Saukewa: ASTM A335P91, kuma aka sani daSaukewa: ASME SA335 P91, ne a m ferritic gami karfe bututu ga high-zazzabi sabis, UNS No. K91560.

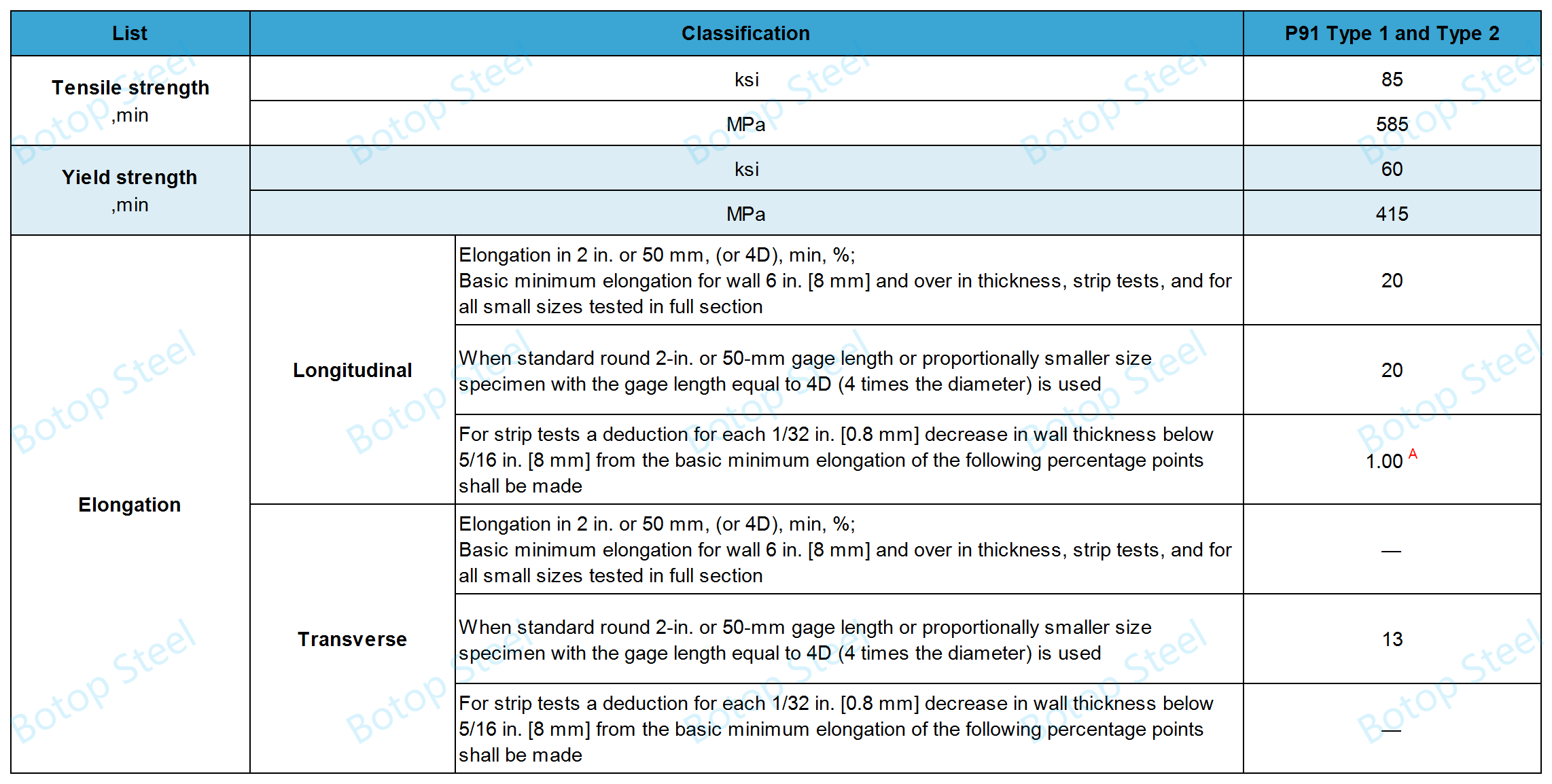

Yana da mafi ƙanƙantaƘarfin ƙarfi na 585 MPa(85 ksi) kuma mafi ƙarancinƘarfin yawan amfanin ƙasa na 415 MPa(60 ka).

P91Ya ƙunshi abubuwa masu haɗawa kamar chromium da molybdenum, kuma ana ƙara wasu abubuwa iri-iri na alloying, na cikinhigh-alloy karfe, don haka yana da babban ƙarfi da kyakkyawan juriya na lalata.

Bugu da ƙari, P91 yana samuwa a cikin nau'i biyu.Nau'i na 1kumaNau'i na 2, kuma yawanci ana amfani dashi a cikin masana'antar wutar lantarki, matatun mai, kayan aikin sinadarai masu mahimmanci, da bututu a cikin yanayin zafi mai zafi da matsananciyar yanayi.

P91 karfe bututu an kasafta zuwa iri biyu, Type 1 da kuma Type 2.

Dukkanin nau'ikan iri ɗaya ne dangane da kaddarorin injina da sauran buƙatu kamar maganin zafi,tare da ƙananan bambance-bambance a cikin sinadaran sinadaran da takamaiman aikace-aikacen mayar da hankali.

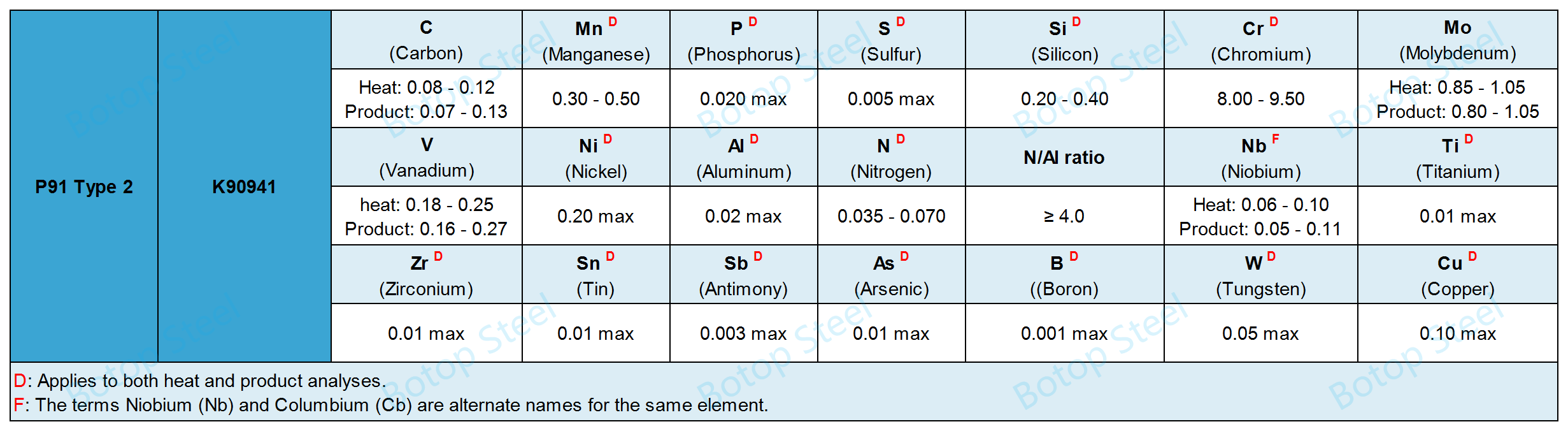

Abubuwan sinadaran: Idan aka kwatanta da Nau'in 1, nau'in sinadarai na Nau'in 2 ya fi tsayi kuma ya ƙunshi abubuwa masu yawa don samar da mafi kyawun zafi da juriya na lalata.

Aikace-aikace: Saboda ingantaccen abun da ke tattare da sinadarai, Nau'in 2 ya fi dacewa da yanayin zafi mai tsayi ko fiye da lalata, ko a aikace-aikacen da ake buƙatar ƙarfin ƙarfi da dorewa.

ASTM A335 karfe bututu dole ne ya zamam.

An rarraba tsarin masana'anta maras kyau a cikizafi gamawakumazana sanyi.

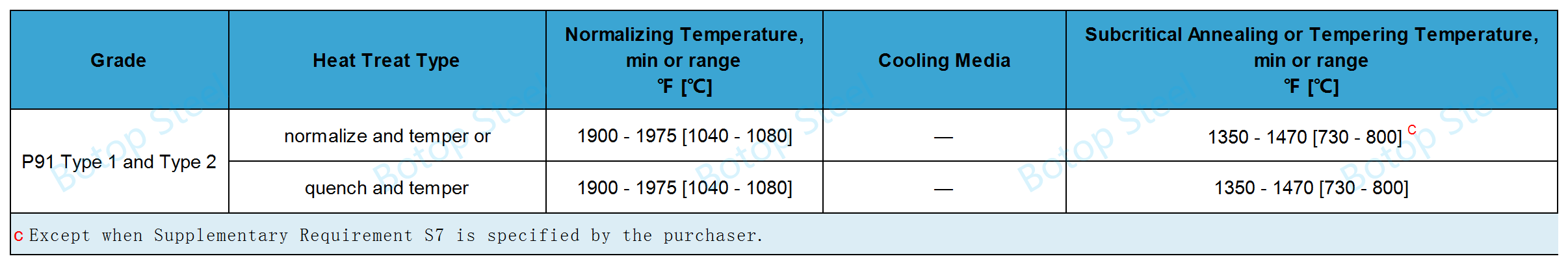

A ƙasa akwai zane na tsari mai zafi.

Musamman, P91, bututun ƙarfe mai ƙarfi, wanda galibi ana amfani da shi a cikin yanayi mai tsauri dangane da yanayin zafi da matsi, bututun ƙarfe mara ƙarfi yana da ƙarfi iri ɗaya kuma ana iya sanya shi cikin bango mai kauri, don haka tabbatar da aminci mafi girma da ingantaccen farashi.

P91 Duk bututu dole ne a yi amfani da zafi don haɓaka microstructure na bututu, haɓaka kayan aikin injinsa, da haɓaka juriya ga babban zafin jiki da matsa lamba.

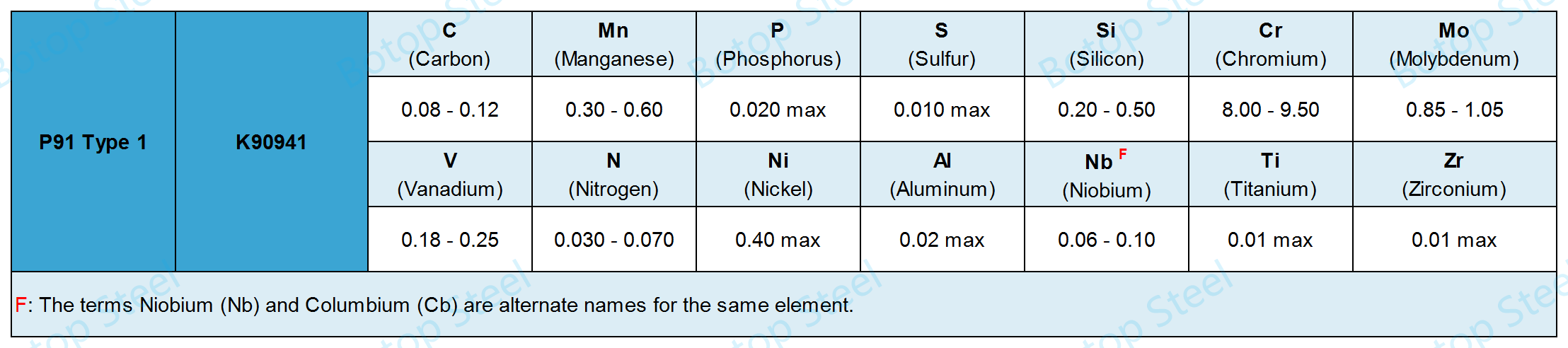

Abubuwan Sinadarai na Nau'in P91

P91 Nau'in Nau'in Sinadaran 2

Tare da hotuna guda biyu da ke sama, yana da sauƙin ganin bambanci tsakanin nau'in 1 da nau'in nau'in sinadarai na 2 da ƙuntatawa.

1. Dukiya mai ƙarfi

Ana amfani da gwajin tensile akai-akai don aunasamar da ƙarfi, karfin jurewa, kumaelongation na shirin gwaji na bututun ƙarfe, kuma ana amfani da shi sosai a cikin kayan kayan gwajin.

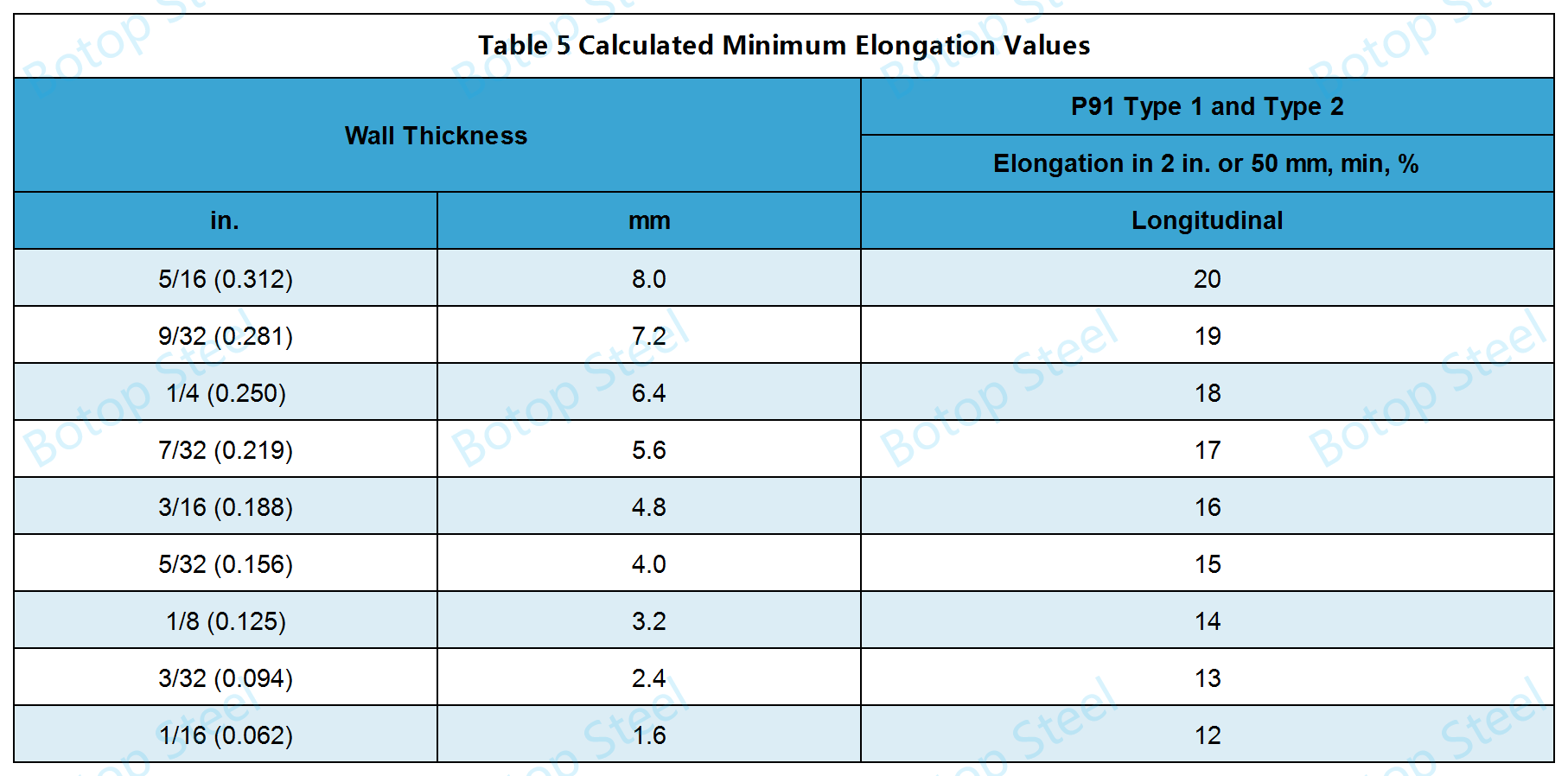

ATebur na 5 yana ba da mafi ƙarancin ƙididdiga.

Inda kaurin bango ya ta'allaka tsakanin dabi'u biyun da ke sama, mafi ƙarancin ƙimar elongation ana ƙaddara ta hanyar dabara mai zuwa:

Tsayi, P91: E = 32t + 15.00 [E = 1.25t + 15.00]

inda:

E = tsawo a cikin 2 in. ko 50 mm,%,

t = ainihin kauri na samfurori, in. [mm].

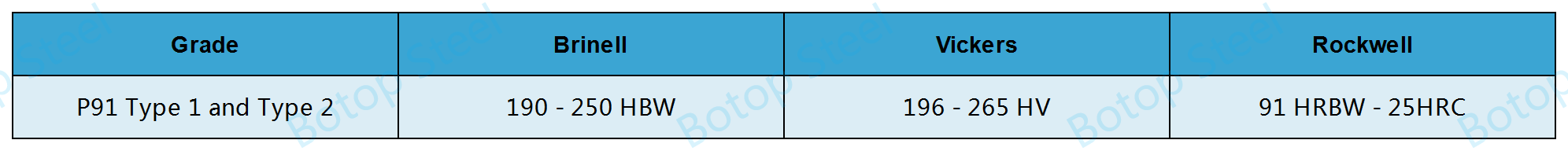

2. Tauri

Ana iya amfani da hanyoyin gwajin taurin iri-iri, gami da Vickers, Brinell, da Rockwell.

Kaurin bango <0.065 in. [1.7 mm]: Babu gwajin taurin da ake buƙata;

0.065 in. [1.7 mm] ≤ kauri bango <0.200 in. [5.1 mm]: Za a yi amfani da gwajin taurin Rockwell;

Kaurin bango ≥ 0.200 in. [5.1 mm]: amfani na zaɓi na gwajin taurin Brinell ko gwajin taurin Rockwell.

Gwajin taurin Vickers ya dace da duk kaurin bango na bututu. Ana aiwatar da hanyar gwajin daidai da bukatun E92.

3. Gwajin Lalacewa

Za a gudanar da gwaje-gwaje daidai da sashe na 20 na ma'aunin ASTM A999.

4. Lankwasawa Gwajin

Lanƙwasa 180° a zafin jiki na ɗaki, babu tsaga ba zai bayyana a wajen ɓangaren lanƙwasa ba.

Girman> NPS25 ko D/t ≥ 7.0: Ya kamata a yi gwajin lanƙwasawa ba tare da gwadawa ba.

5. P91 Shirye-shiryen Gwaji na Zabi

Ba a buƙatar abubuwan gwaji masu zuwa abubuwan gwaji, idan ya cancanta za a iya tantance su ta hanyar shawarwari.

S1: Binciken Samfura

S3: Gwajin Lalacewa

S4: Tsarin Ƙarfe da Gwaje-gwajen Etching

S5: Hotuna

S6: Hotunan Hotuna don Nau'ukan Mutum ɗaya

S7: Madadin Maganin Zafi-Grade P91 Nau'in 1 da Nau'in 2

Gwajin ruwa na P91 zai bi buƙatun masu zuwa.

Diamita na waje sama da inci 10. [250mm] da kaurin bango ≤ 0.75in. [19mm]: wannan yakamata ya zama gwajin hydrostatic.

Wasu masu girma dabam don gwajin lantarki mara lalacewa.

Domin ferritic gami karfe da bakin karfe shambura, bango yana hõre matsa lamba na ba kasa da60% na ƙayyadadden ƙarfin yawan amfanin ƙasa.

Za a kiyaye matsa lamba na gwajin ruwa don aƙalla 5sba tare da yabo ko wasu lahani ba.

Na'ura mai aiki da karfin ruwa matsa lambaza a iya lissafta ta amfani da dabara:

P = 2St/D

P = gwajin gwajin hydrostatic a psi [MPa];

S = damuwa bangon bututu a psi ko [MPa];

t = ƙayyadadden kauri na bango, ƙayyadadden kauri na bango bisa ƙayyadaddun lambar jadawalin ANSI ko sau 1.143 ƙayyadadden ƙayyadadden kauri na bango, a cikin. [mm];

D = ƙayyadaddun diamita na waje, diamita na waje daidai da ƙayyadadden girman bututun ANSI, ko diamita na waje da aka ƙididdige su ta ƙara 2t (kamar yadda aka bayyana a sama) zuwa ƙayyadadden diamita na ciki, in. [mm].

Ana bincika bututu P91 ta hanyar hanyar gwajin E213. Ma'auni na E213 ya fi damuwa da gwajin ultrasonic (UT).

Idan an ƙayyade musamman a cikin tsari, Hakanan ana iya bincika shi bisa ga hanyar gwajin E309 ko E570.

Ma'auni na E309 yawanci yana ma'amala da gwajin lantarki (eddy current), yayin da E570 hanya ce ta dubawa wacce ta ƙunshi eddy current arrays.

Bambance-bambancen da aka halatta a Diamita

Don bututun da aka umarta zuwaciki diamita, Diamita na ciki bazai bambanta fiye da ± 1% daga ƙayyadadden diamita na ciki ba.

Bambance-bambancen da aka halatta a cikin Kaurin bango

Dole ne a yi ma'aunin kauri na bango ta amfani da ma'aunin injina ko ingantattun na'urorin gwaji marasa lalacewa daidai gwargwado. Idan akwai jayayya, ma'aunin da aka ƙayyade ta amfani da ma'aunin injin zai yi nasara.

Matsakaicin kauri na bango da diamita na waje don dubawa don bin wannan buƙatun don bututun da NPS [DN] ya umarta da lambar jadawalin ana nunawa a cikiSaukewa: ASME B36.10M.

Lalacewar

Ana ɗaukar lahani na saman saman idan sun wuce 12.5% na kauri na bangon ƙima ko ya wuce ƙaramin kauri na bango.

Rashin cikawa

Alamomin injina, ɓarna, da ramummuka, kowanne daga cikinsu rashin cikawa ya yi zurfi fiye da 1/16 in. [1.6 mm].

Ana bayyana alamomi da ɓarna a matsayin alamomin kebul, ɗige-ɗige, alamomin jagora, alamun jujjuyawa, ƙwallo, maki, alamun mutuwa, da makamantansu.

Gyara

Ana iya cire lahani ta hanyar niƙa, muddin sauran kaurin bango bai gaza mafi ƙarancin kauri ba.

Hakanan ana iya yin gyare-gyare ta hanyar walda amma dole ne a bi ƙa'idodin A999 masu dacewa.

All gyara welds a P91 za a yi tare da daya daga cikin wadannan waldi matakai da abũbuwan amfãni: SMAW, A5.5/A5.5M E90XX-B9: SAW, A5.23/A5.23M EB9 + tsaka tsaki juyi; GTAW, A5.28/A5.28M ER90S-B9; da FCAW A5.29/A5.29M E91TI-B9. Bugu da kari, jimillar Ni+Mn na duk abubuwan da ake amfani da su na walda da ake amfani da su don gyaran walda P91 Type 1 da Type 2 ba za su wuce 1.0% ba.

Ya kamata a kula da bututu P91 zafi a 1350-1470 °F [730-800°C] bayan gyaran walda.

Wurin waje na bututun ƙarfe da aka bincika zai ƙunshi abubuwa masu zuwa:

Sunan mai ƙira ko alamar kasuwanci; daidaitaccen lamba; daraja; tsawo da ƙarin alamar"S".

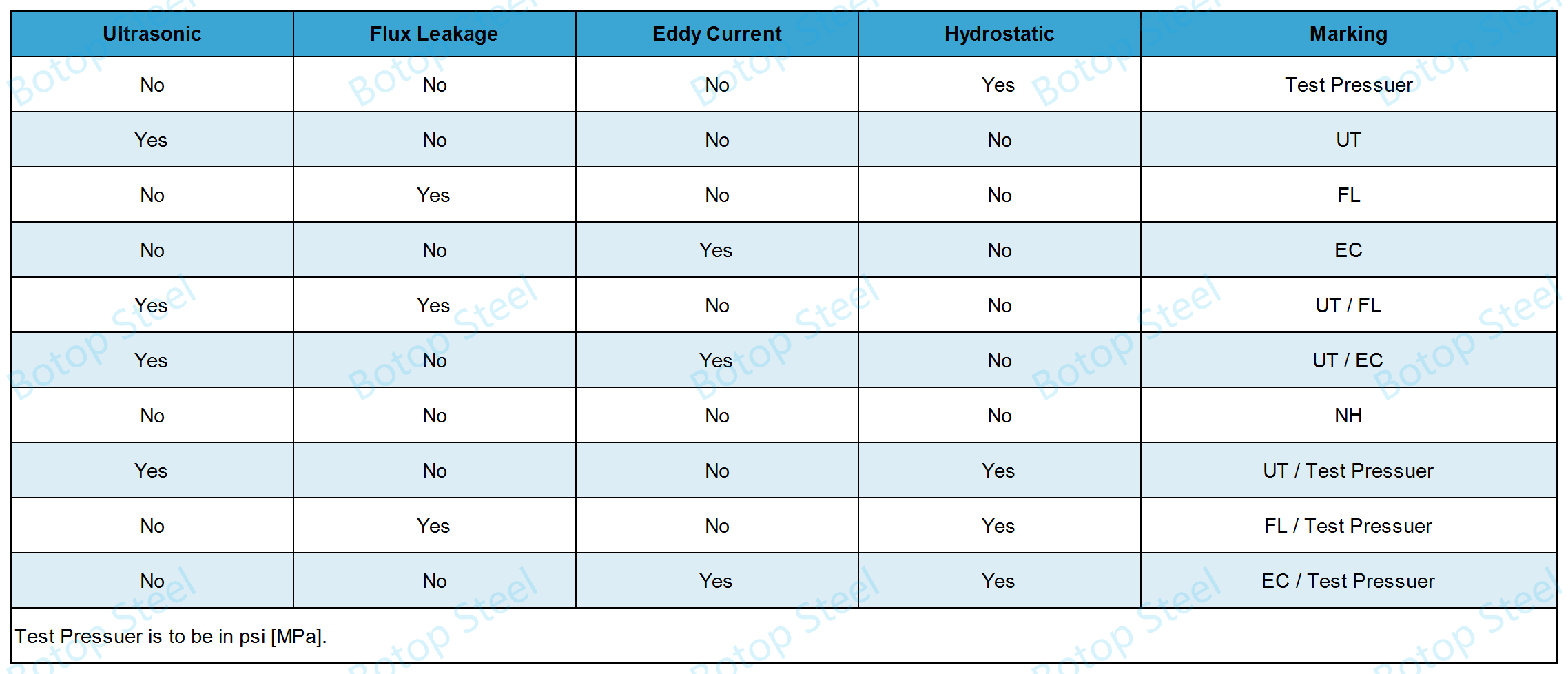

Alamun don matsa lamba na hydrostatic da gwajin mara lalacewa a cikin tebur da ke ƙasa yakamata a haɗa su.

Idan aka gyara bututu ta hanyar walda, za a yi masa alama "WR".

p91 Ya kamata a nuna nau'in (Nau'in 1 ko Nau'in 2).

TS EN 10216-2: X10CrMoVNb9-1 ko 1.4903;

JIS G 3462: STPA 28;

GB/T 5310: 10Cr9Mo1VNb;

Waɗannan kwatankwacin suna da kusanci sosai a cikin abun ciki na sinadarai da kaddarorin inji zuwa ASTM A335 P91.

Material: ASTM A335 P91 bututu mara nauyi;

OD: 1/8" - 24";

WT: daidai daBayanan Bayani na B36.10bukatun;

JadawalinSCH10, SCH20, SCH30,SCH40, SCH60,Farashin SCH80, SCH100, SCH120, SCH140 da SCH160;

Ganewa:STD (misali), XS (ƙarin-ƙarfi), ko XXS (mai ƙarfi biyu);

Keɓancewa: Hakanan ana samun nau'ikan bututun da ba daidai ba, ana samun girma na musamman akan buƙata;

Tsawon: Tsawon tsayi na musamman da bazuwar;

Takaddun shaida na IBR: Za mu iya tuntuɓar ƙungiyar dubawa ta ɓangare na uku don samun takaddun shaida na IBR bisa ga bukatun ku, ƙungiyoyin binciken haɗin gwiwarmu sune BV, SGS, TUV, da dai sauransu;

ƘarsheƘarshen lebur, beveled, ko haɗakar ƙarshen bututu;

Surface: Haske mai haske, fenti, da sauran kariya na wucin gadi, cire tsatsa da gogewa, galvanized da filastik mai rufi, da sauran kariya na dogon lokaci;

Shiryawa: Katako harka, karfe bel ko karfe waya shiryawa, roba ko baƙin ƙarfe bututu kare karshen, da dai sauransu.