ASTM A178karfe shambura ne lantarki juriya welded (ERW) bututu nacarbon da carbon-manganese karfeana amfani dashi azaman bututun tukunyar jirgi, bututun tukunyar jirgi, flues superheater, da ƙarewar aminci.

Ya dace da bututun ƙarfe tare da diamita na waje na 12.7-127mm da kaurin bango tsakanin 0.9-9.1mm.

ASTM A178 bututu sun dace da juriya welded bututu tare dadiamita na waje tsakanin 1/2 - 5 a [12.7 - 127 mm] da kaurin bango tsakanin 0.035 - 0.360 a [0.9 - 9.1 mm], ko da yake wasu masu girma dabam suna samuwa kamar yadda ake buƙata, muddin waɗannan bututun sun cika duk sauran buƙatun wannan ƙayyadaddun.

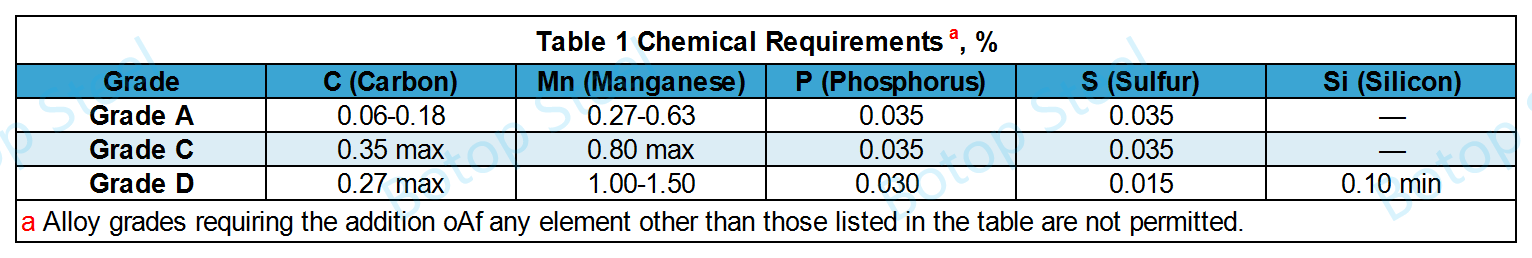

Akwai maki uku don jure yanayin amfani daban-daban.

Darasi A, C, da kuma D.

| Daraja | Nau'in Karfe Carbon |

| Darasi A | Karamin Karfe-Carbon |

| Darasi C | Matsakaici-Carbon Karfe |

| Darasi D | Karfe-Manganese Karfe |

Abubuwan da aka tanadar a ƙarƙashin wannan ƙayyadaddun za su dace da buƙatun da ake buƙata na bugu na Musamman na A450/A450M na yanzu. sai dai idan aka tanadar a nan.

Darasi AkumaDarasi Ckar a ƙayyade takamaiman karfe; zaɓi albarkatun da ya dace kamar yadda ake buƙata.

Karfe donDarasi Dza a kashe.

Karfe da aka kashe ana samar da shi ta hanyar ƙara abubuwan deoxidizers (misali, silicon, aluminum, manganese, da sauransu) don narkakken ƙarfe yayin aikin samar da ƙarfe, ta haka rage ko kawar da abun cikin iskar oxygen na ƙarfe.

Wannan maganin yana inganta daidaituwa da kwanciyar hankali na karfe, yana haɓaka kayan aikin injiniya, kuma yana inganta juriya na lalata.

Don haka ana amfani da karafa da aka kashe a aikace-aikace inda ake buƙatar babban matakin kamanni da kyawawan kaddarorin inji, kamar kera tasoshin matsa lamba, tukunyar jirgi, da manyan abubuwan tsarin.

Ana yin bututun ƙarfe ta amfani daERWtsarin masana'antu.

ERW (Welded Resistance Electric)tsari ne wanda ya dace da masana'antar bututun ƙarfe na carbon.

Tare da abũbuwan amfãni daga high waldi ƙarfi, m ciki da waje saman, da sauri samar gudun, da kuma low price, shi ne yadu amfani a da yawa masana'antu da yi filayen.

ASTM A178karfe bututudole ne a kula da zafia lokacin aikin masana'antu. Ana amfani da shi don inganta kayan aikin injiniya da kwanciyar hankali na tsarin bututu, da kuma kawar da matsalolin da ƙila an gabatar da su yayin aikin walda.

Bayan waldawa, duk bututu za a bi da su da zafi a zafin jiki na 1650°F [900°C] ko sama da haka sannan a bi da su ta hanyar sanyaya a cikin iska ko cikin ɗakin sanyaya na tanderun yanayi mai sarrafawa.

Bututu masu sanyiza a yi maganin zafi bayan wucewar sanyi na ƙarshe a zazzabi na 1200°F [650°C] ko sama.

Lokacin da aka gudanar da bincike na samfur, ana ƙayyade yawan dubawa kamar haka.

| Rabewa | Mitar dubawa |

| Diamita na waje ≤ 3in [76.2mm] | 250 inji mai kwakwalwa / lokaci |

| Diamita na waje = 3in [76.2mm] | 100 inji mai kwakwalwa / lokaci |

| Bambance ta lambar zafi tube | Kowane lambar zafi |

Bukatun kadarorin injina baya aiki ga bututun da ke ƙasa da 1/8 in. [3.2 mm] a cikin diamita ko 0.015 in. [0.4 mm] cikin kauri.

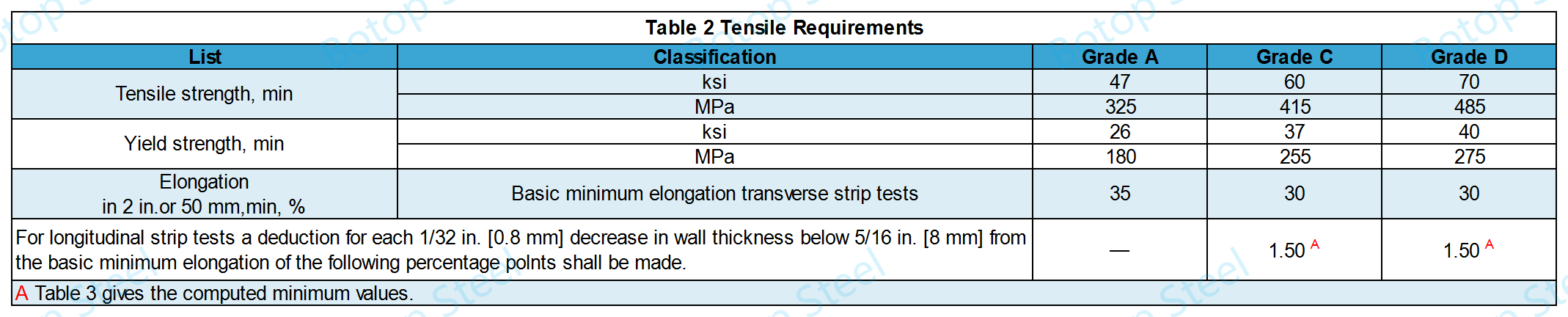

1. Dukiya mai ƙarfi

Don azuzuwan C da D, za a yi gwajin juzu'i akan bututu biyu a kowace kuri'a.

Don tubing na Grade A, ba a buƙatar gwajin juzu'i akai-akai. Wannan ya faru ne saboda gaskiyar cewa tubing na Grade A da farko ana amfani da shi don aikace-aikacen ƙananan matsa lamba da ƙananan zafin jiki.

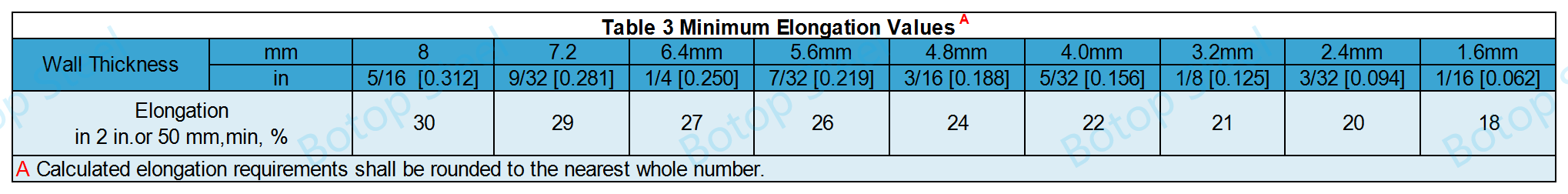

Tebu 3 yana ba da mafi ƙarancin ƙididdige ƙididdige ƙimar haɓakawa ga kowane 1/32 in. [0.8 mm] raguwa a kaurin bango.

Idan kaurin bangon bututun ƙarfe ba ɗaya daga cikin waɗannan kaurin bango ba ne, ana iya ƙididdige shi ta hanyar dabara.

Inci Raka'a: E = 48t + 15.00koISI Raka'a: E = 1.87t + 15.00

E = tsawo a cikin 2 in. ko 50 mm,%,

t= ainihin kauri, in. [mm].

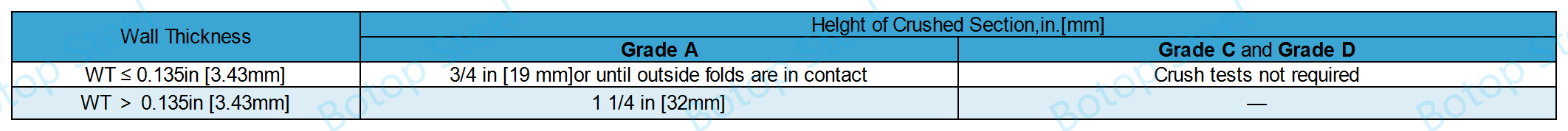

2. Gwajin Murkushewa

Ana yin gwaje-gwajen extrusion akan sassan bututu mai tsawon inci 2 1/2 [63 mm] a tsayi wanda dole ne ya jure extrusion na tsaye ba tare da tsagewa, tsagawa, ko tsagawa a cikin walda ba.

Don tubing kasa da inci 1 [25.4] a diamita na waje, tsawon samfurin zai zama sau 2 1/2 na waje diamita na bututu. Ƙididdigar ƙasa ba za ta zama dalilin ƙin yarda ba.

3. Gwajin Lalacewa

Hanyar gwaji ta dace da abubuwan da suka dace na ASTM A450 Sashe na 19.

4. Gwajin Flange

Hanyar gwaji ta dace da abubuwan da suka dace na ASTM A450 Sashe na 22.

5. Reverse Flattening Test

Hanyar gwaji ta dace da abubuwan da suka dace na ASTM A450, Sashe na 20.

Ana yin gwajin wutar lantarki mai ƙarfi ko mara lalacewa akan kowane bututun ƙarfe.

Abubuwan da ake buƙata sun dace da ASTM A450, Sashe na 24 ko 26.

An samo waɗannan bayanan daga ASTM A450 kuma sun cika buƙatun da suka dace don bututun ƙarfe na walda kawai.

Rage nauyi

0 - +10%.

Rage Kaurin bango

0 - +18%.

Bangaren Diamita na Waje

| Waje Diamita | Bambance-bambancen da aka halatta | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ± 0.004 | ± 0.1 |

| 1½ ≤1½ | 25.4 OD ≤38.4 | ± 0.006 | ± 0.15 |

| 1½ | 2 | 38.1 OD 50.8 | ± 0.008 | ± 0.2 |

| 2≤ OD2½ | 50.8≤ OD | 63.5 | ± 0.010 | ± 0.25 |

| 2½≤ OD3 | 63.5≤ OD.76.2 | ± 0.012 | ± 0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ± 0.015 | ± 0.38 |

| 4<OD ≤7½ | 101.6 OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD≤9 | 190.5 OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Bayan shigar a cikin tukunyar jirgi, bututu ya kamata ya iya jure wa faɗaɗawa da lanƙwasa ba tare da tsagewa ko tsagewa a walda ba.

Babban bututun zafi zai zama mai iya jure duk wani aikin ƙirƙira, walda, da lankwasawa ba tare da lahani ba.

An fi amfani dashi a cikin bututun tukunyar jirgi, bututun tukunyar jirgi, flues mai zafi, da amintattun ƙarewa.

ASTM A178Ƙananan abun ciki na tubing yana ba shi kyakkyawan walƙiya da ƙaƙƙarfan ƙarfi don aikace-aikacen da ba a fuskantar matsanancin matsin lamba.

Ana amfani da shi da farko don aikace-aikacen ƙananan matsa lamba da matsakaita-zazzabi kamar na'urori masu ƙarancin ƙarfi (misali, tukunyar jirgi na gida, ƙaramin ginin ofis, s ko tukunyar masana'anta) da sauran masu musayar zafi a cikin ƙananan yanayin zafi.

ASTM A178yana da babban abun ciki na carbon da manganese yana ba wannan bututu mafi kyawun ƙarfi da juriya mai zafi don ƙarin yanayin aiki mai buƙata.

Ya dace da matsakaicin matsa lamba da aikace-aikacen zafin jiki na matsakaici kamar masana'antu da tukunyar ruwa mai zafi, waɗanda yawanci suna buƙatar matsi da yanayin zafi fiye da na gida.

ASTM A178Dtubes suna da babban abun ciki na manganese da abun ciki na silicon da ya dace don samar da kyakkyawan ƙarfi da juriya na zafi, yana sa su tsaya a cikin yanayin zafi mai zafi da matsa lamba kuma sun dace da tsayayya da matsanancin yanayin aiki.

Yawanci ana amfani da shi a cikin matsanancin matsi da yanayin zafi mai zafi, kamar su tukunyar jirgi na tashar wutar lantarki da manyan dumama masana'antu.

1. ASTM A179 ASME SA179: Marasa ƙarancin ƙarfe mai zafi mai zafi da bututu don sabis na cryogenic. An yi amfani da shi da farko a cikin ƙananan mahalli, yana kama da sinadarai da kaddarorin inji zuwa ASTM A178.

2. ASTM A192 / ASME SA192: Bututun tukunyar jirgi na carbon karfe mara kyau a cikin sabis na matsin lamba. Ana amfani da shi da farko wajen kera bangon ruwa, masana'antar tattalin arziki da sauran abubuwan matsa lamba don tukunyar jirgi mai tsananin zafi.

3. ASTM A210 / ASME SA210: Yana rufe matsakaiciyar carbon da alloy karfe tukunyar jirgi da superheater bututu don babban zafin jiki da matsakaicin matsa lamba tsarin tukunyar jirgi.

4. Farashin 17175: Bututun ƙarfe da bututu marasa ƙarfi don amfani a cikin matsanancin matsin lamba da yanayin zafi mai zafi. Yafi amfani a yi na tururi bututu ga boilers da matsa lamba tasoshin.

5. TS EN 10216-2: Ya tsara yanayin fasaha don bututun da ba su da kyau da kuma bututun da ba a haɗa su da kayan kwalliya da ƙayyadaddun ƙayyadaddun yanayin zafi don aikace-aikacen ƙarƙashin matsin lamba.

6. Saukewa: G3461: Yana rufe bututun ƙarfe na carbon don tukunyar jirgi da masu musayar zafi. Ya dace da yanayin yanayin musayar zafi na ƙasa da matsakaici.

Mu ne babban ingancin welded carbon karfe bututu masana'anta da kuma maroki daga kasar Sin, da kuma wani m karfe bututu stockist, ba ku da fadi da kewayon karfe bututu mafita!

Don kowace tambaya ko don ƙarin koyo game da abubuwan da muke bayarwa, kar a yi shakka a tuntuɓe mu. Mafi kyawun mafitacin bututun ƙarfe ɗinku saƙo ne kawai!