BS EN 10210 S275J0H is a hot-finished hollow structural steel section manufactured to BS EN 10210 in a variety of round, square, rectangular, or oval section shapes.

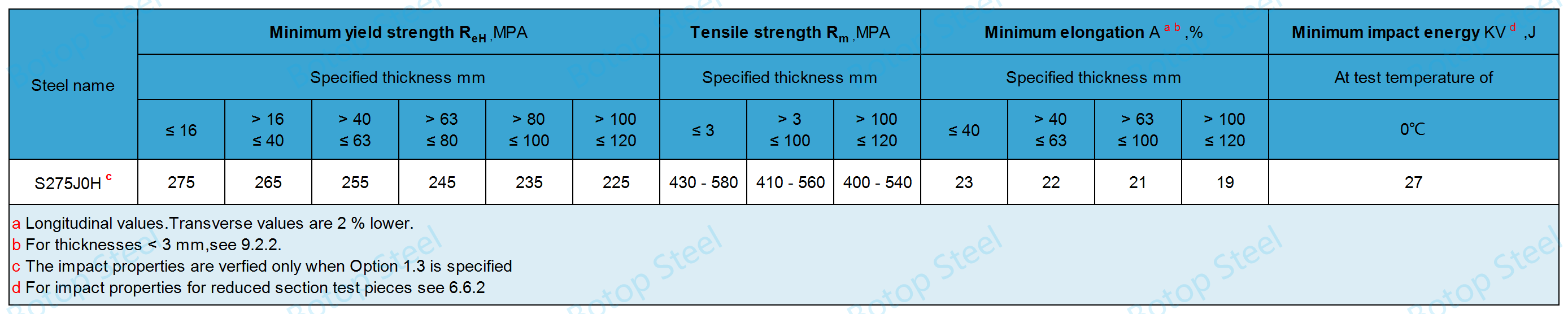

S275J0H material is characterized by a minimum yield strength of 275 MPa at a thickness of not more than 16 mm; its minimum impact energy is a minimum of 27 J at 0℃.

S275J0H belongs to a kind of carbon steel, steel number 1.0149, which has good structural and processing properties, mainly used in building structures, but also used for non-load-bearing components, can give in maintaining structural stability and durability based on the realization of low-cost benefits.

Note: All requirements in BS EN 10210 also apply to EN 10210 and are therefore not repeated here.

Grade designations in BS EN 10210 are assigned in accordance with EN 10027-1 and steel numbers are assigned in accordance with EN 10027-2.

| Steel name | Steel number | Steel Type | Steel name | Steel number | Steel Type |

| S235JRH | 1.0039 | carbon steel | S275NH | 1.0493 | carbon steel |

| S275J0H | 1.0149 | carbon steel | S275NLH | 1.0497 | carbon steel |

| S275J2H | 1.0138 | carbon steel | S355NH | 1.0539 | carbon steel |

| S355J0H | 1.0547 | carbon steel | S355NLH | 1.0549 | carbon steel |

| S355J2H | 1.0576 | carbon steel | S420NH | 1.8750 | alloy steel |

| S355K2H | 1.0512 | carbon steel | S420NLH | 1.8751 | alloy steel |

| S460NH | 1.8953 | alloy steel | |||

| S460NLH | 1.8956 | alloy steel |

For more information on the specific meanings of the letters and numbers in the grades, you can click here.

Wall thickness ≤120mm.

Circular: Outside diameters up to 2500 mm;

Square: Outside dimensions up to 800 mm x 800 mm;

Rectangular: Outside dimensions up to 750 mm x 500 mm;

Elliptical: Outside dimensions up to 500 mm x 250 mm.

We specialize in providing various specifications of Round Hollow Structural Steel Pipe, if you have any needs, please feel free to contact us, looking forward to cooperating with you!

LSAW welded steel pipes are mainly manufactured by forming steel plates into tubes using the JCOE molding process, followed by welding using double-sided submerged arc (DSAW) welding technology, and finalized through a number of inspections and treatments.

How do you choose the right production process? What are the differences and advantages of seamless steel pipe, LSAW, submerged arc welding, and submerged arc welding? And what is the size range of each process? You can click the following link to view it.

Qualities JR, J0, J2 and K2 - hot finished;

Qualities N and NL - normalized. Normalized includes normalized rolled.

| Steel grade | Type of deoxidation a |

% by mass, maximum | |||||||

| C (Carbon) |

Si (Silicon) |

Mn (Manganese) |

P (Phosphorous) |

S (Sulphur) |

N b,c (Nitrogen) |

||||

| Steel name | Steel number | Specified thickness (mm) | |||||||

| ≤40 | >40≤120 | ||||||||

| S275J0H | 1.0149 | FN | 0.20 | 0.22 | — | 1.5 | 0.035 | 0.035 | 0.009 |

a FN = Rimming steel not permitted;

b It is permissible to exceed the specified values provided that for each increase of 0.001 % N the P, max. content is also reduced by 0.005 %. The N content of the cast analysis, however, shall not be more than 0.012 %;

c The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0.020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document.

The mechanical properties of BS EN 10210 include yield strength, tensile strength, elongation, and impact properties.

The hollow sections shall have a smooth surface corresponding to the manufacturing method used; bumps, cavities, or shallow longitudinal grooves resulting from the manufacturing process are permissible, provided the thickness is within tolerance.

EN 10210 Steel pipe surfaces are suitable for hot dip galvanizing.

EN 10210 does not require hydrostatic pressure testing of steel pipes.

This is because the EN 10210 standardized products are mainly used for structural purposes and not for piping systems that need to be subjected to pressure.

If hydrostatic pressure testing is required, reference can be made to EN 10216 (seamless steel tubes) or EN 10217 (welded steel tubes) standards.

There is no mandatory requirement in the standard to carry out NDT on hollow section steel pipes.

If NDT is performed on welded steel pipes, the following requirements can be referred to.

Electric Welded Sections

For round hollow section steel tubes is ERW.

You can choose one of the following experimental methods for testing.

a) EN 10246-3 to acceptance level E4, with the exception that the rotating tube/pancake coil technique shall not be permitted;

b) EN 10246-5 to acceptance level F5;

c) EN 10246-8 to acceptance level U5.

Submerged Arc Welded Sections

For round hollow section steel tubes is LSAW and SSAW.

The weld seam of submerged arc welded hollow sections shall be tested either in accordance with EN 10246-9 to acceptance level U4 or by radiography in accordance with EN 10246-10 with an image quality class R2.

For more detailed information on the requirements related to dimensional tolerances, please click here for more information.

EN 10025 - S275J0;

JIS G3106 - SM400B;

CSA G40.21 - 300W;

When selecting the EN 10210 S275J0H equivalent, a detailed comparison of chemical composition and mechanical properties should be made to ensure that the selected material meets the specific requirements of the project.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.