Graad en gemyske gearstalling (%)

| Klasse | C≤ | Mn | P≤ | S≤ | Si≥ | Cr≤ | Cu≤ | Mo≤ | Ni≤ | V≤ |

| A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15

| 0.40 | 0.08 |

| C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Mechanyske eigenskippen:

|

|

|

| IN% |

|

| A | ≥330 | ≥205 | 20 | Gegloeid |

| B | ≥415 | ≥240 | 20 | Gegloeid |

| C | ≥485 | ≥275 | 20 | Gegloeid |

| Produktnamme | Naadleaze stielen piip |

| Materiaal | Koalstofstiel en legearingstiel |

| Standert | ASTMA53, ASTMA106, ASTMA179, ASTMA192, ASTMA210, ASTM A213, ASTM A335, DIN2391-2, DIN1629, DIN2448, DIN17175.DIN17176,EN10219,EN10210 |

| Klasse | Koalstofstielklassen lykas A53 Gr.B, A106 GrA, B, C, A210 GrA1.Gr.C. API 5L Gr.B.X42, X52.X56, ensfh.; legearingstielkwaliteiten lykas T5, T9, T11, T12, T22, T23, T91, P1, P2, P5, P9, P11, P12 P22.P91, P92,25CrMo4.34CrMo4,42CrMo4SAE4130, SAE4140, SAE4145, SAE4340, ensfh. |

| Grutteberik | 10 * 1-810 * 25, gewicht oant 120 mm maks. |

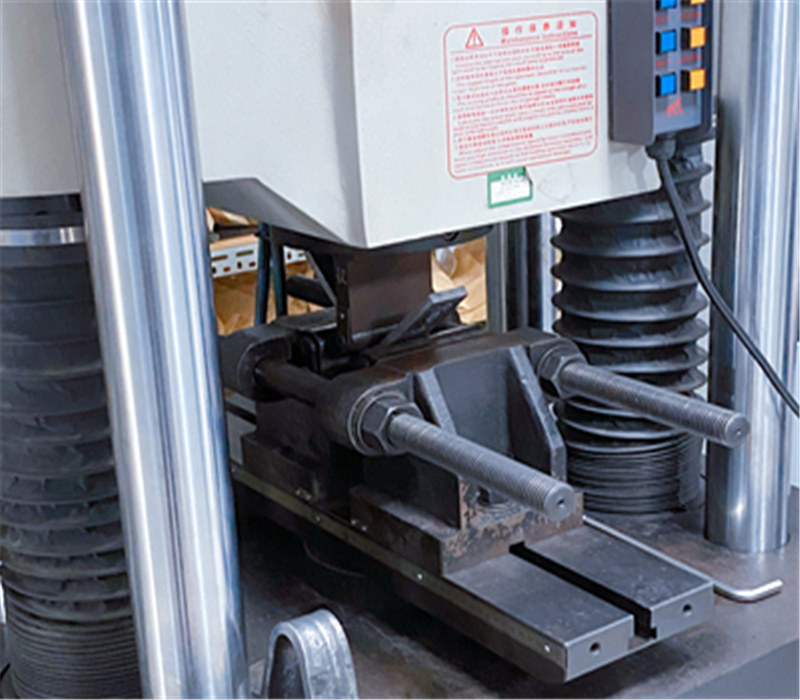

| Produksjemetoade | Kâld lutsen, kâld rôle, hydraulysk kâld lutsen, hjit rôle, hjit útwreide |

| Leveringsbetingsten | As rôle, Stressferliening, Annealed, Normalisearre, Quenched + Tempered |

| Einôfwerking | Gewoane einen mei suqare-snijdingen, ôfskuorde einen, skroefde einen |

| Gebrûk/Tapassing | Drukfetten, Fluidtransport, Struktureel gebrûk. Masines. Oalje en gas ferfier, eksploraasje en boarjen, ensfh. |

| Typen fan buizen | Ketelbuispresyzjebuis, meganyske buizen. silinderbuis.linepipen.ensfh. |

-

-

Diminsjetolerânsjes:

Piiptype

Piipgrutte Tolerânsjes Kâld lutsen

OD ≤48.3mm ±0,40 mm ≥60.3mm ±1 mm WT ±12,5%

-