JIS G 3461 karfe bututubututun karfe ne maras sumul (SMLS) ko lantarki-juriya-welded (ERW) carbon karfe bututu, galibi ana amfani dashi a cikin tukunyar jirgi da masu musayar zafi don aikace-aikace kamar fahimtar musayar zafi tsakanin ciki da wajen bututu.

Saukewa: STB340shi ne wani carbon karfe bututu sa a cikin JIS G 3461 misali. Yana da mafi ƙarancin ƙarfi na 340 MPa da ƙaramar ƙarfin yawan amfanin ƙasa na 175 MPa.

Abu ne na zaɓi don aikace-aikacen masana'antu da yawa saboda ƙarfinsa mai ƙarfi, kwanciyar hankali mai kyau na thermal, daidaitawa, juriya na lalata, ƙimar farashi, da kyakkyawan tsari.

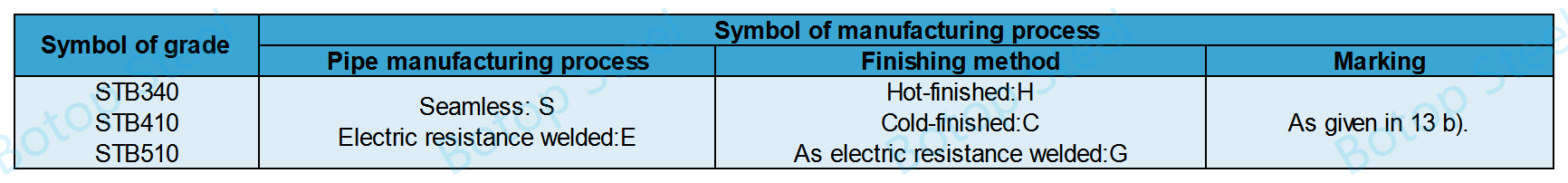

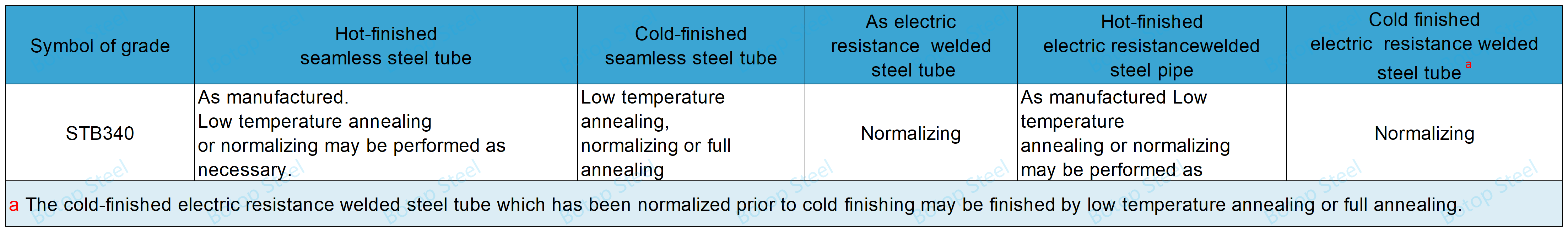

Farashin G3461yana da maki uku.Saukewa: STB340, STB410, STB510.

Saukewa: STB340Mafi ƙarancin ƙarfin ƙarfi: 340 MPa; Ƙarfin yawan amfanin ƙasa: 175 MPa.

Saukewa: STB410Ƙarfin Ƙarfin Ƙarfin Ƙarfi: 410 MPa; Ƙarfin Ƙarfin Haɓaka: 255 MPa.

STB510:Ƙarfin Ƙarfin Ƙarfi: 510 MPa; Ƙarfin Ƙarfin Ƙarfi: 295 MPa.

A gaskiya ma, ba shi da wahala a gano cewa an rarraba darajar JIS G 3461 bisa ga ƙaramin ƙarfi na bututun ƙarfe.

Yayin da darajar kayan ke ƙaruwa, ƙarfin ƙarfinsa da ƙarfinsa yana ƙaruwa daidai da haka, yana ba da damar kayan da za su iya tsayayya da nauyin nauyi da matsa lamba don ƙarin yanayin aiki mai wuyar gaske.

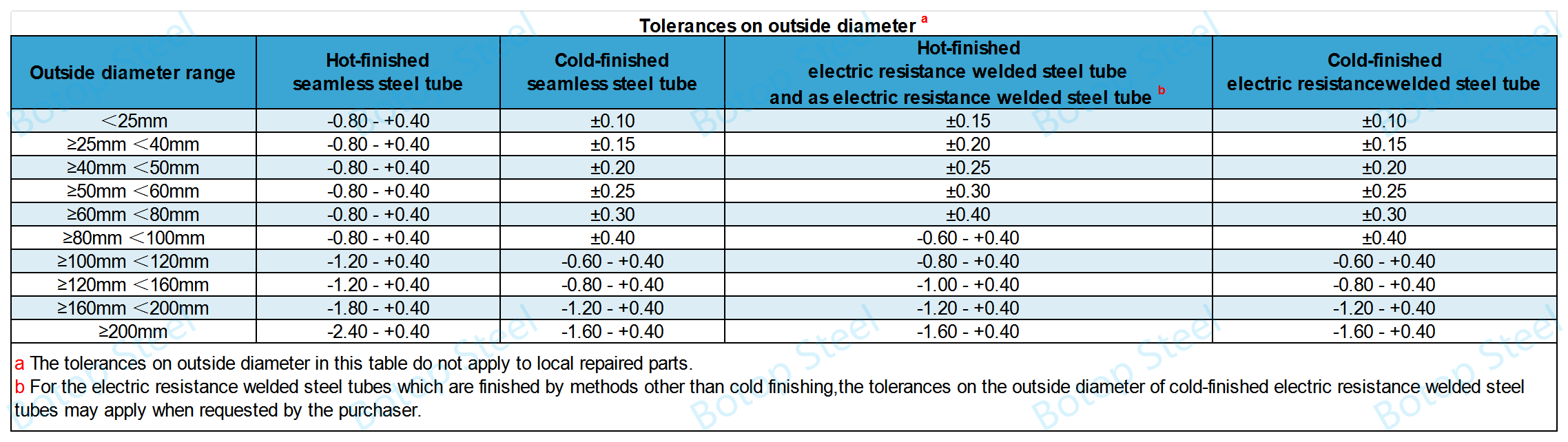

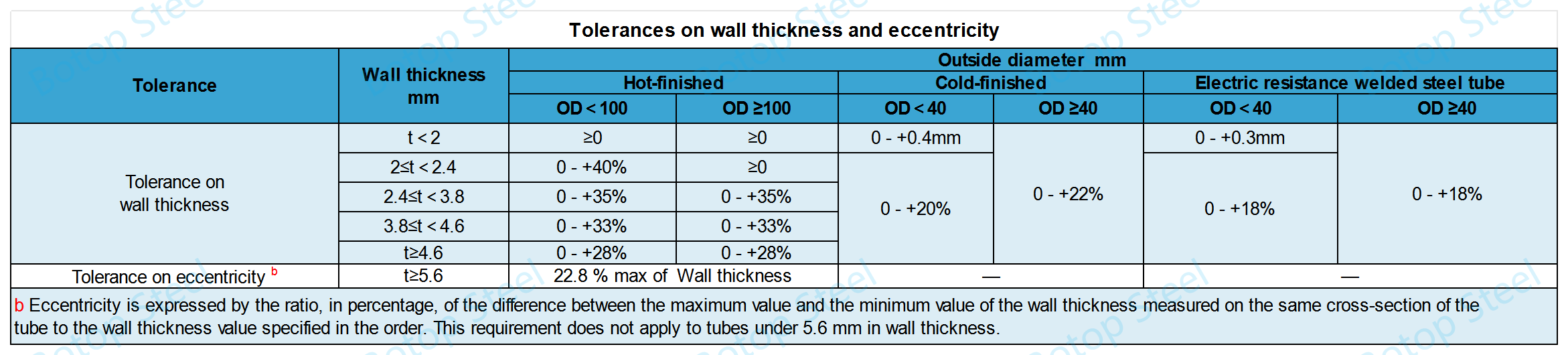

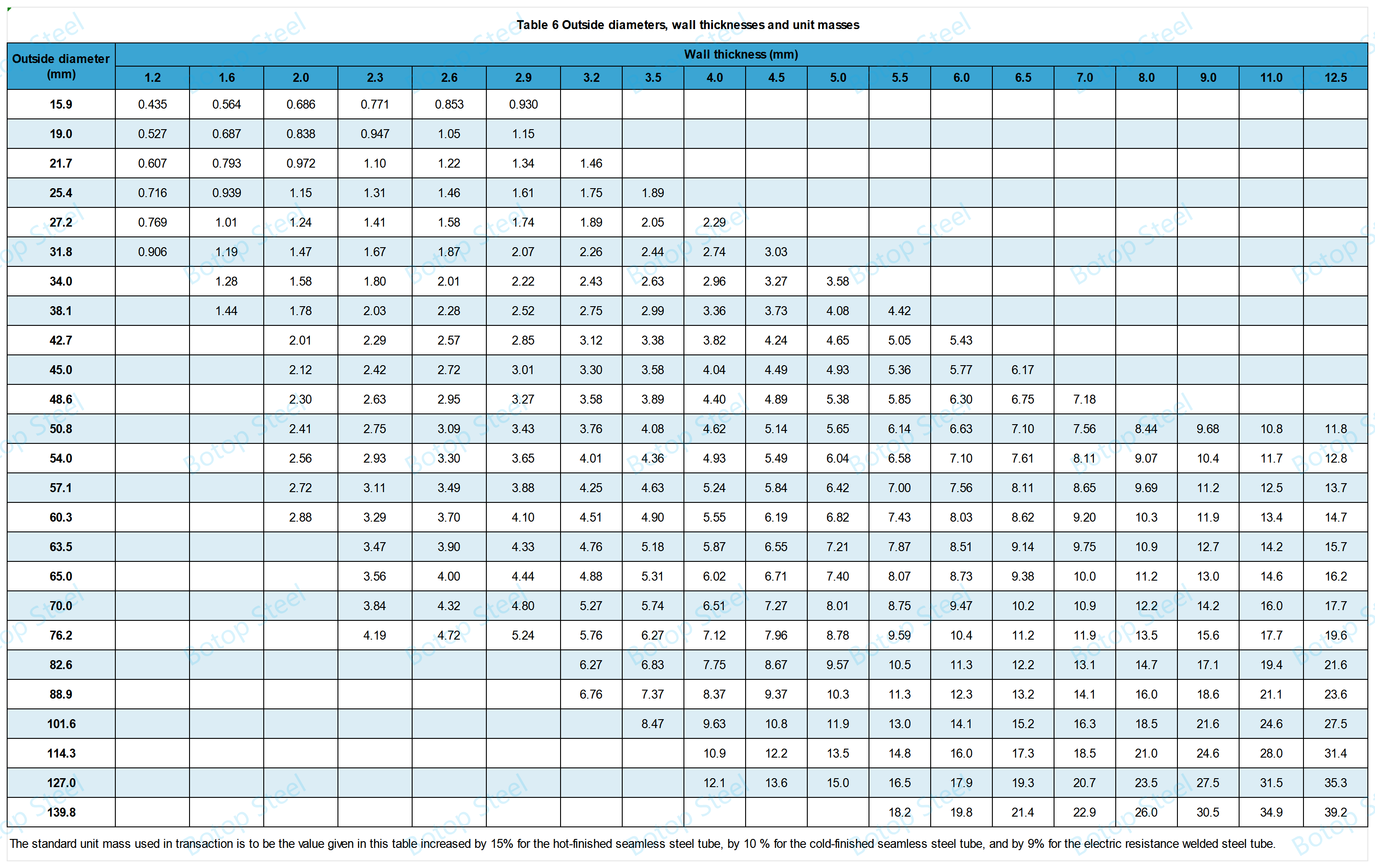

A waje diamita na 15.9-139.8mm.

Aikace-aikace a cikin tukunyar jirgi da masu musayar zafi yawanci basa buƙatar manyan diamita na bututu. Ƙananan diamita na bututu suna ƙara haɓakar thermal saboda yanayin farfajiya zuwa ƙimar ƙara don canja wurin zafi ya fi girma. Wannan yana taimakawa wajen canja wurin makamashin zafi cikin sauri da inganci.

Tubes za a kerarre daga cikinkashe karfe.

Haɗuwa da hanyoyin samar da bututu da hanyoyin gamawa.

Dalla-dalla, ana iya karkasa su kamar haka:

Bututun ƙarfe mara nauyi mai zafi: SH

Bututun ƙarfe mara ƙarfi mai sanyi: SC

Kamar yadda lantarki juriya welded karfe tube: EG

Bututun ƙarfe mai zafi da aka gama da wutar lantarki: EH

Cold-ƙare wutar lantarki juriya welded karfe bututu: EC

Anan akwai kwararar samar da kayan aikin da aka gama da zafi.

Don tsarin masana'anta maras kyau, ana iya rarraba shi zuwa bututun ƙarfe mara nauyi tare da diamita na waje fiye da 30mm ta amfani da samar da ƙarancin zafi, da 30mm ta amfani da samar da ƙarancin sanyi.

Hanyoyin bincike na thermal za su kasance daidai da ma'auni a cikin JIS G 0320.

Ana iya ƙara abubuwan haɗin kai ban da waɗancan don samun takamaiman kaddarorin.

Lokacin da aka bincikar samfurin, ƙimar karkatar da sinadarai na bututu za su dace da buƙatun Tebu 3 na JIS G 0321 don bututun ƙarfe mara nauyi da Tebu 2 na JIS G 0321 don juriya-welded bututun ƙarfe.

| Alamar daraja | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (phosphorus) | S (sulfur) |

| max | max | max | max | ||

| Saukewa: STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Mai siye zai iya ƙayyade adadin Si don kasancewa cikin kewayon 0.10% zuwa 0.35%. | |||||

Abubuwan da ke tattare da sinadarai na STB340 an tsara su don tabbatar da isassun kaddarorin inji da machinability yayin yin kayan da suka dace da walda da aikace-aikace a cikin yanayin zafi mai zafi.

| Alamar daraja | Ƙarfin ɗamara a | Ƙimar bayarwa ko damuwa mai ƙarfi | Tsawaita min, % | ||

| Diamita na waje | |||||

| mm 10 | ≥10mm ~ 20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Gwajin yanki | |||

| Na 11 | Na 11 | Na 11/Na 12 | |||

| min | min | Hanyar gwajin tensile | |||

| Daidai da axis tube | Daidai da axis tube | Daidai da axis tube | |||

| Saukewa: STB340 | 340 | 175 | 27 | 30 | 35 |

Lura: keɓance don bututun musayar zafi, mai siye zai iya, inda ya cancanta, ƙididdige matsakaicin ƙimar ƙarfin ƙarfi. A wannan yanayin, matsakaicin ƙimar ƙarfin ƙarfi zai zama ƙimar da aka samu ta ƙara 120 N/mm² zuwa ƙimar da ke cikin wannan tebur.

Lokacin da aka yi gwajin gwaji a kan Gwajin Gwaji No. 12 don bututu a ƙarƙashin 8 mm a cikin kauri na bango.

| Alamar daraja | An yi amfani da yanki na gwaji | Tsawaitawa min,% | ||||||

| Kaurin bango | ||||||||

| 1 ≤2 mm | 2 ≤3 mm | 3≤4 mm | ≤4 ≤5 mm | 5 ≤6 mm | 6≤7 mm | 7 mm8 ku | ||

| Saukewa: STB340 | Na 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Ana ƙididdige ƙimar elongation a cikin wannan tebur ta hanyar cirewa 1.5% daga ƙimar elongation da aka bayar a cikin Tebura 4 don kowane raguwar mm 1 a cikin kauri daga bangon bututu daga 8 mm, kuma ta hanyar haɗa sakamakon zuwa lamba bisa ga Dokar A na JIS Z 8401.

Hanyar gwajin za ta kasance daidai da JIS Z 2245. Za a auna ƙarfin gwajin gwajin a kan sashin giciye ko saman ciki a wurare uku a kowane yanki na gwaji.

| Alamar daraja | Rockwell hardness (ma'anar darajar matsayi uku) HRBW |

| Saukewa: STB340 | 77 max. |

| Saukewa: STB410 | 79 max. |

| Saukewa: STB510 | 92 max. |

Kada a yi wannan gwajin akan bututu na kauri na bango 2 mm ko ƙasa. Don juriyar wutar lantarki da aka haɗa bututun ƙarfe, za a yi gwajin a cikin wani yanki ban da walda ko yankunan da zafi ya shafa.

Ba ya shafi bututun ƙarfe maras sumul.

Hanyar Gwaji Sanya samfurin a cikin injin kuma daidaita shi har sai nisa tsakanin dandamali biyu ya kai ƙayyadadden ƙimar H. Sannan duba samfurin don tsagewa.

Lokacin gwada juriya mai mahimmancin bututun walda, layin da ke tsakanin walda da tsakiyar bututun yana kan hanyar matsawa.

H=(1+e)t/(e+t/D)

H: nisa tsakanin faranti (mm)

t: kaurin bangon bututu (mm)

D: waje diamita na bututu (mm)

e:akai-akai bayyana ga kowane sa na bututu. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Ba ya shafi bututun ƙarfe maras sumul.

Ɗayan ƙarshen samfurin yana ƙonewa a cikin dakin da zafin jiki (5 ° C zuwa 35 ° C) tare da kayan aiki na conical a kusurwar 60 ° har sai an ƙara girman diamita na waje da kashi 1.2 kuma a duba don tsagewa.

Wannan bukata kuma ta shafi bututu masu diamita na waje fiye da 101.6 mm.

Za a iya tsallake gwajin juzu'i lokacin yin gwajin flaring.

Yanke tsawon 100 mm na gwajin gwaji daga ƙarshen bututu kuma yanke gwajin gwajin a cikin rabin 90 ° daga layin weld a bangarorin biyu na kewaye, ɗaukar rabin da ke ɗauke da weld a matsayin gwajin gwajin.

A cikin zafin jiki (5 ° C zuwa 35 ° C) za a baje samfurin a cikin faranti tare da weld a saman kuma duba samfurin don tsagewa a cikin walda.

Kowane bututun ƙarfe yana buƙatar a gwada shi ta hanyar ruwa ko kuma ba a lalata shi badon tabbatar da inganci da amincin bututu da kuma biyan ka'idojin amfani.

Gwajin Ruwan Ruwa

Rike ciki na bututu a ƙarami ko mafi girma matsa lamba P (P max 10 MPa) na akalla daƙiƙa 5, sa'an nan kuma duba cewa bututun na iya jure matsi ba tare da yadudduka ba.

P=2st/D

P: gwajin gwaji (MPa)

tKaurin bangon bututu (mm)

D: waje diamita na bututu (mm)

s: 60 % na ƙayyadaddun ƙayyadaddun ƙimar ƙimar ƙimar amfanin ƙasa ko matsananciyar hujja.

Gwajin mara lalacewa

Gwajin da ba mai lalacewa ba na bututun ƙarfe ya kamata a yi taultrasonic ko eddy gwajin halin yanzu.

DominultrasonicHalayen dubawa, sigina daga samfurin tunani mai ƙunshe da mizanin tunani na aji UD kamar yadda aka ƙayyade a cikiFarashin 0582za a yi la'akari da matakin ƙararrawa kuma yana da sigina na asali daidai da ko mafi girma fiye da matakin ƙararrawa.

Daidaitaccen ganewar ganewa doneddy halin yanzujarrabawar za ta kasance nau'in EU, EV, EW, ko EX da aka ƙayyade a cikinFarashin 0583, kuma ba za a sami sigina daidai da ko mafi girma fiye da sigina daga samfurin tunani dauke da ma'auni na ma'auni na wannan nau'in.

Don ƙarinCharts Nauyin Bututu da Jadawalin Bututua cikin ma'auni, za ku iya danna ta.

Ɗauki hanyar da ta dace don yin lakabin bayanin da ke gaba.

a) Alamar daraja;

b) Alamar hanyar masana'anta;

c) Girma: diamita na waje da kauri na bango;

d) Sunan masana'anta ko alamar ganowa.

Lokacin da alamar kowane bututu ke da wahala saboda ƙananan diamita na waje ko kuma lokacin da mai siye ya buƙaci haka, ana iya ba da alamar akan kowane tarin bututu ta hanyar da ta dace.

Ana amfani da STB340 sosai wajen kera bututun ruwa da bututun hayaƙi don dumama masana'antu daban-daban, musamman a wuraren da ake buƙatar juriya ga yanayin zafi da matsi.

Saboda kyawawan halayen halayen zafi, ya dace da kera bututu don masu musayar zafi, yana taimakawa wajen canja wurin zafi da kyau tsakanin kafofin watsa labarai daban-daban.

Hakanan ana iya amfani da shi don jigilar ruwan zafi mai zafi ko matsa lamba, kamar tururi ko ruwan zafi, kuma ana amfani dashi sosai a masana'antar kemikal, wutar lantarki, da injina.

ASTM A106

DIN 17175 St35.8

DIN 1629 St37.0

BS 3059-1 Darasi na 320

TS EN 10216-1 P235GH

GB 3087 20#

GB 5310 20G

Kodayake waɗannan kayan na iya zama iri ɗaya dangane da abun da ke tattare da sinadarai da kaddarorin asali, ƙayyadaddun hanyoyin magance zafi da injina na iya shafar kaddarorin samfurin ƙarshe.

Sabili da haka, ya kamata a yi cikakken kwatancen da gwajin da ya dace lokacin zabar kayan daidaitattun don aikace-aikacen aiki.

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun ƙarfe na carbon a Arewacin kasar Sin, wanda aka sani don kyakkyawan sabis, samfurori masu inganci, da cikakkun mafita. Kamfanin yana ba da nau'ikan bututun ƙarfe na carbon da samfuran da ke da alaƙa, waɗanda suka haɗa da marasa ƙarfi, ERW, LSAW, da bututun ƙarfe na SSAW, da kuma cikakken jeri na kayan aikin bututu da flanges.

Kayayyakinsa na musamman sun haɗa da gawa mai daraja da austenitic bakin karafa, waɗanda aka keɓance don biyan buƙatun ayyukan bututun.