| Style | Technical | Material | Standard | Grade | Usage |

| Longitudinal Submerged-arc Welded Pipe(LSAW STEEL PIPE OR JCOE) | SAW | Carbon Steel | API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70 ,etc | Transportation of oil and gas |

| ASTM A671 | CB60,CB65, CC60,CC65,etc | Normal temperature, low temperature and high pressure applications (pressure vessels) | |||

| ASTM A672 | A45,A50,A55,B55,B60,B65,B70,etc | Medium and high temperature steel pipes | |||

| ASTM A252 | GR.1,GR.2, GR.3 | For Structure (Piling) |

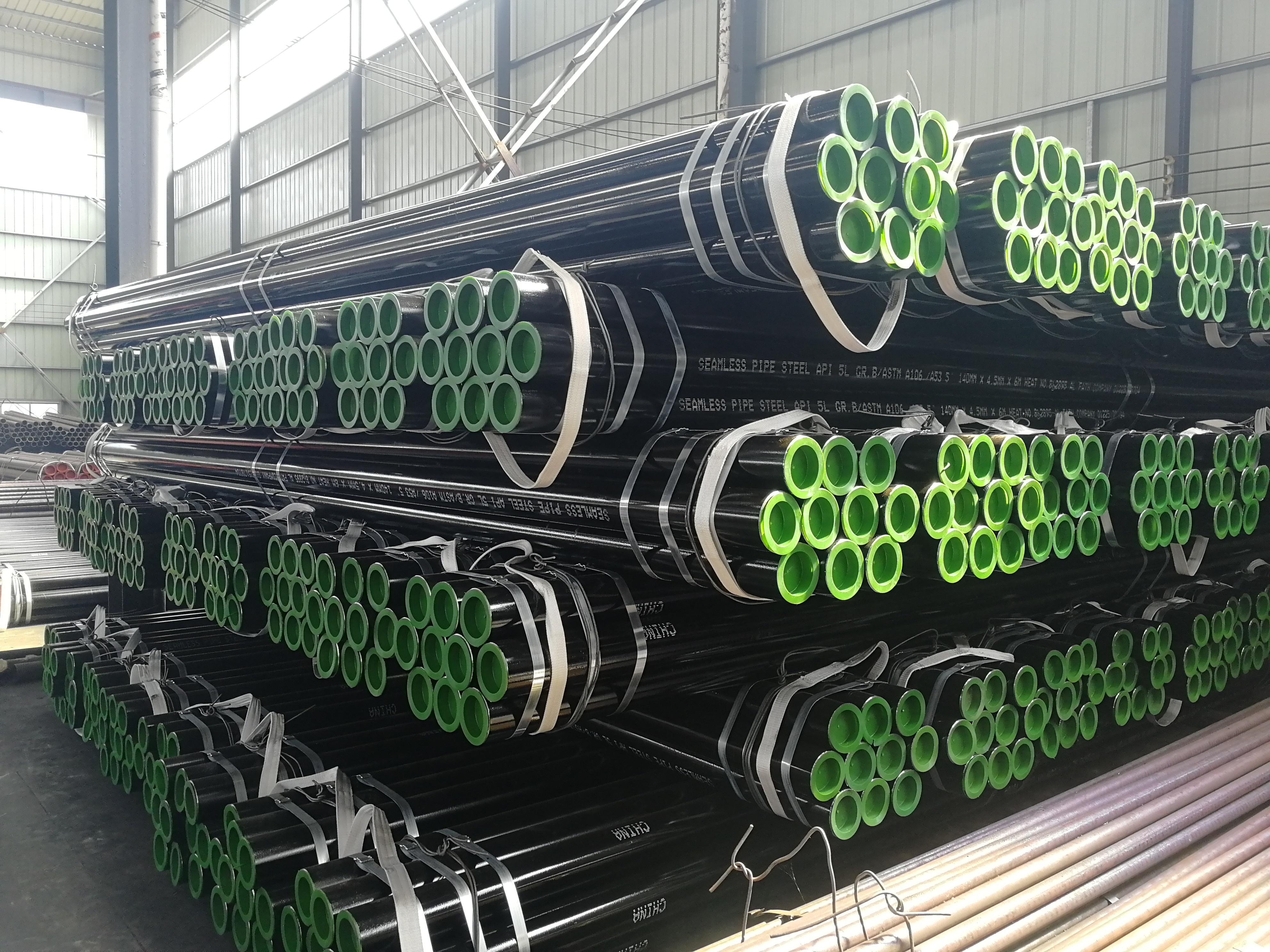

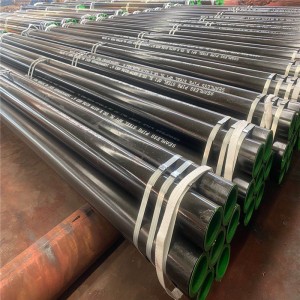

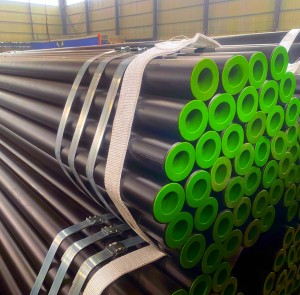

| Style | Material | Standard | Technical | Grade | Usage |

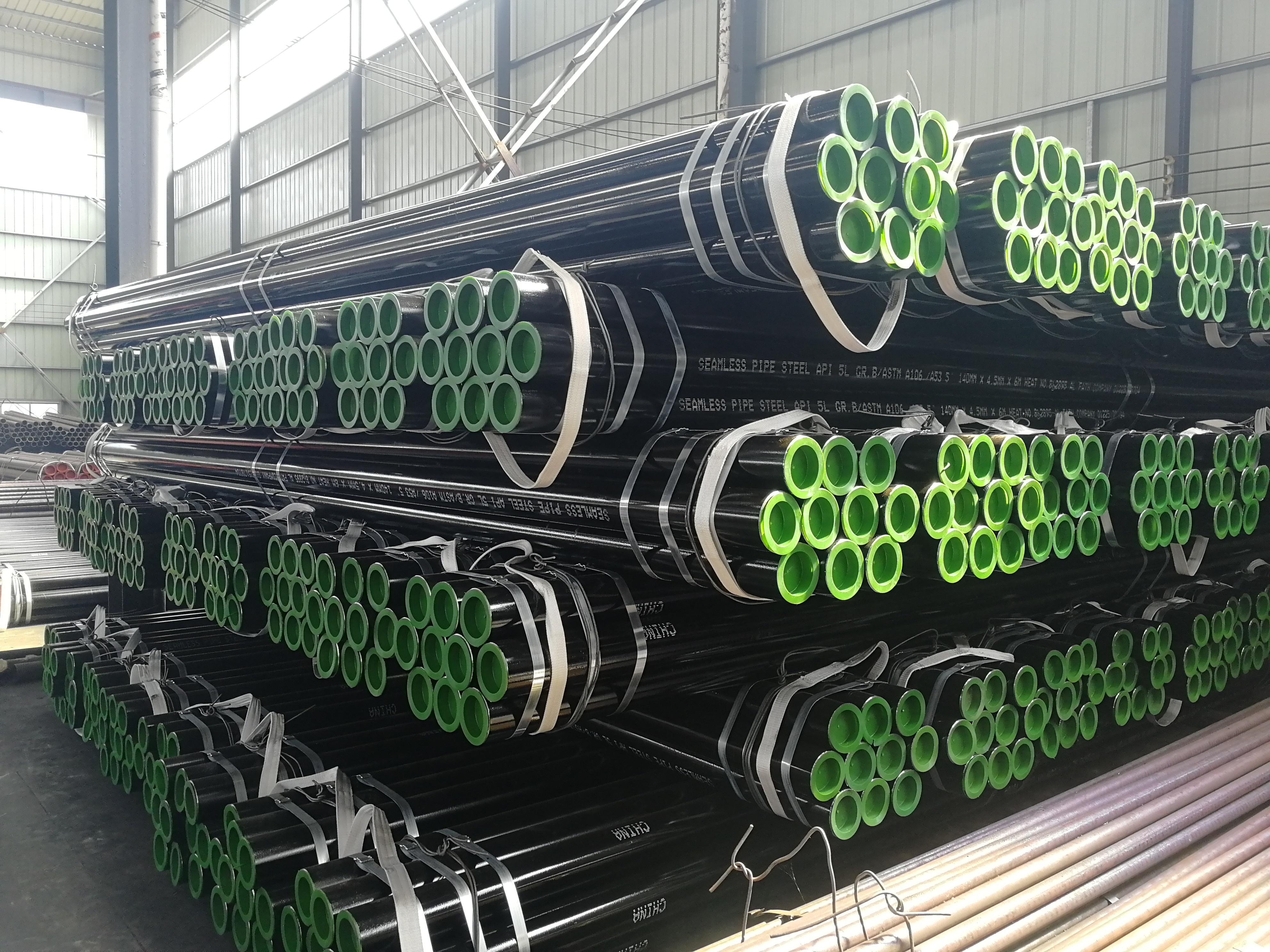

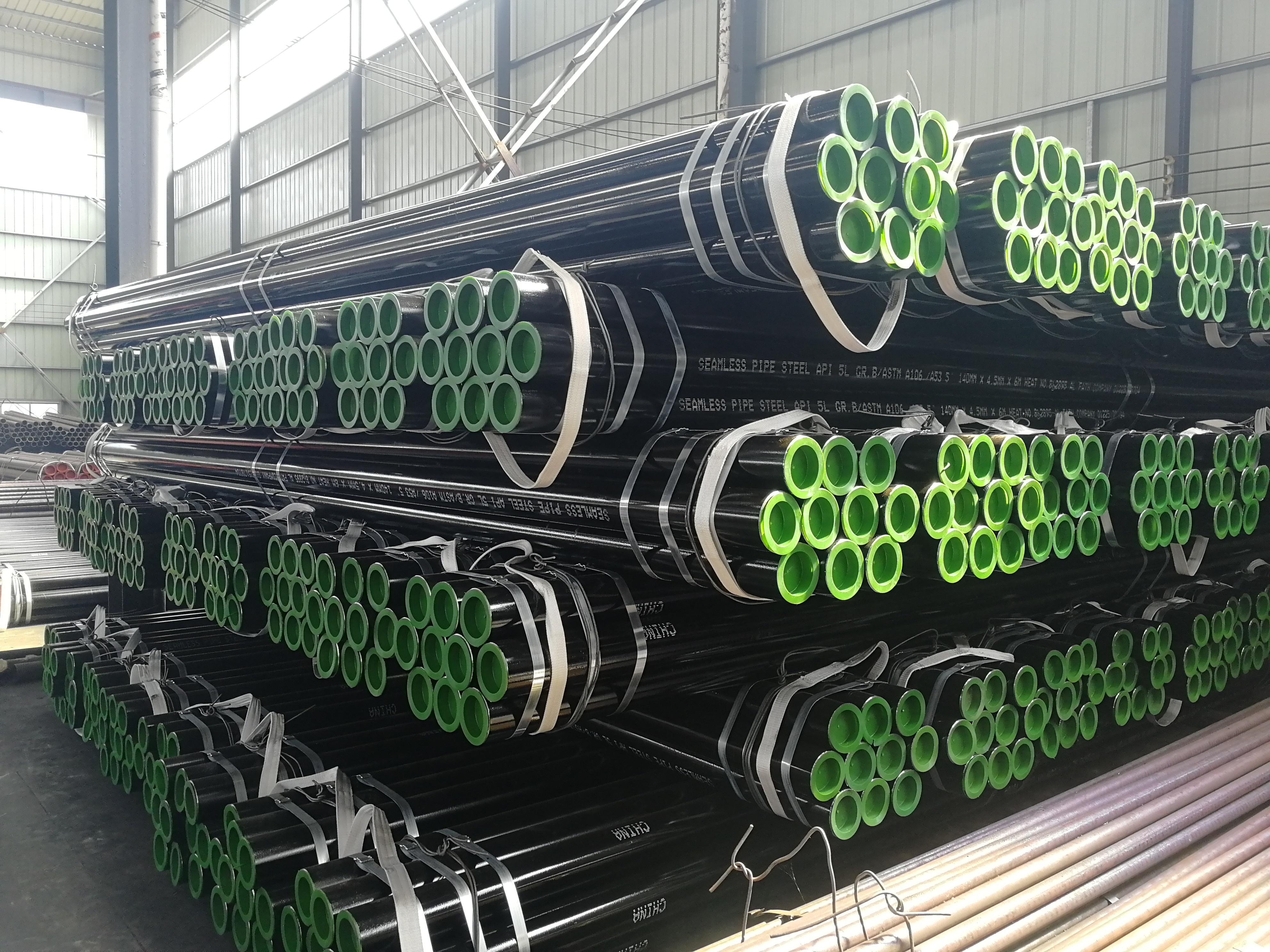

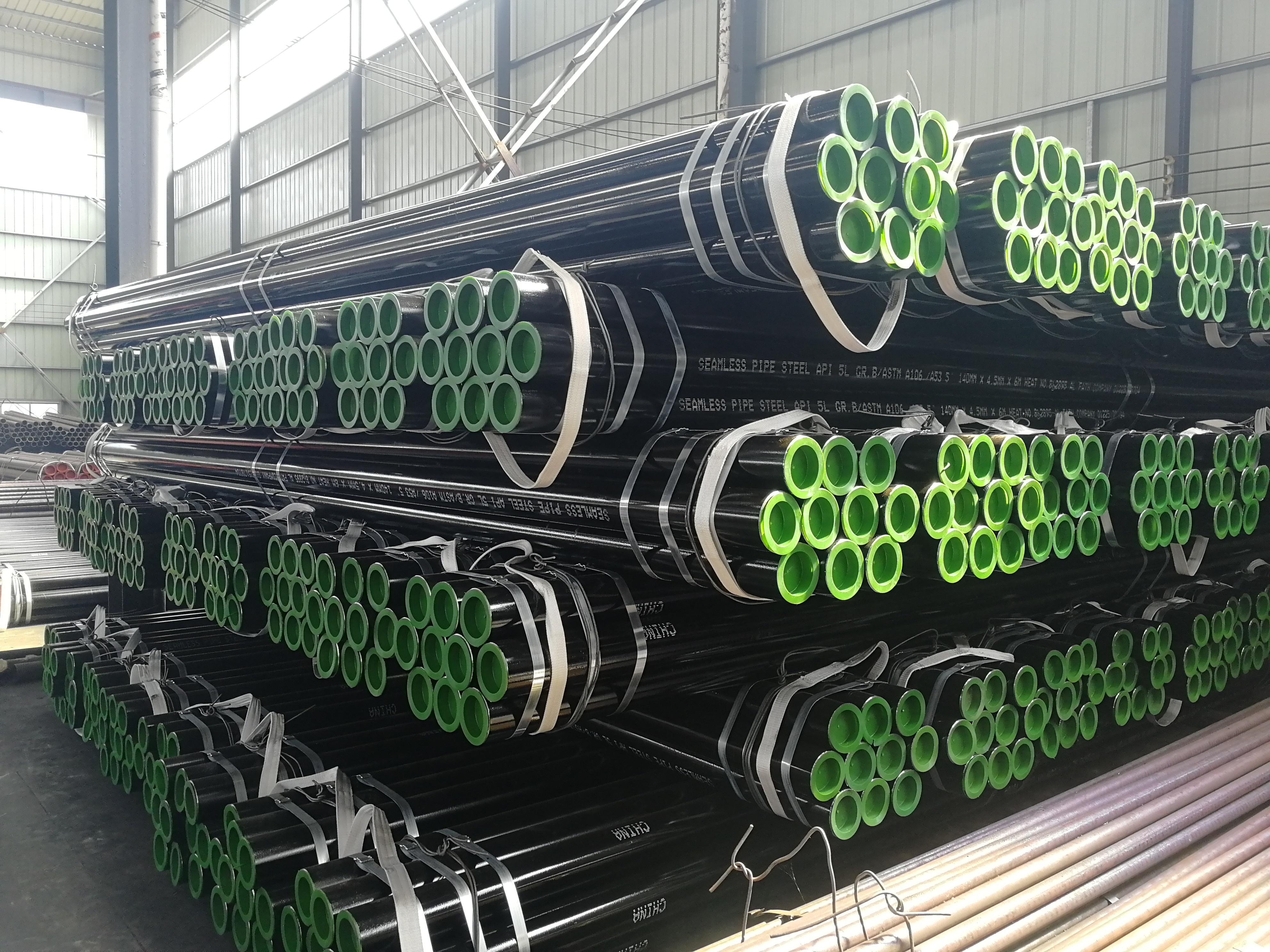

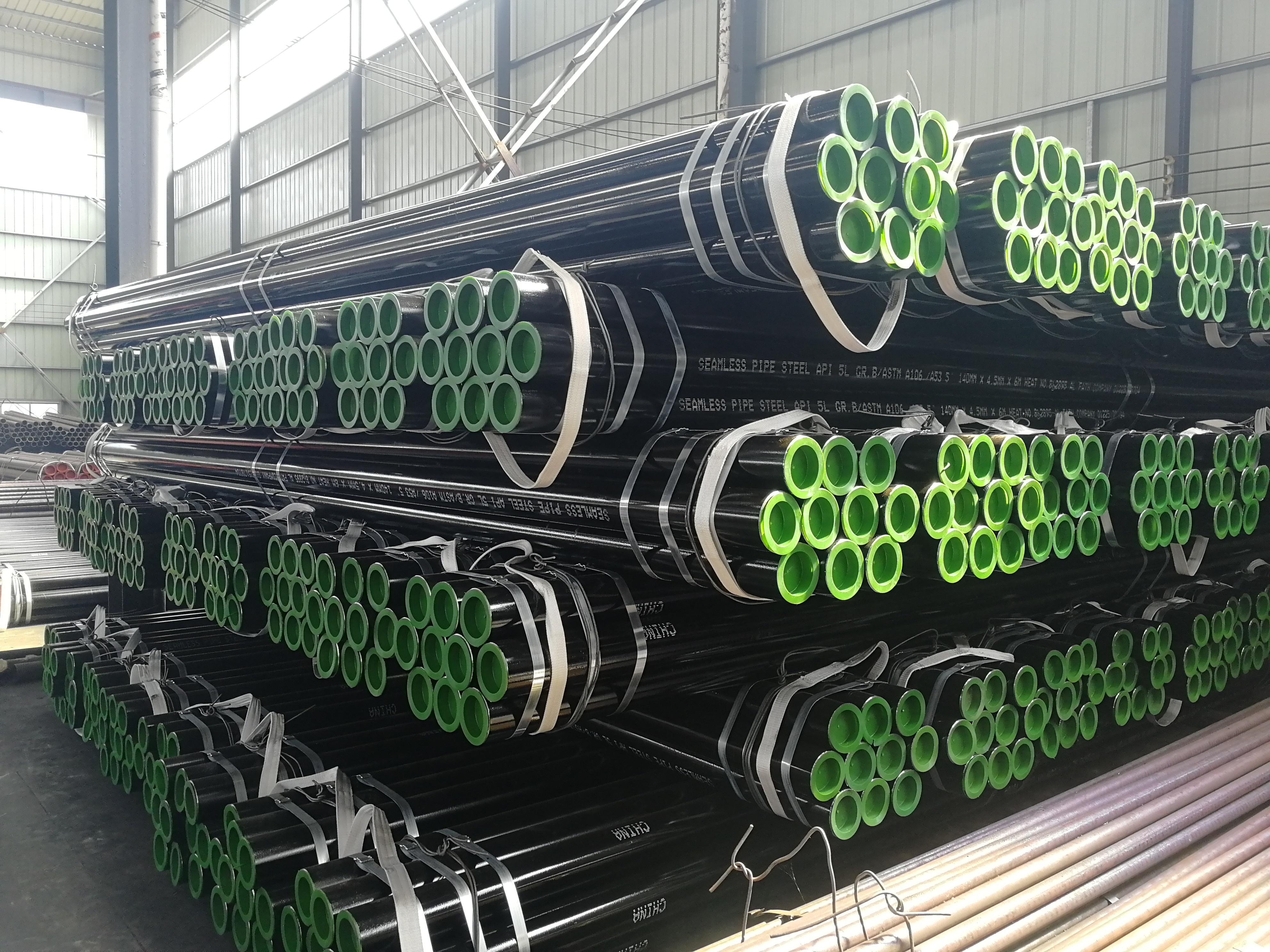

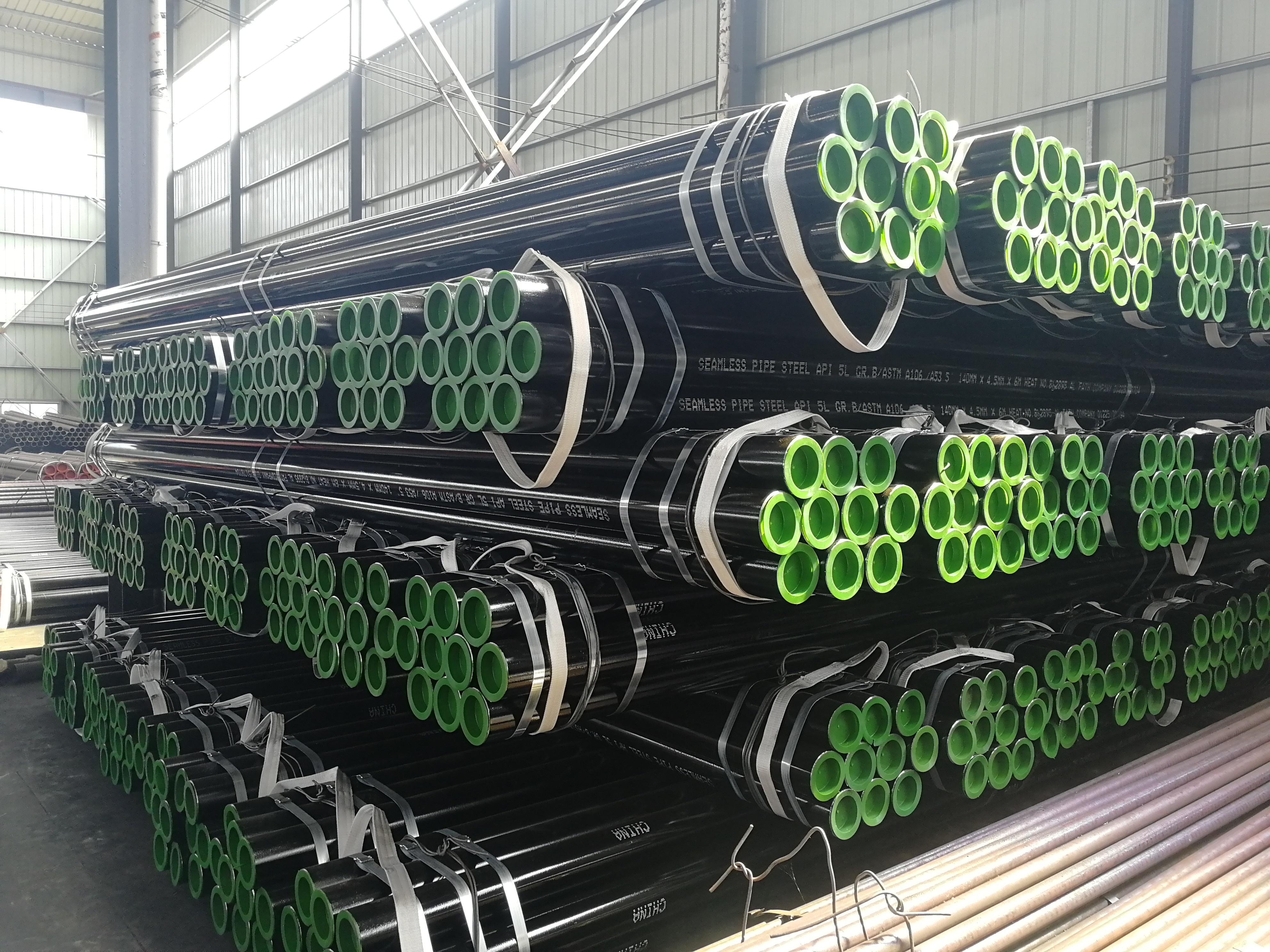

| Seamless Steel Pipe | Carbon Steel | API 5L PSL1&PSL2 | Hot finish or cold finish | GR.B,X42,X46,X52,X60,X65,X70,etc | Transportation of oil ,gas ,water . |

| ASTM A53 | Hot finish or cold finish | GR.A ,GR.B | |||

| ASTM A106 | Hot finish or cold finish | GR.A ,GR.B,GR.C | |||

| ASTM A179 | cold finish | A179 | Steel pipe for heat exchanger and condenser | ||

| ASTM A192 | Hot finish or cold finish | A192 | Carbon steel seamless boiler tube for high pressure | ||

| ASTM A210/SA210 | Hot finish or cold finish | GR.A-1,GR.C | Boiler or boiler flue pipe | ||

| ASTM A252 | Hot finish or cold finish | GR.1, GR.2,GR.3 | For Structure (Piling) | ||

| BS EN10210 | Hot finish or cold finish | S275JRH,S275J0H,S355J0H,S355J2H,etc | For mechanical structures, for the manufacture of automotive or machine parts | ||

| JIS G3454 | Hot finish or cold finish | STPG370,STPG410 | Transportation of High-pressure fluid | ||

| JIS G3456 | Hot finish or cold finish | STPG370,STPG410,STPG480 | Steel pipe for high temperaturer | ||

| Alloy Steel | JIS G3441 | Hot finish or cold finish | SCM420TK,SCM415TK,SCM418TK,SCM430TK,etc | For mechanical structures, for the manufacture of automotive or machine parts | |

| ASTM A213 | Hot finish or cold finish | GR.T11 ,GR.T12,GR.T13 | Boiler and superheater tubes | ||

| ASTM A519 | Hot finish or cold finish | GR.1020,GR.1026,GR.1045,GR.4130,etc | Seamless steel pipe and alloy steel pipe for machinery | ||

| ASTM A335 | Hot finish or cold finish | GR.P9,GR.P11,GR.P5,GR.P22,GR.P91,etc | Suitable for high temperature, high pressure, steam transmission or machinery manufacturing | ||

| ASTM A333 | Hot finish or cold finish | GR.1, GR.3,GR.4,GR.6,etc | Steel pipe for cryogenic equipment |

Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

ASTM A106 seamless steel pipe are produced either by cold-drawn or hot rolled, as specified.

Hot finished pipe need not heat treated. When hot finished pipe is heat treated ,it shall be heat treated at a temperature of 1200°F or higher. Cold drawn pipe shall be heat treated after final cold draw pass at a temperature of 1200°F or higher.

ASTM A106 seamless steel pipe are produced either by cold-drawn or hot rolled, as specified.

Hot finished pipe need not heat treated. When hot finished pipe is heat treated ,it shall be heat treated at a temperature of 1200°F or higher. Cold drawn pipe shall be heat treated after final cold draw pass at a temperature of 1200°F or higher.

Mechanical Properties:

|

|

|

|

A% |

|

|

A |

≥330 |

≥205 |

20 |

Annealed |

|

B |

≥415 |

≥240 |

20 |

Annealed |

|

C |

≥485 |

≥275 |

20 |

Annealed |

Dimension Tolerances:

|

Pipe Type |

Pipe Sizes |

Tolerances |

|

|

Cold Drawn |

OD |

≤48.3mm |

±0.40mm |

|

≥60.3mm |

±1%mm |

||

|

WT |

±12.5% |

||

a.Quantity ( feet,meters,or number of lengths)

b.Name of material(seamless carbon steel pipe)

c.Grade

d.Manufacture (hot rolled or cold drawn)

e.Size (outside or inside diameter,normal wall thickness)

f.Special outside diameter tolerance pipe

g.Inside diameter tolerance pipe ,over 10 inch.

h.Length (specific or random)

i.Optional requirement.

j.NDT reports ,e.g

Mass- the mass of any length of pipe shall not vary more than 10% over and 3.5% under that specified .unless purchaser accept.

Diameter- Over 10” pipe as special O.D tolerance pipe ,the O.D shall not vary more than 1% over or 1% under the specified outside diameter.

Thickness-The minimum wall thickness at any point shall be not more than 12.5% under the specified wall thickness.

Bending Test— a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel.

Flattening test-although testing is not required ,pipe shall be capable of meeting the flattening test requirements.

Hydro-static test—except as allowed ,each length of pipe shall be subjected to the hydro-static test without leakage through the pipe wall.

Nondestructive electric test-as an alternative to the hydro-static test ,the full body of each pipe shall be tested with a nondestructive electric test . where nondestructive electric test is performed,the lengths shall be marked with the letters”NDE”

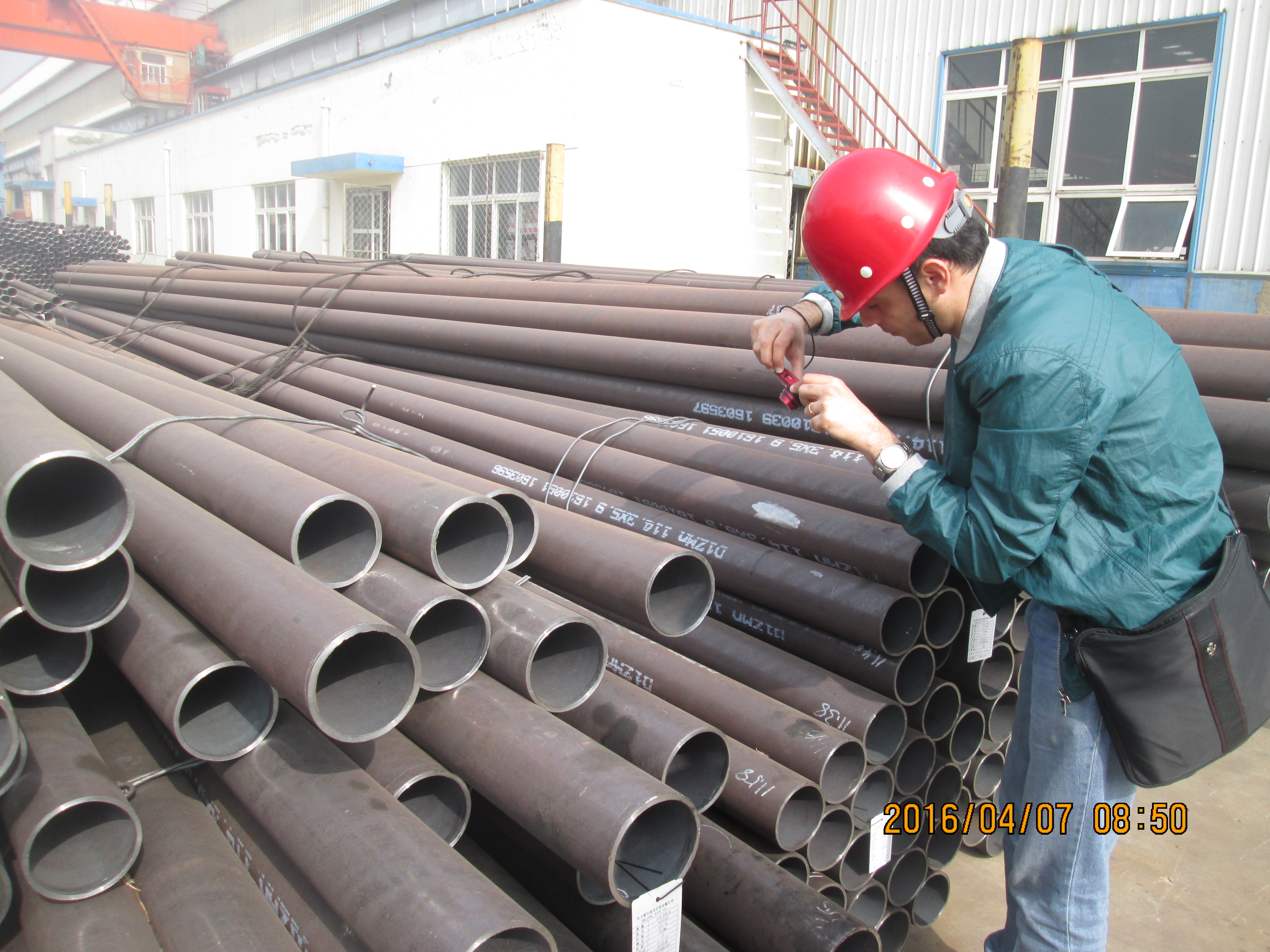

The ultrasonic testing

The eddy current examination

A sufficient number of visual surface imperfections to provide seasonable assurance is necessary. The defect shall be removed or cut off within the limits of requirements on length . The finished pipe shall be reasonably straight.

Manufacturer’s name or mark

Specification number(year-date or required)

Size( OD, W.T, length)

Grade( A or B)

Type of pipe( F, E, or S)

Test pressure( seamless steel pipe only)

Heat Number

Any additional information specified in the purchase order.

Bare pipe, black coating ( customized);

6" and below sizes In bundles with two cotton slings, other sizes in loose;

Both ends with end protectors;

Plain end, bevel end;

Marking.