JIS G 3444: Carbon karfe bututu don tsarin gaba ɗaya.

Yana ƙayyadaddun buƙatun bututun ƙarfe na carbon da ake amfani da su a aikin injiniya da gine-gine, kamar hasumiya na ƙarfe, ƙwanƙwasa, tulin tushe, tulin tushe, da tari mai hana zamewa.

Farashin STK400karfe bututu ne daya daga cikin na kowa maki, tare da inji Properties na amafi ƙarancin ƙarfi na 400 MPakuma aƘarfin yawan amfanin ƙasa na 235 MPa. Kyakkyawan ƙarfin tsarin sa da karkosanya shi dace da yawa daban-daban aikace-aikace.

Dangane da mafi ƙarancin ƙarfi na bututun ƙarfe an kasu kashi 5, waɗanda sune:

STK 290, STK 400, STK 490, STK 500, STK 540.

Babban manufa Diamita na waje: 21.7-1016.0mm;

Tulin tushe da tara don danne zaftarewar ƙasa OD: ƙasa da 318.5mm.

| Alamar daraja | Alamar tsarin masana'anta | |

| Tsarin kera bututu | Hanyar gamawa | |

| Farashin STK290 | Babu shakka: S Juriyar wutar lantarki: E Tushen welded: B Arc welded ta atomatik: A | An gama zafi: H Ciwon sanyi: C Kamar yadda juriya na lantarki: G |

| Farashin STK400 | ||

| Farashin STK490 | ||

| Farashin STK500 | ||

| Farashin STK540 | ||

Za a yi amfani da bututun ta hanyar haɗin hanyar samar da bututu da kuma hanyar ƙarewa waɗanda aka nuna.

Musamman, ana iya karkasa su zuwa nau'ikan guda bakwai masu zuwa, don haka zaɓi nau'in da ya dace bisa ga buƙatu daban-daban:

1) Bututun ƙarfe mara nauyi mai zafi: -SH

2) Tushen ƙarfe mara nauyi mai sanyi: -SC

3) Kamar yadda wutar lantarki juriya welded karfe tube: -EG

4) Hot-gama lantarki juriya welded karfe tube: -EH

5) sanyi-ƙare lantarki juriya welded karfe tube: -EC

6) Bututun ƙarfe na butt-welded: -B

7) Atomatik baka welded karfe bututu: -A

| Haɗin Sinadaria% | |||||

| Alamar daraja | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (phosphorus) | S (sulfur) |

| max | max | max | max | ||

| Farashin STK400 | 0.25 | - | - | 0.040 | 0.040 |

| aAbubuwan da ba a haɗa su a cikin wannan tebur ba kuma ana iya ƙara abubuwan da aka nuna tare da "-" kamar yadda ya cancanta. | |||||

Farashin STK400ne low-carbon karfe tare da mai kyau weldability da workability ga tsarin aikace-aikace bukatar waldi. Phosphorus da sulfur ana sarrafa su a ƙananan matakan don taimakawa wajen kiyaye gaba ɗaya tauri da aiki na kayan. Kodayake ba a ba da takamaiman ƙima na silicon da manganese ba, ana iya daidaita su cikin iyakoki masu izini don haɓaka kaddarorin ƙarfe gabaɗaya.

Ƙarfin Ƙarfin Ƙarfin Ƙarfin Ƙarfin Ƙarfafawa da Ƙarfafa Ƙarfafawa ko Ƙarfafa Ƙarfafawa

Ƙarfin jujjuyawar walda yana aiki da bututu masu waldaran baka ta atomatik. Aikin walda SAW ne.

| Alamar daraja | Ƙarfin ƙarfi | Ƙimar bayarwa ko damuwa mai ƙarfi | Ƙarfin ƙarfi a cikin walda |

| N/mm² (MPA) | N/mm² (MPA) | N/mm² (MPA) | |

| min | min | min | |

| Farashin STK400 | 400 | 235 | 400 |

Saukewa: JIS G3444

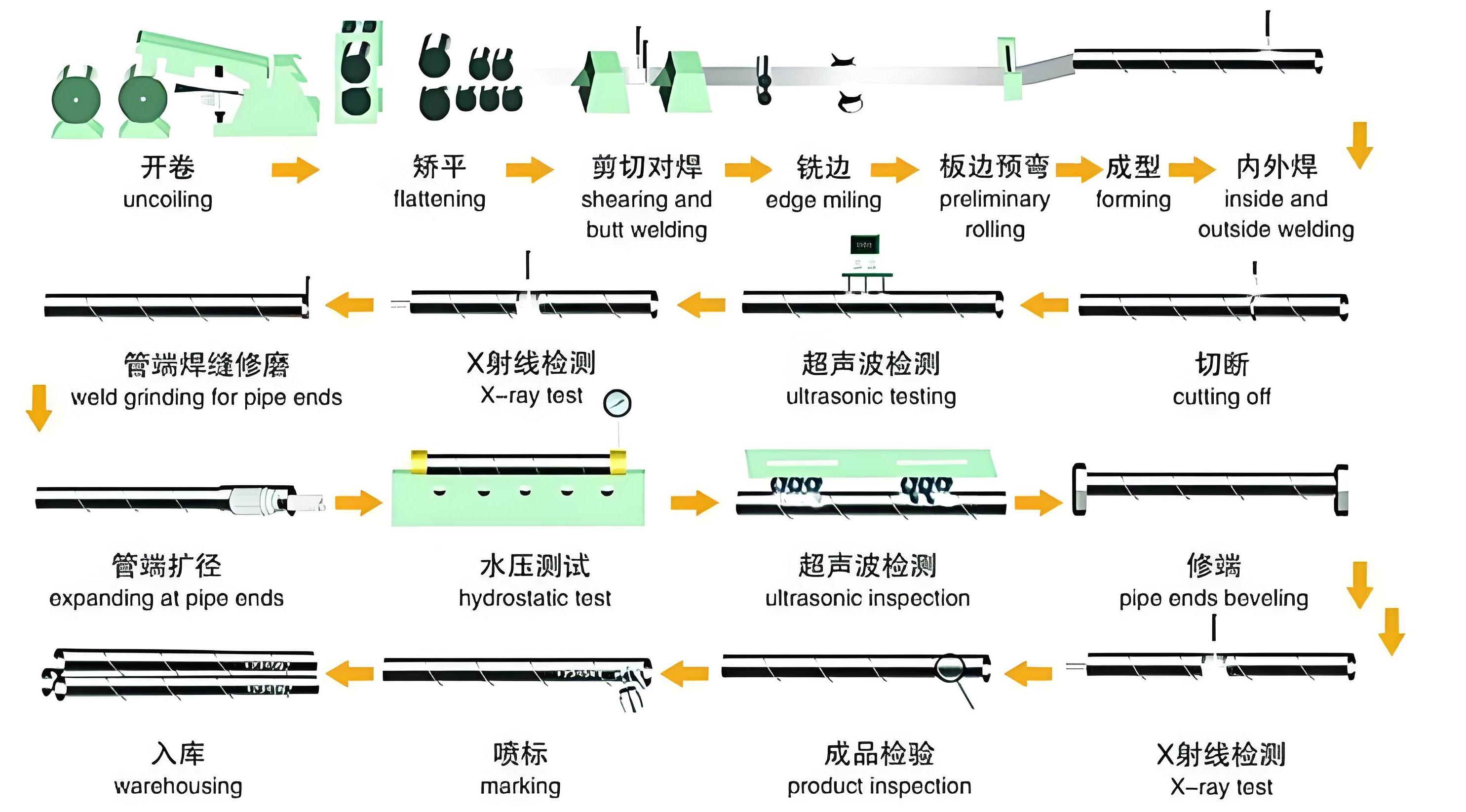

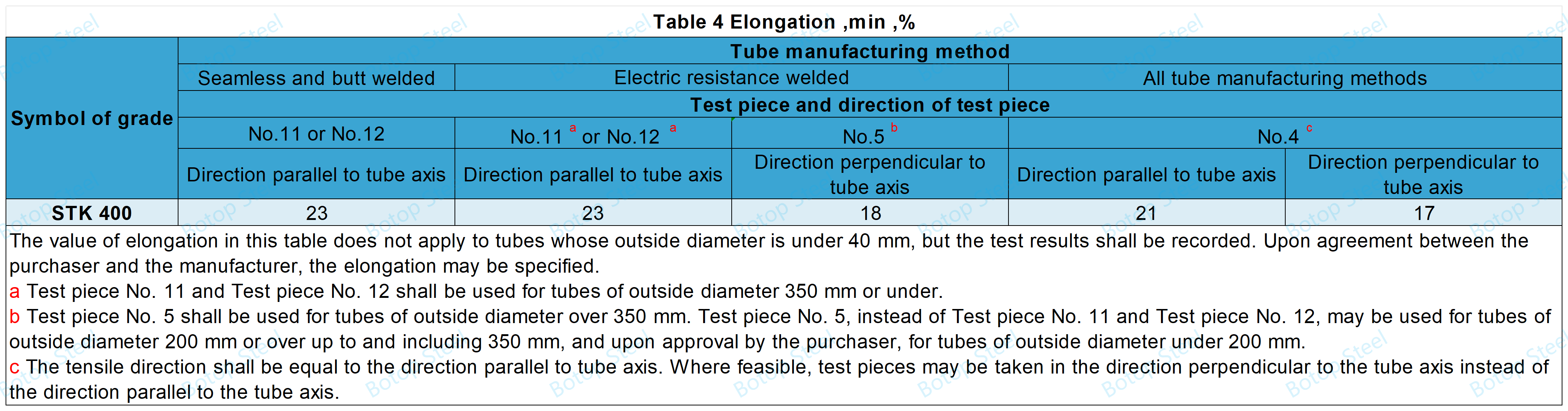

Ana nuna elongation daidai da hanyar kera bututu a cikin Tebu 4.

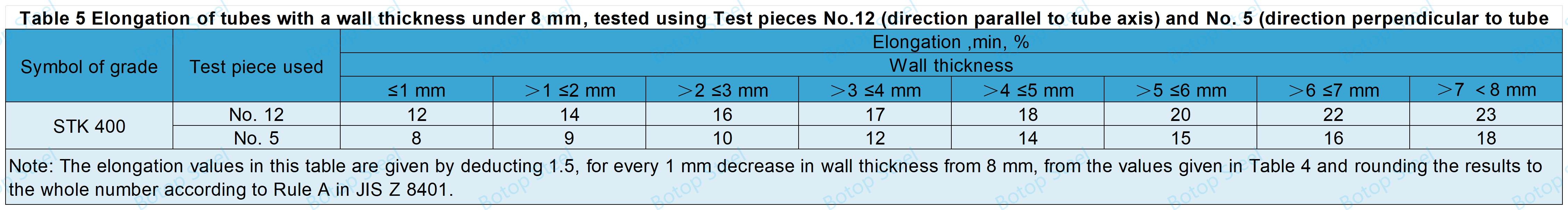

Duk da haka, lokacin da aka yi gwajin juzu'i a kan Gwajin Gwaji No. 12 ko Gwajin Gwajin No.5 da aka ɗauka daga bututun da ke ƙarƙashin 8 mm a cikin kauri na bango, elongation ɗin zai kasance daidai da Table 5.

A dakin da zafin jiki (5 °C zuwa 35 °C), sanya samfurin tsakanin faranti guda biyu kuma latsa sosai don daidaita su har zuwa nisa H ≤ 2/3D tsakanin faranti, sannan a duba fashe a cikin samfurin.

A cikin zafin jiki (5 ° C zuwa 35 ° C), lanƙwasa samfurin a kusa da silinda a mafi ƙarancin kusurwar lanƙwasa 90 ° da matsakaicin radius na ciki wanda bai wuce 6D ba kuma duba samfurin don tsagewa.

Gwaje-gwajen hydrostatic, gwaje-gwaje marasa lalacewa na welds, ko wasu gwaje-gwaje za a yarda da su a gaba kan buƙatun da suka dace.

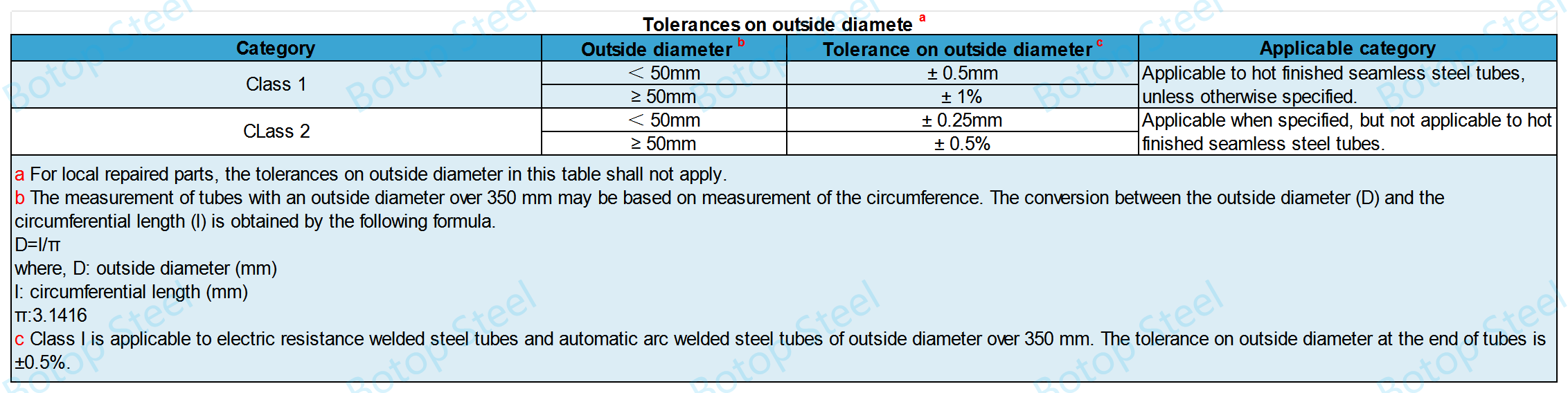

Haƙuri a Waje Diamita

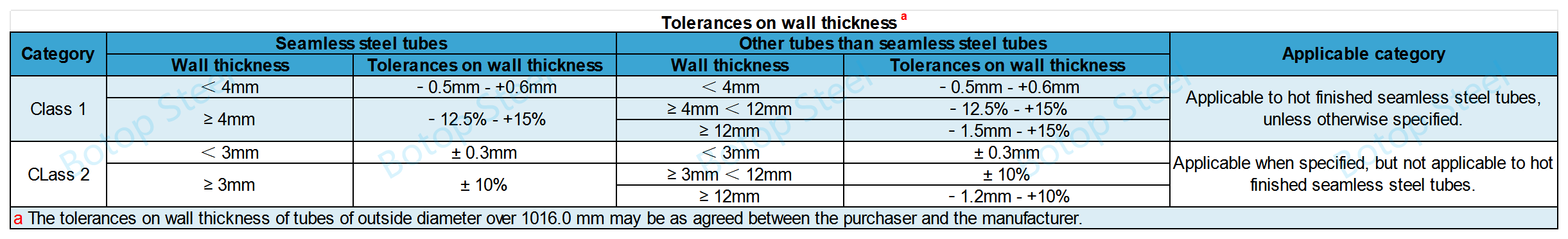

Hakuri da Kaurin bango

Haƙuri Tsawon

Tsawon ≥ ƙayyadadden tsayi

Filayen ciki da na waje na bututun ƙarfe za su kasance santsi kuma ba su da lahani mara kyau ga ues.

Kowane bututun ƙarfe za a yi masa lakabi da waɗannan bayanai.

a)Alamar daraja.

b)Alamar hanyar ƙira.

c)Girma.Za a yi alama diamita na waje da kaurin bango.

d)Sunan masana'anta ko gajarta.

Lokacin da alamar bututu ke da wahala saboda diamita na waje ƙanƙanta ne ko kuma lokacin da mai siye ya buƙaci haka, ana iya ba da alamar akan kowane bututun ta hanyar da ta dace.

Za'a iya amfani da suturar rigakafin lalata irin su kayan kwalliyar zinc-rich, epoxy coatings, fenti, da dai sauransu.

STK 400 yana ba da ma'auni mai kyau na ƙarfi da tattalin arziki, yana mai da shi manufa don yawancin aikin injiniya da gine-gine.

Ana amfani da bututun ƙarfe na STK 400 a cikin masana'antar gine-gine kuma sun dace musamman don amfani da abubuwa na tsari kamar ginshiƙai, katako, ko firam a cikin gine-ginen kasuwanci da na zama.

Hakanan ya dace da gadoji, tsarin tallafi, da sauran ayyukan da ke buƙatar matsakaicin ƙarfi da dorewa.

Hakanan za'a iya amfani da shi don gina hanyoyin tsaro, firam ɗin ababan hawa, da sauran wuraren jama'a.

A cikin masana'antu, ana iya amfani da STK 400 don samar da firam ɗin da tsarin tallafi don kayan aiki da kayan aiki saboda kyakkyawan ƙarfin ɗaukar nauyi da ƙarfin aiki.

Lura cewa yayin da waɗannan ma'aunai suka yi kama da aikace-aikace da aiki, za a iya samun ƙananan bambance-bambance a cikin takamaiman abun da ke tattare da sinadarai da wasu sigogi na kayan inji.

Lokacin canza kayan aiki, ƙayyadaddun ƙayyadaddun ƙa'idodin ya kamata a kwatanta su dalla-dalla don tabbatar da cewa kayan da aka zaɓa za su dace da ƙayyadaddun ƙa'idodin fasaha da aminci na aikin.

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun ƙarfe na carbon a Arewacin kasar Sin, wanda aka sani don kyakkyawan sabis, samfurori masu inganci, da cikakkun mafita.

Kamfanin yana ba da nau'ikan bututun ƙarfe na carbon da samfuran da ke da alaƙa, waɗanda suka haɗa da marasa ƙarfi, ERW, LSAW, da bututun ƙarfe na SSAW, da kuma cikakken jeri na kayan aikin bututu da flanges.

Kayayyakinsa na musamman sun haɗa da gawa mai daraja da austenitic bakin karafa, waɗanda aka keɓance don biyan buƙatun ayyukan bututun.