ASTM A519 tubing shall be manufactured by the seamless process and shall be hot-finished or cold-finished as specified.

For round tubes with an outside diameter not exceeding 12 3/4 in (325 mm).

Steel tubing can also be manufactured in square, rectangular, or other shapes as required.

ASTM A519 can be classified according to the material of steel: Carbon Steel and Alloy Steel.

Carbon steel is subdivided into Low Carbon MT (Mechanical Tubing), High Carbon Steel and Desulfurized or Rephosphorized, or both Carbon Steel, to suit different industrial needs and application scenarios.

When no grade is specified, manufacturers have the option of offering MT1015 or MTX1020 grades.

Outside diameter: 13.7 - 325 mm;

Wall thickness: 2-100mm.

The steel may be made by any process.

Steel may be cast in ingots or may be strand cast.

Tubes shall be made by a seamless process and shall be either hot-finished or cold-finished, as specified.

Seamless steel tubes are tubes with no welded seams throughout.

Cold-finished tubes are recommended for high demands on dimensional accuracy and surface quality.

The main concern is cost-effectiveness and material toughness, hot-finished steel pipe may be a more suitable choice.

Next is the production process of hot-rolled seamless steel pipe.

The steel manufacturer shall analyze the heat of each steel to determine the percentage of specified elements.

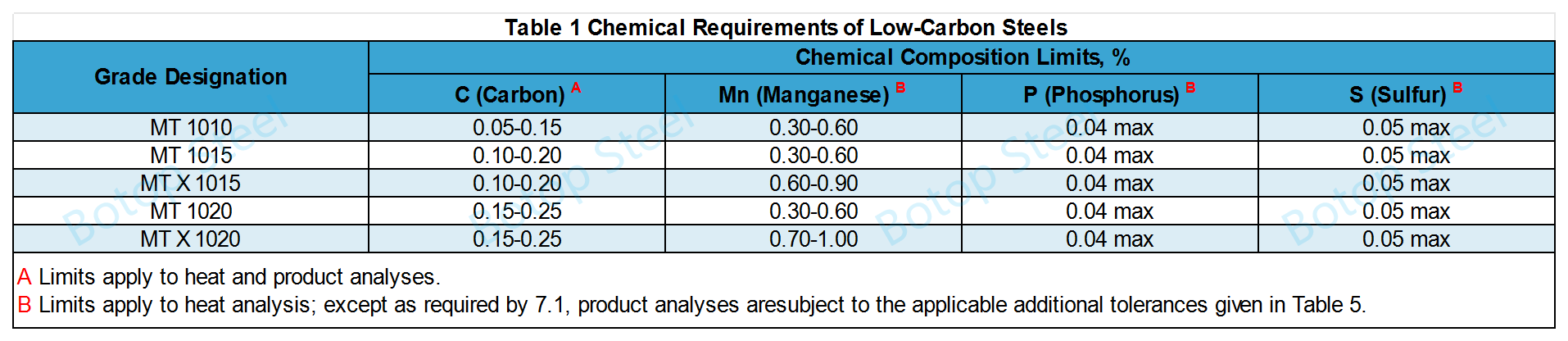

Table 1 Chemical Requirements of Low-Carbon Steels

Mild steel is a steel with a carbon content usually not exceeding 0.25%. Due to its lower carbon content, this steel has better ductility and malleability and is less hard and strong compared to high-carbon steel.

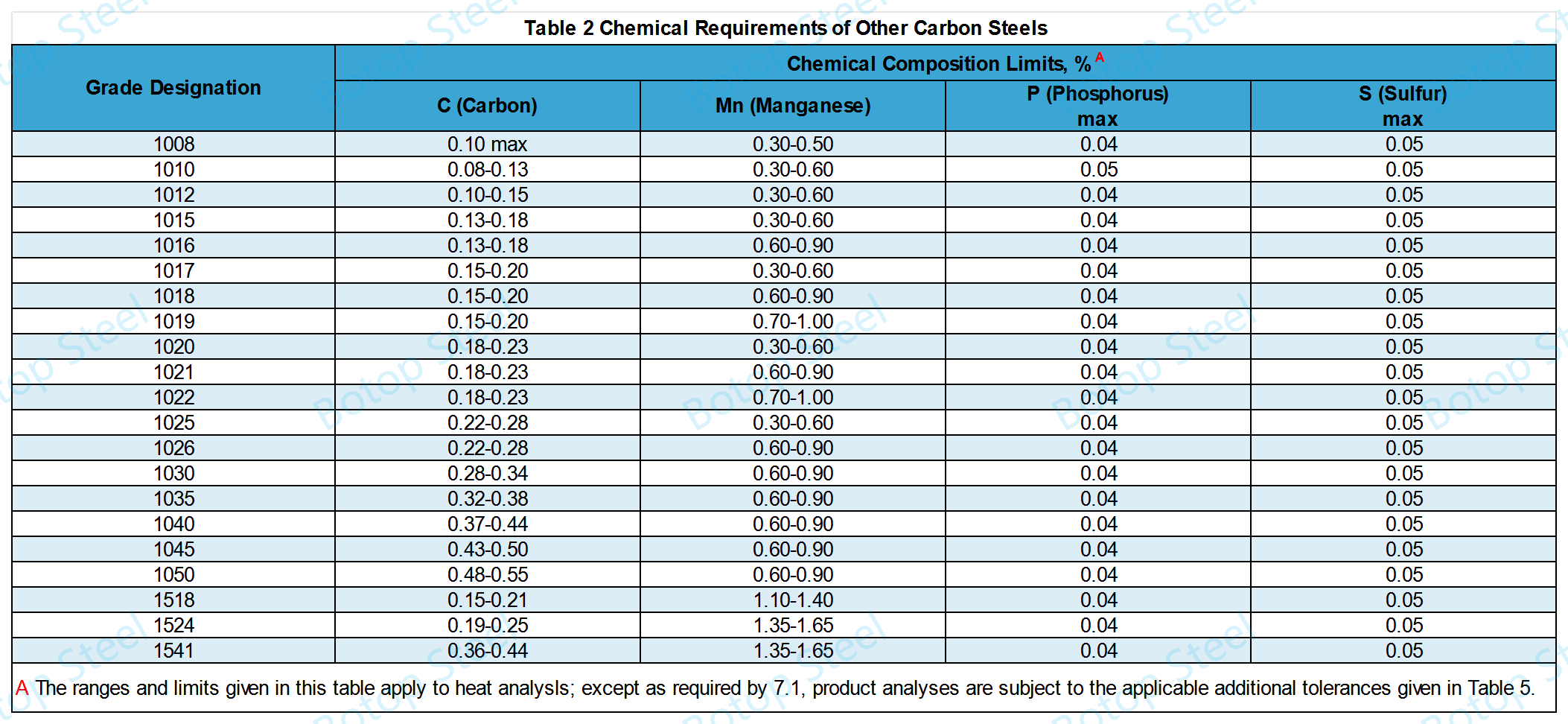

Table 2 Chemical Requirements of Other Carbon Steels

Medium carbon steels: Containing between 0.25% and 0.60% carbon, they provide higher hardness and strength and require heat treatment to improve properties.

High carbon steel: Contains between 0.60% and 1.0% or more carbon, and provides very high hardness and strength, but lower toughness.

Table 3 Chemical Requirements for Alloy Steels

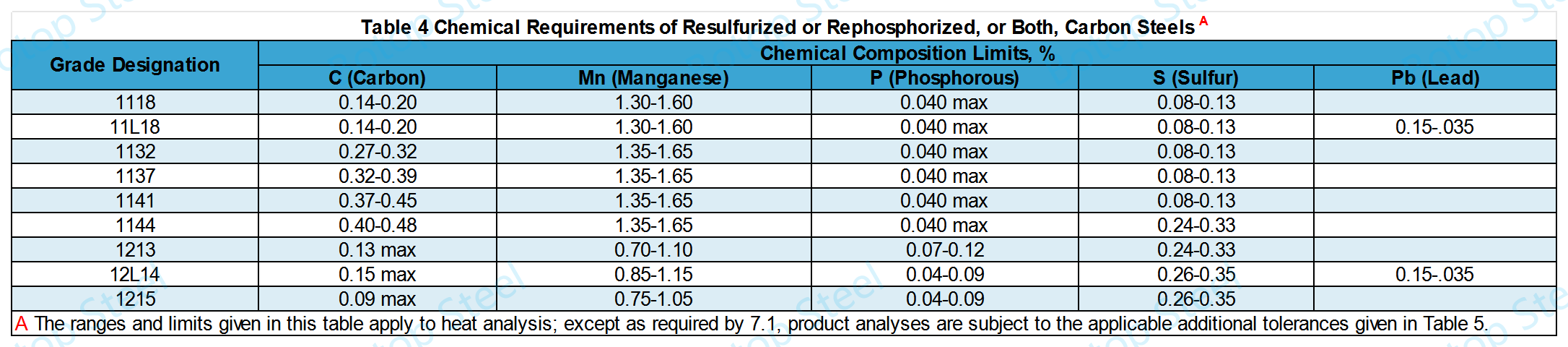

Table 4 Chemical Requirements of Resulfurized or Rephosphorized, or Both, Carbon Steels

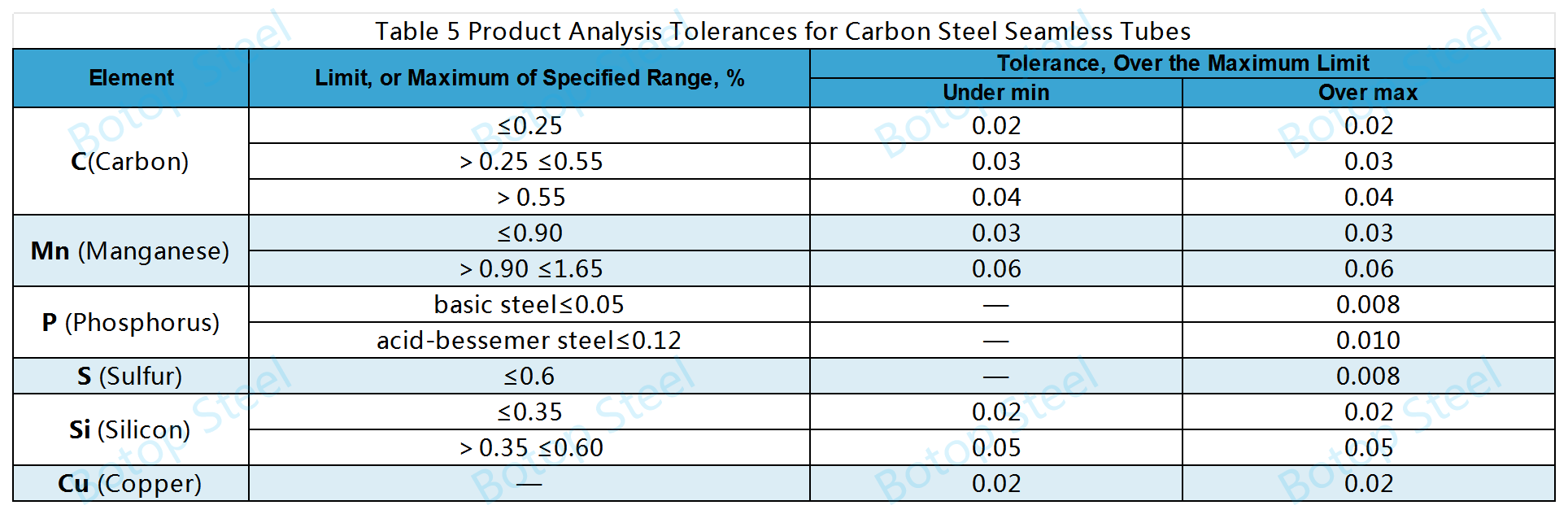

TABLE 5 Product Analysis Tolerances Over or Under Specified Range or Limit

The manufacturer should only be asked to analyze the product if it is required by the order.

ASTM A519 covers the following experimental items:

Hardness Test; Tension Tests; Nondestructive Test; Flaring Test; Steel Cleanliness and Hardenability.

| Grade Designation | Pipe Type | Condition | Uitimate Strength | Yield Strength | Elongation in 2in.[50mm],% | Rockwell, Hardness B Scale |

||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Carbon Steel | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Carbon Steel | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Carbon Steel | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Carbon Steel | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Carbon Steel | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized or Rephosphorized, or Both, Carbon Steels |

HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized or Rephosphorized, or Both, Carbon Steels |

HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Alloy Steels | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Alloy Steels | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Hot Rolled, CW-Cold Worked, SR-Stress Relieved, A-Annealed and N-Normalized.

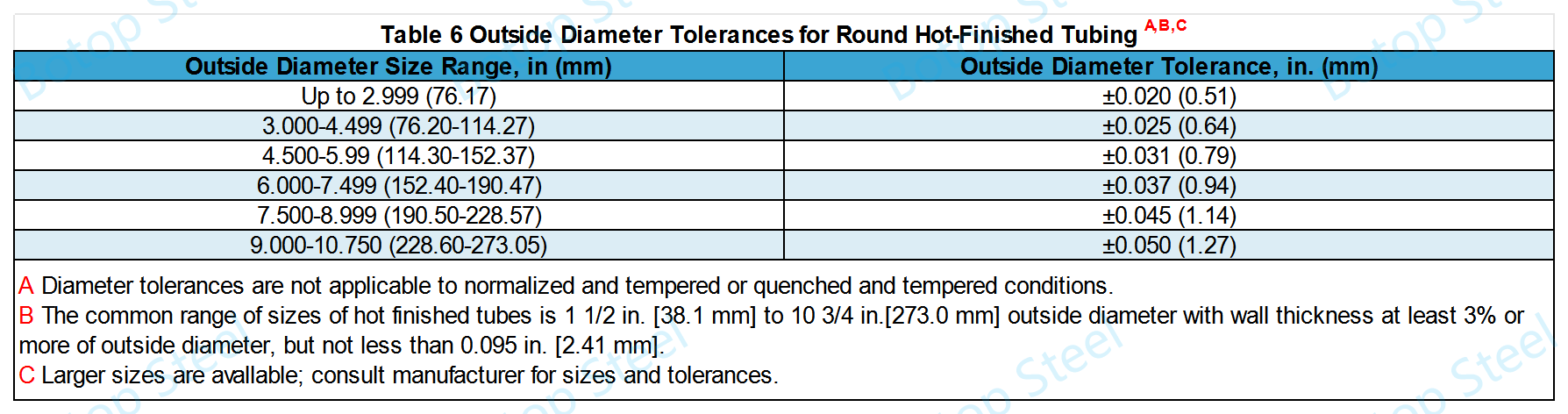

Outside Diameter Tolerance

Table 6 Outside Diameter Tolerances for Round Hot-Finished Tubing

Table 12 Outside Diameter Tolerances for Ground Seamless Tubing

| Size Outside Diameter, in.[mm] |

Outside Diameter Tolerances for Sizes and Lengths Given, in. [mm] | |||

| Over | Under | Over | Under | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] when L≤16ft[4.9m] |

0.000 | 0.004 [0.10] when L>16ft[4.9m] |

0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] when L≤16ft[4.9m] |

0.000 | 0.006 [0.15] when L>16ft[4.9m] |

0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] when L≤12ft[3.7m] |

0.000 | 0.006 [0.15] when L≤16ft[4.9m] |

0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] when L≤12ft[3.7m] |

0.000 | 0.006 [0.15] when L≤16ft[4.9m] |

0.000 |

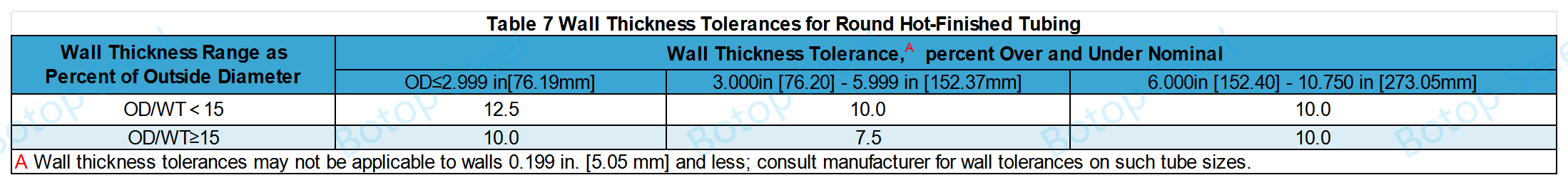

Wall Thickness Tolerance

Table 7 Wall Thickness Tolerances for Round Hot-Finished Tubing

Table 10 Wall Thickness Tolerances for Round Cold-Worked Tubing

| Wall Thickness Ranges as Percent of Outside Diameter |

Wall Thickness Tolerance Over and Under Nominal, % | |

| OD≤1.499in[38.07mm] | OD≥1.500 in [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

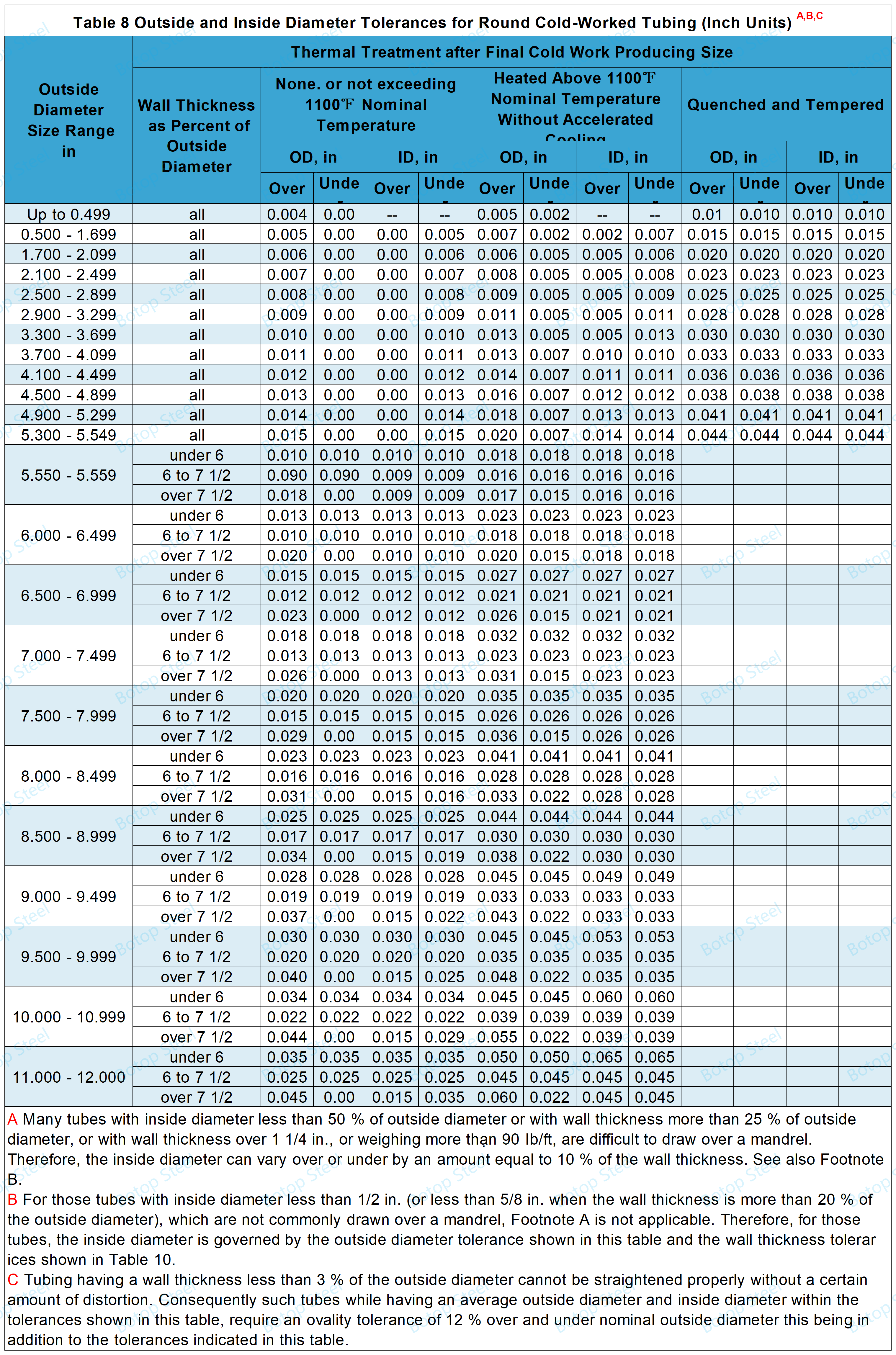

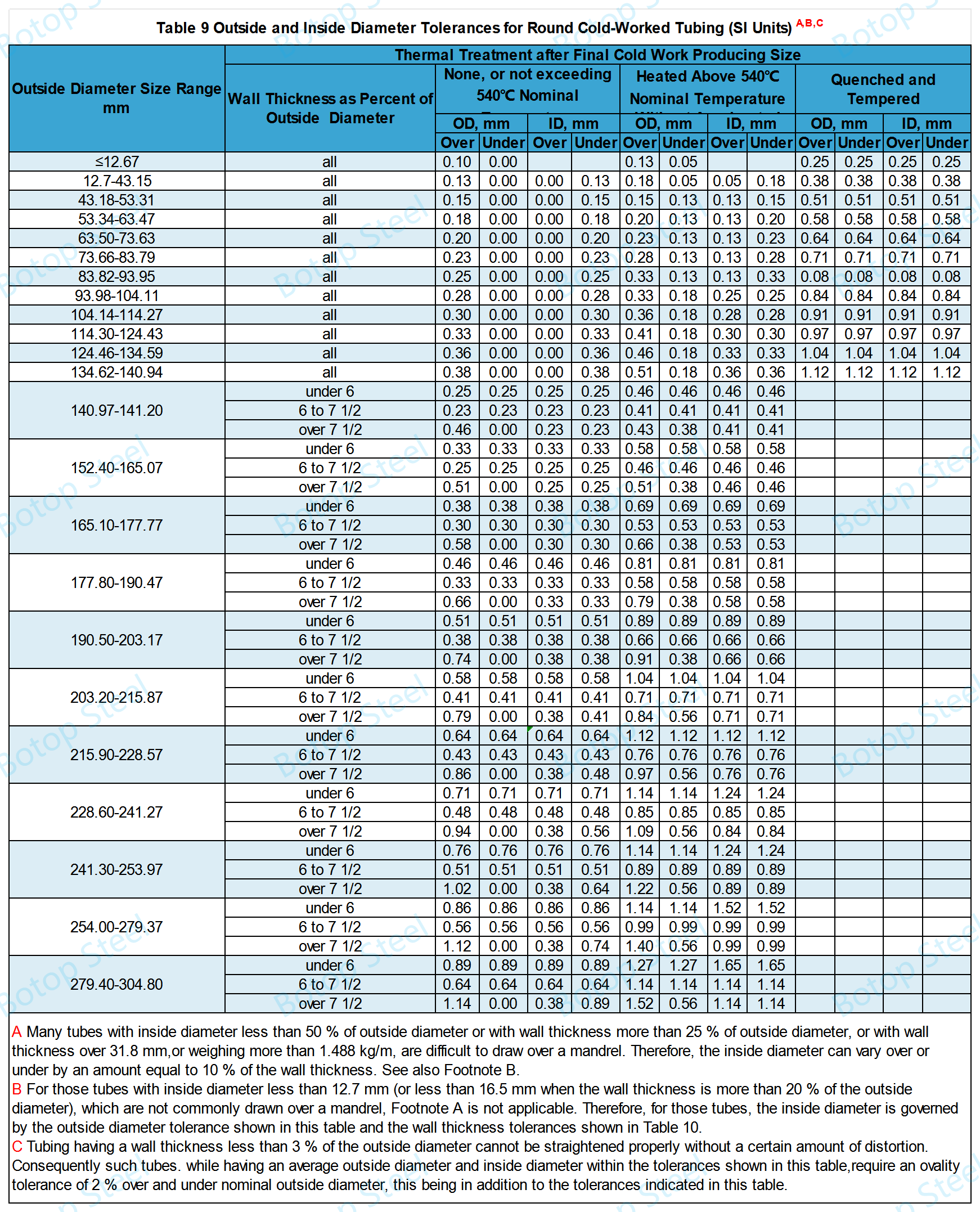

Outside and Inside Diameter Tolerance

Table 8 Outside and Inside Diameter Tolerances for Round Cold-Worked Tubing (Inch Units)

Table 9 Outside and Inside Diameter Tolerances for Round Cold-Worked Tubing (SI Units)

Outside Diameter and Wall Thickness Tolerance

Table 11 Outside Diameter and Wall Tolerances for Rough-Turned Seamless Steel Tubing

| Specified Size Outside Diameter, in. [mm] |

Outside Diameter, in. [mm] |

Wall Thickness, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

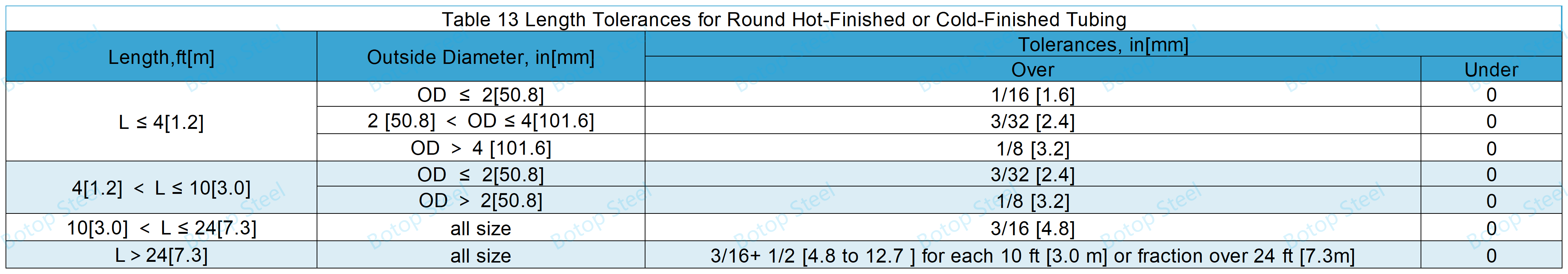

Length Tolerance

Table 13 Length Tolerances for Round Hot-Finished or Cold-Finished Tubing

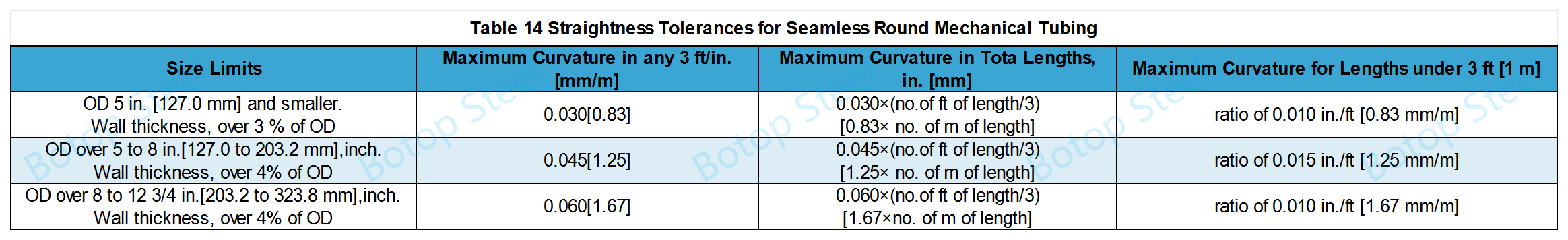

Straightness Tolerance

Table 14 Straightness Tolerances for Seamless Round Mechanical Tubing

The pipe should be coated with a film of oil before molding to prevent rusting.

Rust preventive oil may also be applied to the inner and outer surfaces of the pipe.

Aviation and aerospace: manufacturing of critical components such as aircraft engines and spacecraft support systems.

Energy industry: drilling equipment and high-pressure boiler piping manufacturing.

Machinery and equipment manufacturing: Core components that make up a wide range of industrial machinery and equipment.

Sports equipment: Manufacturing of high-performance bicycle frames and other sports facilities.

Building and construction: structural support elements for buildings and applications in high-pressure environments.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, etc. These materials can be regarded as equivalents of some carbon and alloy steels in ASTM A519.

2. DIN 1629: St52, St37.4, etc. Usually used for mechanical and structural purposes, these are similar to the mild steel grades in ASTM A519.

3. JIS G3445: STKM13A, STKM13B, etc. These are carbon steel tubes used for mechanical and structural purposes.

4. BS 6323:CFS 3, CFS 4, CFS 8, etc. These are seamless and welded steel tubes for automotive, mechanical, and general engineering purposes.

5. GB/T 8162:20#, 45#, 40Cr, 20CrMo, etc. Seamless steel tubes and pipes for general structure and mechanical structure.

6. ISO 683-17:100Cr6, etc., commonly used in bearing manufacture, can also find application in mechanical engineering and has similar applications to certain alloy steels of ASTM A519.

When selecting an equivalent material, it is important to refer to the detailed chemical composition and mechanical property specifications to ensure that the material selected will meet the performance requirements of the particular application.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions. The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.