ASTM A519tubing za a kerarre ta hanyar tsari mara kyau kuma dole ne a gama zafi ko sanyi kamar yadda aka ƙayyade.

Don bututu masu zagaye da diamita na waje wanda bai wuce 12 3/4 in (325 mm).

Hakanan ana iya kera bututun ƙarfe a murabba'i, murabba'i, ko wasu siffofi kamar yadda ake buƙata.

Ana iya rarraba ASTM A519 bisa ga kayan ƙarfe:Karfe Karfeda Alloy Karfe.

Karfe Karfean kasu kashiLow Carbon MT(Tubing Mechanical),Babban Karfe KarfekumaDesulfurized ko Rephosphored, ko duka biyunKarfe Karfe, don dacewa da buƙatun masana'antu daban-daban da yanayin aikace-aikacen.

Lokacin da ba a ƙayyade maki ba, masana'antun suna da zaɓi na bayarwaMT1015 ya da MTX1020maki.

Diamita na waje: 13.7 - 325 mm;

Kaurin bango: 2-100mm.

Ana iya yin ƙarfe ta kowane tsari.

Ana iya yin jifa da ƙarfe a cikin ingots ko ƙila a yi jifa.

Tubes za a yi ta atsari mara kyaukuma za a yi zafi-ƙare ko sanyi, kamar yadda aka ƙayyade.

Bututun ƙarfe maras sumul bututu ne waɗanda ba su da welded ɗin gaba ɗaya.

Bututun da aka gama sanyiana ba da shawarar don manyan buƙatu akan daidaiton girman da ingancin saman.

Babban damuwa shine ingancin farashi da taurin kayan,zafi-ƙare karfe bututuna iya zama zaɓi mafi dacewa.

Na gaba shine tsarin samar da bututun ƙarfe mara nauyi mai zafi.

Mai ƙera ƙarfe zai bincika zafin kowane ƙarfe don tantance adadin abubuwan da aka ƙayyade.

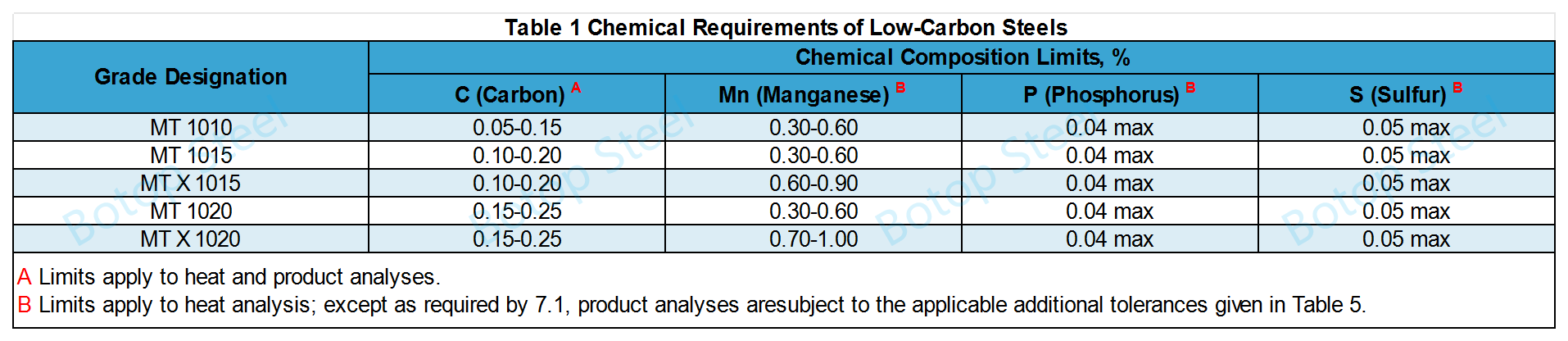

Tebur 1 Abubuwan Buƙatun Sinadarai na Ƙarƙashin Carbon Karfe

Karfe mai laushi karfe ne mai abun ciki na carbon yawanci baya wuce 0.25%. Saboda ƙananan abun ciki na carbon, wannan ƙarfe yana da mafi kyawun ductility da rashin ƙarfi kuma ba shi da wuya kuma yana da ƙarfi idan aka kwatanta da babban karfen carbon.

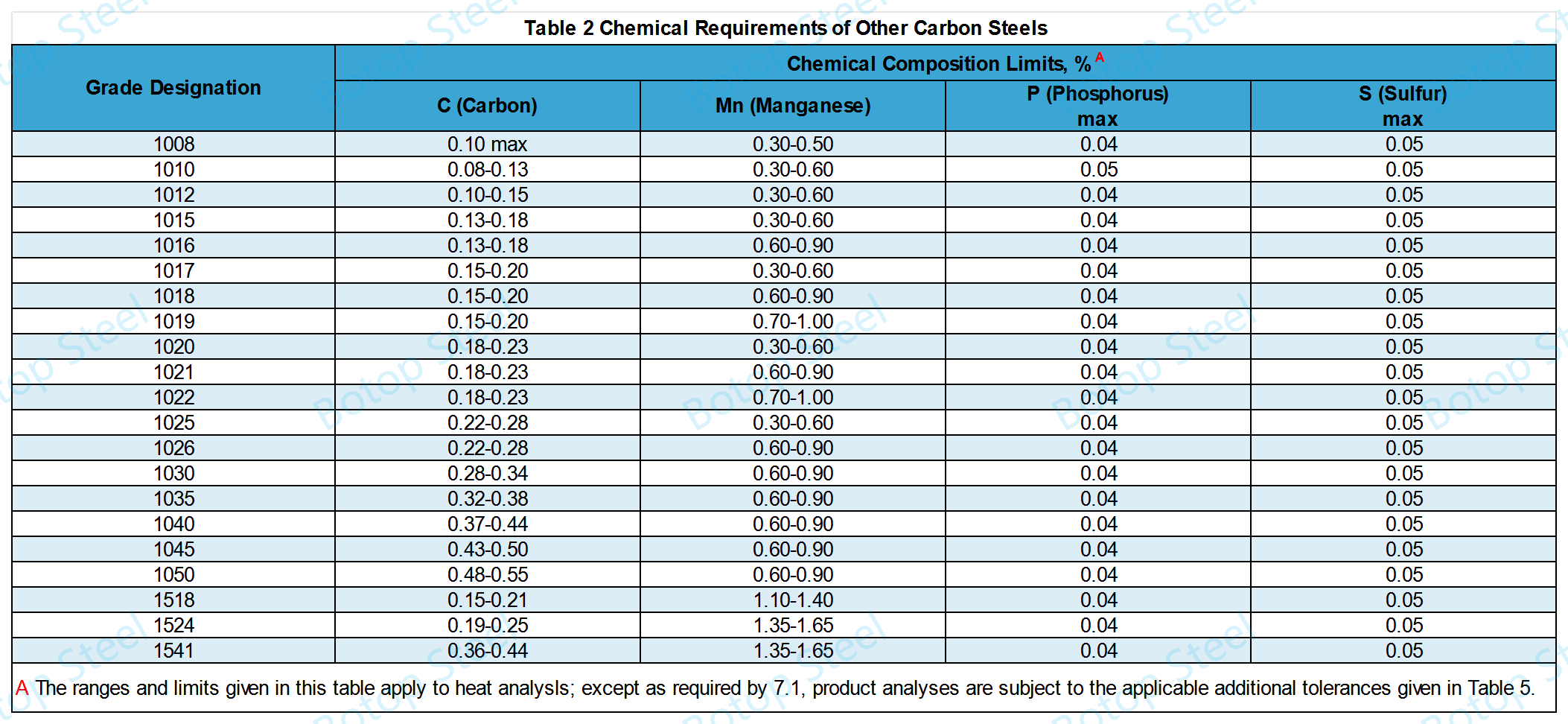

Tebur 2 Abubuwan Buƙatun Sinadarai na Sauran Karfe Carbon

Matsakaicin karfen carbon: Ya ƙunshi tsakanin 0.25% da 0.60% carbon, suna ba da ƙarfin ƙarfi da ƙarfi kuma suna buƙatar magani mai zafi don inganta kaddarorin.

High carbon karfe: Ya ƙunshi tsakanin 0.60% da 1.0% ko fiye da carbon, kuma yana ba da ƙarfi da ƙarfi sosai, amma ƙananan tauri.

Tebur 3 Abubuwan Buƙatun Sinadarai don Alloy Karfe

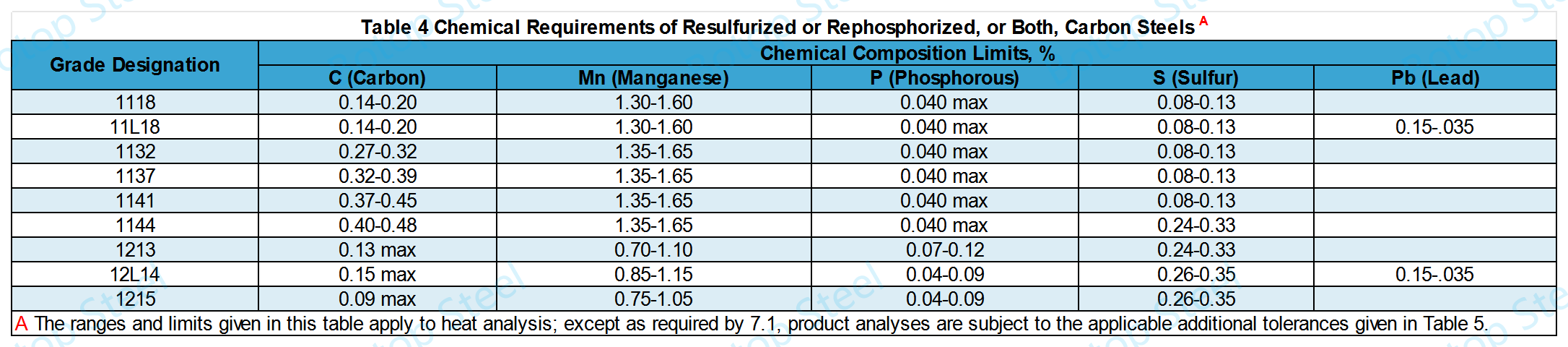

Tebura 4 Abubuwan Bukatun Sinadarai na Resulfurized ko Sake Fada, ko Dukansu, Karfe na Carbon

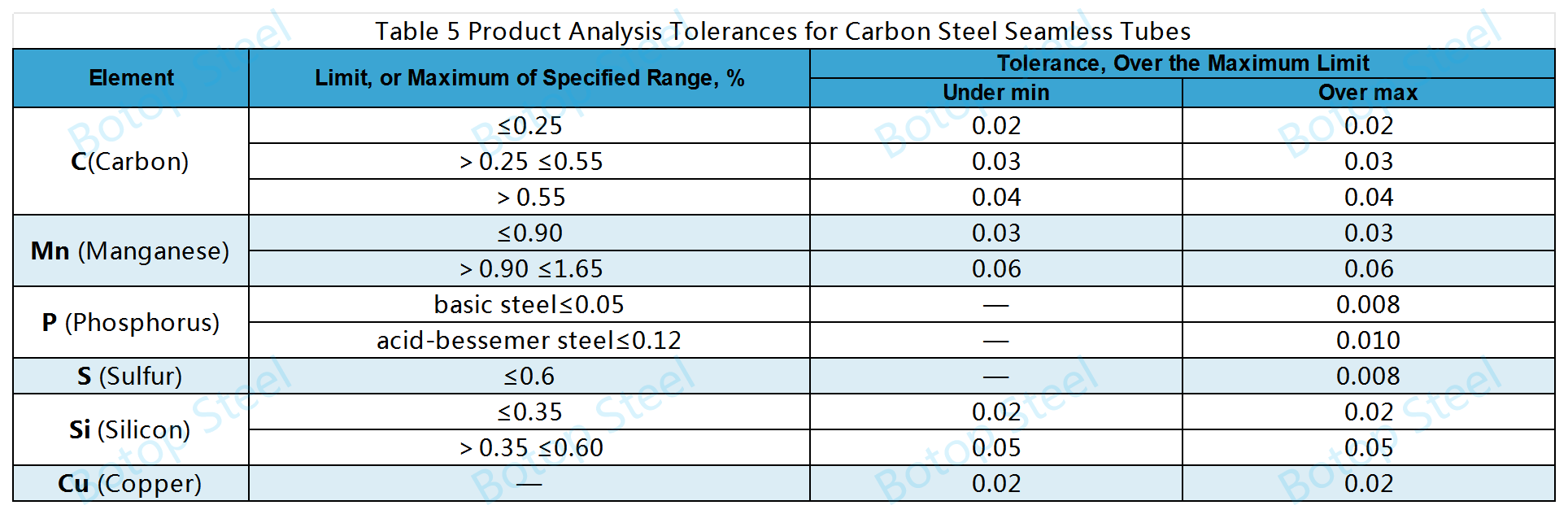

TABLE 5 Hakuri Hakuri Sama da Ƙarƙashin Ƙarƙashin Kewaye ko Iyaka

Ya kamata a nemi mai ƙira don bincika samfurin idan an buƙata ta hanyar oda.

ASTM A519 ya ƙunshi abubuwan gwaji masu zuwa:

Gwajin Tauri; Gwajin tashin hankali; Gwajin mara lalacewa; Gwajin walƙiya; Tsaftar Karfe da Tauri.

| Matsayin Darajoji | Nau'in bututu | Yanayi | Ƙarfin Ƙarfi | Ƙarfin Haɓaka | Tsawaita cikin 2in.[50mm],% | Rockwell, Hardness B Scale | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Karfe Karfe | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Karfe Karfe | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Karfe Karfe | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Karfe Karfe | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Karfe Karfe | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized ko Rephosphorized, ko duka biyu, Karfe Karfe | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized ko Rephosphorized, ko duka biyu, Karfe Karfe | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Alloy Karfe | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Alloy Karfe | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Hot Rolled, CW-Cold Worked, SR-Stress Relieved, A-Annealed da N-Normalized.

Haƙuri a Waje Diamita

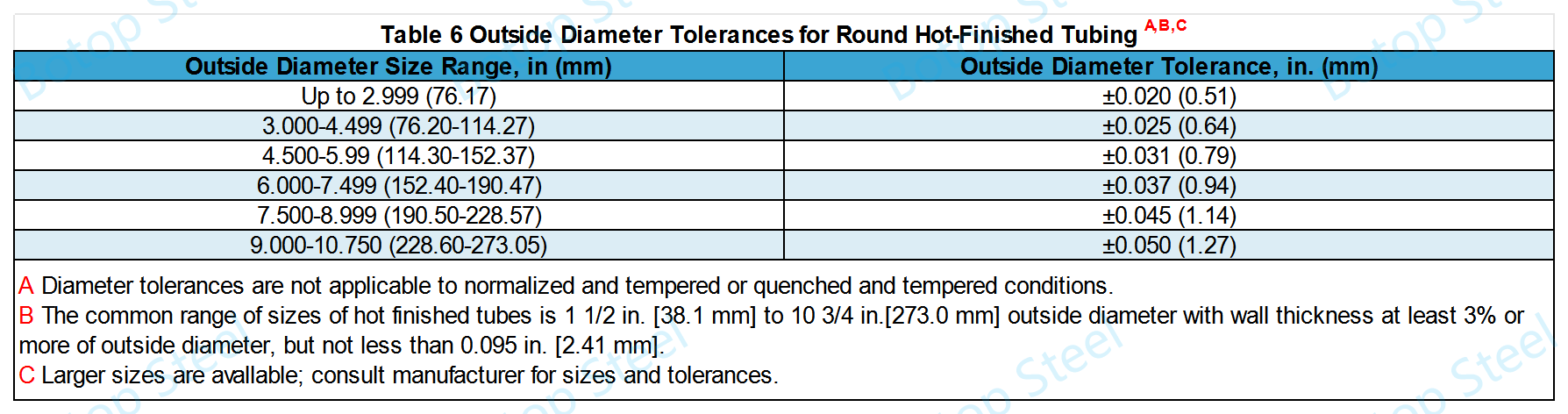

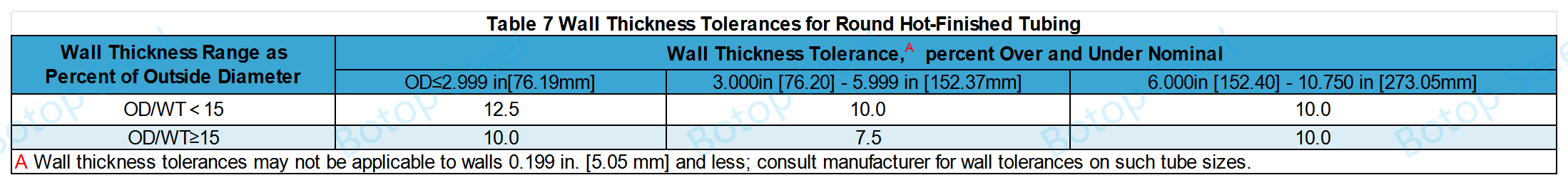

Tebur 6 Hakuri na Diamita na Wajedon Zagaye-Zafi-Gama Tubin

Tebur 12 Hakuri na Diamita na Waje donTuba mara kyau a ƙasa

| Girman Diamita, in.[mm] | Haƙuri na Diamita na Waje don Girma da Tsawon Da Aka Ba, a cikin. [mm] | |||

| Ƙarshe | Karkashin | Ƙarshe | Karkashin | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] lokacin L≤16ft[4.9m] | 0.000 | 0.004 [0.10] lokacin L >16ft[4.9m] | 0.000 |

| 1 1/4 [31.8] OD ≤2[50.8] | 0.005 [0.13] lokacin L≤16ft[4.9m] | 0.000 | 0.006 [0.15] lokacin L >16ft[4.9m] | 0.000 |

| 2 [50.8] OD ≤3 [76.2] | 0.005 [0.13] lokacin L≤12ft[3.7m] | 0.000 | 0.006 [0.15] lokacin L≤16ft[4.9m] | 0.000 |

| 3 [76.2] OD ≤4 [101.6] | 0.006 [0.15] lokacin L≤12ft[3.7m] | 0.000 | 0.006 [0.15] lokacin L≤16ft[4.9m] | 0.000 |

Hakuri da Kaurin bango

Tebur 7 Hakuri da Kaurin bangodon Zagaye-Zafi-Gama Tubin

Tebur 10 Hakuri da Kaurin bangodon Zagaye-zanen Tushen Sanyi

| Kaurin bango kamar Kashi na Diamita na Waje | Hakurin Hakuri Kan bango da Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin bango % | |

| OD≤1.499in[38.07mm] | OD≥1.500 a cikin [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT:25 | 12.5 | 10.0 |

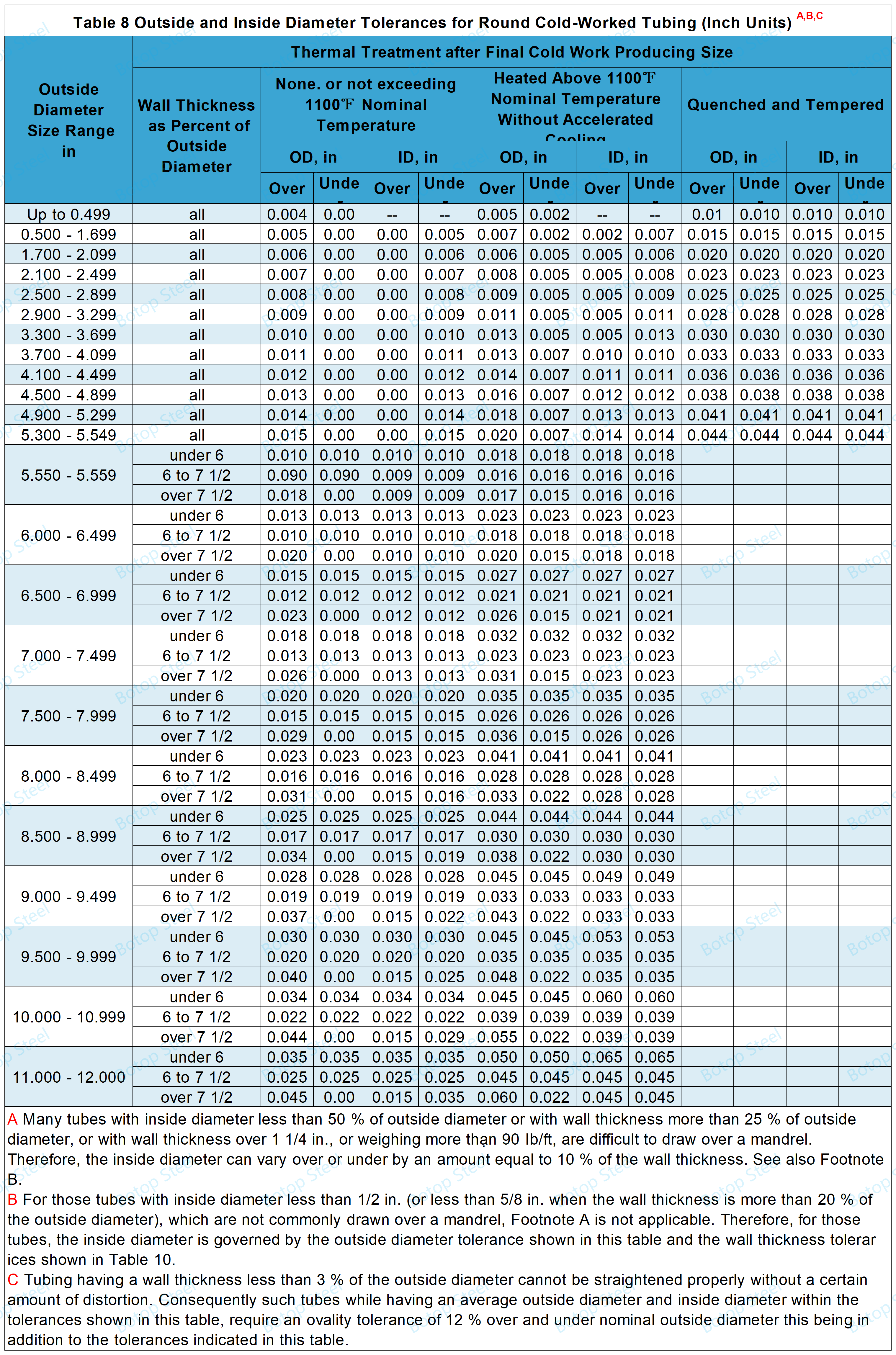

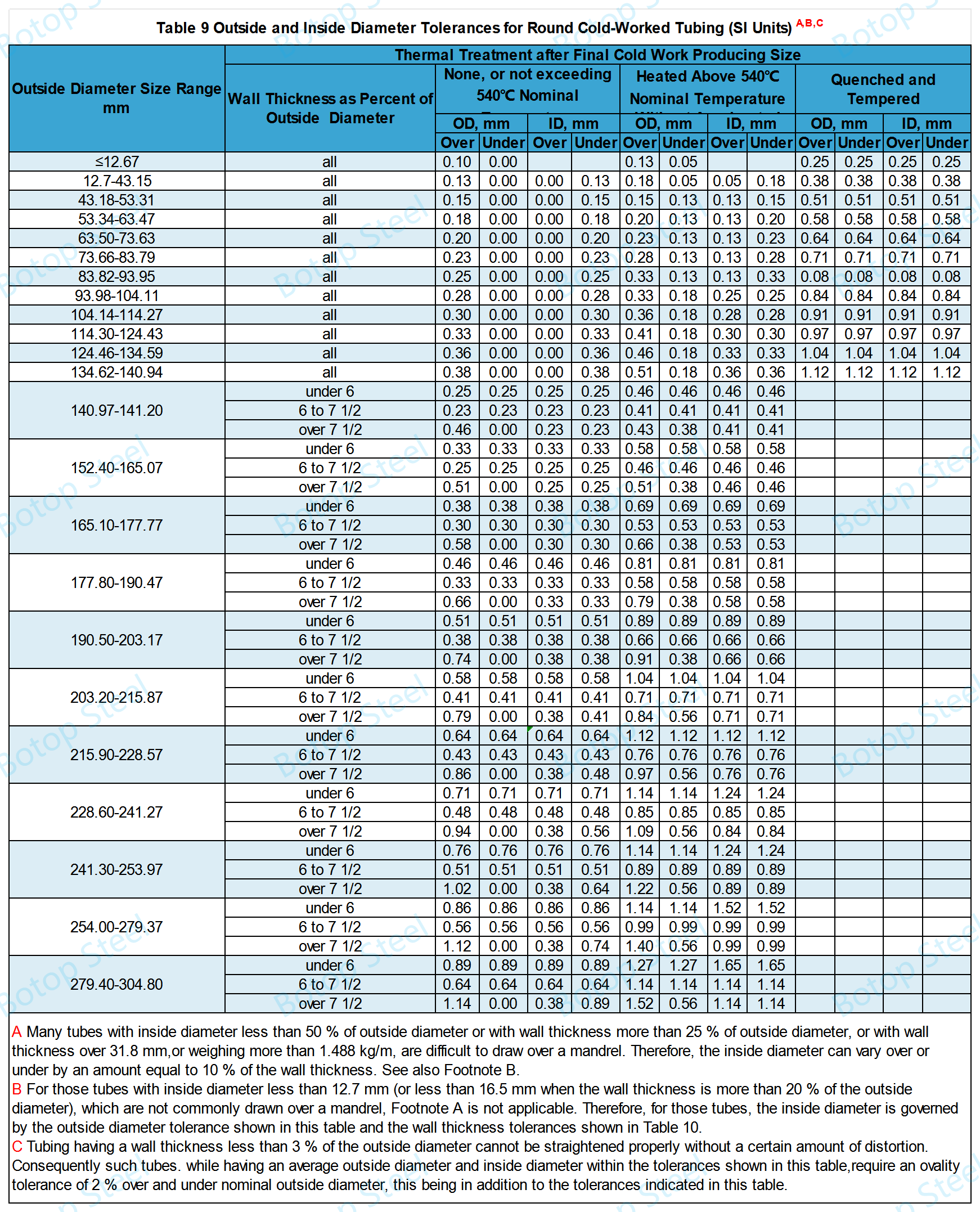

Haƙuri na Diamita na Waje da Ciki

Tebur 8 Waje da Hakurin Ciki donZagaye Mai Aiki Mai Sanyi (Raka'a Inci)

Tebur 9 Waje da Haƙuri na Cikidon Rukunin Sanyi Mai Aiki (Raka'a SI)

Waje Diamita da Haƙurin Kaurin bango

Tebur 11 Waje Diamita da Haƙurin bangoDon Rumbun Karfe mara Tsaftataccen Juyi

| Ƙayyadadden Girman Wajen Diamita, in. [mm] | Diamita na Waje, in. [mm] | Kaurin bango, % |

| 6 3/4 [171.4] | ± 0.005 [0.13] | ± 12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ± 0.010 [0.25] | ± 12.5 |

Haƙuri Tsawon

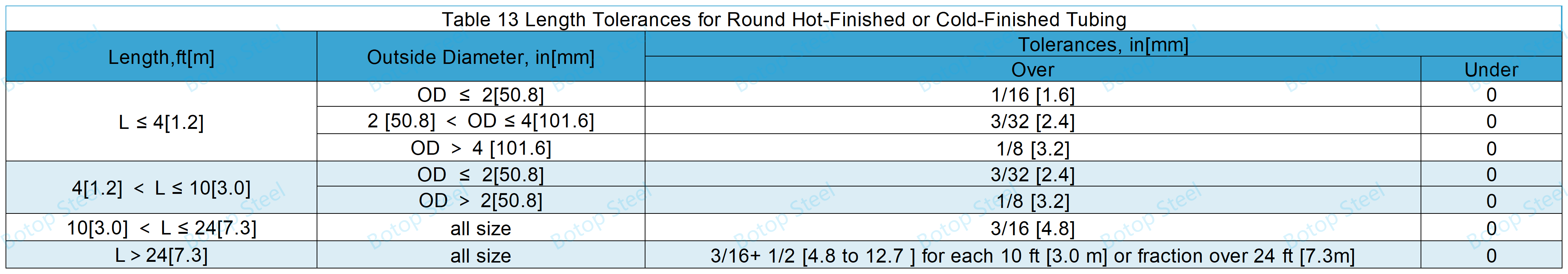

Tebur 13 Haƙuri Tsawon Tsawondon Zagaye-Zafi-Gama ko Sanyi-Gama Tubing

Hakuri Madaidaici

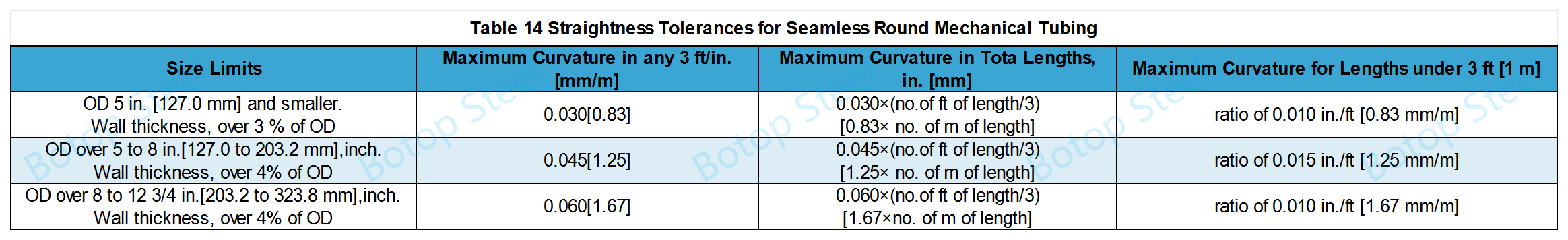

Tebur 14 Hakuri Madaidaicidon Bututun Injiniyan Zagaye mara sumul

Ya kamata a rufe bututun da fim ɗin mai kafin yin gyare-gyare don hana tsatsa.

Hakanan ana iya shafa man rigakafin tsatsa a saman ciki da waje na bututu.

Jirgin sama da sararin samaniya: ƙera abubuwa masu mahimmanci kamar injunan jirgin sama da tsarin tallafin jiragen sama.

Masana'antar makamashi: hakowa kayan aiki da high-matsi tukunyar jirgi bututu masana'antu.

Masana'antu da kayan aiki: Mahimman abubuwan da suka ƙunshi nau'ikan injunan masana'antu da kayan aiki.

Kayan wasanni: Kera manyan firam ɗin kekuna da sauran wuraren wasanni.

Gine-gine da gine-gine: abubuwan tallafi na tsari don gine-gine da aikace-aikace a cikin matsanancin yanayi.

TS EN 10297-1: E355, 25CrMo4, 42CrMo4, da sauransu.

2. DIN 1629: St52, St37.4, da dai sauransu Yawancin lokaci ana amfani da su don dalilai na injiniya da tsarin, waɗannan suna kama da ma'aunin ƙarfe mai laushi a cikin ASTM A519.

3. JIS G3445: STKM13A, STKM13B, da dai sauransu Waɗannan su ne bututun ƙarfe na carbon da aka yi amfani da su don dalilai na injiniya da tsarin.

4. BS 6323: CFS 3, CFS 4, CFS 8, da dai sauransu Waɗannan ba sumul da welded karfe shambura don mota, inji, da kuma janar injiniya dalilai.

5. GB/T 8162: 20 #, 45#, 40Cr, 20CrMo, da dai sauransu. Bututun ƙarfe mara nauyi da bututu don tsarin gabaɗaya da tsarin injiniya.

6. ISO 683-17: 100Cr6, da sauransu, waɗanda aka fi amfani da su a cikin masana'anta, kuma ana iya samun aikace-aikacen a cikin injiniyan injiniya kuma yana da aikace-aikace iri ɗaya zuwa wasu ƙarfe na ƙarfe na ASTM A519.

Lokacin zabar wani abu makamancin haka, yana da mahimmanci a koma zuwa ga cikakken abun da ke tattare da sinadarai da ƙayyadaddun kayan aikin injiniya don tabbatar da cewa kayan da aka zaɓa zai cika buƙatun aiki na takamaiman aikace-aikacen.

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun ƙarfe na carbon a Arewacin kasar Sin, wanda aka sani don kyakkyawan sabis, samfurori masu inganci, da cikakkun mafita. Kamfanin yana ba da nau'ikan bututun ƙarfe na carbon da samfuran da ke da alaƙa, waɗanda suka haɗa da marasa ƙarfi, ERW, LSAW, da bututun ƙarfe na SSAW, da kuma cikakken jeri na kayan aikin bututu da flanges.

Kayayyakinsa na musamman sun haɗa da gawa mai daraja da austenitic bakin karafa, waɗanda aka keɓance don biyan buƙatun ayyukan bututun.