250 HBW | 196 - 265 HV | 91 HRBW - 25HRC |

Wall thickness <0.065 in. [1.7 mm]: No hardness test required;

0.065 in. [1.7 mm] ≤ wall thickness <0.200 in. [5.1 mm]: Rockwell hardness test shall be used;

Wall thickness ≥ 0.200 in. [5.1 mm]: optional use of Brinell hardness test or Rockwell hardness test.

The Vickers hardness test is applicable to all wall thicknesses of tubing. The test method is carried out in accordance with the requirements of E92.

3. Flattening Test

Experiments shall be conducted in accordance with Section 20 of the ASTM A999 standard.

4. Bend Test

Bend 180° at room temperature, no cracks shall appear on the outside of the bent part.

Size > NPS25 or D/t ≥ 7.0: Bending test should be performed without flattening test.

5. P91 Optional Experimental Programs

The following experimental items are not required test items, if necessary can be determined by negotiation.

S1: Product Analysis

S3: Flattening Test

S4: Metal Structure and Etching Tests

S5: Photomicrographs

S6: Photomicrographs for Individual Pieces

S7: Alternative Heat Treatment-Grade P91 Type 1 and Type 2

The P91 hydro test shall comply with the following requirements.

Outside diameter>10in. [250mm] and wall thickness ≤ 0.75in. [19mm]: this should be a hydrostatic test.

Other sizes for non-destructive electrical testing.

For ferritic alloy steel and stainless steel tubes, the wall is subjected to a pressure of not less than 60% of the specified minimum yield strength.

The hydro test pressure shall be maintained for at least 5s without leakage or other defects.

Hydraulic pressure can be calculated using the formula:

P = 2St/D

P= hydrostatic test pressure in psi [MPa];

S = pipe wall stress in psi or [MPa];

t = specified wall thickness, nominal wall thickness according to specified ANSI schedule number or 1.143 times the specified minimum wall thickness, in. [mm];

D = specified outside diameter, outside diameter corresponding to specified ANSI pipe size, or outside diameter calculated by adding 2t (as defined above) to the specified inside diameter, in. [mm].

P91 pipe is inspected by means of the E213 test method. The E213 standard is primarily concerned with ultrasonic testing (UT).

If specifically specified in the order, it can also be inspected according to the E309 or E570 test method.

The E309 standard usually deals with electromagnetic (eddy current) inspection, while E570 is an inspection method involving eddy current arrays.

Permissible Variations in Diameter

For pipe ordered to inside diameter, the inside diameter shall not vary more than ±1% from the specified inside diameter.

Permissible Variations in Wall Thickness

Wall thickness measurements shall be made using mechanical calipers or properly calibrated nondestructive testing devices of appropriate accuracy. In case of dispute, the measurement determined using mechanical calipers shall prevail.

The minimum wall thickness and outside diameter for inspection for compliance with this requirement for the pipe ordered by NPS [DN] and schedule number are shown in ASME B36.10M.

Defects

Surface imperfections are considered defects if they exceed 12.5% of the nominal wall thickness or exceed the minimum wall thickness.

Imperfections

Mechanical marks, abrasions, and pits, any of which imperfections are deeper than 1/16 in. [1.6 mm].

Marks and abrasions are defined as cable marks, dinges, guide marks, roll marks, ball scratches, scores, die marks, and the like.

Repair

Defects may be removed by grinding, provided that the remaining wall thickness is not less than the minimum wall thickness.

Repairs can also be made by welding but must comply with the relevant requirements of A999.

All repair welds in P91 shall be made with one of the following welding processes and consumables: SMAW, A5.5/A5.5M E90XX-B9:SAW, A5.23/A5.23M EB9 + neutral flux; GTAW, A5.28/A5.28M ER90S-B9; and FCAW A5.29/A5.29M E91TI-B9. In addition, the sum of the Ni+Mn content of all welding consumables used to weld repair P91 Type 1 and Type 2 shall not exceed 1.0%.

P91 pipe should be heat treated at 1350-1470 °F [730-800°C] after weld repair.

The external surface of the inspected steel pipe shall contain the following elements:

Manufacturer's name or trademark; standard number; grade; length and additional symbol "S".

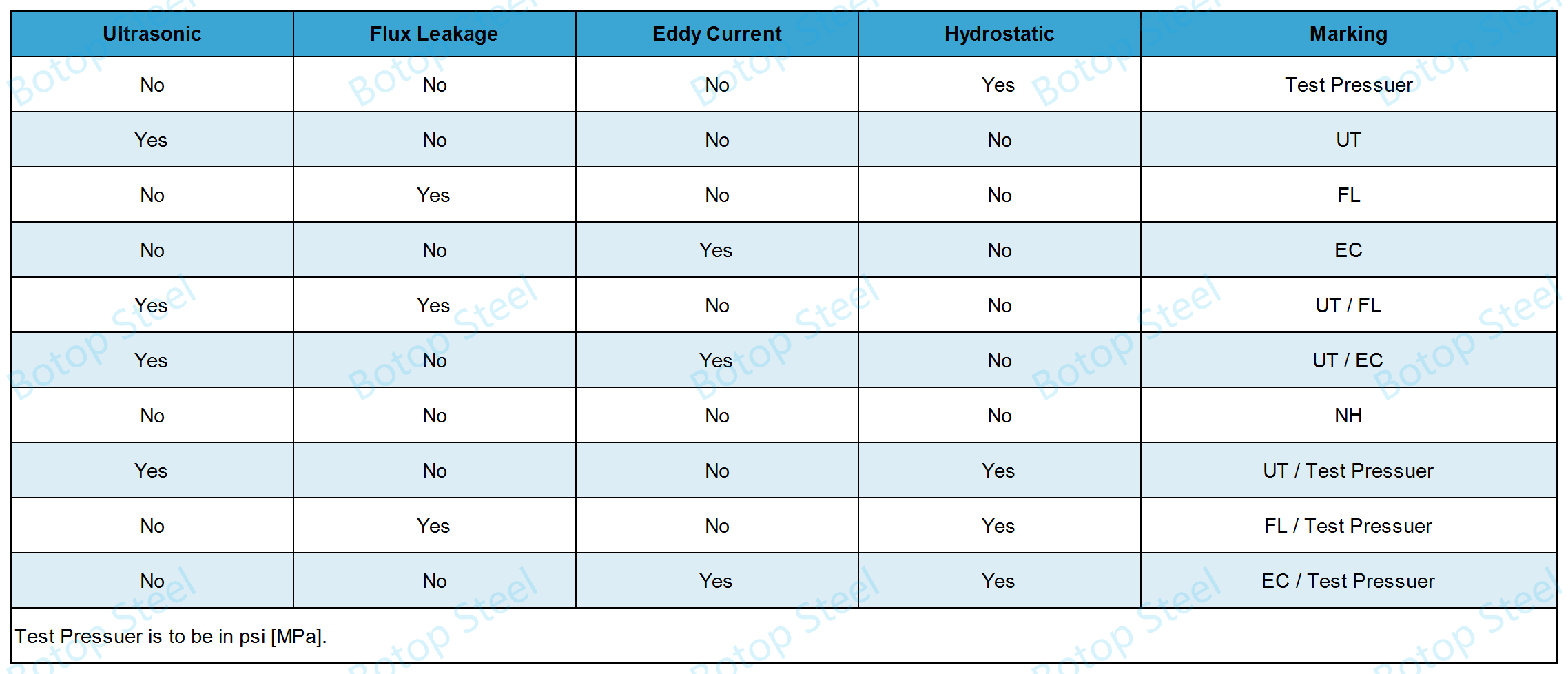

The markings for hydrostatic pressure and non-destructive testing in the table below should also be included.

If the pipe is repaired by welding, it shall be marked "WR".

p91 The type (Type 1 or Type 2) should be indicated.

| ASME | ASTM | EN | GB |

| ASME SA335 P91 | ASTM A213 T91 | EN 10216-2 X10CrMoVNb9-1 | GB/T 5310 10Cr9Mo1VNbN |

Material: ASTM A335 P91 seamless steel pipe;

OD: 1/8"- 24";

WT: in accordance with ASME B36.10 requirements;

Schedule: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 and SCH160;

Identification: STD (standard), XS (extra-strong), or XXS (double extra-strong);

Customization: Non-standard pipe sizes are also available, customized sizes are available upon request;

Length: Specific and random lengths;

IBR Certification: We can contact the third-party inspection organization to get IBR certification according to your needs, our cooperation inspection organizations are BV, SGS, TUV, etc.;

End: Flat end, beveled, or composite pipe end;

Surface: Light pipe, paint, and other temporary protection, rust removal and polishing, galvanized and plastic coated, and other long-term protection;

Packing: Wooden case, steel belt or steel wire packing, plastic or iron pipe end protector, etc.