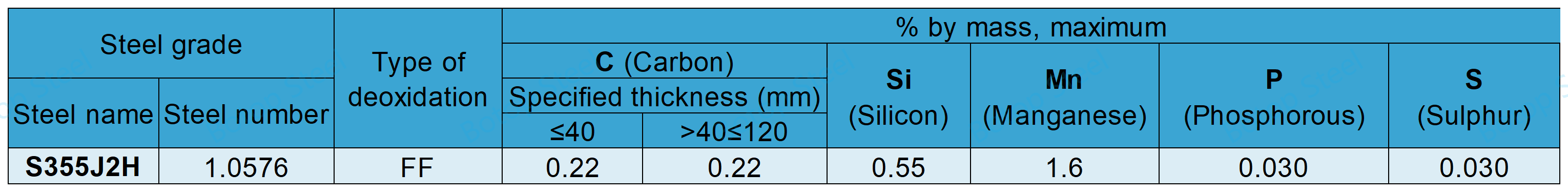

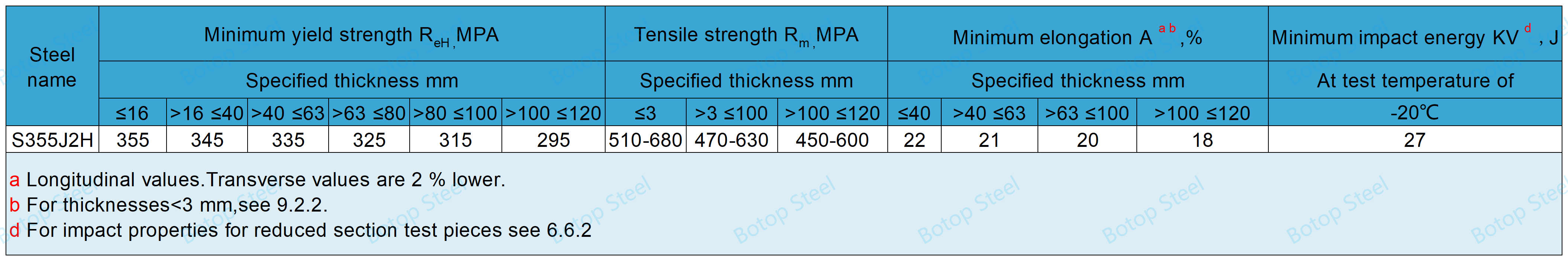

EN 10210 S355J2H is a hot-finished structural hollow section steel according to EN 10210 with a minimum yield strength of 355 MPa (for wall thicknesses ≤ 16 mm) and good impact properties at low temperatures down to -20°C, making it ideal for use in a wide range of building and engineering structures.

Yes, EN 10210 = BS EN 10210.

BS EN 10210 and EN 10210 are identical in technical content and both represent European standards for the design, manufacture, and requirements for thermoformed structural hollow sections.

BS EN 10210 is the version adopted in the UK, whereas EN 10210 is a European-wide standard. Different national standardization bodies may prefix the standard with specific national abbreviations, but the core content of the standard remains consistent.

Hollow sections can be categorized as circular, square or rectangular, or elliptical.

Also because it is a hot finished process in accordance with EN 10210, the following abbreviation can be used.

HFCHS = hot finished circular hollow sections;

HFRHS = hot finished square or rectangular hollow sections;

HFEHS = hot finished elliptical hollow sections.

Round: Outer diameter up to 2500 mm;

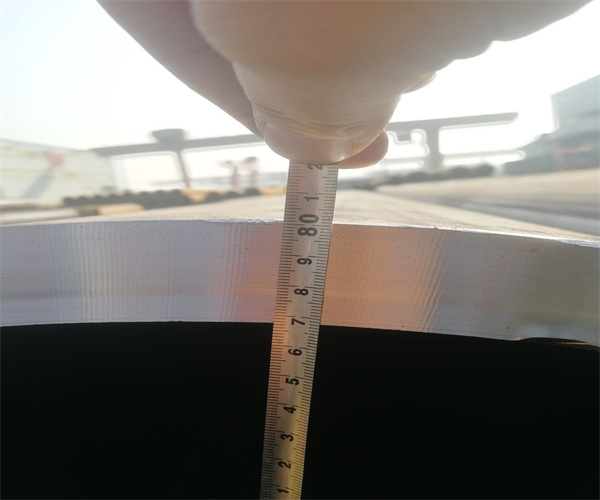

Wall thicknesses up to 120 mm.

Of course, there is no way to produce tubes of this size and wall thickness if the ERW welding process is used.

ERW can produce tubes up to 660mm with a wall thickness of 20mm.

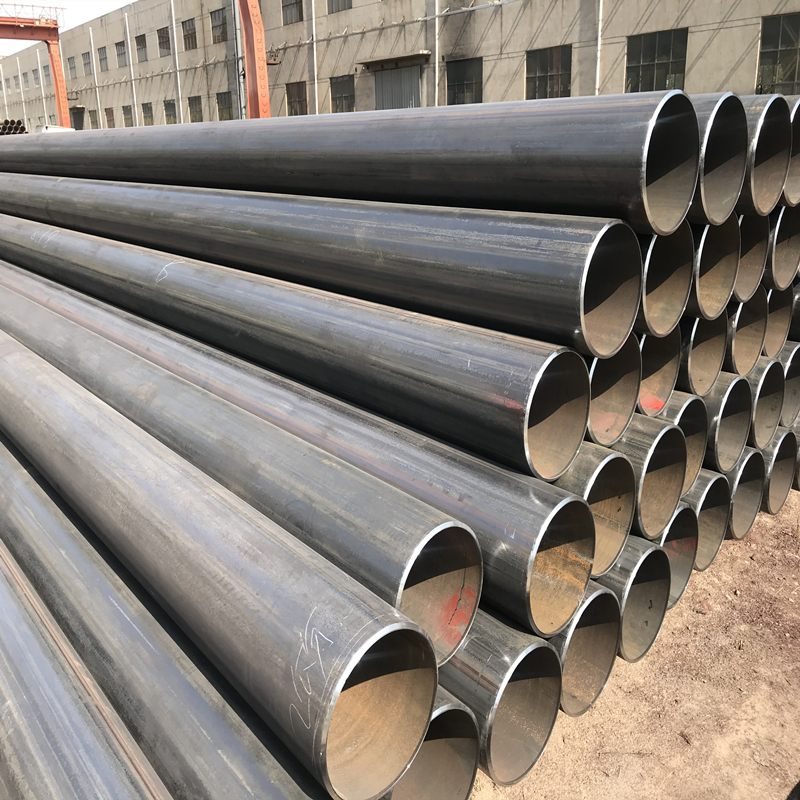

Steel can be manufactured either through a seamless or welding process.

Among the welding processes, common welding methods include ERW (electrical resistance welding) and SAW (submerged arc welding).

Among others, ERW is a welding technique that joins metal parts together by means of resistive heat and pressure. This technique is applicable to a wide range of materials and thicknesses and enables an efficient welding process.

SAW, on the other hand, is a welding method that uses a granular flux to cover the arc, which provides deeper penetration and better weld quality and is particularly suitable for welding thick plates.

Next, is the ERW process, which is a highly efficient manufacturing technique widely used to produce a wide range of steel tubes and profiles.

It should be noted that for unalloyed and fine-grain hollow sections fabricated by the welding process, repair welds are not permitted except for submerged arc welding.

Qualities JR, JO, J2 and K2 - hot finished,

The minimum yield strength of S355J2H steel pipe is not fixed, it will change with the different wall thickness.

Specifically, the yield strength of S355J2H is set according to the standard when the wall thickness is less than or equal to 16mm, but when the wall thickness increases, the yield strength will be reduced, so not all S355J2H steel pipe can reach the minimum yield strength of 355MPa.

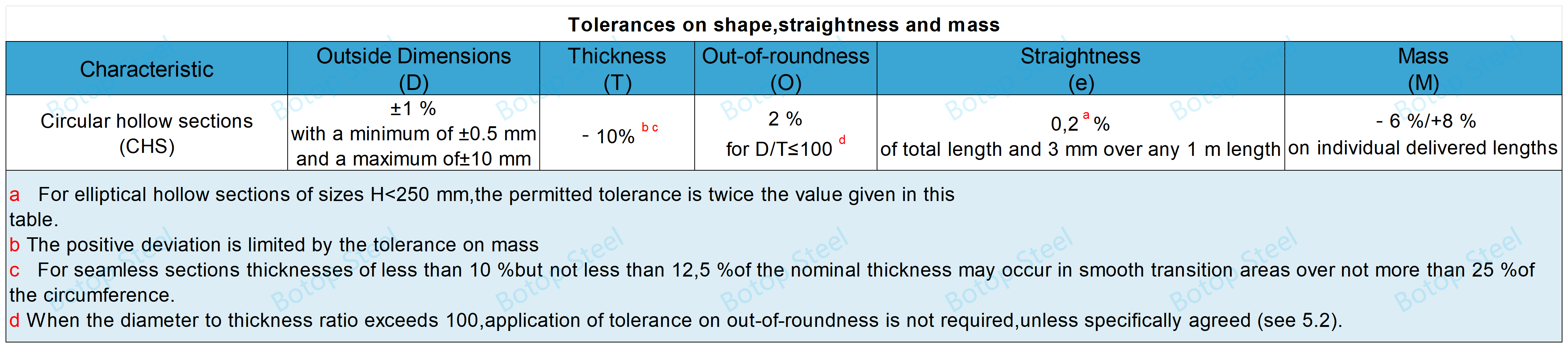

Tolerances on shape, straightness and mass

Tolerances length

| Type of length a | Range of length or length L | Tolerance |

| Random length | 4000≤L≤16000 with a range of 2000 per order item | 10 %of sections supplied may be below the minimum for the ordered range but not shorter than 75 %of the minimum range length |

| Approximate length | 4000≤L≤16000 | ±500 mm b |

| Exact length | 2000≤L≤6000 | 0 - +10mm |

| 6000<L c | 0 - +15mm | |

| a The manufacturer shall establish at the time of inquiry and order the type of length required and the length range or length. b Ontion 21 the tolerance on annrevimata length is 0 - +150mm c Common lengths available are 6 m and 12 m. |

||

S355J2H steel pipe is a high-strength structural steel pipe with good welding performance and low-temperature impact toughness, so it has a wide range of uses in several industrial fields.

1. Construction: used in bridges, towers, frame structures, rail transportation, subways, roof frames, wall panels, and other building structures.

2. Piping system: Used as piping for transporting fluids, especially in occasions where high strength and pressure resistance are required.

3. Marine and offshore engineering: used in ship structures, offshore platforms, and other marine engineering structures.

4. Energy industry: used in energy facilities such as wind power towers, oil drilling platforms, and pipelines.

5. Pressure vessels: used in the manufacture of pressure vessels in compliance with specific welding and heat treatment requirements.

6. Mining industry: used for structural parts of mine support structures, conveyor systems, and ore processing equipment.

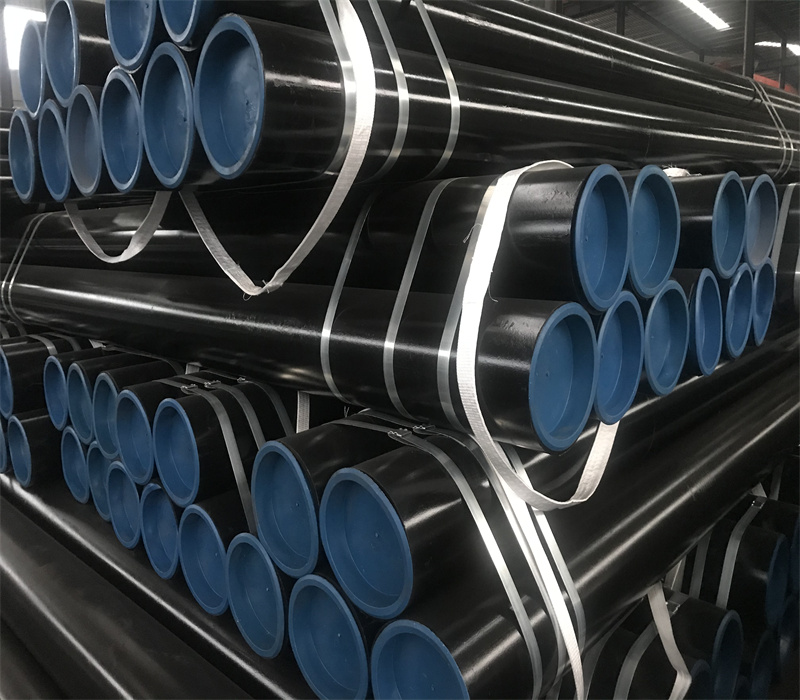

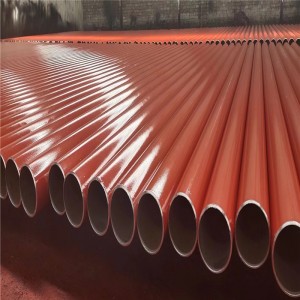

Bare pipe or Black / Varnish coating ( customized);

in bundles or in loose;

Both ends with end protectors;

Plain end, bevel end(2"and above with bevel ends, degree: 30~35°), threaded and coupling;

Marking.