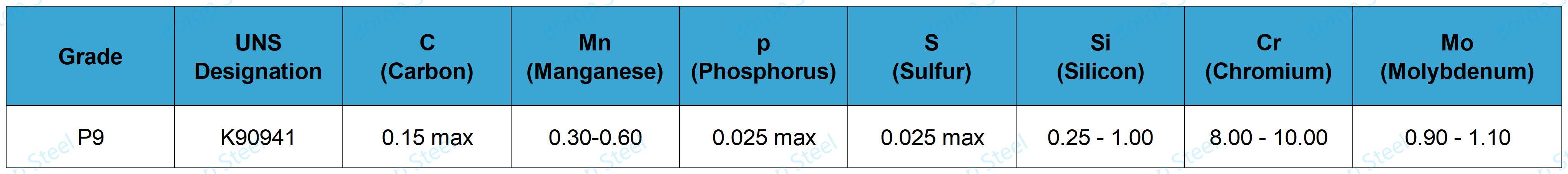

ASTM A335 P9, also known as ASME SA335 P9, is a seamless ferritic alloy steel pipe for high-temperature service with UNS No. K90941.

The alloying elements are primarily chromium and molybdenum. The chromium content ranges from 8.00 - 10.00%, while the molybdenum content is in the range of 0.90% - 1.10%.

P9 has excellent strength and good corrosion resistance in high-temperature environments and is widely used in boilers, petrochemical equipment, and power stations where high-temperature and high-pressure environments are required.

⇒ Material: ASTM A335 P9 / ASME SA335 P9 seamless alloy steel pipe.

⇒ Outside diameter: 1/8"- 24".

⇒ Wall thickness: ASME B36.10 requirements.

⇒ Schedule: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 and SCH160.

⇒ Identification: STD (standard), XS (extra-strong), or XXS (double extra-strong).

⇒ Length: Specific or random lengths.

⇒ Customization: Non-standard outer diameter, wall thickness, length, etc. according to requirements.

⇒ Fittings: We can provide the same material bends, stamping flanges, and other steel pipe-supporting products.

⇒ IBR certification: An IBR certificate can be provided if required.

⇒ End: Plain end, beveled end, or composite pipe end.

⇒ Packing: wooden case, steel belt or steel wire packing, plastic or iron pipe end protector.

⇒ Transportation: by marine or aviation.

ASTM A335 steel pipe must be seamless.

Seamless steel pipe is a steel pipe with no welds throughout.

Since seamless steel pipe has no welded seams in its structure, it avoids the potential safety hazards that may be associated with weld quality issues. This feature allows the seamless pipe to withstand higher pressures, and its homogeneous internal structure further ensures the integrity and safety of the pipe in high-pressure environments.

In addition, the reliability of ASTM A335 tubing is enhanced by the addition of specific alloying elements for high-temperature and high-pressure conditions.

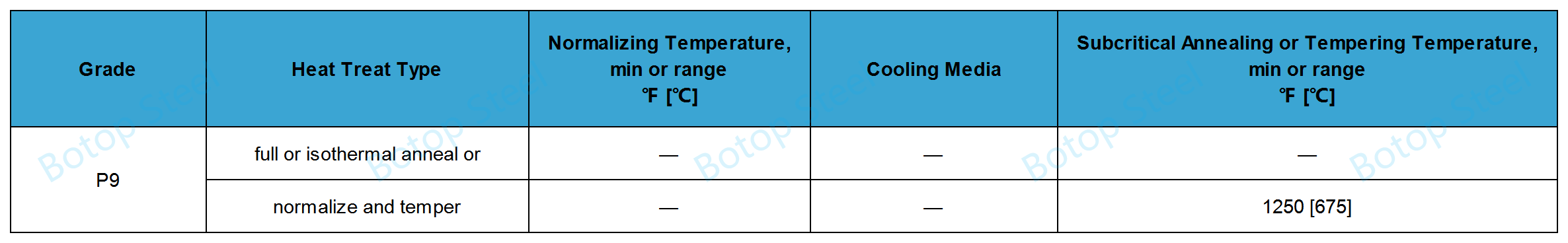

The types of heat treatments available for P9 material include full or isothermal annealing, as well as normalizing and tempering. The normalizing and tempering process has a tempering temperature of 1250°F [675°C].

The main alloying elements of P9 are Cr and Mo, which are chromium-molybdenum alloys.

Cr (Chromium): As the main element of the alloy, Cr provides excellent high-temperature strength and resistance to oxidation. It forms a dense chromium oxide film on the surface of the steel, increasing the stability and corrosion resistance of the pipe at high temperatures.

Mo (Molybdenum): The addition of Mo significantly improves the strength and toughness of alloys, especially in high-temperature environments. Mo also helps to improve the creep strength of the material, i.e. the ability to resist deformation under prolonged heat exposure.

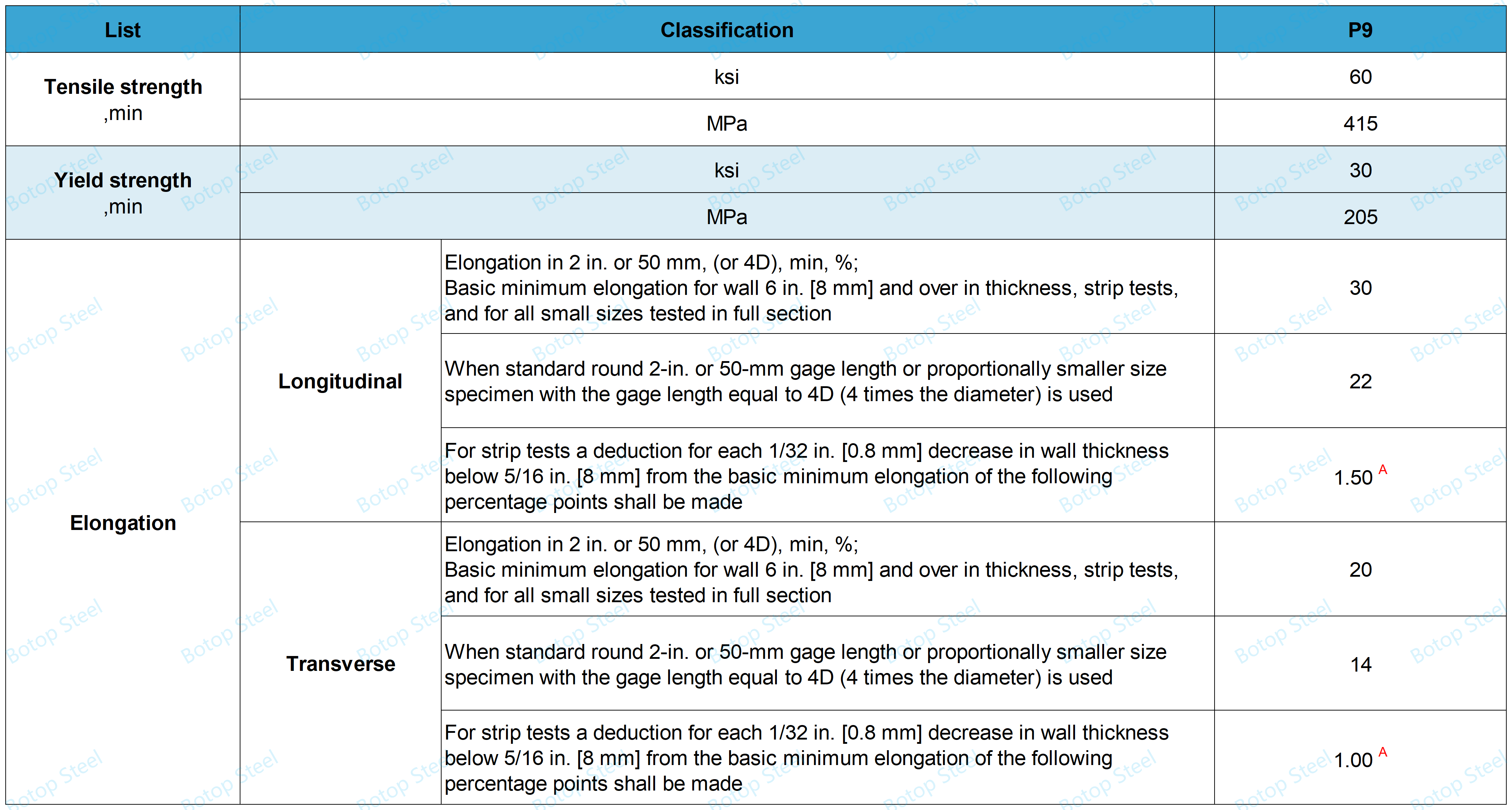

Tensile Properties

P5, P5b, P5c, P9, P11, P15, P21, and P22: The tensile and yield strengths are the same.

P1, P2, P5, P5b, P5c,P9, P11, P12, P15, P21, and P22: The same elongation.

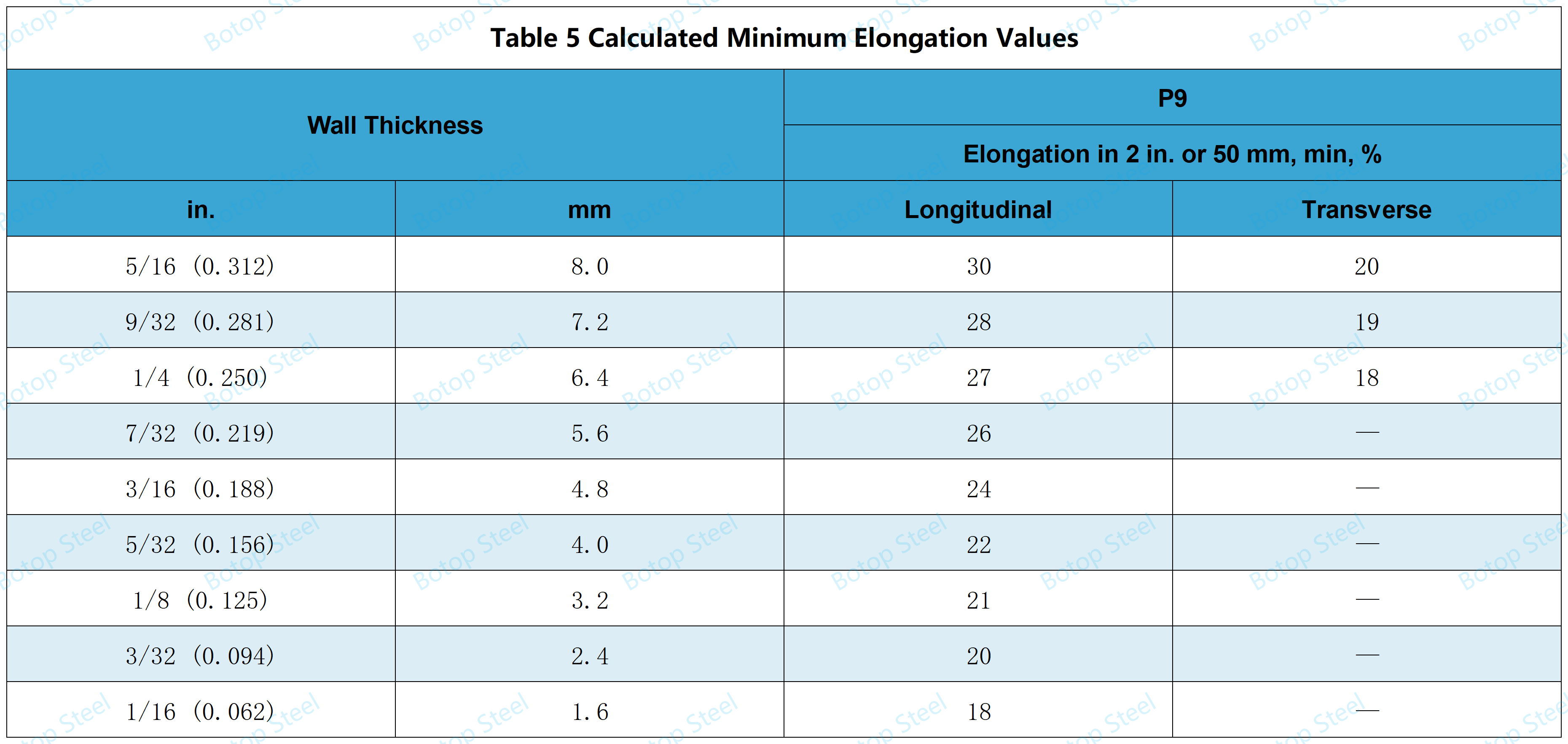

A Table 5 gives the calculated minimum values.

Where the wall thickness lies between the two values above, the minimum elongation value is determined by the following formula:

Longitudinal, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

where:

E = elongation in 2 in. or 50 mm, %,

t = actual thickness of specimens, in. [mm].

Hardness

P9 does not require hardness testing.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, and P921: No hardness test is required.

When the outside diameter > 10 in. [250 mm] and wall thickness ≤ 0.75 in. [19 mm], all shall be hydrostatically tested.

The experimental pressure can be calculated using the following equation.

P = 2St/D

P = hydrostatic test pressure in psi [MPa];

S = pipe wall stress in psi or [MPa];

t = specified wall thickness, nominal wall thickness according to specified ANSI schedule number or 1.143 times the specified minimum wall thickness, in. [mm];

D = specified outside diameter, outside diameter corresponding to specified ANSI pipe size, or outside diameter calculated by adding 2t (as defined above) to the specified inside diameter, in. [mm].

Experiment time: keep at least 5s, no leakage.

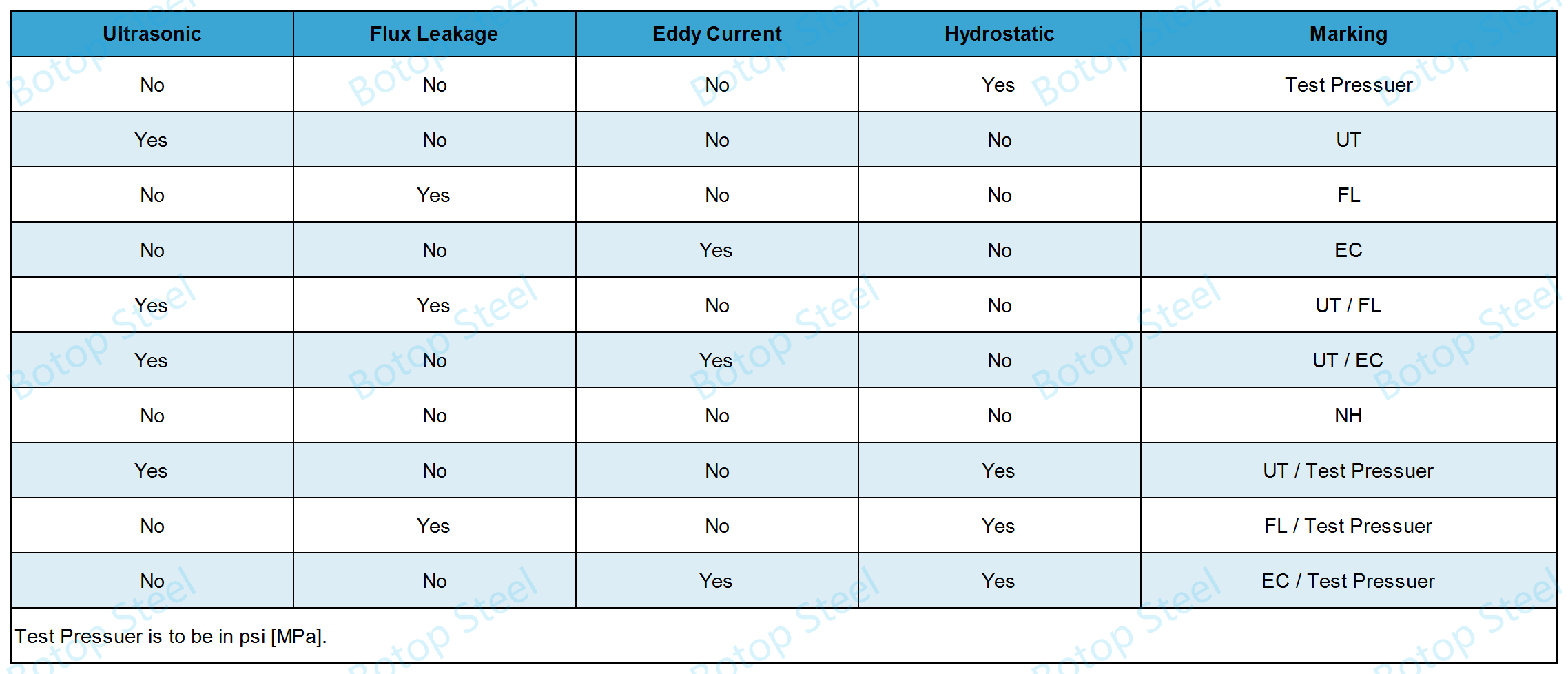

When the pipe is not to be hydrotested, a non-destructive test shall be performed on each pipe to detect defects.

Non-destructive testing of P9 material should be performed by one of the methods E213, E309 or E570.

E213: Practice for Ultrasonic Testing of Metal Pipe and Tubing;

E309: Practice for Eddy Current Examination of Steel Tubular Products Using Magnetic Saturation;

E570: Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products;

Permissible Variations in Diameter

Diameter deviations can be classified according to either 1. based on the inner diameter or 2. based on the nominal or outer diameter.

1. Inner diameter: ±1%.

2. NPS [DN] or outside diameter: This conforms to the permissible deviations in the table below.

Permissible Variations in Wall Thickness

The thickness of the pipe wall at any point shall not exceed the specified tolerance.

The minimum wall thickness and outside diameter for inspection for compliance with this requirement for pipe ordered by NPS [DN] and schedule number is shown in ASME B36.10M.

Contents of marking: Manufacturer's name or trademark; standard number; grade; length and additional symbol "S".

The markings for hydrostatic pressure and non-destructive testing in the table below should also be included.

Marking location: Marking should begin approximately 12 inches (300 mm) from the end of the pipe.

For pipes up to NPS 2 or less than 3 ft (1 m) in length, the information marking may be attached to the tag.

ASTM A335 P9 steel pipe is widely used in boilers, petrochemical equipment power stations, etc., which need to withstand high temperature and high pressure because of its superior high temperature and high-pressure resistance.

Boilers: Especially in the main steam piping and reheater piping of supercritical and ultra-supercritical boilers for very high temperatures and pressures.

Petrochemical equipment: Such as cracker pipes and high-temperature piping, which handle high-temperature vapors and chemicals, require materials with excellent temperature and corrosion resistance.

Power stations: For main steam piping and high-pressure heaters, as well as for internal turbine piping to cope with long periods of high temperature and pressure.

P9 Materials have their own standard grades in different national standard systems.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

GOST 550: 12ChM;

Before selecting any equivalent material, it is recommended that detailed performance comparisons and testing be carried out to ensure that the alternative material will meet the requirements of the original design.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Please feel free to contact us if you have any needs or questions about steel tubing. We look forward to receiving your information and look forward to assisting you.