Farashin G3455Standarda'idar Masana'antu ta Jafananci (JIS) ce don sabis na matsin lamba a yanayin zafi na 350 ° C ko ƙasa, galibi don sassan injina.

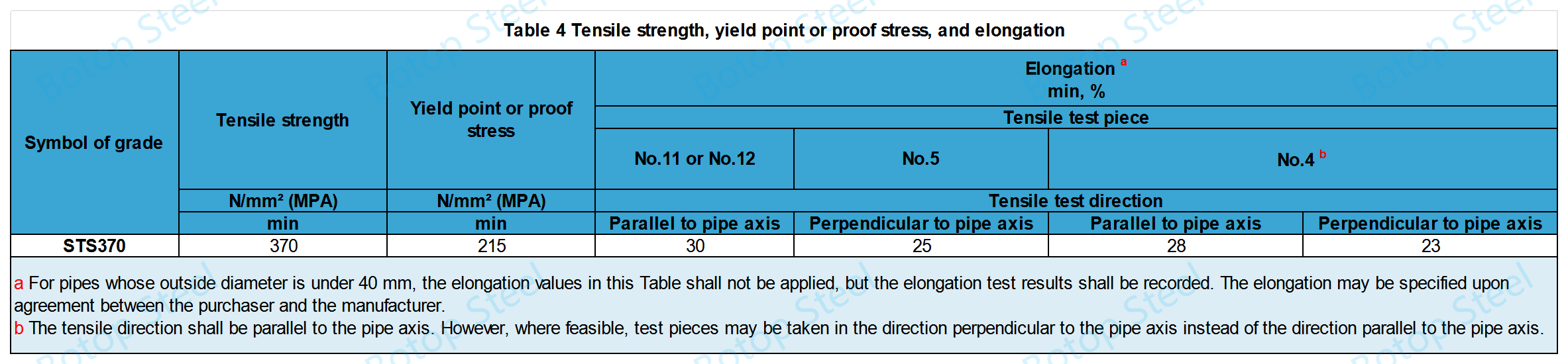

STS370 karfe bututushi ne bututun ƙarfe tare da ƙaramin ƙarfin ƙarfi na 370 MPa da ƙaramin ƙarfin amfanin ƙasa na 215 MPa, tare da abun ciki na carbon ba fiye da 0.25% da abun ciki na silicon tsakanin 0.10% da 0.35%, kuma galibi ana amfani dashi a aikace-aikacen da ke buƙatar ƙarfi mai ƙarfi da kyakkyawan walƙiya, kamar tsarin gini, gadoji, tasoshin matsa lamba, da jigilar kaya.

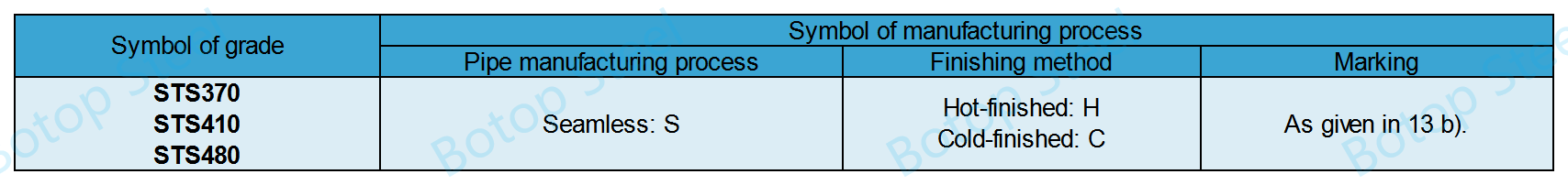

JIS G 3455 tana da maki uku.STS370, STS410, STA480.

Diamita na waje na 10.5-660.4mm (6-650A) (1/8-26B).

Tubes za a kerarre daga cikinkashe karfe.

Karfe da aka kashe shine karfe wanda aka cire gaba daya kafin a jefa shi cikin ingots ko wasu nau'ikan. Tsarin ya ƙunshi ƙara wani wakili na deoxidizing kamar silicon, aluminum, ko manganese zuwa karfe kafin ya ƙarfafa. Kalmar "kashe" tana nuna cewa babu iskar oxygen da ke faruwa a cikin karfe yayin aikin ƙarfafawa.

Ta hanyar kawar da iskar oxygen, karfen da aka kashe yana hana samuwar kumfa na iska a cikin narkakkar karfe, don haka guje wa porosity da kumfa na iska a cikin samfurin ƙarshe. Wannan yana haifar da ƙarin kamanni da ƙarfe mai yawa tare da ingantattun kaddarorin inji da daidaiton tsari.

Karfe da aka kashe ya dace musamman don aikace-aikacen da ke buƙatar babban inganci da dorewa, kamar tasoshin matsa lamba, manyan sifofi, da bututun bututu tare da buƙatu masu inganci.

Ta amfani da ƙarfe da aka kashe don samar da bututu, za ku iya tabbatar da kyakkyawan aiki da tsawon rayuwar sabis, musamman a cikin mahallin da ke ƙarƙashin nauyi da matsi.

Samar da ta amfani da tsarin masana'anta maras kyau tare da hanyar gamawa.

Bututun ƙarfe mara nauyi mai zafi: SH;

Bututun ƙarfe mara ƙarfi mai sanyi: SC.

Don tsarin masana'anta maras kyau, ana iya rarraba shi zuwa bututun ƙarfe mara nauyi tare da diamita na waje fiye da 30mm ta amfani da samar da ƙarancin zafi, da 30mm ta amfani da samar da ƙarancin sanyi.

Anan akwai kwararar samar da kayan aikin da aka gama da zafi.

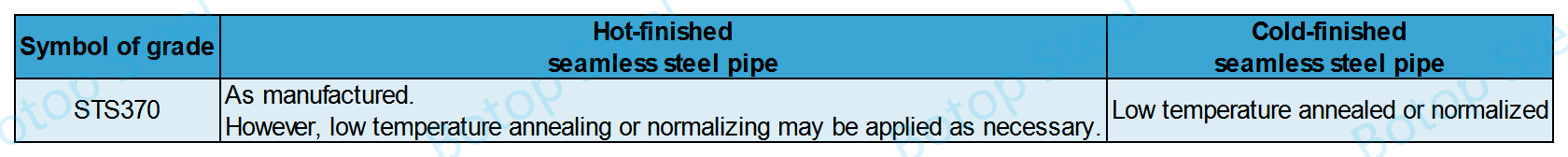

Ana amfani da ƙananan ƙananan zafin jiki don inganta aikin kayan aiki, rage taurin, da inganta ƙarfin, kuma ya dace da karfe mai sanyi.

Ana amfani da al'ada don inganta ƙarfin da ƙarfin kayan aiki, don haka karfe ya fi dacewa don tsayayya da damuwa na inji da gajiya, sau da yawa ana amfani dashi don inganta aikin karfe mai sanyi.

Ta hanyar waɗannan hanyoyin maganin zafi, an inganta tsarin ciki na karfe kuma an inganta kaddarorinsa, yana sa ya fi dacewa don amfani da buƙatar aikace-aikacen masana'antu.

Binciken zafi zai kasance daidai da JIS G 0320. Binciken samfurin zai kasance daidai da JIS G 0321.

| daraja | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (phosphorus) | S (sulfur) |

| Saukewa: STS370 | 0.25% max | 0.10-0.35% | 0.30-1.10% | 0.35% max | 0.35% max |

Binciken zafian fi yin nufin gwada sinadarai na albarkatun kasa.

Ta hanyar nazarin nau'in sinadarai na kayan albarkatun kasa, yana yiwuwa a iya hangowa da daidaita matakan sarrafawa da yanayin da za a iya buƙata a cikin tsarin samarwa, kamar ma'auni na maganin zafi da ƙari na abubuwan haɗin gwiwa.

Binciken samfuryayi nazarin abubuwan sinadaran gamayya don tabbatar da yarda da ingancin samfurin ƙarshe.

Binciken samfur yana tabbatar da cewa duk canje-canje, ƙari ko kowane mai yuwuwar ƙazanta a cikin samfurin yayin aikin masana'anta suna ƙarƙashin sarrafawa kuma samfurin ƙarshe ya cika ƙayyadaddun fasaha da buƙatun aikace-aikace.

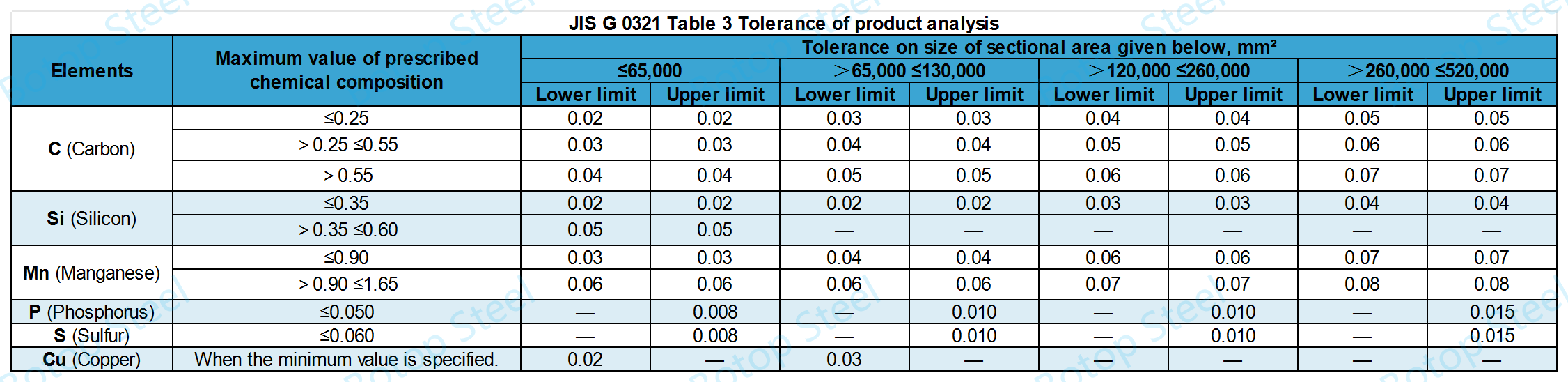

JIS G 3455 dabi'un nazarin samfurin ba za su bi ka'idodin abubuwan da ke cikin teburin da ke sama kawai ba, har ma da kewayon haƙuri zai dace da buƙatun JIS G 3021 Table 3.

Ƙimar haɓakawa don Gwajin Gwaji No. 12 (daidai da axis bututu) da Gwajin Gwaji A'a. 5 (daidaitacce zuwa axis bututu) wanda aka ɗauka daga bututu a ƙarƙashin 8 mm a cikin kauri na bango.

| Alamar daraja | An yi amfani da yanki na gwaji | Tsawaitawa min,% | ||||||

| Kaurin bango | ||||||||

| 1 ≤2 mm | 2 ≤3 mm | 3≤4 mm | ≤4 ≤5 mm | 5 ≤6 mm | 6≤7 mm | 7 mm8 ku | ||

| Saukewa: STS370 | Na 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Na 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Ana samun ƙimar elongation a cikin wannan tebur ta hanyar cire 1.5% daga ƙimar tsawo da aka bayar a cikin Tebura 4 don kowane raguwar 1 mm a cikin kauri daga 8 mm, kuma ta hanyar tattara sakamakon zuwa lamba bisa ga Dokar A na JIS Z 8401. | ||||||||

Za a iya tsallake gwajin lallaɓawa sai dai in an ƙayyade ta mai siye.

Sanya samfurin a cikin injin kuma daidaita shi har sai nisa tsakanin dandamali biyu ya kai ƙayyadadden ƙimar H. Sa'an nan kuma duba samfurin don tsagewa.

Lokacin gwada juriya mai mahimmancin bututun walda, layin da ke tsakanin walda da tsakiyar bututun yana kan hanyar matsawa.

H=(1+e)t/(e+t/D)

H: nisa tsakanin faranti (mm)

t: kaurin bangon bututu (mm)

D: waje diamita na bututu (mm)

e:akai-akai bayyana ga kowane sa na bututu.0.08 don STS370: 0.07 don STS410 da STS480.

Ya dace da bututu tare da diamita na waje na ≤ 50 mm.

Samfurin ba zai zama mai fashe ba lokacin lanƙwasa a 90° tare da diamita na ciki sau 6 fiye da diamita na waje na bututu.

Za a auna kusurwar lanƙwasa a farkon lanƙwasa.

Kowane bututun ƙarfe yana buƙatar a gwada shi ta hanyar ruwa ko kuma ba a lalata shi badon tabbatar da inganci da amincin bututu da kuma biyan ka'idojin amfani.

Gwajin Ruwan Ruwa

Idan ba a ƙayyade matsa lamba na gwaji ba, za a ƙayyade mafi ƙarancin gwajin gwajin ruwa daidai da Jadawalin Bututu.

| Kaurin bango mara kyau | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Matsakaicin gwajin hydraulic, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Lokacin da kauri na bangon diamita na waje na bututun ƙarfe ba daidai ba ne a cikin tebur na nauyin bututun ƙarfe, ya zama dole a yi amfani da dabara don ƙididdige ƙimar matsa lamba.

P=2st/D

P: gwajin gwaji (MPa)

t: kaurin bango na bututu (mm)

D: waje diamita na bututu (mm)

s: 60 % na mafi ƙarancin ƙimar ma'aunin yawan amfanin ƙasa ko ƙarfin tabbacin da aka bayar.

Lokacin da mafi ƙarancin gwajin gwajin hydrostatic na lambar shirin da aka zaɓa ya wuce gwajin gwajin P da aka samu ta dabarar, za a yi amfani da matsa lamba P azaman ƙaramin gwajin gwaji na hydrostatic maimakon zaɓi mafi ƙarancin gwajin gwajin hydrostatic a cikin tebur a sama.

Gwajin mara lalacewa

Gwajin da ba mai lalacewa ba na bututun ƙarfe ya kamata a yi taultrasonic ko eddy gwajin halin yanzu.

DominultrasonicHalayen dubawa, sigina daga samfurin tunani mai ƙunshe da mizanin tunani na aji UD kamar yadda aka ƙayyade a cikiFarashin 0582za a yi la'akari da matakin ƙararrawa kuma yana da sigina na asali daidai da ko mafi girma fiye da matakin ƙararrawa.

Daidaitaccen ganewar ganewa doneddy halin yanzujarrabawar za ta kasance nau'in EU, EV, EW, ko EX da aka ƙayyade a cikinFarashin 0583, kuma ba za a sami sigina daidai da ko mafi girma fiye da sigina daga samfurin tunani dauke da ma'auni na ma'auni na wannan nau'in.

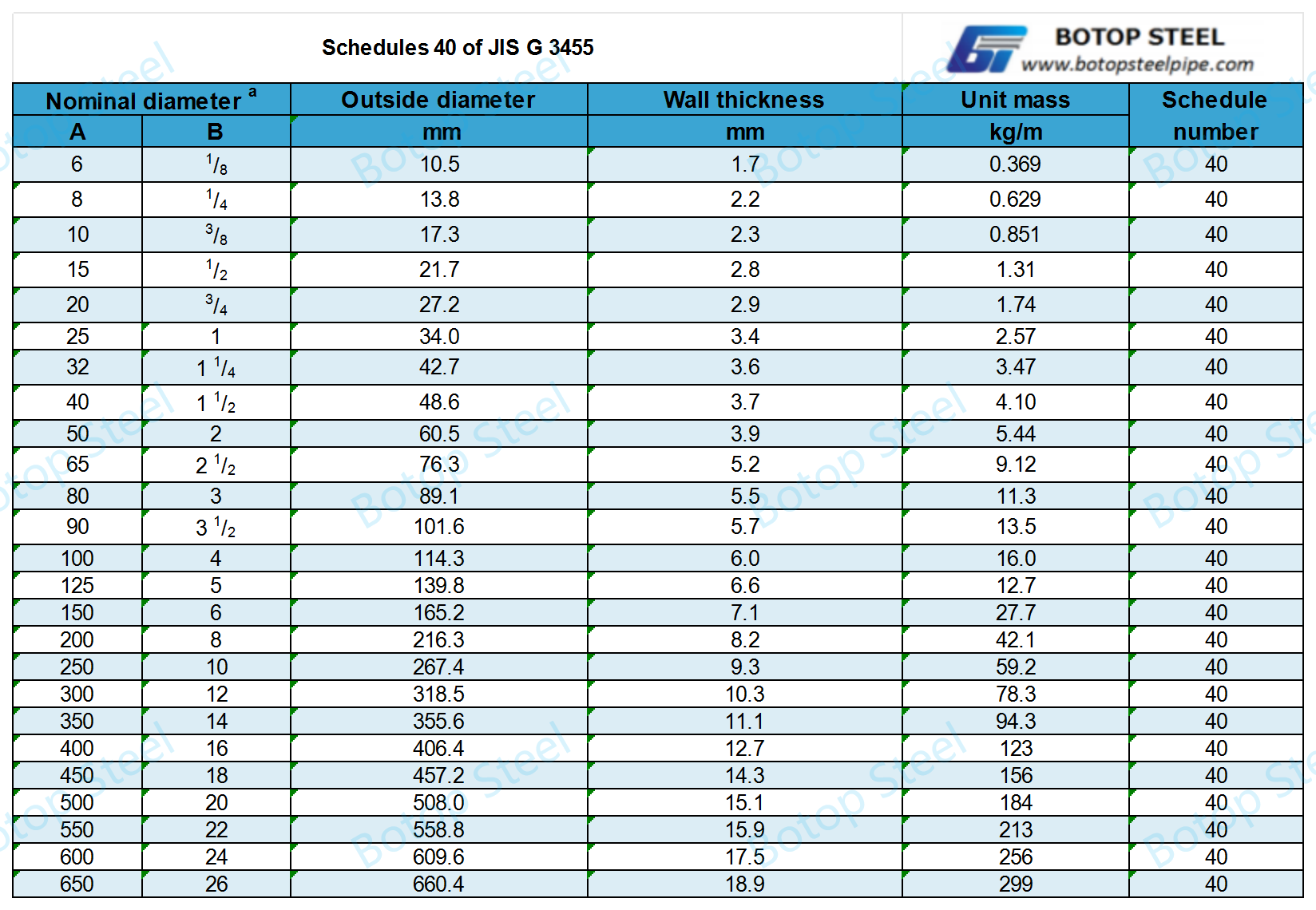

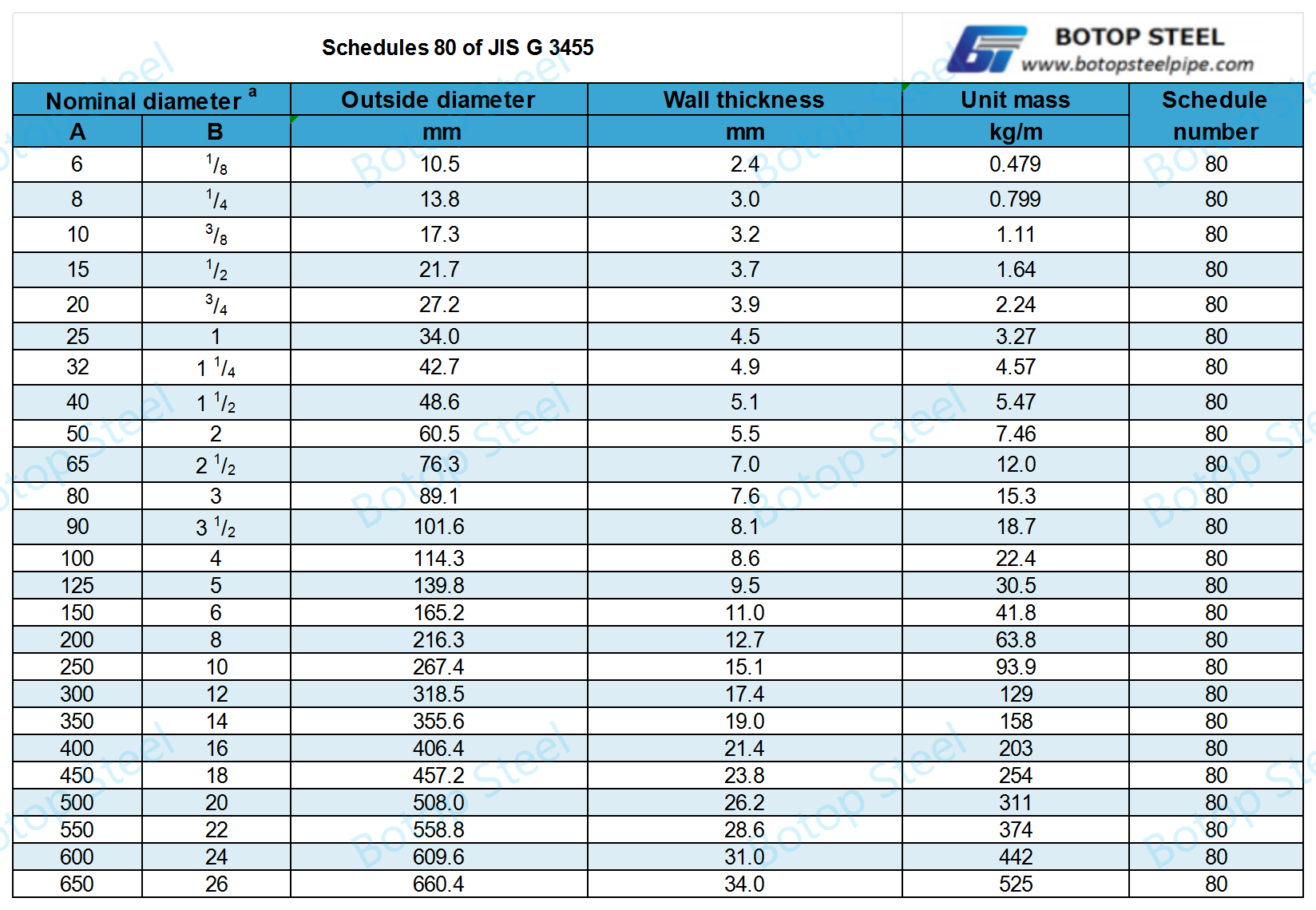

Don ƙarinCharts Nauyin Bututu da Jadawalin Bututua cikin ma'auni, za ku iya danna ta.

Jadawalin bututu na 40 ya dace da ƙananan aikace-aikacen matsa lamba saboda yana ba da kauri mai matsakaicin bango wanda ke guje wa nauyi mai yawa da farashi yayin tabbatar da isasshen ƙarfi.

Jadawalin 80 bututu ana amfani dashi ko'ina a cikin mahallin masana'antu waɗanda ke buƙatar ɗaukar nauyi mai ƙarfi, kamar tsarin sarrafa sinadarai da bututun mai da iskar gas, saboda ikonsa na jure matsi mafi girma da tasirin injina mai ƙarfi saboda kaurin bangon sa, yana ba da ƙarin aminci, tsaro, da dorewa.

Kowane bututu za a yi wa lakabi da bayanin da ke gaba.

a)Alamar daraja;

b)Alamar hanyar masana'anta;

c)GirmaMisali 50AxSch80 ko 60.5x5.5;

d)Sunan masana'anta ko alamar ganowa.

Lokacin da diamita na waje na kowane bututu ya yi ƙanƙanta kuma yana da wahala a yiwa kowane bututu alama, ko kuma lokacin da mai siye ya buƙaci a yiwa kowane bututun alama alama, kowane damshi na iya yin alama ta hanyar da ta dace.

STS370 ya dace da ƙananan matsa lamba amma in mun gwada da tsarin canja wurin ruwa mai zafi.

Tsarin dumama: A cikin dumama gari ko manyan tsarin dumama ginin, ana iya amfani da STS370 don jigilar ruwan zafi ko tururi saboda yana iya jure matsa lamba da canjin yanayin zafi a cikin tsarin.

Tushen wutar lantarki: A cikin samar da wutar lantarki, ana buƙatar babban adadin bututun tururi mai mahimmanci, kuma STS370 shine kayan aiki mai mahimmanci don kera waɗannan bututu saboda yana iya jure wa dogon lokaci na yanayin zafi da matsanancin yanayin aiki.

Matsakaicin tsarin iska: A cikin masana'antu da kuma samar da kayan aiki na atomatik, iska mai matsa lamba shine muhimmin tushen wutar lantarki, kuma ana amfani da bututun ƙarfe na STS370 don gina bututu don waɗannan tsarin don tabbatar da isar da iska mai lafiya da inganci.

Tsarin amfani da injina gabaɗaya: Saboda kyawawan kaddarorin inji, STS370 kuma ana iya amfani dashi a cikin kera na'urori daban-daban na tsarin da injiniyoyi, musamman a cikin aikace-aikacen da ake buƙatar takamaiman ƙarfi.

JIS G 3455 STS370 shine kayan ƙarfe na carbon da aka yi amfani da shi a cikin sabis na matsin lamba. Ana iya ɗaukar abubuwa masu zuwa daidai ko kusan daidai:

1. ASTM A53 Babban darajar B: Ya dace da aikace-aikacen tsarin gabaɗaya da injina kuma don jigilar ruwa.

2. API 5L Daraja B: Don manyan bututun sufuri na man fetur da iskar gas.

3. DIN 1629 St37.0: Domin injiniyan injiniya na gabaɗaya da ginin jirgin ruwa.

4. EN 10216-1 P235TR1: Bututun ƙarfe mara nauyi don yanayin zafi mai zafi da yanayin matsa lamba.

5. Bayani na ASTM A106: Bututun ƙarfe na carbon mara ƙarfi don sabis na zafi mai zafi.

6.ASTM A179: Bututun ƙarfe mai laushi mai laushi mara ƙarancin sanyi da bututu don sabis na ƙarancin zafin jiki.

7. DIN 17175 St35.8: Kayan bututu maras kyau don tukunyar jirgi da tasoshin matsa lamba.

8. TS EN 10216-2 P235GH: Bututun da ba su da kyau da kuma bututun da ba a yi amfani da su ba da kuma ƙarfe na ƙarfe don yanayin zafi da matsanancin yanayi.

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun ƙarfe na carbon a Arewacin kasar Sin, wanda aka sani don kyakkyawan sabis, samfurori masu inganci, da cikakkun mafita. Kamfanin yana ba da nau'ikan bututun ƙarfe na carbon da samfuran da ke da alaƙa, waɗanda suka haɗa da marasa ƙarfi, ERW, LSAW, da bututun ƙarfe na SSAW, da kuma cikakken jeri na kayan aikin bututu da flanges.

Kayayyakinsa na musamman sun haɗa da gawa mai daraja da austenitic bakin karafa, waɗanda aka keɓance don biyan buƙatun ayyukan bututun.