Grade and Chemical Composition (%)

|

Grade |

C≤ |

Mn |

P≤ |

S≤ |

Si≥ |

Cr≤ |

Cu≤ |

Mo≤ |

Ni≤ | V≤ |

|

A |

0.25 |

0.27-0.93 |

0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

|

B |

0.30 |

0.29-1.06 |

0.035 |

0.035 | 0.10 |

0.40 |

0.40 |

0.15

|

0.40 | 0.08 |

|

C |

0.35 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Mechanical Properties:

|

|

|

|

A% |

|

|

A |

≥330 |

≥205 |

20 |

Annealed |

|

B |

≥415 |

≥240 |

20 |

Annealed |

|

C |

≥485 |

≥275 |

20 |

Annealed |

| Product Name | Seamless steel pipe |

| Material | Carbon steel and alloy steel |

| Standard | ASTMA53,ASTMA106,ASTMA179,ASTMA192,ASTMA210,ASTM A213,ASTM A335,DIN2391-2,DIN1629.DIN2448, DIN17175.DIN17176,EN10219,EN10210 |

| Grade | Carbon steel grades like A53 Gr.B,A106 GrA,B,C,A210 GrA1.Gr.C. API 5L Gr.B.X42,X52.X56,etc; alloy steel grades like T5,T9,T11,T12,T22,T23,T91,P1,P2,P5,P9.P11,P12 P22.P91,P92,25CrMo4.34CrMo4,42CrMo4SAE4130,SAE4140,SAE4145,SAE4340,etc |

| Size range | 10*1-810*25,W.T upto 120mm max |

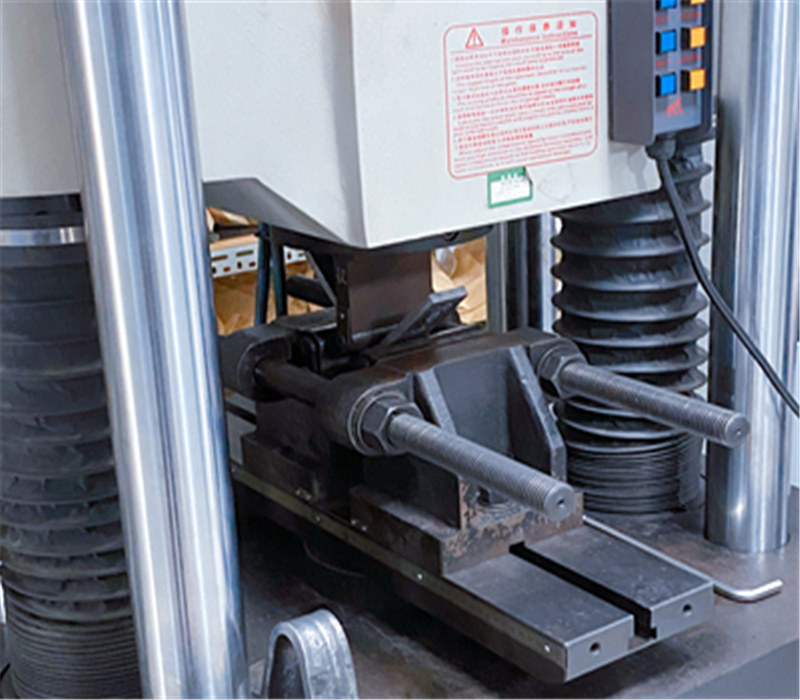

| Manufacture method | Cold drawn, cold rolled, hydraulic cold drawn, Hot rolled, hot expanded |

| Delivery condition | As rolled,Stress relieved, Annealed,Normalized,Quenched+Tempered |

| End finish | Plain ends with suqare cuts, bevelled ends, threaded ends |

| Usage/Application | Pressure vessels, Fluid conveyance,Structural use. Machinery.Oil&gas transportation,Exploration&Drilling,etc |

| Typies of tube | Boiler tube precision tube,mechanical tubing.cylinder tube.line pipes.etc. |

-

-

Dimension Tolerances:

Pipe Type

Pipe Sizes Tolerances Cold Drawn

OD ≤48.3mm ±0.40mm ≥60.3mm ±1%mm WT ±12.5%

-