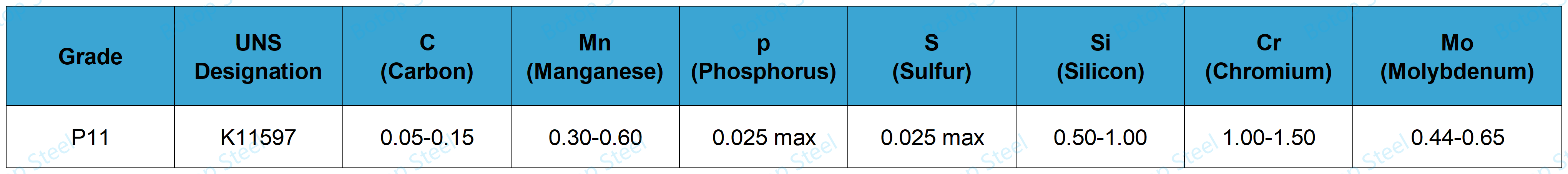

ASTM A335 P11 steel pipe is a seamless ferritic low alloy steel pipe for high-temperature service, UNS designation K11597.

P11 is a chromium-molybdenum alloy with a chromium content of 1.00-1.50% and a molybdenum content of 0.44-0.65%.

It is commonly used in boilers, superheaters, and heat exchangers in power stations and chemical plants.

The technical requirements of ASME SA335 and ASTM A335 are the same, so for ease of presentation, we will use "ASTM A335" to refer to these two standards.

Material: ASTM A335 P11 seamless steel pipe;

OD: 1/8"- 24";

WT: in accordance with ASME B36.10 requirements;

Schedule: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 and SCH160;

Identification: STD, XS, XXS;

Customization: Non-standard pipe sizes are also available, customized sizes are available upon request;

Length: Specific and random lengths;

IBR Certification: We can contact the third-party inspection organization to get IBR certification according to your needs, our cooperation inspection organizations are BV, SGS, TUV, etc.;

End: Flat end, beveled, or composite pipe end;

Surface: Light pipe, paint, and other temporary protection, rust removal and polishing, galvanized and plastic coated, and other long-term protection;

Packing: Wooden case, steel belt or steel wire packing, plastic or iron pipe end protector, etc.

Unless otherwise specified in A335, materials furnished under this specification shall conform to the applicable requirements of the current edition of Specification A999/A999M.

ASTM A335 steel pipe must be seamless. Seamless steel tubes offer greater reliability and uniformity when subjected to high-pressure and temperature environments.

Seamless can be specifically categorized as cold drawn and hot finished, depending on the specific application and size.

Cold drawing is usually used for small diameters or for tubes that require high precision and good surface quality. Hot finishing is usually used to produce large straight and thick-walled steel pipes.

Below is a flow chart of the manufacturing process for hot-finished seamless steel pipe.

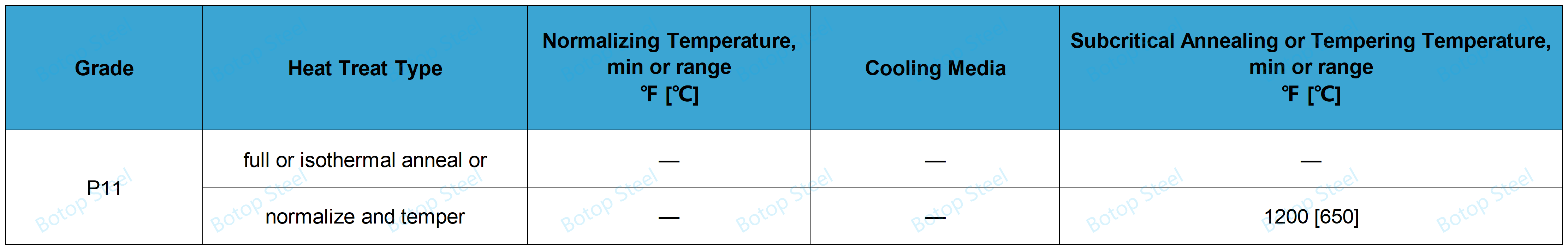

Heat treatment of P11 materials may be either full or isothermal annealing or tempering after normalizing, and when normalizing and tempering, the tempering temperature should be at least 1200°F (650°C).

From the chemical composition, we can easily see that P11 is a chromium-molybdenum alloy.

Chromium-molybdenum alloys are a class of steels with chromium (Cr) and molybdenum (Mo) as the main alloying elements. The addition of these elements significantly increases the strength, hardness, wear resistance, and corrosion resistance of the steel. At high temperatures, Cr-Mo alloys are able to maintain good mechanical properties and a stable structure.

Cr: improves the oxidation resistance and corrosion resistance of the alloy, helps to form a stronger oxide film, and protects the material from corrosive media.

Mo: Enhances the strength of the alloy, especially at high temperatures, improves creep resistance, and enhances the high-temperature strength of the material.

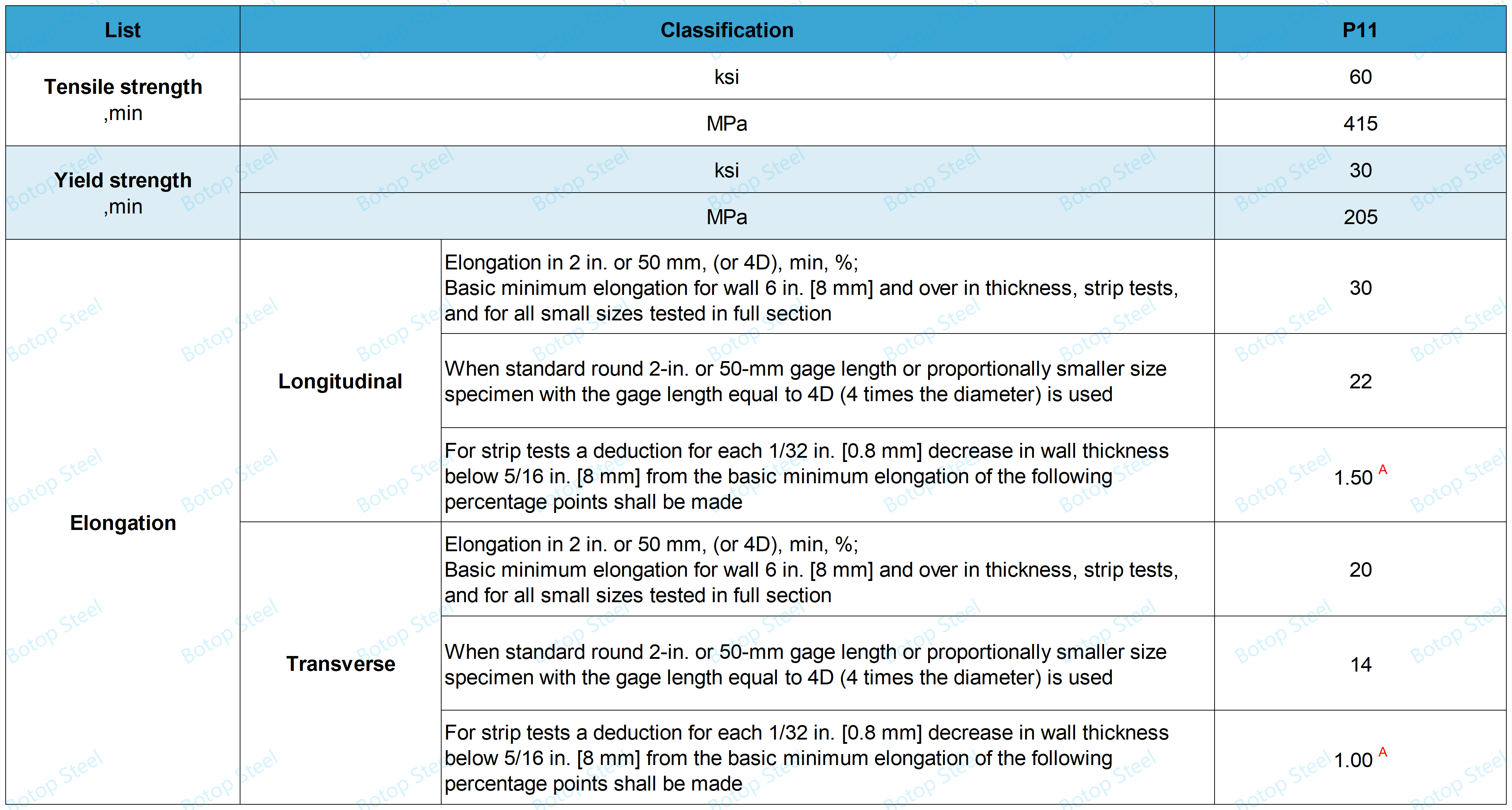

1. Tensile Property

The tensile test is commonly used to measure the yield strength, tensile strength, and elongation of the steel pipe experimental program, and is widely used in the material properties of the test.

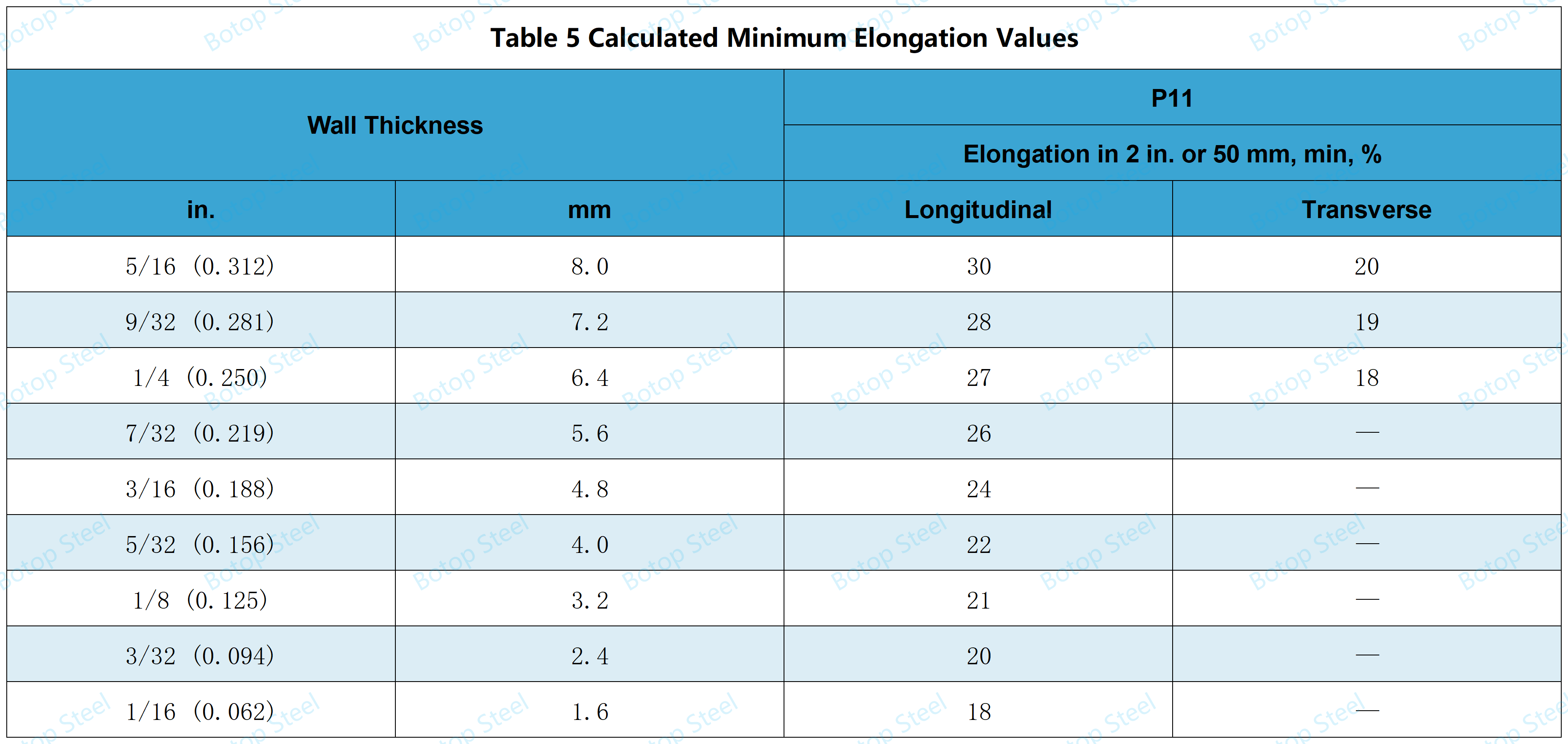

A Table 5 gives the calculated minimum values.

Where the wall thickness lies between the two values above, the minimum elongation value is determined by the following formula:

Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

where:

E = elongation in 2 in. or 50 mm, %,

t = actual thickness of specimens, in. [mm].

2. Hardness

Grade P11 pipe does not require hardness testing.

A reference hardness value is provided below.

Annealed condition:

The hardness is usually between 150 and 200 HB.

Normalized and tempered condition:

Hardness ranges from approximately 170 to 220 HB.

Hardened and tempered condition:

Hardness can reach 250 to 300 HB or more, depending on tempering temperature and time.

3. Optional Experimental Programs

The following experimental items are not required test items, if necessary can be determined by negotiation.

Product Analysis

Flattening Test

Bend Test

Metal Structure and Etching Tests

Photomicrographs

Photomicrographs for Individual Pieces

The P11 hydrotest shall comply with the following requirements.

Outside diameter>10in. [250mm] and wall thickness ≤ 0.75in. [19mm]: this should be a hydrostatic test.

Other sizes for non-destructive electrical testing.

The following hydrostatic test requirements are compiled from the requirements of ASTM A999:

For ferritic alloy steel and stainless steel tubes, the wall is subjected to a pressure of not less than 60% of the specified minimum yield strength.

The hydro test pressure shall be maintained for at least 5s without leakage or other defects.

Hydraulic pressure can be calculated using the formula:

P = 2St/D

P= hydrostatic test pressure in psi [MPa];

S = pipe wall stress in psi or [MPa];

t = specified wall thickness, nominal wall thickness according to specified ANSI schedule number or 1.143 times the specified minimum wall thickness, in. [mm];

D = specified outside diameter, outside diameter corresponding to specified ANSI pipe size, or outside diameter calculated by adding 2t (as defined above) to the specified inside diameter, in. [mm].

Each pipe shall be examined by a non-destructive examination method in accordance with Practice E213, Practice E309, or Practice E570.

Permissible Variations in Diameter

For pipe ordered to inside diameter, the inside diameter shall not vary more than ±1% from the specified inside diameter.

Permissible Variations in Wall Thickness

Wall thickness measurements shall be made using mechanical calipers or properly calibrated nondestructive testing devices of appropriate accuracy. In case of dispute, the measurement determined using mechanical calipers shall prevail.

The minimum wall thickness and outside diameter for inspection for compliance with this requirement for the pipe ordered by NPS [DN] and schedule number are shown in ASME B36.10M.

Typically used in boilers, superheaters, and heat exchangers in power stations and chemical plants.

Boilers: P11 is widely used in the construction of boilers due to its resistance to high temperatures and pressures, especially in sections that are subjected to extreme temperatures and pressures.

Superheater: Used to increase the steam temperature to further enhance thermal efficiency. p11 ensures that the strength and durability of the material is maintained even at high temperatures.

Heat exchangers: P11 enhances the corrosion and high-temperature resistance of heat exchangers, thus improving the reliability and safety of the equipment.

Piping systems: Piping systems in chemical plants often need to transport high-temperature fluids or steam. the high-temperature strength and good mechanical properties of P11 make it ideal for these applications.

a) What is the ASTM A335 P11 equivalent to?

GB/T 5310: 12CrMo;

DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

BS 3604: 10CrMo9-10;

JIS G3462: STPA23;

GOST 550-75: 12Kh1MF.

b) Is P11 a low-alloy steel?

Yes, P11 is a low alloy steel.

Low alloy steel is an iron-carbon alloy to which one or more alloying elements (e.g., chromium, molybdenum, nickel, etc.) have been added, with a total alloying element content generally ranging from 1 to 5 %.

c) What is the tensile strength of ASTM A335 P11?

Minimum tensile strength of 415 MPa [60 ksi].

d) What is the yield strength of ASTM A335 P11?

Minimum tensile strength of 205 MPa [30 ksi].

e) What is the temperature limit for ASTM A335 P11?

In oxidizing environments: Maximum service temperatures are typically about 593°C (1100°F).

In non-oxidizing environments: maximum service temperatures of approximately 650°C (1200°F) can be achieved.

f) Is the A335 P11 magnetic?

It is magnetic at room temperature. This property may be useful in certain applications, such as when the material is required to be compatible with magnetic detection equipment.

g) What is the price of ASTM A335 P11?

Prices vary with the market, contact us for an accurate quote.