ASTM A53 seamless steel pipe is classified as A53 Type S and is a seamless steel pipe.

It is divided into two grades, Grade A and Grade B, and is suitable for mechanical and pressure applications, as well as general use for steam, water, gas, and air. This steel pipe is a carbon steel pipe that is suitable for welding and forming operations including coiling, bending, and flange connections.

| Standard | ASTM A53/A53M |

| Nominal Diameter | DN 6- 650 [NPS 1/8 - 26] |

| Specified Outer Diameter | 10.3 - 660 mm [0.405 - 26 in.] |

| Weight Class | STD (Standard), XS (Extra Strong), XXS (Double Extra Strong) |

| Schedule No. | Schedule 10, Schedule 20, Schedule 30, Schedule 40, Schedule 60, Schedule 80, Schedule 100, Schedule 120, Schedule 140, Schedule 160, |

In practice, Schedule 40 and Schedule 80 are the two most widely used pipe wall thickness grades. For more information, please refer to the Schedule grade PDF file we provide.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

ASTM A53 steel pipes can be either seamless or welded.

The seamless (Type S) manufacturing method is a hot working of steel and, if necessary, cold finishing of the hot-worked tubular product to achieve the required shape, dimensions, and properties.

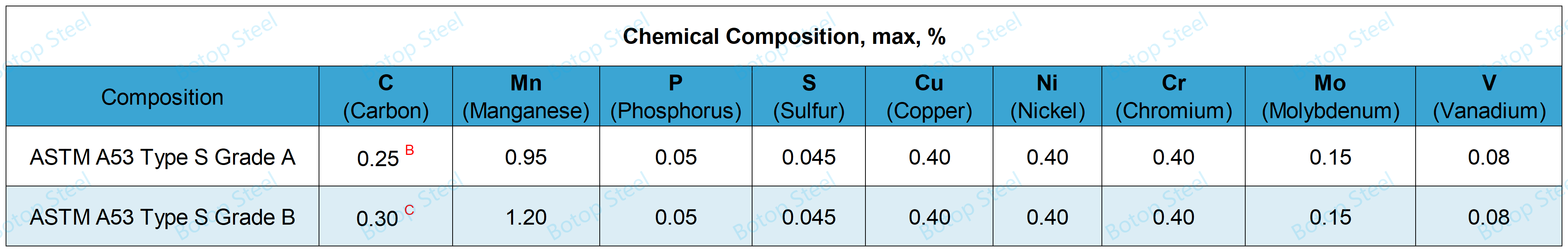

In the ASTM A53 standard, the chemical composition requirements for Type S and Type E steel pipes are the same, while the chemical composition requirements for Type F are different.

A The five elements Cu, Ni, Cr, Mo, and V together must not exceed 1.00%.

B For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % of manganese above the specified maximum will be permitted up to a maximum of 1.35 %.

C For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % of manganese above the specified maximum will be permitted up to a maximum of 1.65 %.

Tension Performance

| List | Classification | Grade A | Grade B |

| Tensile strength, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Yield strength, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation in 50 mm [2 in.] | Note | A, B | A, B |

Bend Test

For DN ≤ 50 [NPS ≤ 2], a sufficient length of pipe shall be capable of being bent cold through 90° around a cylindrical mandrel, the diameter of which is twelve times the specified outside diameter of the pipe, without developing cracks at any portion.

Double-extra-strong (XXS) pipe over DN 32 [NPS 1 1/4] need not be subjected to the bend test.

Flattening Test

Seamless steel tubes do not need to be subjected to the flattening test.

If required by the contract, the experiment can be carried out according to the procedure in S1.

All sizes of seamless steel pipes shall maintain a certain water pressure value without leakage for at least 5 seconds.

The test pressure for plain-ended steel pipes can be found in Table X2.2.

The test pressures for threaded and coupled steel pipes can be found in Table X2.3.

It can be used as an alternative to the hydrostatic test.

The entire length of each seamless pipe shall be subjected to a non-destructive electrical test in accordance with E213, E309, or E570.

When purchasing ASTM A53, the steel pipe size tolerance should meet the following requirements.

| List | Sort | Tolerance |

| mass | Theoretical weight | ±10% |

| Diameter | DN 40mm[NPS 1/2] or smaller | ±0.4mm |

| DN 50mm[NPS 2] or larger | ±1% | |

| Thickness | minimum wall thickness shall be in accordance with Table X2.4 | min 87.5% |

| Lengths | lighter than extra-strong(XS) weight | 4.88m-6.71m (not more than 5 % of the total number of threaded lengths furnished being jointers (two pieces coupled together)) |

| lighter than extra-strong(XS) weight (plain-end pipe) |

3.66m-4.88m (Not more than 5% of the total number) |

|

| XS, XXS, or thicker wall thickness | 3.66m-6.71m ( no more than 5% total of pipe 1.83m-3.66m) |

|

| lighter than extra-strong(XS) weight (double-random lengths) |

≥6.71m (Minimum average length of 10.67m) |

ASTM A53 standard specifies the requirements for black pipe condition and hot-dip galvanized coating of steel pipes.

Black Pipe

Black pipe refers to the state of steel pipe without any surface treatment.

Black pipes are often used in places where the storage time is short, the environment is dry and non-corrosive, and the price is usually lower because there is no coating.

Hot-dip Galvanized Coating

Galvanized pipes, also known as white pipes, are often used in humid or corrosive environments.

The zinc in the zinc coating can be any grade of zinc in ASTM B6.

The galvanized pipe shall be free from uncoated areas, blisters, flux deposits, and gross dross inclusions. Lumps, projections, globules, or heavy deposits of zinc which will interfere with the intended use of the material will not be permitted.

Zinc content not less than 0.55 kg/m² [ 1.8 oz/ft² ].

Other Coatings

In addition to black pipe and galvanized coating, common coating types include paint, 3LPE, FBE, etc. The appropriate coating type can be selected according to the specific requirements of the operating environment.

Providing the following information will make your purchasing process more efficient and accurate.

Standard name: ASTM A53/A53M;

Quantity: Total length or total number;

Grade: Grade A or Grade B;

Type: S, E, or F;

Surface treatment: black or galvanized;

Size: Outside diameter, wall thickness, or schedule No. or weight grade;

Length: specified length or random length;

Pipe end: plain end, beveled end, or threaded end;