ASTM A53 ERWkarfe bututu neNau'in Ea cikin A53 ƙayyadaddun, kerarre ta hanyar juriya walda tsari, kuma yana samuwa a duka Grade A da Grade B maki.

Ya dace da farko don aikace-aikacen inji da matsa lamba kuma ana amfani da shi azaman babban manufa don isar da tururi, ruwa, gas, da iska.

A abũbuwan amfãni daga ERW karfe bututu, kamarlow farashinkumahigh yawan aiki, sanya shi kayan zaɓi don aikace-aikacen masana'antu da yawa.

Botop Karfewani babban ingancin welded carbon karfe bututu manufacturer da kuma maroki daga kasar Sin, da kuma wani m karfe bututu stockist, ba ku da fadi da kewayon karfe bututu mafita!

Kayan mu yana cike da kyau kuma muna iya biyan buƙatun abokan cinikinmu da sauri don girma da yawa.

ASTM A53/A53M ya hada da nau'ikan da maki masu zuwa:

Nau'in E: Electric-resistance-welded, maki A da B.

Nau'in S: Mara lafiya, maki A da B.

Nau'in F: Furnace-butt-welded, ci gaba da welded maki A da B.

Nau'in EkumaNau'in Snau'ikan bututu ne guda biyu da ake amfani da su sosai. Da bambanci,Nau'in Fyawanci ana amfani dashi don ƙananan bututun diamita. Saboda ci gaban fasahar walda, ana amfani da wannan hanyar kera ƙasa akai-akai.

Matsakaicin Suna: DN 6 - 650 [NPS 1/8 - 26];

Diamita na waje: 10.3 - 660 mm [0.405 - 26 in.];

Kaurin bango da sigogin nauyin bututun ƙarfe:

Za a iya kallon bututun da ba su da ƙarfi a cikin Tebur X2.2;

Za a iya kallon bututun da aka zare da haɗe-haɗe a cikin Tebur X2.3.

ASTM A53 kuma yana ba da izinin samar da bututu tare da wasu girma idan bututun ya cika duk sauran buƙatun wannan ƙayyadaddun.

ERWAna amfani da ko'ina don kera zagaye, murabba'i, da carbon rectangular da ƙananan bututun ƙarfe na ƙarfe.

Abinda ke biyo baya shine tsarin samarwa don samarwazagaye ERW karfe bututu:

a) Shirye-shiryen kayan aiki: Na farko abu yawanci zafi-birgima karfe coils. Waɗannan muryoyin ana fara baje kolin su kuma an yanke su zuwa faɗin da ake buƙata.

b) Samuwar: A hankali, ta hanyar jerin nadi, an samar da tsiri zuwa tsarin tubular da'irar da aka bude. A lokacin wannan tsari, gefuna na tsiri suna kusa da juna a hankali don shirye-shiryen walda.

c) Walda: Bayan kafa tsarin tubular, gefuna na tsiri na karfe suna zafi da juriya na lantarki a yankin waldawa. Ana amfani da madaidaicin mita mai girma ta cikin kayan, kuma ana amfani da zafin da aka haifar da juriya don zafi da gefuna zuwa wurin narkewa, sa'an nan kuma an haɗa su tare da matsa lamba.

d) Tashin hankali: Bayan waldawa, ana cire burbushin walda (ƙarfe da yawa daga walda) daga ciki da wajen bututun don tabbatar da tsayayyen wuri a cikin bututun.

e) Girma da tsayin saitin: Bayan an gama waldawa da cirewa, ana ratsa bututun ta na'ura mai ƙima don gyaran ƙima don tabbatar da cewa sun cika ainihin buƙatun diamita da zagaye. Ana yanke bututun zuwa tsayin da aka ƙaddara.

f) Dubawa da gwaji: Bututun ƙarfe zai yi gwajin gwaji da dubawa sosai, gami da gwajin ultrasonic, gwajin hydrostatic, da dai sauransu, don tabbatar da cewa ingancin bututun ƙarfe ya dace da ƙa'idodi da ƙayyadaddun bayanai.

g) Maganin saman: A ƙarshe, ana iya yin amfani da bututun ƙarfe don ƙarin jiyya irin su galvanizing mai zafi mai zafi, zanen, ko wasu jiyya na saman don samar da ƙarin kariya ta lalata da kayan kwalliya.

Welds a Nau'in E ko Nau'in F Grade Bbututu za a yi zafi-magani ko akasin haka a bi da bayan walda sabõda haka, untempered martensite.

Zafin zafin zafin zafi ya zama aƙalla1000°F [540°C].

Lokacin da bututu ya faɗaɗa sanyi, haɓakar ba zai wuce ba1.5%na ƙayyadadden diamita na waje na bututu.

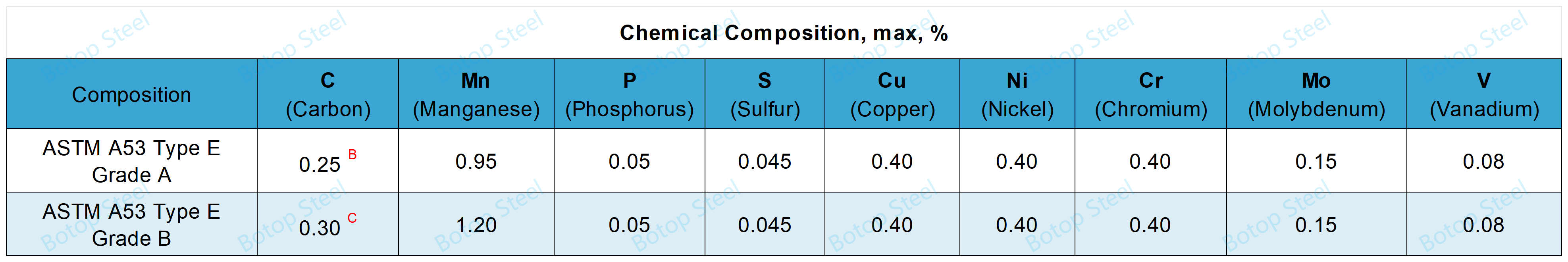

AAbubuwa biyarCu, Ni, Cr, Mo, kumaVtare kada ya wuce 1.00%.

BGa kowane raguwa na 0.01 % ƙasa da ƙayyadadden ƙimar carbon, haɓakar 0.06 % na manganese sama da ƙayyadadden ƙayyadadden ƙima za a ba da izini har zuwa iyakar 1.35 %.

CGa kowane raguwa na 0.01 % ƙasa da ƙayyadadden iyakar carbon, haɓakar 0.06 % na manganese sama da iyakar ƙayyadaddun za a ba da izini har zuwa iyakar 1.65 %.

Dukiyar Tensile

| Jerin | Rabewa | Darasi A | Darasi B |

| Ƙarfin ɗaure, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Ƙarfin bayarwa, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Tsawaitawa a cikin mm 50 [2 in.] | Lura | A,B | A,B |

Note A: Matsakaicin tsayin daka a cikin 2 a [50 mm] za a ƙaddara ta hanyar ma'auni mai zuwa:

e = 625,000 [1940] A0.2/U0.9

e = ƙaramar haɓakawa a cikin 2 a cikin ko 50 mm a cikin kashi, taso zuwa kashi mafi kusa

A = mafi ƙarancin 0.75 in2[500 mm2] da yankin giciye na samfurin gwajin tashin hankali, ana ƙididdige su ta amfani da ƙayyadaddun diamita na waje na bututu, ko faɗin ƙima na samfurin gwajin tashin hankali da ƙayyadadden kauri na bangon bututu, tare da ƙididdige ƙimar zuwa mafi kusa 0.01 in2 [1 mm2].

U= ƙayyadaddun ƙayyadaddun ƙarfin ƙarfi, psi [MPa].

Bayanin B: Duba Tebu X4.1 ko Tebu X4.2, duk abin da ya dace, don ƙananan ƙimar haɓakawa waɗanda ake buƙata don haɗuwa daban-daban na girman samfurin gwajin tashin hankali da ƙayyadaddun ƙarancin ƙarfi.

Lanƙwasa Gwajin

Don bututu DN ≤ 50 [NPS ≤ 2], isasshen tsayin bututu zai iya zama mai lankwasa sanyi ta hanyar 90 ° a kusa da mandrel na cylindrical, diamita wanda shine sau goma sha biyu ƙayyadaddun diamita na bututu, ba tare da haɓaka fasa a kowane yanki ba kuma ba tare da buɗe walda ba.

Biyu-karin-ƙarfi(jin nauyi:XXS) bututu sama da DN 32 [NPS 1 1/4] baya buƙatar yin gwajin lanƙwasa.

Gwajin Lalacewa

Za a yi gwajin ƙwanƙwasa akan bututun walda sama da DN 50 a cikin ƙarin nauyi mai ƙarfi (XS) ko mai sauƙi.

Ya dace da Nau'in E, Grade A da B; da Bututun Nau'in F, Grade B.

Ba dole ba ne a gwada bututun ƙarfe marasa ƙarfi.

Lokacin Gwaji

Don kowane nau'in nau'in S, Nau'in E, da Nau'in F Gilashin bututun B, za a kiyaye matsa lamba na gwaji don aƙalla 5s.

Za a yi amfani da gwajin hydrostatic, ba tare da yayyo ba ta cikin kabu ko jikin bututu.

Matsalolin Gwaji

Bututu mai tsayiza a gwada hydrostatically zuwa matsa lamba da aka bayar a cikiTable X2.2,

Bututu mai zare-da-haɗe-haɗeza a gwada hydrostatically zuwa matsa lamba da aka bayar a cikiTable X2.3.

Don bututun ƙarfe tare da DN ≤ 80 [NPS ≤ 80], gwajin gwajin ba zai wuce 17.2MPa ba;

Don bututun ƙarfe tare da DN >80 [NPS:80], gwajin gwajin ba zai wuce 19.3MPa ba;

Za'a iya zaɓar matsi mafi girma na gwaji idan akwai buƙatun injiniya na musamman, amma wannan yana buƙatar tattaunawa tsakanin masana'anta da abokin ciniki.

Alama

Idan an gwada bututun ta hanyar hydrostatically, alamar ya kamata ya nunagwajin gwaji.

Abubuwan buƙatu masu zuwa sun shafi Nau'in E da Nau'in F Grade B Pipe.

Bututu mara nauyi yana da ƙarin buƙatun waɗanda ba a tattauna su a cikin wannan takaddar ba.

Hanyoyin Gwaji

Bututun da aka samar ta hanyar haɓakawa da injuna ba zafi ba: DN ≥ 50 [NPS ≥ 2], dawaldaa kowane sashe na bututu yana buƙatar wucewa gwajin lantarki mara lalacewa, kuma hanyar gwajin yana buƙatar zama daidai daE213, E273, E309 ko E570misali.

Bututun ERW da aka samar ta injin mai rage diamita mai zafiDN ≥ 50 [NPS ≥ 2]Kowane sashena bututu za a bincika gaba ɗaya ta hanyar gwajin lantarki mara lalacewa, wanda zai kasance daidai daE213, E309, kuE570ma'auni.

Lura: Hot Stretch Expansion Diamita Machine inji ce da ke ci gaba da shimfiɗawa da matse bututun ƙarfe ta rollers a yanayin zafi don daidaita diamita da kaurin bango.

Alama

Idan bututun da aka yi wa gwajin mara lalacewa, ya zama dole a nunaNDEa kan alamar.

Mass

± 10%.

Pipe DN ≤ 100 [NPS ≤ 4], an auna shi azaman tsari.

Bututu DN> 100 [NPS> 4], an auna su guda ɗaya.

Diamita

Don bututu DN ≤40 [NPS≤ 1 1/2], OD bambancin ba zai wuce ± 0.4 mm [1/64 in.].

Don bututu DN ≥50 [NPS> 2], OD bambancin ba zai wuce ± 1%.

Kauri

Matsakaicin kaurin bango ba zai zama ƙasa da ƙasa ba87.5%na ƙayyadadden kauri na bango.

ya fi nauyi fiye da ƙarfi (XS).:

a) bututu mai ƙarewa: 3.66 - 4.88m [12 - 16 ft], Bai wuce 5% na jimlar adadin ba.

b) Tsawon bazuwar ninki biyu: ≥ 6.71 m [22 ft], Matsakaicin matsakaicin tsayi na 10.67m [35 ft].

c) Tsawon bazuwar guda ɗaya: 4.88 -6.71m [16 - 22 ft], bai wuce 5 % na jimlar tsayin zaren da aka tanada ba kasancewar masu haɗin gwiwa (guda biyu an haɗa su tare).

Maɗaukaki mai ƙarfi (XS) nauyi ko nauyi: 3.66-6.71 m [12 - 22 ft], bai wuce 5% jimlar bututu 1.83 - 3.66 m [6 - 12 ft].

Don ASTM A53 karfe bututu gama yana samuwa a baki ko galvanized.

Baki: Karfe tubing ba tare da wani surface jiyya, yawanci sayar kai tsaye bayan da masana'antu tsari, ga wadanda aikace-aikace inda babu wani ƙarin lalata juriya da ake bukata.

Ya kamata bututun galvanized ya dace da abubuwan da suka dace.

Tsari

Za a shafe zinc a ciki da waje ta hanyar tsomawa mai zafi.

Albarkatun kasa

Zinc ɗin da aka yi amfani da shi don sutura ya zama kowane nau'i na zinc wanda ya dace da buƙatun ƘayyadaddunFarashin ASTM B6.

Bayyanar

Bututun galvanized ba zai zama maras rufaffiyar wuraren da ba a rufe ba, kumfa na iska, madaidaitan ma'auni, da ƙaƙƙarfan haɗe-haɗe. Kullun, dunƙulewa, globules, ko manyan adadin ma'adinan zinc waɗanda ke tsoma baki tare da abin da aka yi niyyar amfani da su ba za a ba su izini ba.

Galvanized Coating Weight

Za a ƙayyade ta gwajin kwasfa bisa ga hanyar gwaji ASTM A90.

Nauyin sutura kada ya zama ƙasa da 0.55 kg/m² [1.8 oz/ft²].

ASTM A53 ERW karfe bututuyawanci ana amfani da shi a cikin ƙananan aikace-aikacen matsa lamba kamar injiniyan birni, gini, da bututun tsarin injiniya. Yanayin amfani na yau da kullun sun haɗa da isar da ruwa, tururi, iska, da sauran ruwa mara ƙarfi.

Tare da kyakkyawan walƙiya, sun dace don ƙirƙirar ayyukan da suka haɗa da murɗa, lankwasa, da flanging.