EN 10219 S275J0H da S275J2HTS EN 10219 sassa ne masu walƙiya masu sanyi waɗanda aka yi da ƙarfe mara ƙarfi kamar EN 10219.

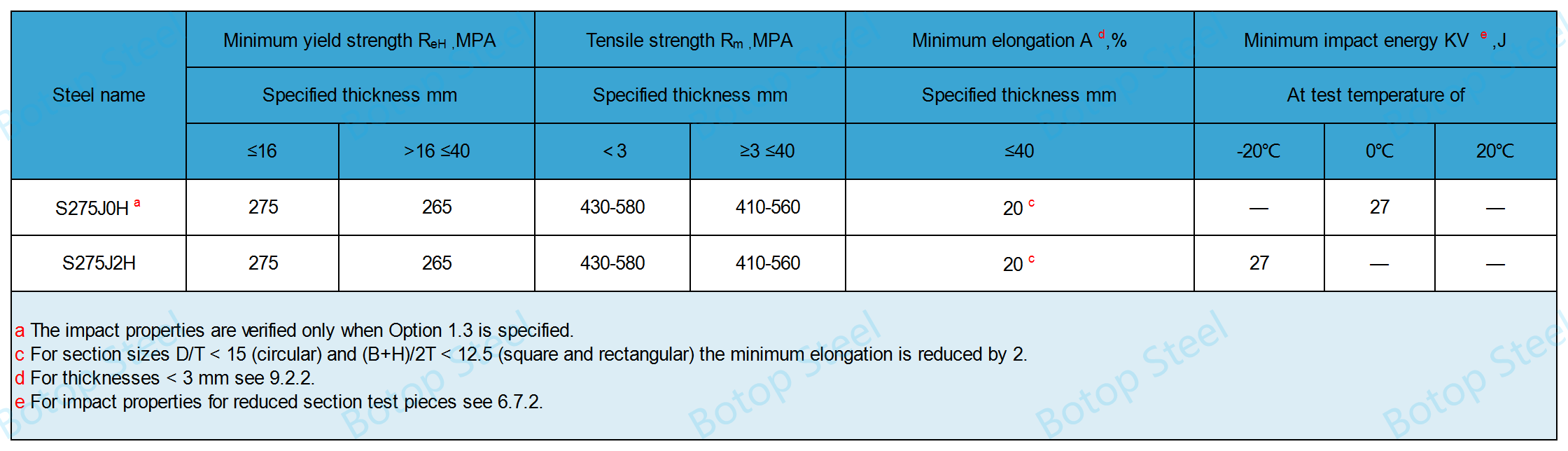

Dukansu suna da ƙaramin ƙarfin amfanin gona na 275MPa (kaurin bango ≤16mm). Babban bambanci yana cikin kaddarorin tasiri: S275J0H yana da ƙaramin ƙarfin tasiri na 27 J a 0 ° C, yayin da S275J2H yana da ƙaramin ƙarfin tasiri na 27 J a -20 ° C.

Ya dace da aikace-aikace a cikin gine-gine da tsarin injiniya waɗanda ke ƙarƙashin nauyin nauyi.

BS EN 10219 shine Matsayin Turai EN 10219 wanda Burtaniya ta karɓi.

Wall kauri ≤40mm, Outer diamita ≤2500mm.

CFCHS gajarta ce ga Sashin Ramin Da'ira na Cold-Formed Circular Hollow.

Ma'auni na EN 10219 ya ƙunshi nau'ikan nau'ikan nau'ikan ƙarfe masu fa'ida, gami da zagaye, murabba'i, rectangular, da oval, don dacewa da buƙatun amfani daban-daban.

Botop Karfeya ƙware wajen samar da bututun ƙarfe na zagaye mara tushe a cikin nau'ikan nau'ikan girma da tsari don dacewa da aikace-aikacen masana'antu da yawa, tabbatar da cewa za a iya biyan takamaiman bukatun abokan cinikinmu.

Tun lokacin da aka kafa shi a cikin 2014.Botop Karfeya zama babban mai samar da bututun ƙarfe na carbon a Arewacin kasar Sin, wanda aka sani don kyakkyawan sabis, samfurori masu inganci, da cikakkun mafita.

Kamfanin yana ba da nau'ikan bututun ƙarfe na carbon da samfuran da ke da alaƙa, gami daSMLS, ERW, LSAW, kumaSSAWkarfe bututu, kazalika da cikakken jeri na bututu kayan aiki da flanges. Kayayyakinsa na musamman sun haɗa da gawa mai daraja da austenitic bakin karafa, waɗanda aka keɓance don biyan buƙatun ayyukan bututun.

Muna sa ran kafa dangantakar haɗin gwiwa tare da ku da ƙirƙirar makoma mai nasara tare.

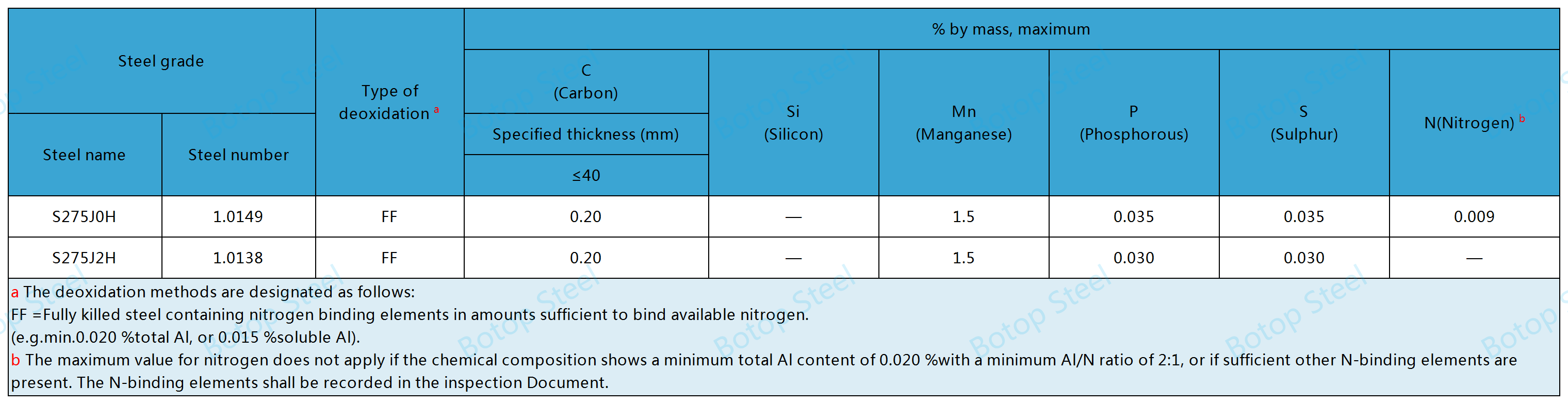

Raw karfe domin kera na sanyi-kafa m sassa an deoxidized kuma dole ne saduwa da takamaiman yanayin bayarwa.

Abubuwan da suka dace don S275J0H da S275J2H suneFF(Karshen da aka kashe cikakke mai ɗauke da abubuwan daurin nitrogen a cikin adadin da ya isa ya ɗaure samuwan nitrogen (misali min.0,020 % jimlar Al ko 0,015 % mai narkewa Al)).

Yanayin isarwa: Mirgina ko na al'ada/madaidaita birgima (N) don karafan JR, J0, J2, da K2.

Ana iya samar da bututun ƙarfe zuwa EN 10219 ta duka biyuERW(electro juriya waldi) daSAW(Submerged baka waldi) masana'antu tafiyar matakai.

Samar daFarashin ERWyana da fa'idar kasancewa cikin sauri kuma mai sauƙin araha kuma galibi ana zaɓa don ayyukan da ke buƙatar samar da manyan ayyuka da ƙimar farashi mai yawa.

ERWAna amfani da bututu yawanci don samar da ƙananan diamita da ƙananan kauri na bango, yayin daSAWtubes sun fi dacewa da manyan diamita da ganuwar kauri. Da fatan za a zaɓi nau'in bututun ƙarfe da ya dace don aikin ku.

Bututun ERW da aka kera bisa ga EN 10219 ba sa buƙatar datsa walda na ciki.

Wannan saboda bututun EN 10219 galibi ana amfani da su a aikace-aikacen tsarin, kamar gini da injiniyan injiniya, inda buƙatun bayyanar walda yawanci ba su da ƙarfi fiye da tasoshin matsa lamba ko bututun matsa lamba. Sabili da haka, muddin ƙarfi da amincin walda sun cika buƙatun ma'auni, ana iya amfani da weld na ciki ba tare da ƙarin datsa ba.

Ba a yi maganin zafi na gaba ba, sai dai cewa waldar na iya kasancewa cikin yanayin walda ko yanayin zafi.

Binciken Cast (Hanyoyin Kemikal na Raw Materials)

Dukansu S275J0H da S275J2H suna da matsakaicin ƙimar daidai carbon (CEV) na 0.40%.

S725J0H da S275J2H tare da matsakaicin CEV na 0.4% suna kwatanta mafi kyawun weldability tare da ƙarancin haɗarin taurin da fashe yayin walda.

Hakanan ana iya lissafta ta ta amfani da dabara mai zuwa:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

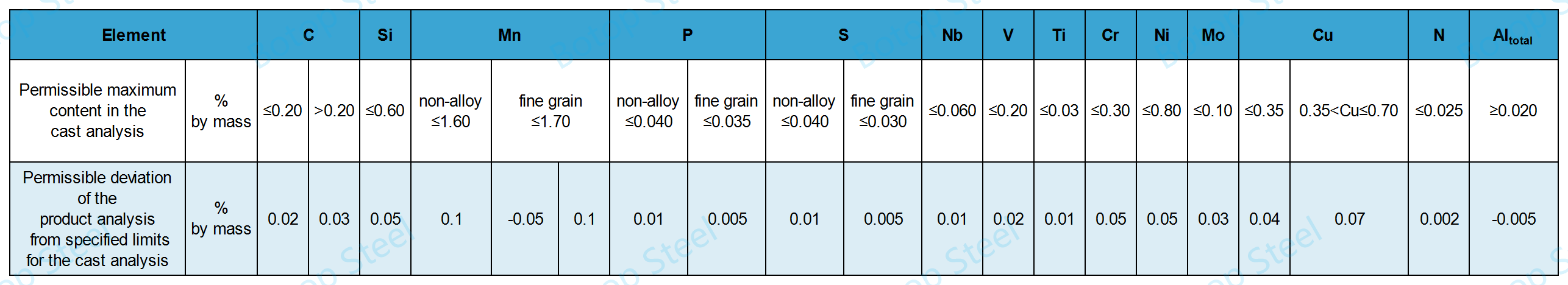

Binciken Samfura (Hanyoyin Kemikal na Kayayyakin Kammala)

A lokacin samar da karfe, sinadarai na iya canzawa saboda dalilai masu yawa, kuma waɗannan canje-canje na iya shafar kaddarorin da ingancin karfe.

Ƙarshen ƙaƙƙarfan ƙaƙƙarfan bututun sinadarai dole ne ya dace da sinadarai na simintin gyare-gyaren da aka halatta.

Siffofin kaddarorin injina sun haɗa da ƙarfin samarwa, ƙarfin juzu'i, haɓakawa, da ƙarfin tasiri.

Rage damuwa fiye da 580 ℃ ko fiye da sa'a daya na iya haifar da lalacewa na kayan aikin injiniya.

Bayanan kula:

Ba a buƙatar gwajin tasiri lokacin da ƙayyadadden kauri ya kasance <6mm.

Ba a tabbatar da tasirin tasirin bututun ingancin JR da J0 ba sai an ƙayyade.

TS EN 10219 Welds a cikin bututun ƙarfe na ERW ana iya gwada shi ta zaɓi ɗaya daga cikin masu zuwa.

TS EN 10246-3 zuwa matakin karɓa na E4, ban da cewa ba za a ba da izinin fasahar jujjuyawar bututu / pancake ba;

TS EN 10246-5 zuwa matakin karɓa F5;

TS EN 10246-8 zuwa matakin karɓa U5.

Lissafin ma'aunin ma'auni na bututun EN 10219 na iya dogara ne akan girman bututu na 7.85 kg/dm³.

M=(DT)×T×0.02466

M shine yawan adadin kowane tsawon raka'a;

D shine ƙayyadadden diamita na waje, raka'a a mm;

T shine ƙayyadadden kauri na bango, raka'a a mm.

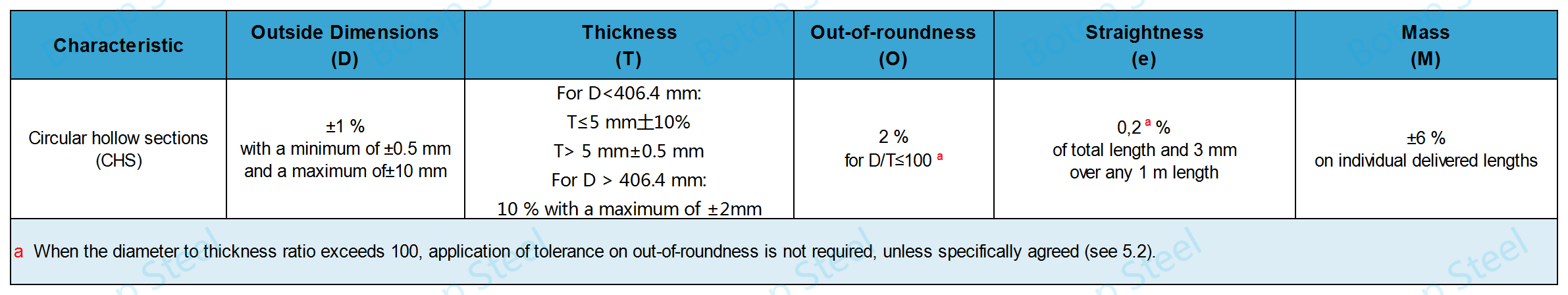

Haƙuri akan Siffai, Miƙewa da Taro

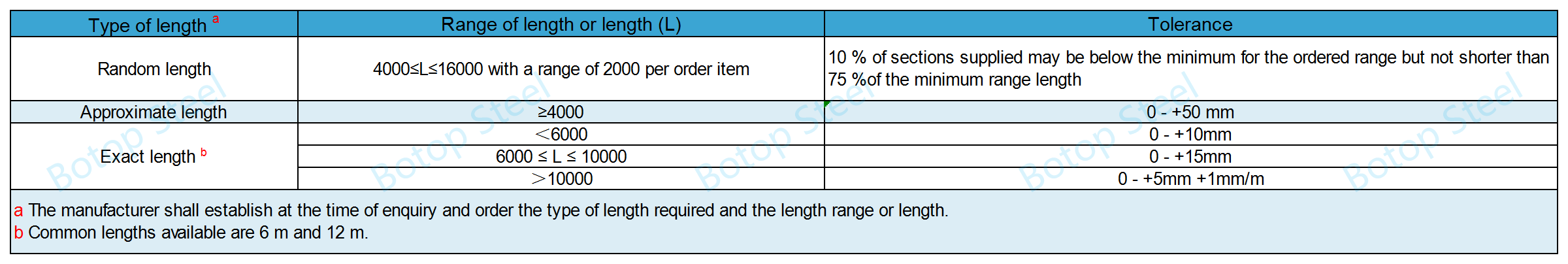

Tsawon Haƙuri

Bututun sassan sassan da aka kera bisa ga EN 10219 suna walƙiya.

Lokacin walda, fashewar sanyi a yankin walda shine babban haɗari yayin da kauri, matakin ƙarfi, da CEV na samfur ke ƙaruwa. Ana samun fashewar sanyi ta hanyar haɗuwa da abubuwa da yawa:

high matakan hydrogen diffusible a cikin weld karfe;

wani tsari mai laushi a cikin yankin da zafi ya shafa;

mahimmin matakan damuwa mai ƙarfi a cikin haɗin gwiwa mai walda.

Ya kamata saman bututun ƙarfe ya zama santsi kuma ba shi da wata lahani da za ta shafi aikin samfur, kamar tsagewa, ramuka, tarkace, ko lalata.

Kumburi, tsagi, ko tsagi mai tsayi mara zurfi da tsarin masana'antu ya ƙirƙira ana karɓar karɓuwa muddin sauran kaurin bango yana cikin juriya, ana iya cire lahani ta hanyar niƙa, kuma kaurin bangon da aka gyara ya dace da mafi ƙarancin buƙatun kauri.

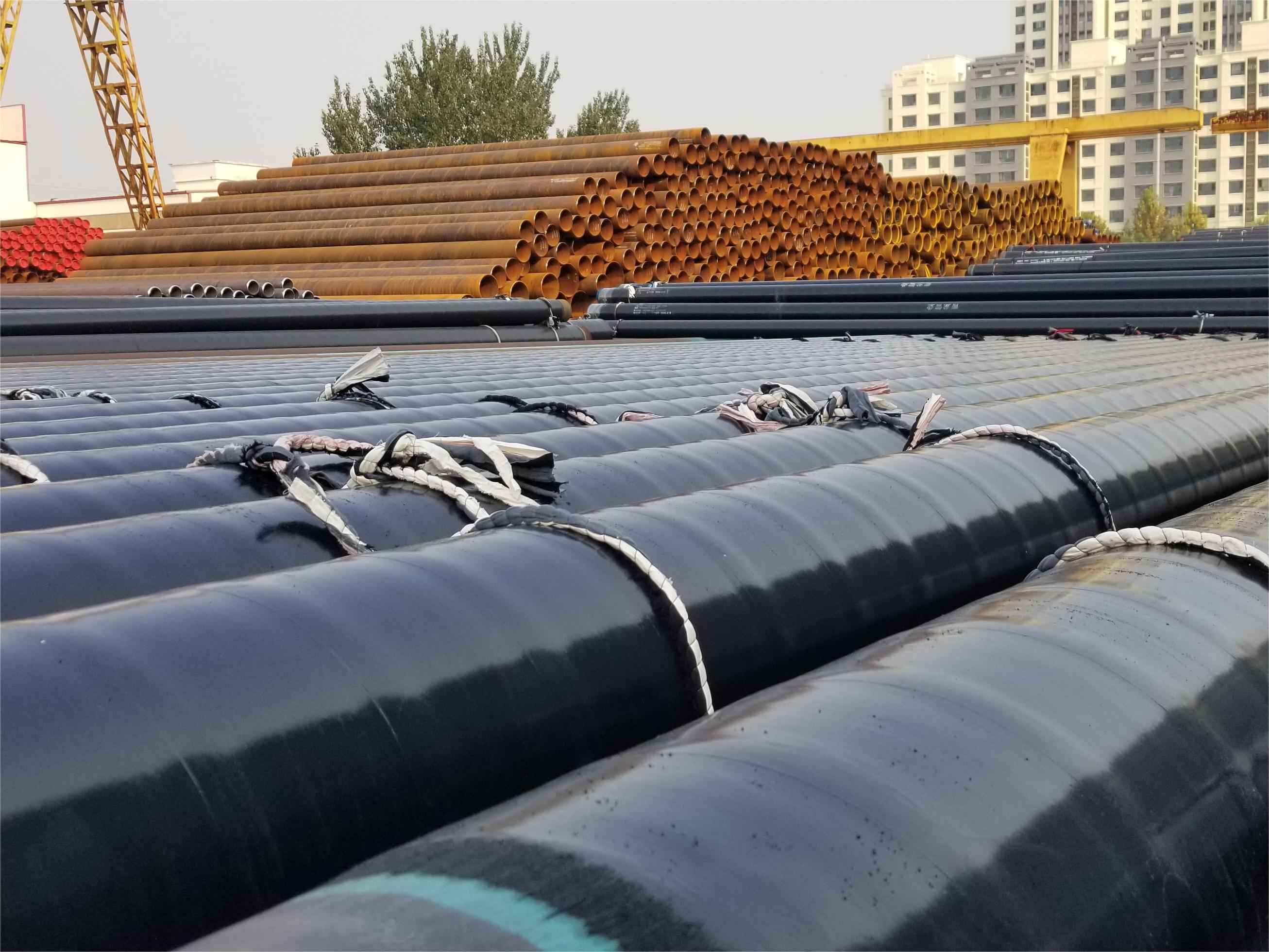

Botop KarfeBa wai kawai yana ba da bututun ƙarfe masu inganci daidai da EN 10219 ba, har ila yau yana ba da zaɓuɓɓuka da yawa don rufin bututun ƙarfe don dacewa da takamaiman bukatun abokan cinikinsa a cikin ayyukan injiniya daban-daban. An tsara waɗannan suturar don haɓaka juriya na lalata na bututu da kuma ƙara ƙarin kariya, don haka ƙara rayuwar sabis ɗin su.

Hot-tsoma Galvanizing

3LPE (HDPE) rufi

Farashin FBE

Rufin Varnish

Rufin fenti

Rufi Nauyin Siminti

Abubuwan gada: kayan da ba na farko ba na ɗaukar kaya da ake amfani da su a gadoji, irin su dogo da tarkace.

Gine-ginen ginshiƙai: ginshiƙan tallafi da katako da ake amfani da su a cikin gini da injiniyan farar hula.

Tsarin bututu: bututu don jigilar ruwa da iskar gas, musamman a aikace-aikacen da ke buƙatar matakin sassauci da juriya na lalata.

Tsarin wucin gadi: tallafi na wucin gadi da firam ɗin da suka dace da gine-gine da wuraren aikin injiniya.

Waɗannan aikace-aikacen suna amfani da ingantattun kaddarorin injiniyoyi da weldability na S275J0H da S275J2H don saduwa da buƙatun sifofi masu nauyi amma barga.

ASTM A500:Madaidaicin Ƙimar Ƙirƙirar Tushen Welded-Kafaffen Sanyi da Tsarin Tsarin Tsarin Tsarin Karfe Carbon Karfe a Zagaye da Siffai.

ASTM A501: Madaidaicin Ƙimar Ƙaƙƙarfan Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfe.

EN 10210: Hot gama tsarin m sassa na wadanda ba gami da lafiya hatsi karfe.

EN 10219: Cold kafa welded tsarin m sassa na wadanda ba gami da lafiya hatsi karafa.

Farashin G3466: Carbon karfe murabba'in da rectangular shambura ga general tsarin.

AS/NZS 1163: Sanyi-kafa tsarin karfe m sassa.

Ana amfani da waɗannan ka'idoji a ko'ina cikin duniya, kuma suna taimakawa wajen tabbatar da cewa bututun ƙarfe na tsarin ya cika ka'idojin aikin da ake sa ran a aikace-aikacen injiniya daban-daban. Lokacin zabar ma'auni na bututun ƙarfe, yana da mahimmanci a yi la'akari da ƙayyadaddun bukatun aikace-aikacen sa, ƙa'idodin yanki, da buƙatun aiki.

ASTM A252 GR.3 Tsarin LSAW(JCOE) Carbon Karfe Bututu

TS EN10210 S275J0H LSAW(JCOE) Bututu Karfe

ASTM A671/A671M LSAW Karfe Bututu

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Karfe bututu

API 5L X65 PSL1/PSL 2 LSAW Carbon Karfe Bututu / API 5L Grade X70 LSAW Bututu Karfe

EN10219 S355J0H Tsarin LSAW(JCOE) Bututu Karfe