| Sunan samfur | Carbon Karfe Bututu / Boiler Karfe Bututu |

| Kayan abu | A53 GrB, A36,ST52,ST35,ST42,ST45,X42,X46,X52,X60,X65,X70 |

| Daidaitawa | API 5L, ASTM A106 Gr.B, ASTM A53 Gr.B, ASTMA179/A192, ASTM A335 P9, ASTM A210, ASTM A333 |

| Takaddun shaida | API 5L, ISO9001, SGS, BV, CCIC |

| Diamita na waje | 13.7mm-762mm |

| Kaurin bango | SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160,XS,XXS |

| Tsawon | 1m,4m,6m,8m,12m bisa ga bukatar mai siye |

| Maganin Sama | baki fenti,varnish,mai,galvanized,anti-lalata mai rufi |

| Alama | Daidaitaccen alama, ko bisa ga buƙatarku.Hanyar Alamar:Fada farin fenti |

| Ƙarshen Jiyya | Ƙarshen Ƙarshen Ƙarshe / Ƙarshen Ƙarshen Ƙarshe / Ƙarshen Zare Tare da Filastik |

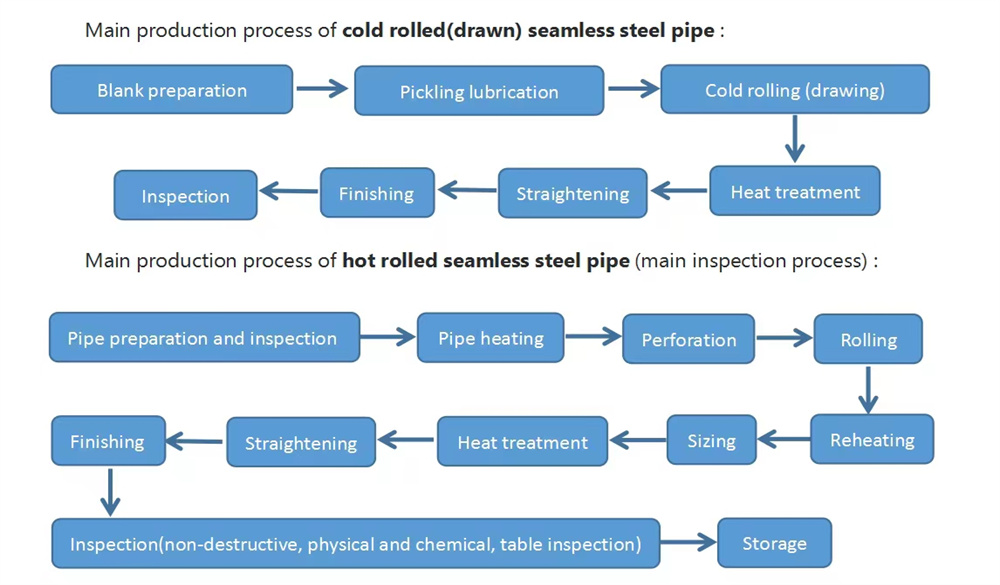

| Dabaru | Hot Rolled ko Cold Rolled ERW |

| Kunshin | Kunshin sako-sako; Cushe a cikin daure (2Ton Max); bututu masu tarin yawa tare da majajjawa a ƙarshen duka biyun.don sauƙin saukewa da fitarwa; katakolokuta; jakar saƙa mai hana ruwa |

| Gwaji | Binciken Abubuwan Sinadarai, Kayayyakin Injini, Abubuwan Fasaha, Girman Waje Dubawa, na'ura mai aiki da karfin ruwa gwajin, X-ray Test |

| Aikace-aikace | Liquid bayarwa, tsarin bututu, gini, man fetur fatattaka, man bututu, gas bututu |

API 5L X42-X80, PSL1&PSL2 Mai da GasCarbon Seamless Karfe BututuAna amfani dashi don isar da iskar gas, ruwa, da man fetur na masana'antar mai da iskar gas.

API 5L X42-X80, PSL1&PSL2 Oil da Gas Carbon Seamless Karfe bututu ana yin su ta hanyar sanyi-ja ko birgima, kamar yadda abokan ciniki suka buƙata.

API 5L X52 PSL1&PSL2 Man Fetur da Gas Carbon Seamless Karfe bututu ana yin su ta hanyar sanyi-jawo ko nadi mai zafi, yawanci ƙananan masu girma dabam ta hanyar sanyi-ja da manyan masu girma ta hanyar birgima mai zafi.

Haɗin Gwargwadon Daraja da Kemikal (%)Don API 5L PSL1

| Daidaitawa |

Daraja | Abubuwan sinadaran(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.28 | ≤1.30 | ≤0.030 | ≤0.030 |

| X46,X52,X56 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X60,X65 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X70 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X52 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

Haɗin Gwargwadon Daraja da Kemikal (%)Don API 5L PSL2

| Daidaitawa |

Daraja | Abubuwan sinadaran(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.24 | ≤1.30 | ≤0.025 | ≤0.015 |

| X46,X52,X56 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X60,X65 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X70,X80 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X52 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

Abubuwan Injini na API 5L GR.B X42-X80/X52(PSL1):

| Daraja | Ƙarfin Haɓaka(MPa) | Ƙarfin Ƙarfi(MPa) | Tsawaitawa A% | ||

|

| psi | MPa | psi | MPa | Tsawaitawa (Min) |

| X42 | 42,000 | 290 | 60,000 | 414 | 21-27 |

| X46 | 46,000 | 317 | 63,000 | 434 | 20-26 |

| X52 | 52,000 | 359 | 66,000 | 455 | 20-24 |

| X56 | 56,000 | 386 | 71,000 | 490 |

|

| X60 | 60,000 | 414 | 75,000 | 517 |

|

| X65 | 65,000 | 448 | 77,000 | 531 |

|

| X70 | 70,000 | 483 | 82,000 | 565 |

|

| X52 | 52,000 | 359 | 66,000 | 455 | 20-24 |

Abubuwan Injini na API 5L/X52GR.B Bututun Layi mara Sumul (PSL2):

| Daraja | Ƙarfin Haɓaka(MPa) | Ƙarfin Ƙarfi(MPa) | Tsawaitawa A% | Tasiri (J) | ||

|

| psi | MPa | psi | MPa | Tsawaitawa (Min) | Min |

| X42 | 290 | 496 | 414 | 758 | 21-27 | 41 (27) |

| X46 | 317 | 524 | 434 | 758 | 20-26 | 41 (27) |

| X52 | 359 | 531 | 455 | 758 | 20-24 | 41 (27) |

| X56 | 386 | 544 | 490 | 758 |

|

|

| X60 | 414 | 565 | 517 | 758 |

|

|

| X65 | 448 | 600 | 531 | 758 |

|

|

| X70 | 483 | 621 | 565 | 758 |

|

|

| X80 | 552 | 690 | 621 | 827 |

| |

| X52 | 359 | 531 | 455 | 758 | 20-24 | 41 (27) |

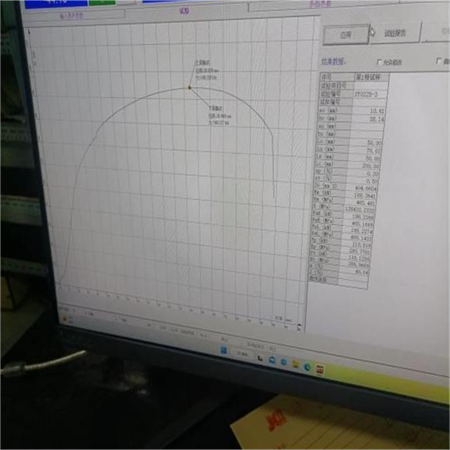

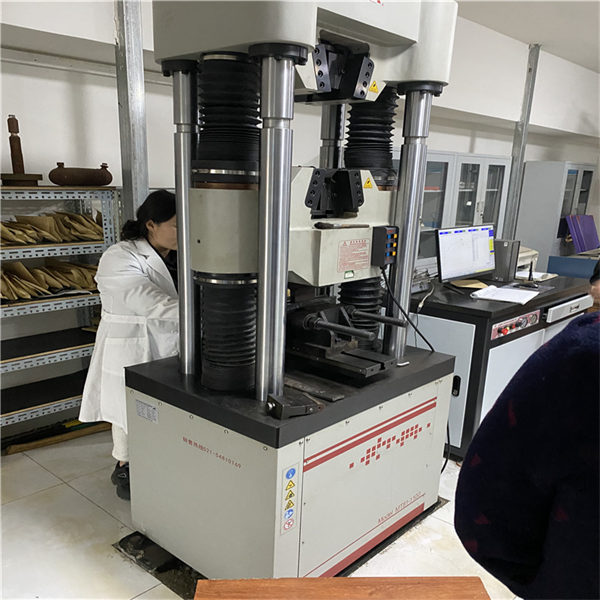

Gwajin Injini

Gwajin Tauri

Lanƙwasa Gwajin

Gwajin juzu'i na jikin bututu-Ya kamata a gudanar da gwajin gwagwarmaya daidai da ISO6892 ko ASTM A370.Ya kamata a yi amfani da samfuran tsayin tsayi. Sau biyu a kowace naúrar gwaji na bututu tare da daidaitaccen haɓakawar sanyi abd.

Gwajin flattening - Za a yi gwajin ƙwanƙwasa ɗaya akan samfurori daga kowane ƙarshen bututu biyu da aka zaɓa daga kowane kuri'a.

Gwajin tasiri na CVN-Ya kamata a yi gwajin Charpy daidai da ASTM A370. Sau biyu a kowace naúrar gwajin da ba ta wuce tsayin 100 na bututu ba tare da rabon faɗaɗa sanyi iri ɗaya abd

Gwajin taurin-Lokacin da aka gano wuraren da ake zargi da ƙarfi ta hanyar dubawa na gani, za a gudanar da gwaje-gwaje taurin daidai da ISO 6506, ISO 6507, ISO 6508 ko ASTM A 370 ta amfani da kayan gwajin ƙarfi mai ɗaukar nauyi da hanyoyin da suka dace da ASTM A956, ASTM A 1038 ko ASTM E 110 dangane da yadda ake amfani da su.

Gwajin-tsattsauran ra'ayi-Kowane bututu za a yi shi da gwajin matsa lamba na ruwa

Lankwasawa Gwajin- isashen tsawon bututu zai tsaya yana lanƙwasa sanyi ta 90° a kusa da madaidaicin silinda.

Gwajin X-ray 100% don kabu na weld

Gwajin ultrasonic

Gwajin halin yanzu

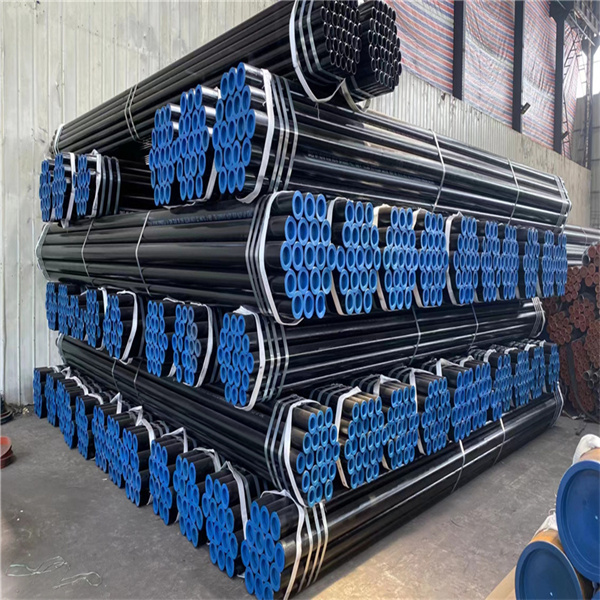

Bare bututu ko Black / Varnish shafi (bisa ga abokin ciniki ta bukatun);

6" kuma a ƙasa a cikin daure tare da majajjawa auduga guda biyu;

Dukansu sun ƙare tare da masu kare ƙarshen;

Ƙarshen Ƙarshen, Ƙarshen bevel (2 "da sama tare da iyakar bevel, digiri: 30 ~ 35 °), threaded da haɗuwa;

Alama.

| Girman | Tolerance (tare da girmamawat to ayyana wajediamita) |

| <2 3/8 | + 0.016 in., - 0.031 in. (+ 0.41 mm, - 0.79 mm) |

| > 2 3/8 da ≤4 1/2, ci gaba da walda | ± 1.00% |

| > 2 3/8 da kuma <20 | ± 0.75% |

| > 20. m | ± 1.00% |

| > 20 da <36, welded | + 0.75% - 0.25% |

| > 36, welded | + 1/4 in.. - 1/8 in. (+ 6.35 mm, -3.20 mm) |

Dangane da yanayin bututun ruwa da aka gwada zuwa matsi fiye da matsi na gwaji, ana iya yarda da sauran juriya tsakanin masana'anta da mai siye.

| Fita-da-Roundness | |||||

| Girman | Rage Haƙuri | Ƙarin Haƙuri | Haƙuri na Ƙarshe-zuwa-Ƙarshe | Diamita, Haƙurin Axis (Kashi na Musamman OD) | Matsakaicin Bambanci Tsakanin Mafi ƙanƙanta da Matsakaicin Diamita (Ya Aiwatar da Bututu Kawai Tare da D/t≤75) |

| ≤10 3/4 l&V4 | 1/64 (0.40mm) | 1/16 (1.59mm) | - | - | |

| > 10 3/4 da ≤20 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | - | - | - |

| > 20 da ≤ 42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | <0.500 in. (12.7 mm) |

| >42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | £625 in. (15.9 mm) |

Haƙuri na waje-na-zagaye yana aiki zuwa mafi girma da mafi ƙarancin diamita kamar yadda aka auna tare da ma'aunin mashaya, caliper, ko na'urar da ke auna madaidaicin matsakaici da ƙananan diamita.

Matsakaicin diamita (kamar yadda aka auna da tef ɗin diamita) na ƙarshen bututu ɗaya ba zai bambanta da fiye da 3/32 in. (2.38 mm) daga wancan ƙarshen.

| Girman | Nau'in Bututu | Haƙuri1 (Kashi na Ƙashin Ƙaƙƙarfan bango) | |

| Daraja B ko Ƙananan | Darasi X42 ko mafi girma | ||

| <2 7/8 | Duka | +20.- 12.5 | + 15.0.-12.5 |

| > 2 7/8 da <20 | Duka | + 15,0,-12.5 | + 15-I2.5 |

| >20 | Welded | + 17.5.-12.5 | + 19.5.-8.0 |

| >20 | M | + 15.0.-12.5 | + 17.5.-10,0 |

Idan mai siye ya kayyade rashin haƙurin da ba su da kyau fiye da waɗanda aka jera, za a ƙara ingantaccen haƙuri zuwa jimlar juriyar haƙuri a cikin kashi ƙasa da kaurin bango mara kyau.

| Yawan | Toiyawa (kashi) |

| Tsawon tsayi ɗaya, bututun fili na musamman ko bututu A25Tsawon tsayi guda ɗaya, sauran bututuCarloads.GradeA25,40,000lb(18 144kg) ko fiyeCarloads, ban da Grade A25,40.0001b (18 144 kg) ko fiyeCarloads, duk maki kasa da 40000 lb (18 144 kg) Yi oda abubuwa. Babban darajar A25. 40.000 lb (18 144 kg) ko fiye Oda abubuwa, ban da Grade A25,40,000 lb (18 144 kg) ko fiye Yi oda abubuwa, duk maki, ƙasa da 40.000 lb (18 144 kg) | + 10.-5.0 + 10,-35 -2.5 -1.75 -15 -3.5 -1.75 -3.5 |

Bayanan kula:

1.Weight tolerances shafi ma'auni na lissafi don threaded-da-coupled bututu da kuma zuwa ma'auni ko ƙididdiga ma'auni na fili-karshen bututu. Idan mai siye ya ayyana kaurin kaurin bango mara kyau fiye da waɗanda aka jera a teburin sama ta mai siye, ƙarin juriyar juriya don tsayi ɗaya za a ƙara zuwa kashi 22.5 ƙasa da kauri mara kyau.

2.Domin motocin da ke kunshe da bututu daga abubuwa fiye da ɗaya, za a yi amfani da juzu'i na jigilar kaya akan wani tsari na kowane mutum.

3. Haƙurin yin oda ya shafi jimillar bututun da aka aika don abin oda.