Botop Steel, located in the elbow and pipe fitting capital of China, has the advantage of a large inventory and purchasing power to offer a wide range of flanges and fittings in a variety of standards and sizes, as well as customized non-standard products according to customers' requirements.

Flanges and pipe fittings have many types, models, and implementation standards and are complex. When purchasing, it is recommended to look for professional suppliers or manufacturers to ensure product quality and compliance with relevant standards.

| Types | Type of Supply |

| Flanges | Plate Flange, Weld Neck Flange, Socket Weld Flange, Threaded Flange, Blind Flange, Loose Flange, Integral Flange, Flat Face Welding Flange, Raised Face Welding Flange, Ring Type Joint Flange |

| Fittings | Elbow, Tee, Cross, Reducer, Cap, Coupling, Plug, Bend, Adapter, Union |

Raised Face Welding Flange

Concentric Reducer

Caps

Weldolet

Straight Tee

Elbow

Below are some common standards and ratings for specific purchases, please ensure that the product selected meets your project requirements and relevant specifications. For assistance, please contact us, we will provide you with professional services.

| Types | Standard | Grade | Dimension |

| Flanges | ASME B16.5 | class150, class300, class600, class900, class1500,class2500 | 1/2 "- 24 " |

| ASME B16.47 | class75, class150, class300, class400,class600, class900 | 26 "- 60 " | |

| DIN 2573, DIN 2503, DIN 2544, DIN 2565, DIN 2641, DIN 2655, DIN 2656 | PN6, PN10, PN16, PN25, PN40, PN64, PN100 | DN 15 - DN 2000 | |

| EN 1092-1 | PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, PN100 | DN 10 - DN 2000 | |

| BS 4504 | PN2.5, PN6, PN10, PN16, PN25, PN40 | DN 15 - DN 160 | |

| GOST 12820 - 80, GOST 12821 - 80 | PN6, PN10, PN16, PN25, PN40, PN63 | DN 10 - DN 1600 | |

| JIS B 2220, JIS B 8210 | 1K, 2K, 5K, 10K, 16K, 20K, 30K,40K | 15A - 1500A |

| Types | Standard | Dimension | Wall Thickness |

| Fitting | ASME B16.9, ASME B16.11, ASME B16.28, | Seamless 1/2" - 24"

Seamless and Welded 4" - 48" |

2 - 25 mm

schedule 10, schedule 20, schedule 30, schedule 40, schedule 60, schedule 80, schedule 100, schedule 120, schedule 140, STD, XS, XXS |

| ISO 5254, ISO 3419 | |||

| DIN 2605, DIN 2615, DIN 2616, DIN 2617 | |||

| JIS B 2311 | |||

| GOST 17375, GOST 17376, GOST 17377, GOST 17378 |

Flanges and fittings are available in a variety of materials, including carbon steel, stainless steel, alloy steel, etc., to meet the needs of different industrial environments.

| Material Type | Specifications |

| Carbon steel | A105, SS400, SF440, RST37.2, S235JRG2, P250GH, C22.8, ASTM A234 WPB, WPC, ASTM A420 WPL9, WPL3, WPL6, WPHY-42, WPHY-46, WPHY-52, WPHY-60, WPHY-65, WPHY-70, ASTM A105/ A105N/ A694 F42/46/52/56/60/65/70, A350 LF3/ A350 LF2 |

| Alloy steel | ASTM A234 WP1, WP11, WP12, WP22, WP5, WP9, WP91, ASTM A182 F1/ F5/ F9/ F11/ F22/ F91 |

| Stainless steel | F304 / 304L / 304H / 316 / 316L / 317 / 317L / 321/310/347 / 904L, ASTM A403 WP304/304L, WP316/316L, WP321, WP347 |

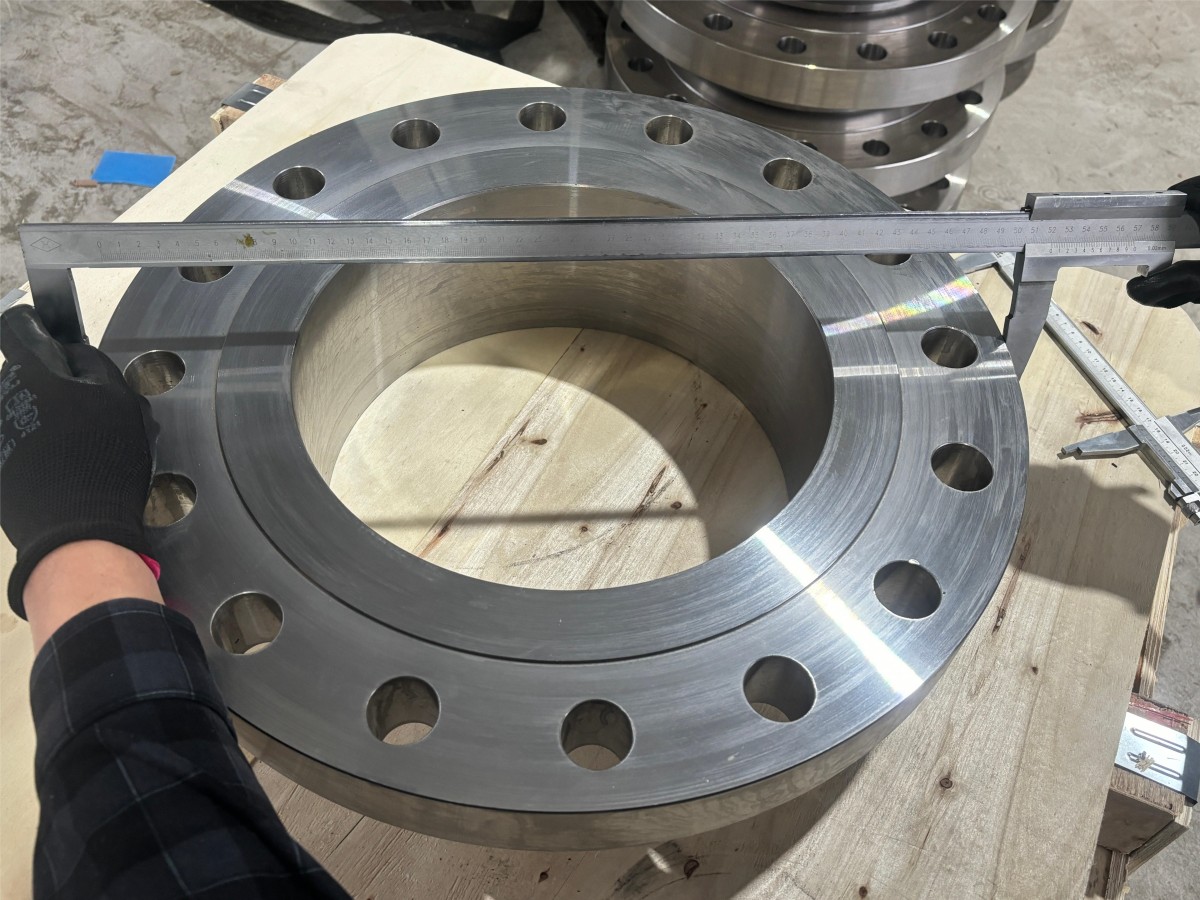

● Geometric dimension checking;

● Magnetic particle inspection;

● Spectral analysis;

● Coloring experiment;

● Ultrasound Detection;

● Metallographic analysis;

Prior to shipment, flanges and fittings are usually coated with a protective coating, which not only reduces the potential for corrosion during transportation but also extends their storage time. In addition, special coatings are sometimes applied to ensure optimum corrosion protection.

Commonly used: rust-preventive oil, varnish, paint, galvanized, PE, FBE, epoxy zinc-rich;

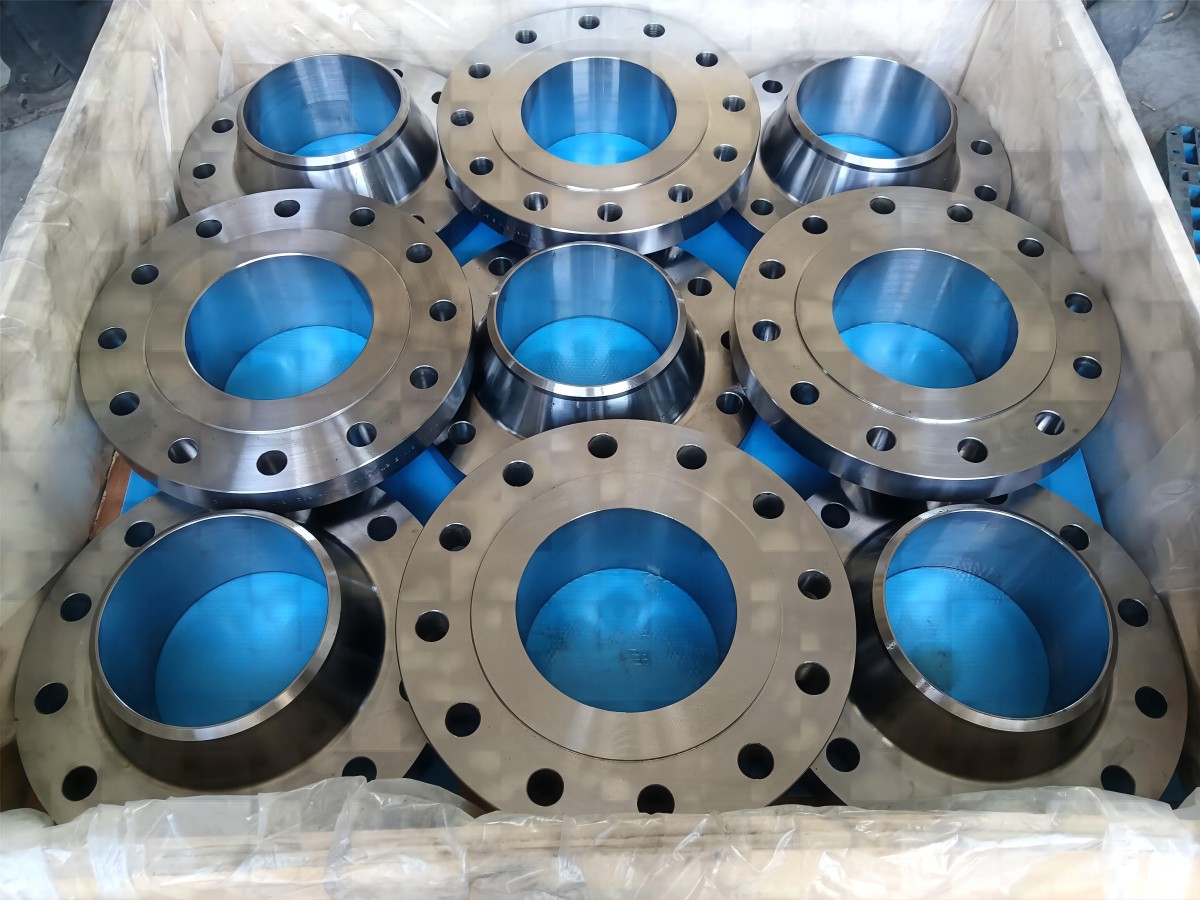

Our company can provide the following packing methods for your choice:

● Containerized direct shipments;

● Plastic packing;

● Carton Packaging;

● Pallet packaging;

● Plywood box packaging;

We can customize it according to your specific needs.

Since the working conditions, environmental requirements, pressure-bearing capacity, connection methods, etc. of each engineering project are different, there are unique requirements for the specifications, dimensions, materials, etc. of flanges and pipe fittings.

Contact us to help you find the most suitable solution.