ASTM A513 steel is a carbon and alloy steel pipe and tube made from hot-rolled or cold-rolled steel as raw material by resistance welding (ERW) process, which is widely used in all kinds of mechanical structures.

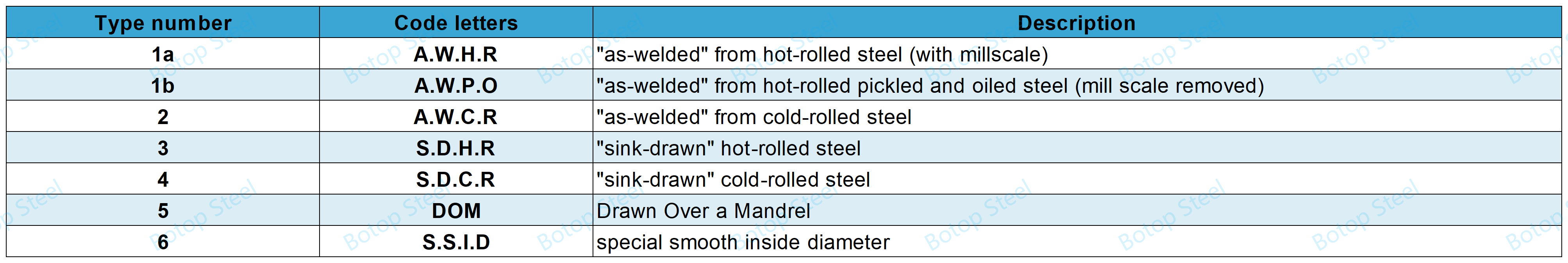

Type 1 can be divided into 1a and 1b.

Type 1a (A.W.H.R): "as-welded" from hot-rolled steel (with mill scale).

This form of pipe is welded directly from hot-rolled steel with iron oxide (mill scale) formed during rolling. This type of pipe is often used in applications where surface integrity is not critical because the surface contains mill scale.

Type 1b (A.W.P.O): "as-welded" from hot-rolled pickled and oiled steel (mill scale removed).

This form of pipe is welded from hot-rolled steel that has been pickled and oiled and is characterized by the removal of the mill scale. The pickling and oiling treatment not only removes surface oxidation but also provides some corrosion protection and lubrication during processing, making this pipe more suitable for applications that require a cleaner surface or slightly tighter processing conditions.

Execution standard: ASTM A513

Material: Hot-rolled or Cold-rolled Steel

Type number:Type1 (1a or 1b), Type2, Type3, Type4, Type5, Type6.

Grade: MT 1010, MT 1015,1006, 1008, 1009 etc.

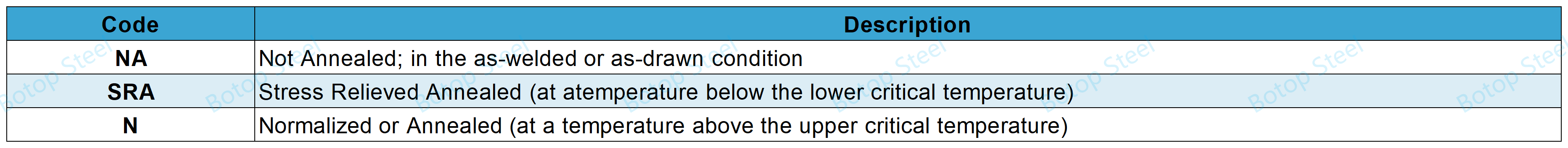

Heat treatment: NA, SRA, N.

Size and wall thickness

Hollow section shape: Round, square, or other shapes

Length

Total quantity

Round

Square or rectangular

Other shapes

such as streamlined, hexagonal, octagonal, round inside and hexagonal or octagonal outside, ribbed inside or out, triangular, rounded rectangular, and D shapes.

ASTM A513 Round Tubing Type 1 Common grades are:

1008,1009,1010,1015,1020,1021,1025,1026,1030,1035,1040,1340,1524,4130,4140.

Hot-rolled

In the production process, hot-rolled steel is first heated at high temperatures, allowing the steel to be rolled in a plastic state, which makes it easy to change the shape and size of the steel. At the end of the hot rolling process, the material is usually scaled and deformed.

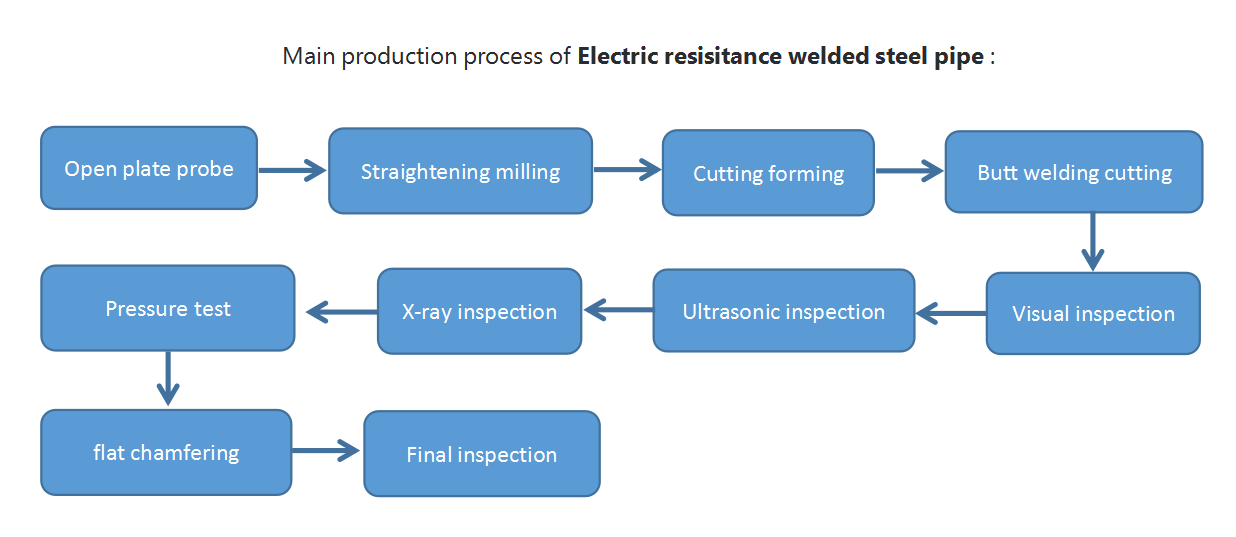

Tubes shall be made by the electric-resistance-welded (ERW) process.

ERW pipe is the process of creating a weld by coiling a metallic material into a cylinder and applying resistance and pressure along its length.

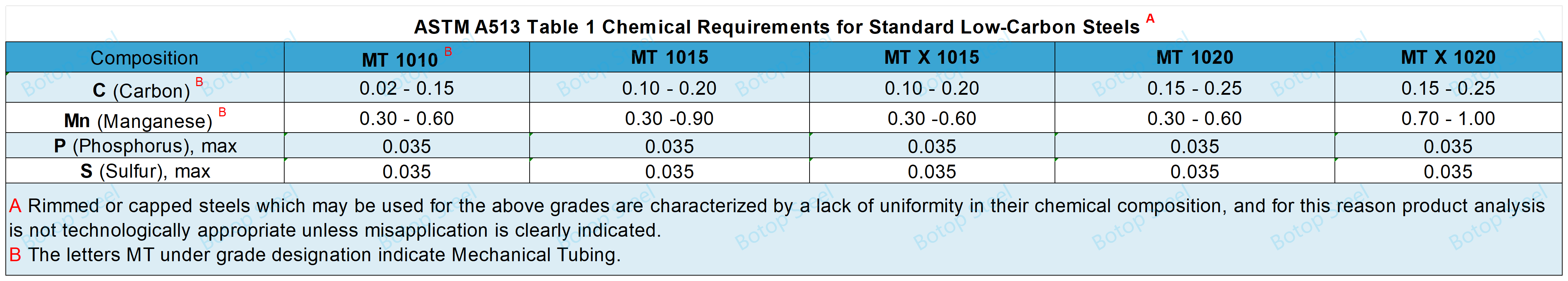

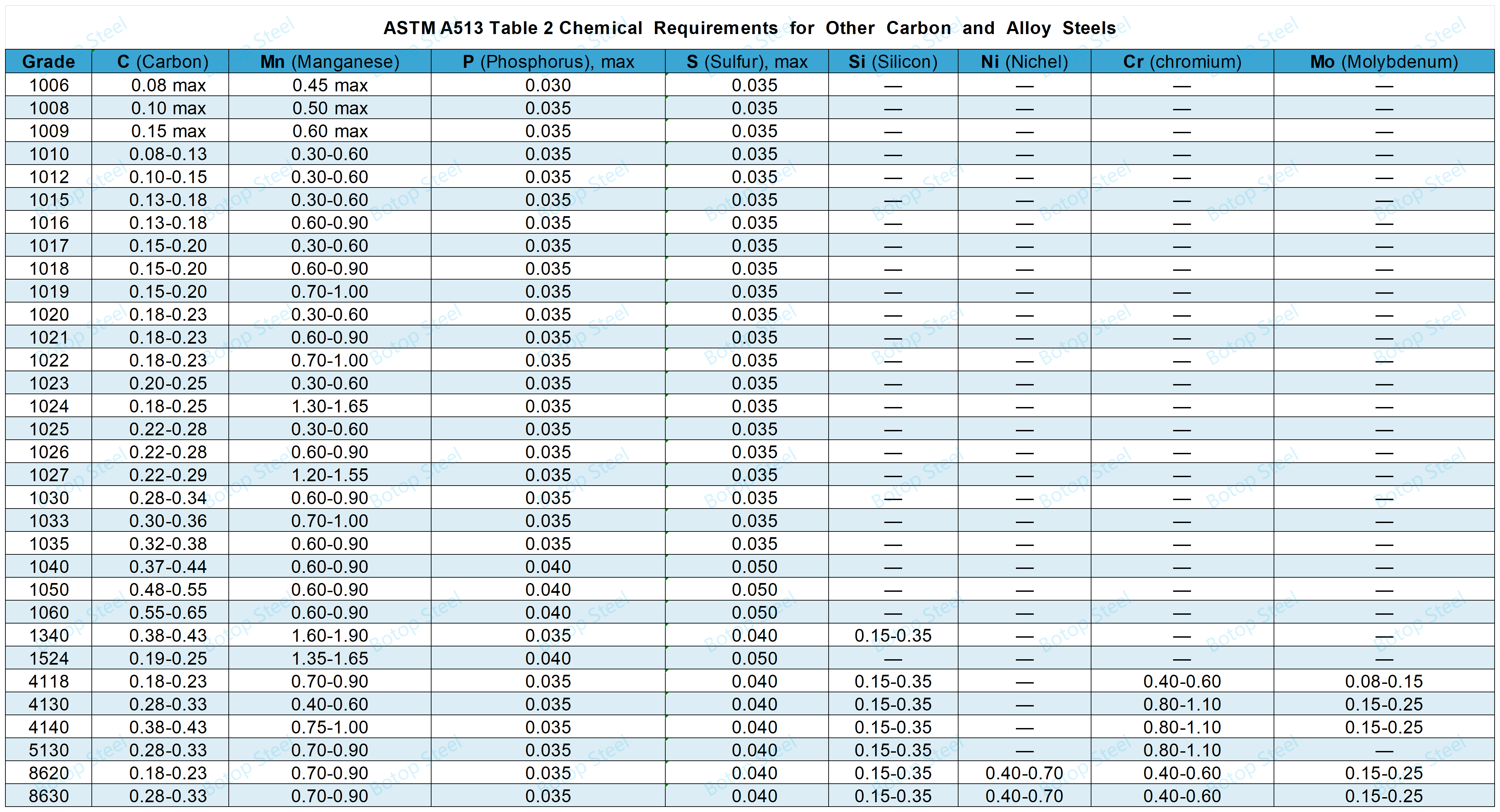

Steel shall conform to the chemical composition requirements specified in Table 1 or Table 2.

| Grade | Yied Strength ksi[MPa],min |

Ultimate Strength ksi[MPa],min |

Elongation in 2 in.(50 mm), min, |

RB min |

RB max |

| As-Welded Tubing | |||||

| 1008 | 30 [205] | 42 [290] | 15 | 50 | — |

| 1009 | 30 [205] | 42 [290] | 15 | 50 | — |

| 1010 | 32 [220] | 45 [310] | 15 | 55 | — |

| 1015 | 35 [240] | 48 [330] | 15 | 58 | — |

| 1020 | 38 [260] | 52 [360] | 12 | 62 | — |

| 1021 | 40 [275] | 54 [370] | 12 | 62 | — |

| 1025 | 40 [275] | 56 [385] | 12 | 65 | — |

| 1026 | 45 [310] | 62 [425] | 12 | 68 | — |

| 1030 | 45 [310] | 62 [425] | 10 | 70 | — |

| 1035 | 50 [345] | 66 [455] | 10 | 75 | — |

| 1040 | 50 [345] | 66 [455] | 10 | 75 | — |

| 1340 | 55 [380] | 72 [495] | 10 | 80 | — |

| 1524 | 50 [345] | 66 [455] | 10 | 75 | — |

| 4130 | 55 [380] | 72 [495] | 10 | 80 | — |

| 4140 | 70 [480] | 90 [620] | 10 | 85 | — |

RB refers to the Rockwell Hardness B Scale.

The hardness requirements corresponding to specific grades can be viewed in the table above for RB.

1% of all tubes in each lot and not less than 5 tubes.

Round tubes and tubes that form other shapes when they are round are applicable.

All tubing will be given a hydrostatic test.

Maintain the minimum hydro test pressure for not less than 5s.

The pressure is calculated as:

P=2St/D

P = minimum hydrostatic test pressure, psi or MPa,

S = allowable fiber stress of 14,000 psi or 96.5 MPa,

t = specified wall thickness, in. or mm,

D = specified outside diameter, in. or mm.

It is the intent of this test to reject tubes containing injurious defects.

Each tube shall be tested with a nondestructive electric test in accordance with Practice E213, Practice E273, Practice E309, or Practice E570.

Outer Diameter

Table 4 Diameter Tolerances for Type I (A.W.H.R.) Round Tubing

Wall Thickness

Table 6 Wall Thickness Tolerance for Type I (A.W.H.R.) Round Tubing (Inch Units)

Table 7 Wall Thickness Tolerance for Type I (A.W.H.R.) Round Tubing (SI Units)

Length

Table 13 Cut-Length Tolerances for Lathe-Cut Round Tubing

Table 14 Length Tolerances for Punch-, Saw-, or Disc-Cut Round Tubing

Squareness

Table 16 Tolerances, Outside Dimensions Square and Rectangular Tubing

Mark the following information in an appropriate manner for each stick or bundle.

manufacturer name or brand, specified size, type, purchaser's order number, and this specification number.

Barcoding is acceptable as a supplementary identification method.

The tubing shall be free of injurious defects and shall have a workmanlike finish.

The ends of the tubing shall be neatly cut and free of burrs or sharp edges.

Rolled Chip (for Type 1a): Type 1a (direct from hot rolled steel with rolled chips) typically has a rolled chip surface. This surface condition is acceptable for certain applications where high surface quality is not required.

Removed Rolled Chip (for Type 1b): Type 1b (made from hot rolled pickled and oiled steel with rolled chips removed) provides a cleaner surface for applications that require painting or better surface quality.

Tubing shall be coated with a film of oil before shipping to retard rust.

Should the order specify that tubing be shipped without rust retarding oil, the film of oils incidental to manufacture will remain on the surface.

It can effectively prevent the surface of the pipe from reacting with moisture and oxygen in the air, thus avoiding rust and corrosion.

Cheaper: The welding process for hot rolled steel makes ASTM A513 Type 1 more affordable compared to cold-drawn products.

Wide range of applications: ASTM A513 Type 1 is suitable for a variety of applications, including structural components, frames, shelving, and more. Its versatility in different environments and functions makes it a popular choice for industries such as automotive, construction, and machinery.

Excellent weldability: The chemical composition of ASTM A513 Type 1 is favorable for welding, and it can be welded using most conventional welding methods, making it more practical in a variety of manufacturing environments.

Good strength and toughness: Although not as strong as some alloy steels or treated steels, it meets the requirement of providing adequate strength for many structural and mechanical applications. Further processing, such as heat treatment, can also improve the mechanical properties of the pipe to meet specific requirements.

Surface Finish: Type 1b provides a cleaner surface, which is beneficial in applications where a good surface finish is required and where painting or further surface preparation is needed.

ASTM A513 Type 1 provides a good balance of cost, performance, and versatility, making it suitable for many mechanical and structural applications where cost-effective tubing with good mechanical properties is required.

Used in construction as supporting structures such as beams and columns.

Used in the production of structural parts of various mechanical equipment, such as bearings and shafts.

Frame and support structures in agricultural machinery.

Used to construct metal shelving and storage systems in warehouses and stores.

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions.

For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!