It is a seamless steel pipe that must meet the chemical composition and mechanical property requirements of Grade B of API 5L, ASTM A106, and ASTM A53 at the same time.

This type of pipe can be flexibly used in different projects without having to worry about standard compatibility issues. It also simplifies inventory management by reducing the need to purchase tubes of many different standards.

Note: It is important to note that API 5L GR.B here refers to API 5L PSL1 grade B.

Botop Steel is a leading steel pipe manufacturer and stockist in China, specializing in the production and supply of round seamless carbon steel pipe for liquid and oil applications. Since our establishment in 2014, our products have been exported to many countries and regions such as Australia, Canada, India, Saudi Arabia, and so on, and we have accumulated rich experience in international trade.

We manufacture steel pipes in strict compliance with international standards such as API 5L, ASTM A106, and ASTM A53 to ensure high-quality and standardized products. The product range covers seamless steel pipes with outside diameters from 10.3 - 660 mm and thicknesses from 2 - 100 mm.

With over 8,000 tons of seamless steel pipes in stock, we are able to ensure immediate delivery of regular sizes. For special types and sizes, we also offer customized production services to meet specific customer requirements.

Seamless steel tubes are manufactured in two main processes: hot finishing and cold drawing.

DN ≤ 40 can make hot finished or cold drawn, mostly cold drawn.

DN ≥ 50 shall be hot finished. Cold-drawn seamless steel tubes are also available upon request.

| Nominal Diameter | DN 6- 650 [NPS 1/8 - 26] |

| Specified Outer Diameter | 10.3 - 660 mm [0.405 - 26 in.] |

| Weight Class | STD (Standard), XS (Extra Strong), XXS (Double Extra Strong) |

| Schedule No. | Schedule 10, Schedule 20, Schedule 30, Schedule 40, Schedule 60, Schedule 80, Schedule 100, Schedule 120, Schedule 140, Schedule 160, |

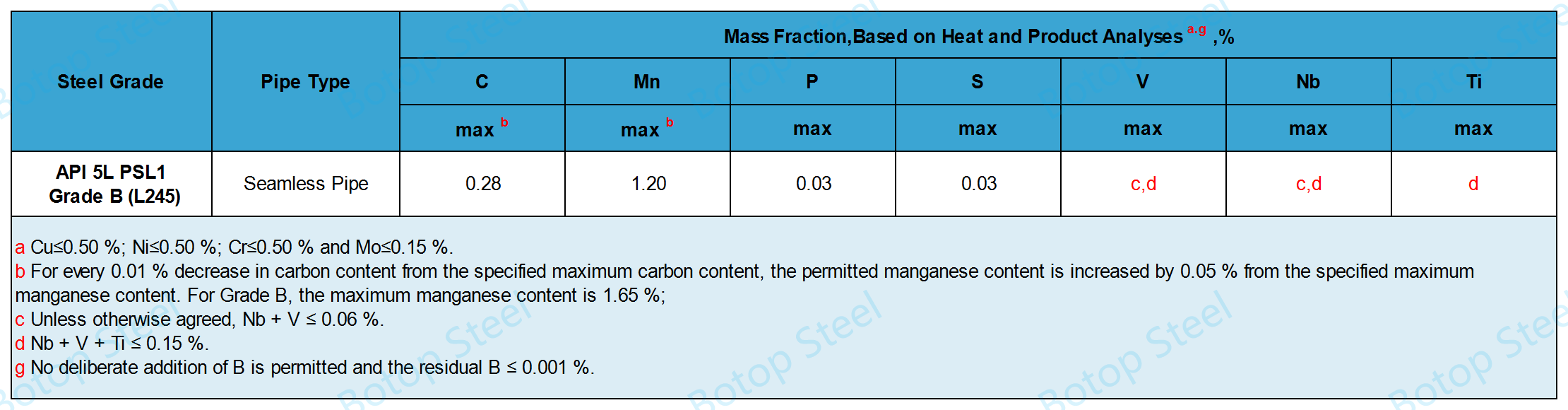

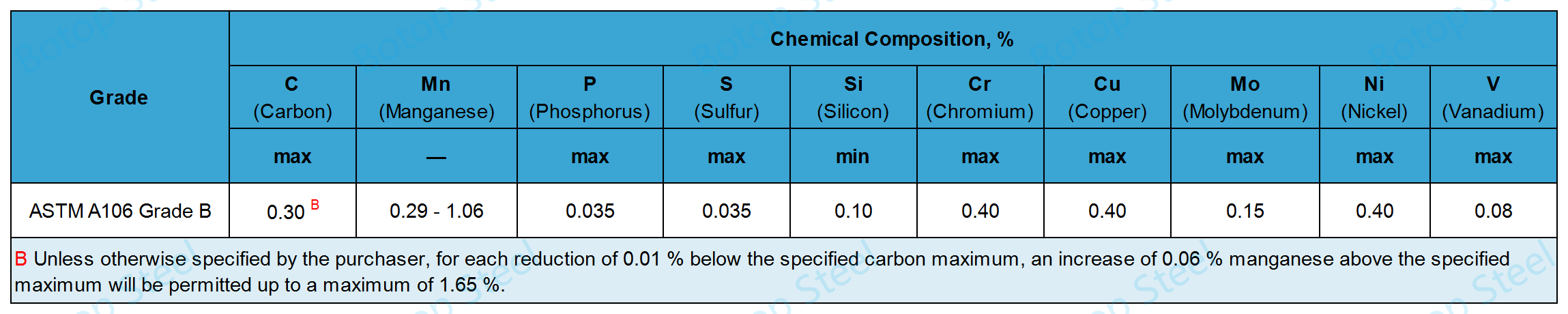

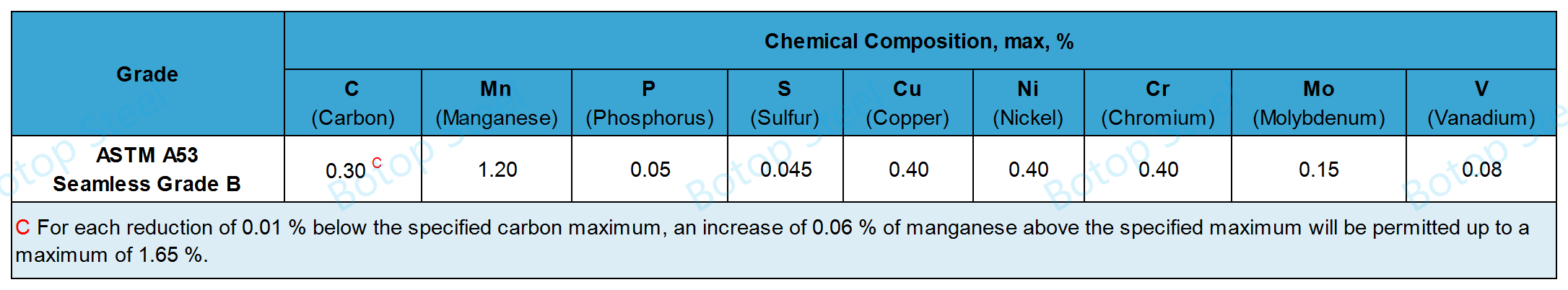

In order to ensure that the pipe meets the chemical composition requirements of Grade B of all three standards, API 5L, ASTM A106, and ASTM A53, the chemical composition of the material must be tightly controlled during the manufacturing process. The following are the specific requirements for the chemical composition of these three standards:

API 5L Grade B Chemical Composition

ASTM A106 Grade B Chemical Composition

ASTM A53 Grade B Chemical Composition

| Test | API 5L PSL1 Grade B | ASTM A106 Grade B | ASTM A53 Grade B | |

| Yield strength, min | MPa [psi] | 245 [35,500] |

240 [35,000] |

240 [35,000] |

| Tensile strength, min | MPa [psi] | 415 [60,200] |

415 [60,000] |

415 [60,000] |

A comparison of the mechanical requirements for Grade B in API 5L, ASTM A106, and ASTM A53 shows that they have the same requirements for tensile and yield strength. This consistency is the basis for the interchangeability of these standards and ensures that tubular products can be used in a wide variety of applications without concern for mismatched properties.

Mechanical Properties Test

Mechanical Properties Test

In addition to providing high-quality seamless steel tubes, Botop Steel offers a wide range of surface coating services to meet different corrosion protection needs and environmental conditions.

Steel pipe coatings are usually categorized into temporary protection and long-term corrosion prevention. We often see seamless steel pipe coated with a black coating, which is used to provide temporary protection to minimize corrosion during sea transportation and storage of the pipe.

Common types of coatings for corrosion protection include paint, hot dip galvanizing, 3LPE, FBE, and others. Choosing the right coating not only helps to extend the service life of the steel pipe but also effectively reduces the overall operating costs.

API 5L, ASTM A106, and ASTM A53 Grade B seamless steel pipe are commonly used in piping systems for the transportation of steam, water, gas, and air. These tubes are also suitable for making bends, flanges, and other forming operations.

Botop Steel has always insisted on quality as the root of the enterprise, which we believe is the key to winning customers' trust and market recognition. In the long-term industry practice, we have accumulated rich experience and many successful cases.