ASTM A556 steel pipe is mainly used as cold-drawn seamless carbon steel pipe for tubular feedwater heaters.

Its scope of application is seamless steel pipe with outside diameter size between 15.9-31.8mm and wall thickness not less than 1.1mm.

This article focuses on steel pipe and does not include U-tubes mentioned in the standard.

Outer diameter: 5/8 - 1 1/4 in. [15.9 -31.8 mm].

Wall thickness: ≥ 0.045 in [1.1 mm].

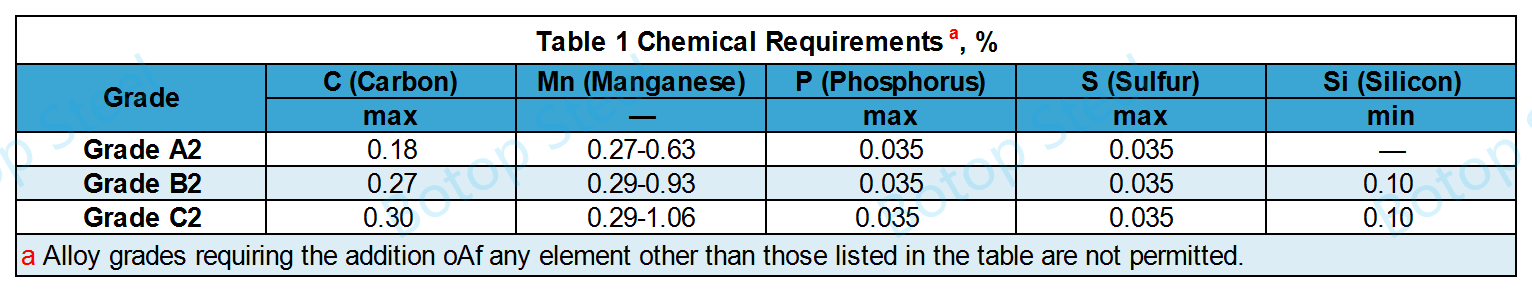

ASTM A556 classifies three grades, Grade A2, Grade B2, and Grade C2.

Steel tubes shall be manufactured by a seamless process and shall be cold drawn.

Cold-drawn seamless steel tubes offer high dimensional accuracy and good surface finish while refining the microstructure and enhancing its mechanical properties such as strength and hardness. The seamless structure makes the tubes more stable and safe when subjected to high pressures and temperatures, making them suitable for industrial applications requiring high precision and performance.

However, cold-drawn seamless steel tubes are more expensive to produce because their production process is more complex and requires more sophisticated operations and equipment. In addition, their relatively low production efficiency, especially in high volume production, is not as economical as the hot rolling process, and in some cases there may be more material loss, limiting their use in certain applications.

Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F [640°C] or higher to ensure ductility satisfactory for rolling into tube sheets and to meet mechanical properties as specified.

If product analysis is performed, refer to ASTM A751 for test methods.

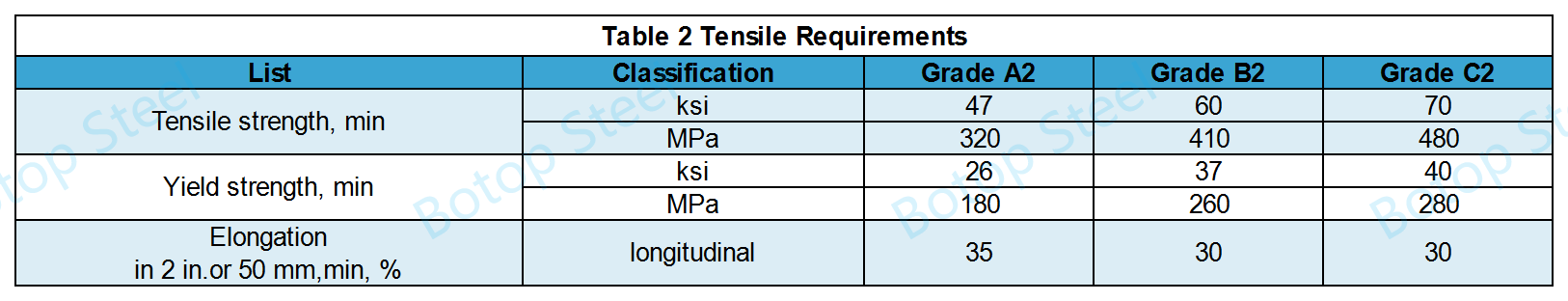

1. Tensile Property

Test method: ASTM A450 Section 7.

For batches of up to 50 tubes, 1 tube shall be selected for testing.

For batches of more than 50 tubes, 2 tubes shall be selected for testing.

2. Hardness

Test method: ASTM A450 Section 23.

Specimens from two test tubes from each lot shall be tested for Brinell or Rockwell hardness.

The Rockwell hardness of the pipe shall not exceed that shown in the table.

| Grade | Hardness |

| Grade A2 | 72 HRBW |

| Grade B2 | 79 HRBW |

| Grade C2 | 89 HRBW |

3. Flattening Test

Test method: ASTM A450 Section 19.

A flattening test shall be performed on one specimen from each end of a finished steel tube from a selection of not more than 125 tubes from each lot.

4. Flaring Test

Test method: ASTM A450 Section 21.

Flaring tests shall be carried out on one specimen from each end of the finished tube, with not more than 125 tubes selected from each batch.

There is no mandatory hydrostatic test for steel pipes.

However, every U-pipe must be hydrostatically tested with a non-corrosive fluid.

Each tube shall be tested by a nondestructive testing instrument capable of detecting defects in the entire cross-section of the tube after surface heat treatment following final cold drawing through.

The non-destructive test methods of Specification E213, Specification E309 (for ferromagnetic materials), Specification E426 (for non-magnetic materials), or Specification E570 may be selected for the test.

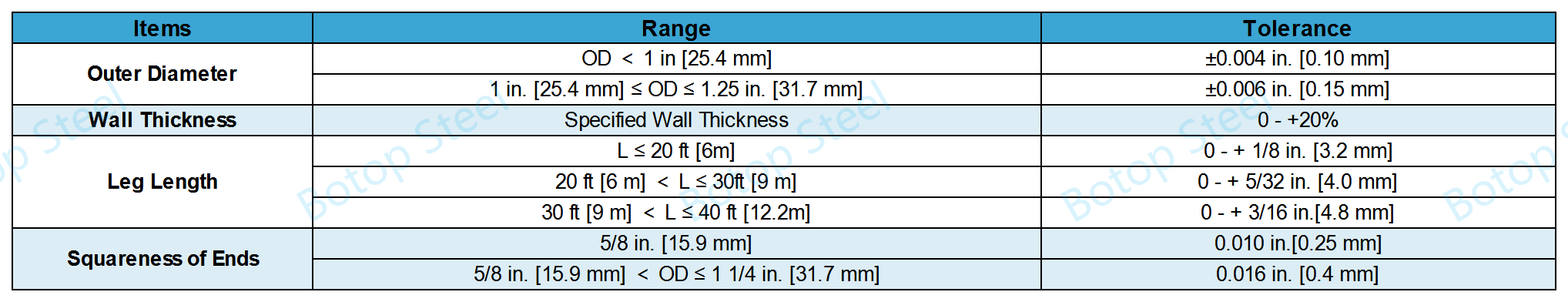

The following tolerances do not apply to the bent portion of the U-tube.

The finished pipe should be free of scale but may have a surface oxide film on the surface.

Finished tubes shall be reasonably straight and have smooth ends free from burrs. Tubes shall have a workmanlike finish and shall be free of surface imperfections that cannot be removed within the allowable wall tolerances.

Removal of surface imperfections such as handling marks, straightening marks, light mandrel and die marks, shallow pits, and scale patterns will not be required provided they are within the allowable wall tolerances.

The inner and outer diameters of the finished pipe should be coated to prevent corrosion during transportation.

Common coatings are rust preventive oils, varnishes, or paints.

The choice of coating material usually depends on the specific application requirements of the steel pipe, the intended use environment, and the duration of protection.

Tubular feedwater heaters: This is one of the most common applications for ASTM A556 steel tubing.

In the power industry, feedwater heaters are used to preheat boiler feedwater, usually by extracting steam. The use of this type of steel tubing allows for efficient transfer of thermal energy, improving overall energy efficiency and system performance.

Heat exchangers and condensers: Because of its excellent heat transfer properties and corrosion resistance, ASTM A556 steel tubing is also suitable for use in other types of heat exchangers and condensers, which are used in a wide range of chemical, petrochemical, and other industrial processes.

High-pressure steam systems: The high-temperature and high-pressure resistance of ASTM A556 tubing makes it suitable for use in high-pressure steam systems and other applications requiring extremely high pressure and temperature resistance.

ASTM A179/A179M - This is a standard for cold-drawn seamless carbon steel heat exchangers and condenser tubes for cryogenic service.

ASTM A192/A192M - Specifies technical requirements for seamless carbon steel boiler tubes for boilers used in high-pressure service.

ASTM A210/A210M - Standard for seamless medium carbon and carbon-manganese steel boiler tubes for boilers and superheaters.

ASTM A213/A213M - Provides standards for seamless ferritic and austenitic alloy steel boiler, superheater, and heat exchanger tubes.

ASTM A249/A249M - Standard applicable to welded austenitic steel boiler, superheater, heat exchanger, and condenser tubes.

ASTM A334/A334M - Standard for seamless and welded carbon and alloy steel tubing for cryogenic service.

Each of these standards covers steel tubes used in heat exchangers, boilers or similar applications. Which standard is chosen depends on the specific application requirements, such as operating temperature, pressure rating, and expected corrosion resistance.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.