BS EN 10210 S355J0H, steel number 1.0547, belongs to the hot-formed hollow structural steel section and can be seamless or welded steel pipe, mostly used in structures requiring high strength and good toughness, such as large building frames and bridges.

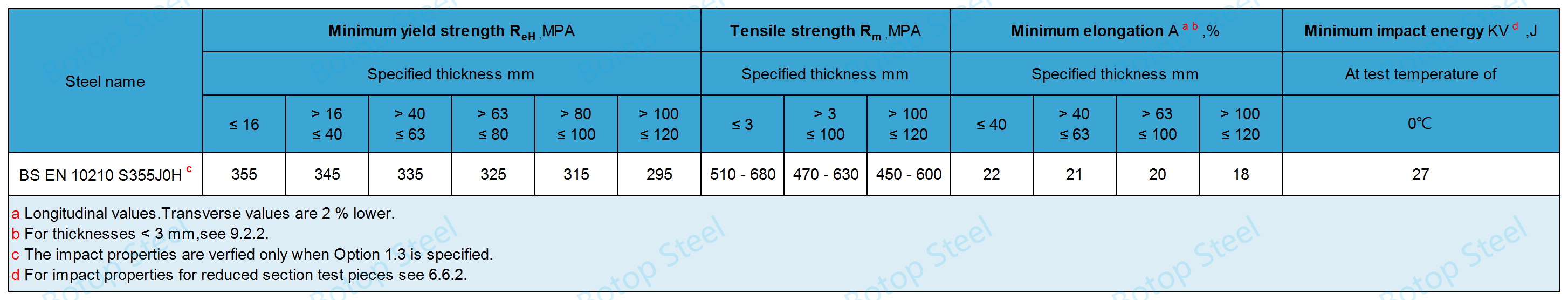

S355J0H material has the mechanical properties that the minimum yield strength is 355MPa when the wall thickness does not exceed 16 mm and meets the minimum impact strength of 27J at 0℃.

BS EN 10210 contains a variety of cross-sectional shapes, such as circular, square, rectangular, or elliptical, Botop Steel specializes in circular steel tubes in various sizes, providing you with high quality and standard-compliant steel tube materials with factory direct sale and competitive price.

Note: All requirements in this document also apply to EN 10210.

Wall thickness ≤120mm.

Circular (HFCHS): Outside diameters up to 2500 mm;

Square (HFRHS): Outside dimensions up to 800 mm x 800 mm;

Rectangular (HFRHS): Outside dimensions up to 750 mm x 500 mm;

Elliptical (HFEHS): Outside dimensions up to 500 mm x 250 mm.

| Steel grade | Type of deoxidation a |

% by mass, maximum | |||||||

| C | Si | Mn | P | S | N b,c | ||||

| Steel name | Steel number | Specified thickness (mm) | |||||||

| ≤40 | >40 ≤120 | ||||||||

| BS EN 10210 S355J0H | 1.0547 | FN | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

a FN = Rimming steel not permitted;

b It is permissible to exceed the specified values provided that for each increase of 0.001 % N the P, max. content is also reduced by 0.005 %. The N content of the cast analysis, however, shall not be more than 0.012 %;

c The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0.020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document.

Material designations in BS EN 10210 are based on their minimum yield strength at 16mm wall thickness and impact properties at specific temperatures. The yield strength, tensile strength, and elongation of BS EN 10210 S355J0H decrease as the wall thickness increases.

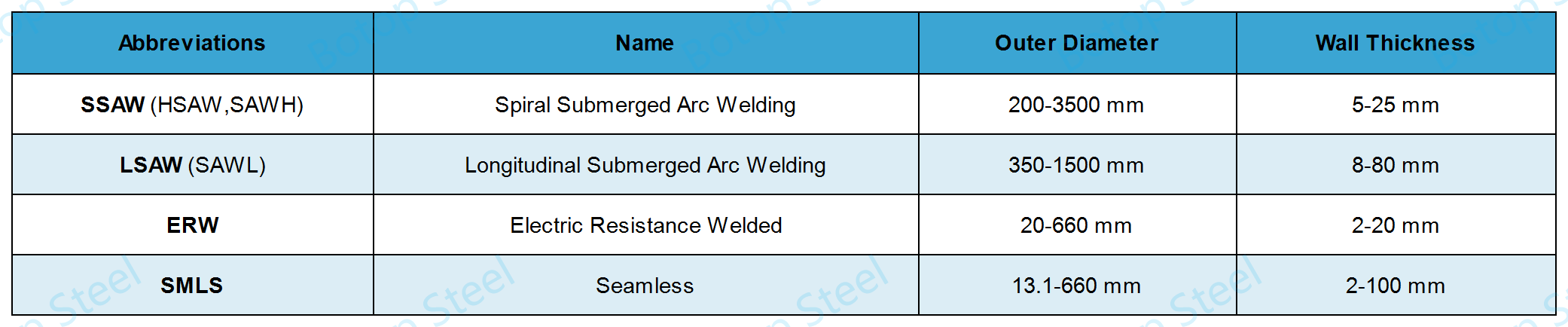

BS EN 10210 allows for production using a variety of manufacturing processes, commonly including seamless, LSAW, SSAW, and ERW welding processes.

Below is a range of sizes for common production processes.

From the above comparison, it can be seen that seamless steel pipe has an inherent advantage in the production of thick-walled steel pipe, especially small-diameter thick-walled steel pipe, but its size will be limited. If you need to produce steel pipes with a diameter of more than 660mm, it will be more difficult.

Black Pipe

This refers to steel pipe without any surface treatment.

Temporary Protective Coating

To prevent corrosion of steel pipes during storage, transportation, or installation, a common method is to coat the surface of the pipe with a layer of paint or varnish.

Anti-corrosion Coating

There are numerous types of anti-corrosion coatings, including paint, FBE, 3LPE, and galvanized. Each type of coating has unique characteristics and applicable environments. Corrosion and rust can be effectively prevented by applying a suitable anti-corrosion coating to steel surfaces.

EN 10210 Hot dip galvanized coatings on steel pipe surfaces shall comply with the relevant requirements of EN ISO 1461.

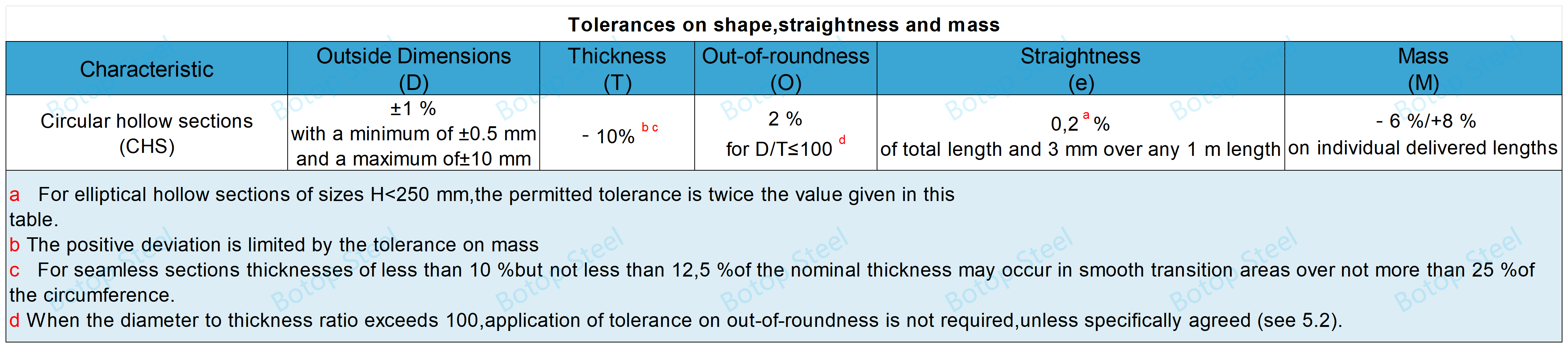

Tolerances on Shape,Straightness and Mass

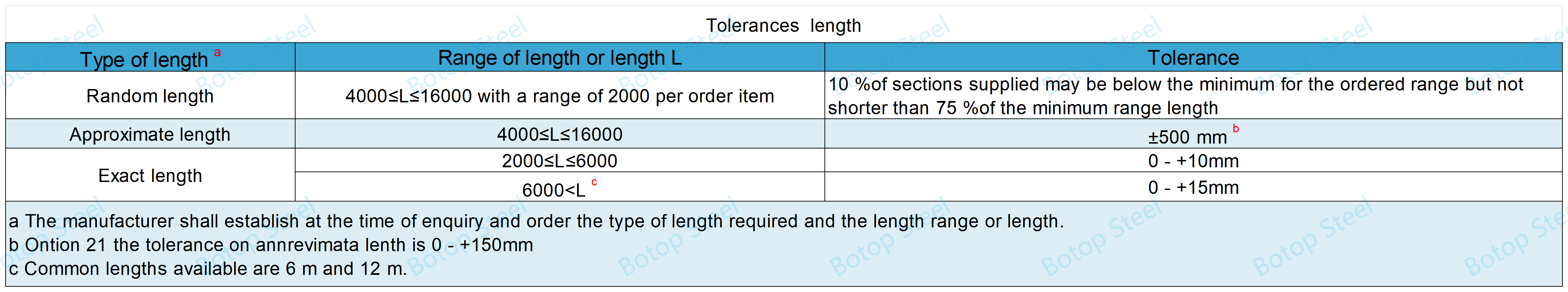

Tolerances on Length

Seam Height of SAW Weld

| Thickness, T | Maximum weld bead height, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

The height of the resistance weld seam usually does not extend much beyond the surface of the pipe, and during the manufacturing process, the weld seam is treated so that it is essentially flush with the surface of the pipe and does not appear to be visible.

BS EN 10210 S355J0H is widely used in building structures, machinery manufacturing, transportation pipelines, infrastructure construction, ships, and marine engineering. Its high strength and good toughness make it excellent in projects such as bridges, high-rise buildings, industrial plants, cranes, oil and gas pipelines, and wind power towers.

| GB/T | GOST | ASTM | JIS |

| GB/T 1591 Q345B | GOST 19281 09G2S | ASTM A501 Grade C | JIS G 3101 SS490 |

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Other related products:

Contact us for a free quote and consultation on your project.