EN 10219 S275J0H and S275J2H are cold-formed welded structural hollow sections made of non-alloyed steel according to EN 10219.

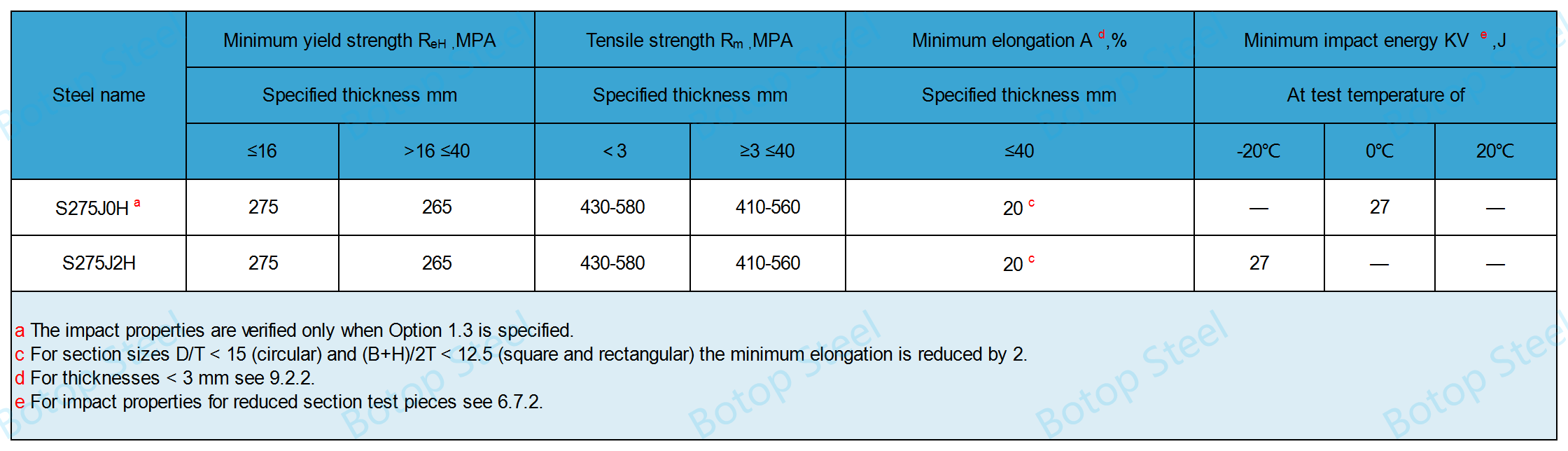

They both have a minimum yield strength of 275MPa (wall thickness ≤16mm). The main difference is in the impact properties: S275J0H has a minimum impact energy of 27 J at 0°C, while S275J2H has a minimum impact energy of 27 J at -20°C.

Suitable for applications in buildings and engineering structures subject to lighter loads.

BS EN 10219 is the European Standard EN 10219 adopted by the UK.

Wall thickness ≤40mm, Outer diameter ≤2500mm.

CFCHS is an abbreviation for Cold-Formed Circular Hollow Section.

The EN 10219 standard covers a wide range of hollow structural steel shapes, including round, square, rectangular, and oval, to suit different usage requirements.

Botop Steel specializes in providing round hollow section steel tubes in a variety of sizes and processes to suit a wide range of industry applications, ensuring that the specific needs of our customers can be met.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including SMLS, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

We look forward to establishing a cooperative relationship with you and creating a win-win future together.

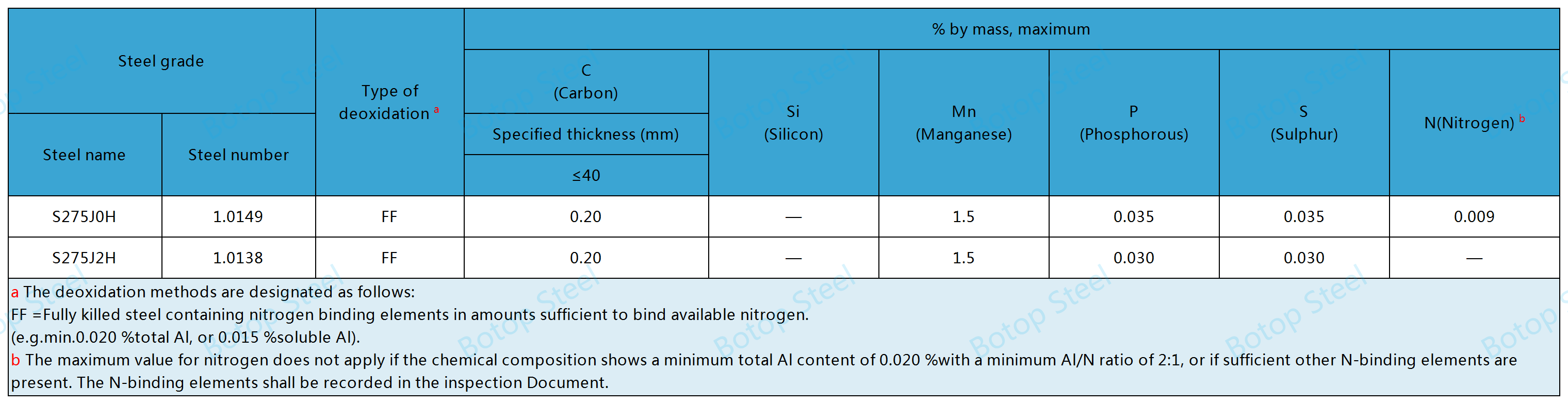

Raw steel for the manufacture of cold-formed hollow sections is deoxidized and must meet specific delivery conditions.

The relevant requirements for S275J0H and S275J2H are FF (Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min.0,020 % total Al or 0,015 % soluble Al)).

Delivery condition: Rolled or normalized/normalized rolled (N) for JR, J0, J2, and K2 steels.

Steel pipes to EN 10219 can be produced by both ERW ( electro resistance welding ) and SAW ( submerged arc welding ) manufacturing processes.

The production of ERW tubes has the advantage of being faster and relatively more affordable and is often chosen for projects that require large-scale production and high cost-effectiveness.

ERW tubes are typically used to produce smaller diameters and thinner wall thicknesses, while SAW tubes are more suitable for larger diameters and thicker walls. Please select the appropriate type of steel pipe for your project.

ERW pipes manufactured according to EN 10219 do not normally require internal weld trimming.

This is because EN 10219 tubes are mainly used in structural applications, such as construction and mechanical engineering, where the requirements for weld appearance are usually less stringent than for pressure vessels or high-pressure pipelines. Therefore, as long as the strength and integrity of the weld meet the requirements of the standard, internal welds can be used without additional trimming.

No subsequent heat treatment is performed, except that the weld may be in a welded or heat-treated condition.

Cast Analysis (Chemical Composition of Raw Materials)

Both S275J0H and S275J2H have a maximum carbon equivalent value (CEV) of 0.40%.

S725J0H and S275J2H with a maximum CEV of 0.4% illustrate better weldability with less risk of hardening and cracking during welding.

It can also be calculated using the following formula:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

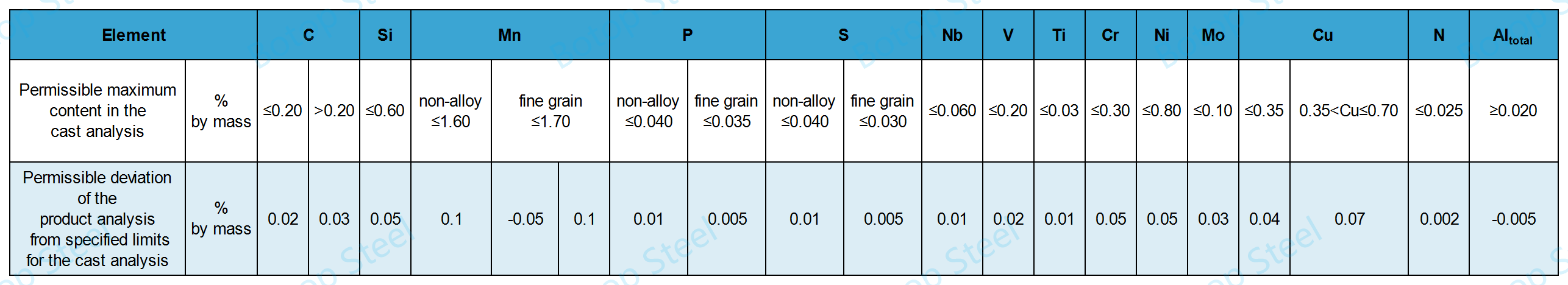

Product Analysis (Chemical Composition of Finished Products)

During the production of steel, the chemical composition may change for a number of reasons, and these changes may affect the properties and quality of the steel.

The final finished steel pipe chemical composition must comply with the chemical composition of the casting and its permissible deviation.

Mechanical property parameters include yield strength, tensile strength, elongation, and impact strength.

Stress relief annealing at more than 580 ℃ or for over one hour may lead to deterioration of the mechanical properties.

Notes:

Impact testing is not required when the specified thickness is <6mm.

The impact properties of JR and J0 quality tubes are not verified unless specified.

EN 10219 Welds in ERW steel pipes can be tested by selecting one of the following.

EN 10246-3 to acceptance level E4, with the exception that the rotating tube/pancake coil technique shall not be permitted;

EN 10246-5 to acceptance level F5;

EN 10246-8 to acceptance level U5.

Calculation of the theoretical weight of EN 10219 tubes can be based on a tube density of 7.85 kg/dm³.

M=(D-T)×T×0.02466

M is the mass per unit length;

D is the specified outside diameter, units in mm;

T is the specified wall thickness, units in mm.

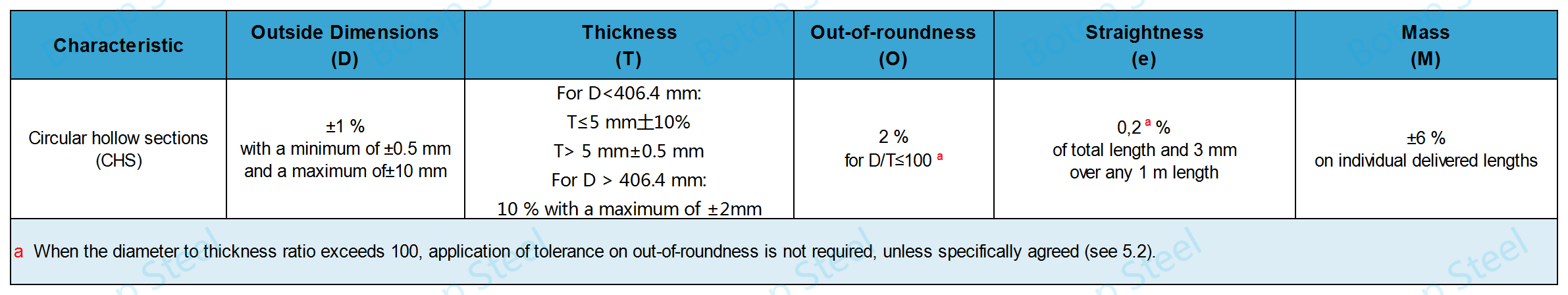

Tolerances on Shape,Straightness and Mass

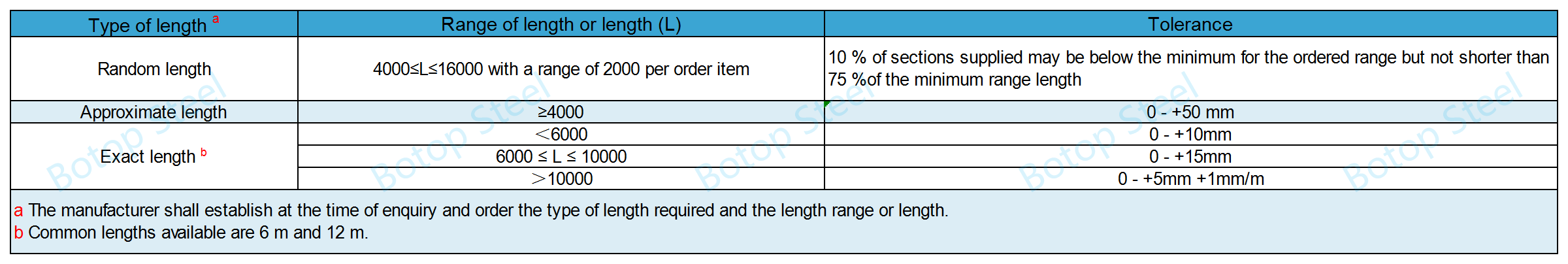

Tolerances Length

Hollow section tubes manufactured according to EN 10219 are weldable.

When welding, cold cracking in the weld zone is the main risk as the thickness, strength level, and CEV of the product increase. Cold cracking is caused by a combination of several factors:

high levels of diffusible hydrogen in the weld metal;

a brittle structure in the heat-affected zone;

significant tensile stress concentrations in the welded joint.

The surface of the steel pipe should be smooth and free from any defects that would affect the performance of the product, such as cracks, pits, scratches, or corrosion.

Bumps, grooves, or shallow longitudinal grooves created by the manufacturing process are acceptable as long as the remaining wall thickness is within tolerance, the defect can be removed by grinding, and the repaired wall thickness meets the minimum thickness requirements.

Botop Steel not only offers high-quality steel tubes in accordance with EN 10219, it also offers a wide range of options for surface coating of steel tubes to suit the specific needs of its customers in different engineering projects. These coatings are designed to enhance the corrosion resistance of the tubes and add additional protection, thus extending their service life.

Hot-dip Galvanizing

3LPE (HDPE) Coating

FBE Coating

Varnish Coating

Paint Coating

Cement Weight Coating

Bridge components: non-primary load-bearing structures used in bridges, such as railings and parapets.

Architectural pillars: support columns and beams used in building and civil engineering.

Piping systems: piping for the transportation of liquids and gases, especially in applications requiring a degree of flexibility and corrosion resistance.

Temporary structures: temporary supports and frames suitable for construction and engineering sites.

These applications take advantage of the excellent mechanical properties and weldability of S275J0H and S275J2H to meet the needs of lightweight but stable structures.

ASTM A500: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes.

ASTM A501: Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing.

EN 10210: Hot finished structural hollow sections of non-alloy and fine grain steels.

EN 10219: Cold formed welded structural hollow sections of non-alloy and fine grain steels.

JIS G 3466: Carbon steel square and rectangular tubes for general structure.

AS/NZS 1163: Cold-formed structural steel hollow sections.

These standards are widely used around the world, and they help ensure that structural steel tubes meet the expected performance criteria in different engineering applications. When selecting a steel pipe standard, it is important to consider its specific application needs, regional regulations, and performance requirements.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) Steel Pipe

ASTM A671/A671M LSAW Steel Pipe

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Grade X70 LSAW Steel Pipe

EN10219 S355J0H Structural LSAW(JCOE) Steel Pipe