ASTM A500 is cold-formed welded and seamless carbon steel structural tubing for welded, riveted, or bolted bridges and building structures and general structural purposes.

Grade B is a versatile cold-formed welded or seamless carbon steel structural tube with a yield strength of not less than 315 MPa [46,000 psi] and a tensile strength of not less than 400 MPa [58,000], which is used in a wide variety of architectural and mechanical structural projects due to its excellent structural stability and durability.

ASTM A500 classifies steel pipe into three grades, grade B, grade C, and grade D.

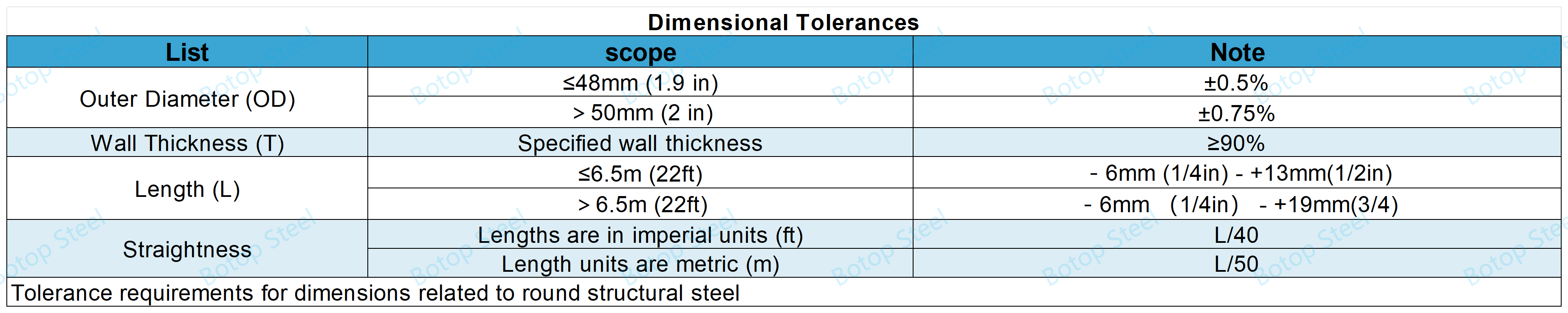

For tubes with outside diameter ≤ 2235mm [88in] and wall thickness ≤ 25.4mm [1in].

However, if the ERW welding process is used, only pipes with a maximum diameter of 660 mm and a wall thickness of 20 mm can be made.

If you want to purchase a pipe with a larger diameter wall thickness, you can choose to use the SAW welding process.

CHS: Circular hollow sections.

RHS: Square or rectangular hollow sections.

EHS: Elliptical hollow sections.

The steel shall be made by one or more of the following processes: basic oxygen or electric furnace.

Basic Oxygen Process: This is a modern rapid method of steel production, which reduces the carbon content by blowing oxygen into the molten pig iron while removing other unwanted elements such as sulfur and phosphorus. It is suitable for the rapid production of large quantities of steel.

Electric Furnace Process: The Electric Furnace Process uses a high-temperature electric arc to melt scrap and directly reduce iron, and is particularly useful for producing specialty grades and controlling alloy compositions, as well as for small batch production.

Tubes shall be made by the electric-resistance-welded (ERW) process.

ERW pipe is the process of creating a weld by coiling a metallic material into a cylinder and applying resistance and pressure along its length.

Grade B tubing can be annealed or stress-relieved.

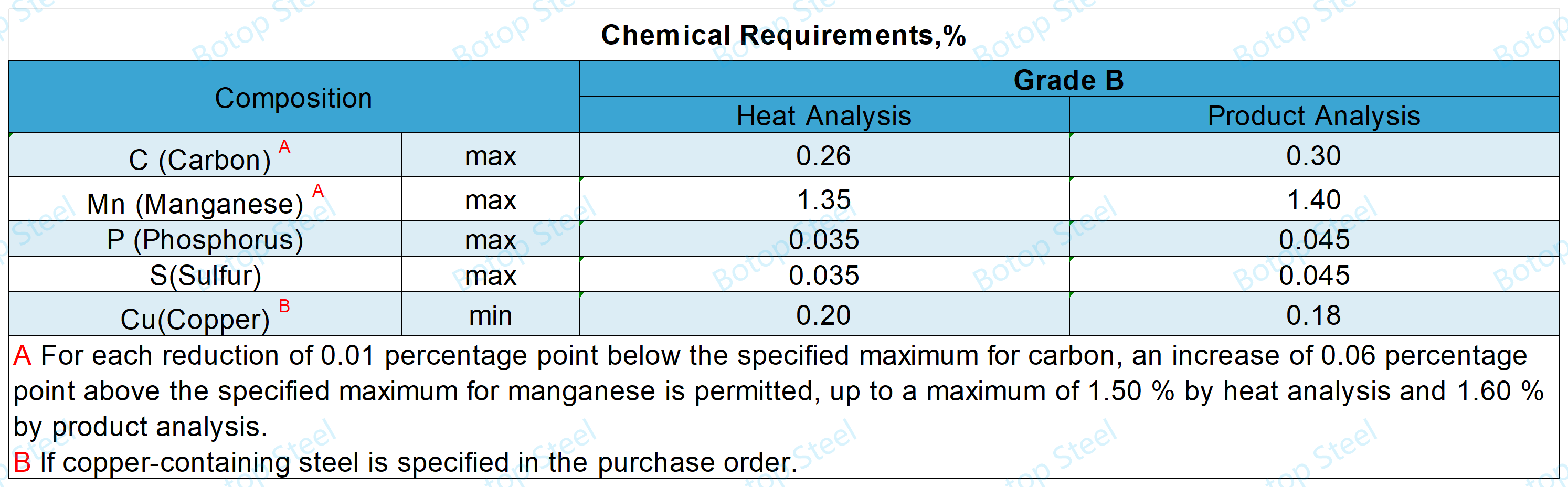

The chemical composition of ASTM A500 Grade B steel includes moderate amounts of carbon and manganese to ensure good mechanical properties and weldability. At the same time, phosphorus and sulfur levels are tightly controlled to avoid embrittlement, and moderate additions of copper improve corrosion resistance.

These properties are ideally suited for structural applications, especially in environments where good weldability and durability are required.

Specimens shall meet the applicable requirements of ASTM A370, Appendix A2.

| List | Grade B | |

| Tensile strength, min | psi | 58,000 |

| MPa | 400 | |

| Yield strength, min | psi | 46,000 |

| MPa | 315 | |

| Elongation in 2 in. (50 mm), min, C | % | 23 A |

| A Applies to specified wall thicknesses (t ) equal to or greater than 0.180 in. [4.57mm]. For lighter specified wall thicknesses, the minimum elongation values shall be calculated by the formula: percent elongation in 2 in. [50 mm] = 61t+ 12, rounded to the nearest percent. For A500M use the following formula: 2.4t+ 12, rounded to the nearest percent. C The minimum elongation values specified apply only to tests performed prior to shipment of the tubing. |

||

Weld ductility test: Using a specimen at least 4 inches (100 mm) long, flatten the specimen with the weld at 90° to the direction of loading until the distance between the plates is less than 2/3 of the outside diameter of the pipe. the specimen shall not be cracked or broken on the inside or outside surfaces during this process.

Pipe ductility test: continue to flatten the specimen until the distance between the plates is less than 1/2 of the pipe's outer diameter. at this time, the pipe should not have cracks or fractures on the inner and outer surfaces.

Integrity test: Continue to flatten the specimen until a fracture occurs or until the relative wall thickness requirements are met. If evidence of ply peeling, unstable material, or incomplete welds is found during the flattening test, the specimen will be judged unsatisfactory.

A flaring test is available for round tubes ≤ 254 mm (10 in) in diameter, but is not mandatory.

All tubing shall be free from defects and shall have a workmanlike finish.

Surface imperfections shall be classed as defects when their depth reduces the remaining wall thickness to less than 90 % of the specified wall thickness.

Defects up to 33% of the specified wall thickness in depth may be completely eliminated by cutting or grinding to complete metal.

If filler welding is used, the wet welding process shall be used and the protruding weld metal shall be removed to maintain a smooth surface.

Surface defects, such as handling marks, minor mold or roll marks, or shallow pits, are not considered defects provided they can be removed within the specified wall thickness.

The following information should be included:

Manufacturer's name: This can be the manufacturer's full name or an abbreviation.

Brand or Trademark: The brand name or trademark used by the manufacturer to distinguish its products.

Specification Designator: ASTM A500, which need not include the year of publication.

Grade Letter: B, C or D grade.

For structural tubes ≤ 100mm (4in) in diameter, labels can be used to mark the identification information clearly.

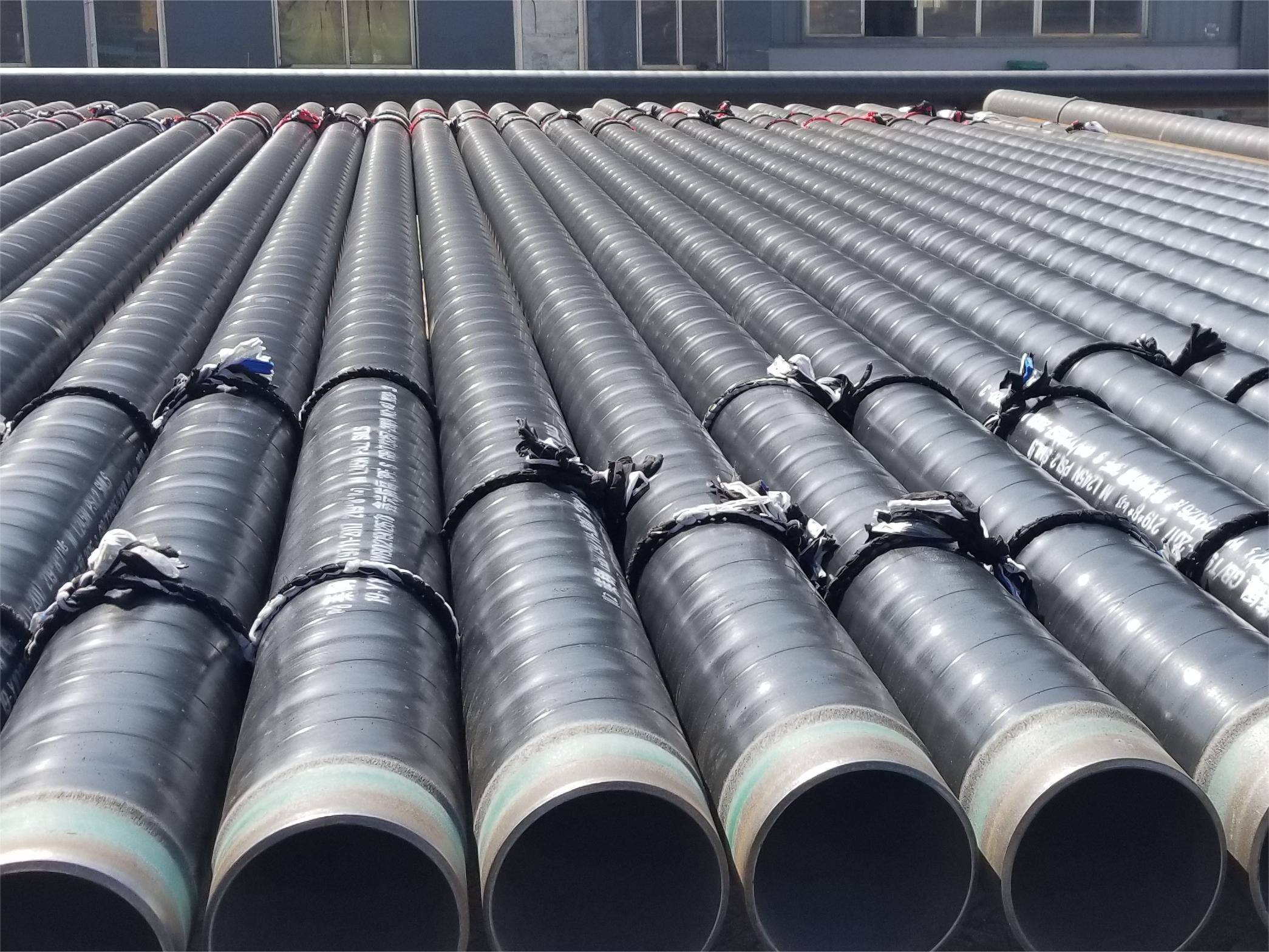

Primarily used for structural purposes, it provides the necessary mechanical strength and weldability to support the design and construction of architectural and engineering structures.

This steel pipe is widely used in building frames, bridges, industrial facilities, and a variety of other structural components that require strength and durability.

ASTM A370: Test Methods and Definitions for Mechanical Testing of Steel Products.

ASTM A700: Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment.

ASTM A751: Test Methods and Practices for Chemical Analysis of Steel Products.

ASTM A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys.

According to customers' requirements, the anti-corrosion treatment of steel pipe surfaces can be done in many different ways to enhance its corrosion resistance and prolong its service life.

Including varnish, paint, galvanization, 3PE, FBE, and other methods.

We are a high-quality welded carbon steel pipe manufacturer and supplier from China, and also a seamless steel pipe stockist, offering you a wide range of steel pipe solutions!

If you want to know more information about steel pipe products, you can contact us!