API (Standar Cibiyar Man Fetur ta Amurka) 5L shine ma'auni na duniya don bututun ƙarfe da ake amfani da su a cikin tsarin jigilar bututun mai.

API 5L yana rufe bututun ƙarfe don aikace-aikace iri-iri don jigilar iskar gas, mai, da sauran ruwaye.Ƙayyadaddun kwanan watan bugu na 46: aiki daga Nuwamba 1, 2018.

Idan kawai kuna son samun cikakken ra'ayi na API 5L, da fatan za a dannaAPI 5L Bayanin Ƙimar Bututu.

Maɓallan kewayawa

Abin da Aka Sabunta a API 5L 46th

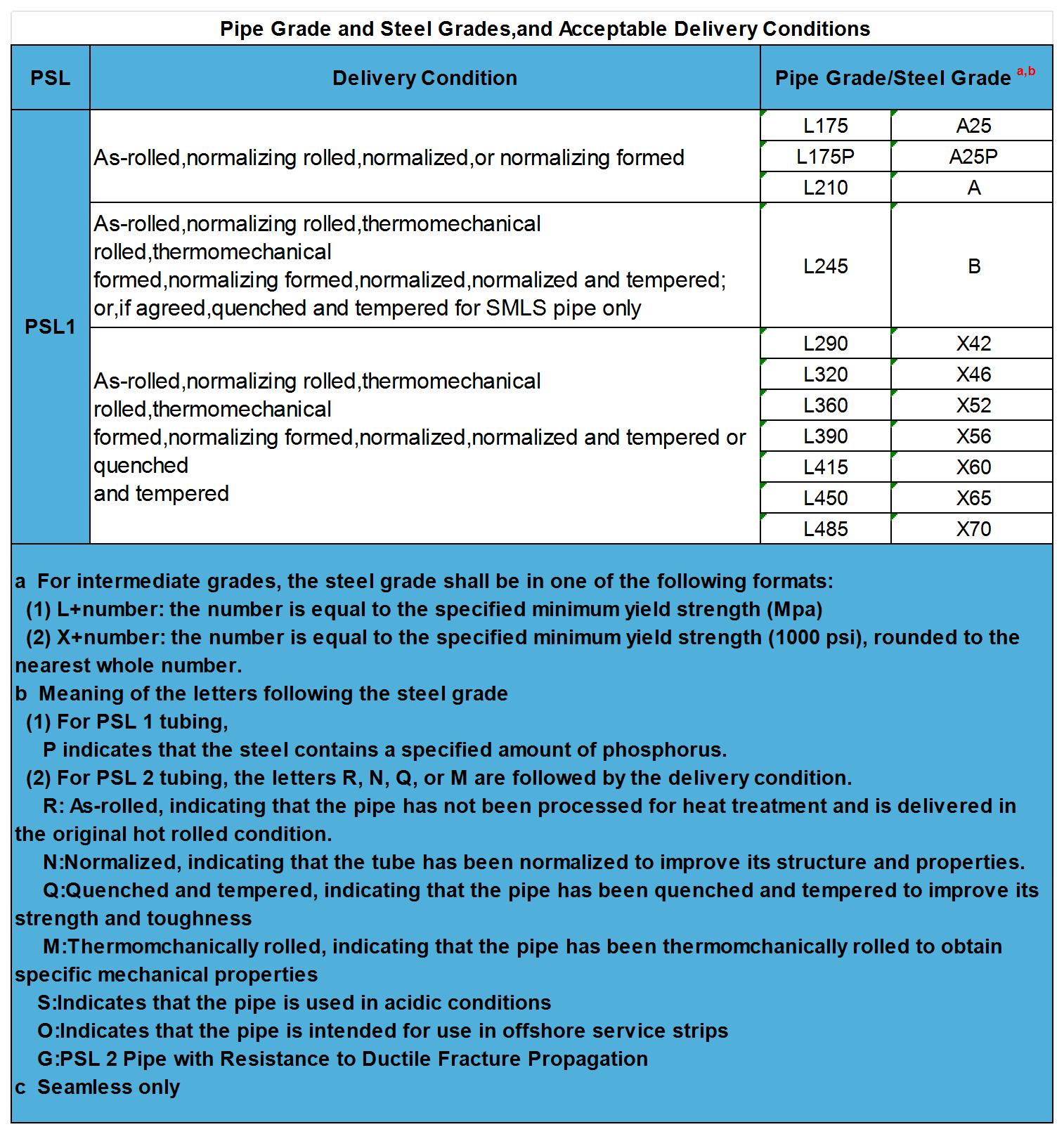

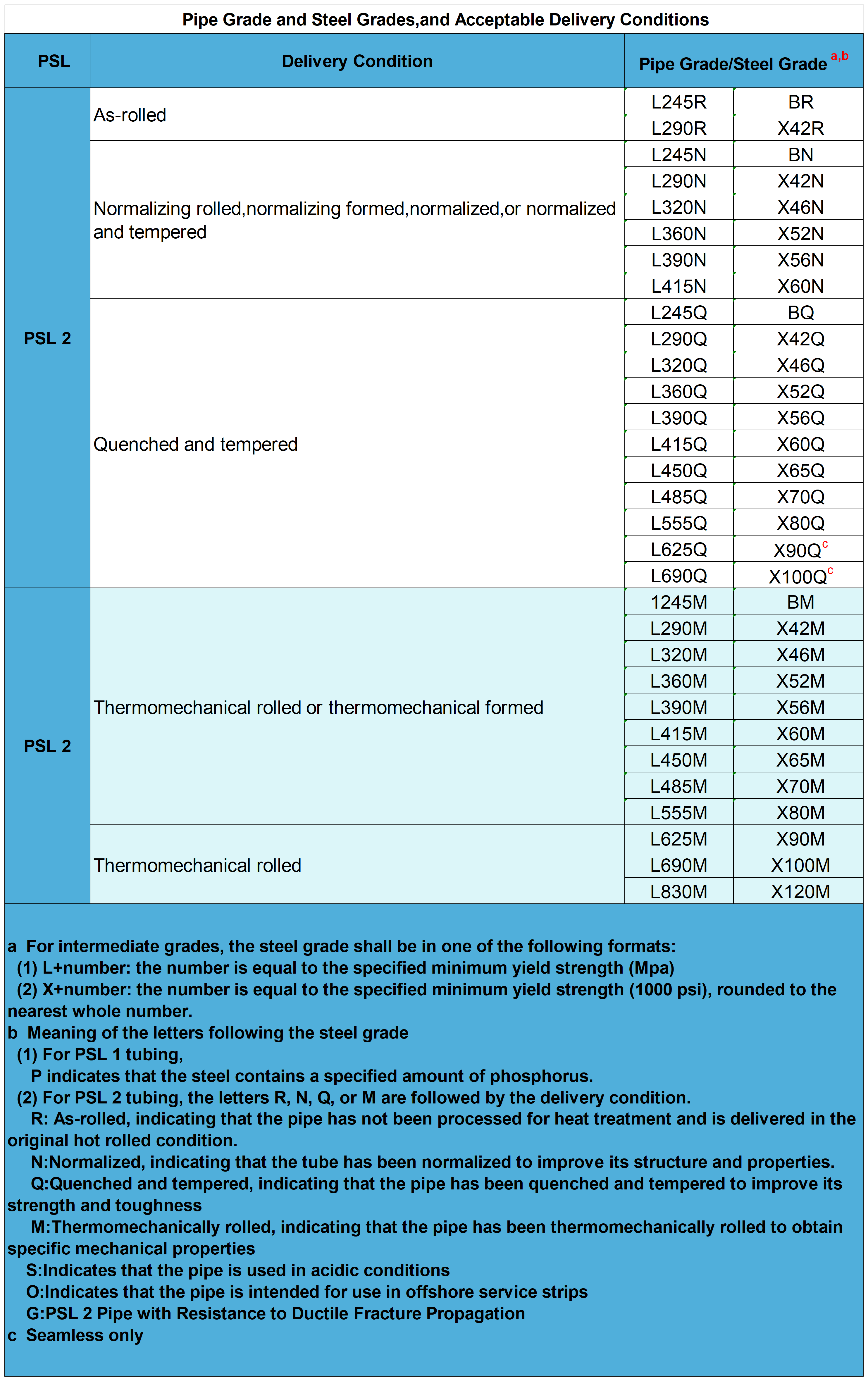

Asalin API 5L PSL

Rarraba Makin Karfe da Makin Bututu

Jihohin Bayarwa Karɓaɓɓu

Raw Materials for Karfe Bututu

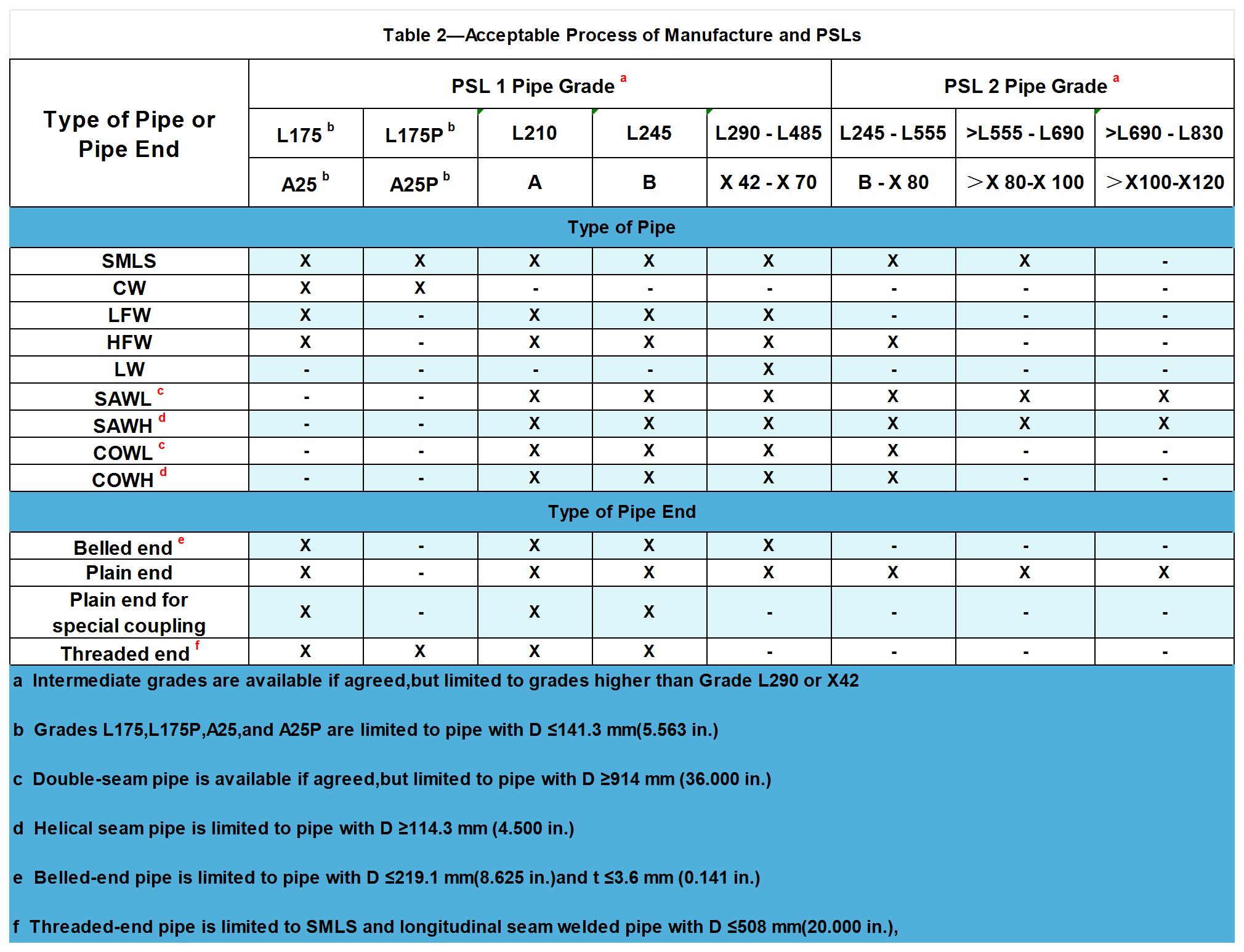

Nau'o'in Bututun Karfe da Ƙarshen Tube An Rufe ta API 5L

Tsare-tsaren Ƙirƙirar Ƙarfafa don PSL2 Tubin Karfe

Binciken bayyanar da lahani na kowa na API 5L

Duban Girma (Bambancin Girma)

API 5L Abubuwan Gwajin

Alamar Bututu da Wuri

Daidaiton Daidaitawa

Kayayyakinmu masu alaƙa

Abin da Aka Sabunta a API 5L 46th

Sabuntawa

Sabuntawa da faɗaɗa buƙatun don mahaɗin niƙa;

Abubuwan buƙatun da aka sabunta don madaidaicin ƙarshen bututu;

Sabbin buƙatun gwajin taurin ƙarfi don bututun API 5LPSL 2 don mahalli mai tsami da bututun API 5L PSL 2 don mahallin teku;

Sabo

API 5L PSL 2 bututu don aikace-aikacen da ke buƙatar ƙarfin nau'in filastik mai tsayi.

Asalin API 5L PSL

PSL: Ƙayyadaddun Matsayin Ƙayyadaddun Bututu;

Rarraba zuwa: API 5L PSL 1 da API 5L PSL 2.

Rarraba Makin Karfe da Makin Bututu

L + lamba(harafin L yana biye da ƙayyadaddun ƙarfin yawan amfanin ƙasa a MPa):

L175,L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485,L555,L625,L683,L690.

X + lamba(lambar da ke biye da harafin X yana ƙayyadad da mafi ƙarancin ƙarfin samarwa a cikin 1000 psi):

X42,X46,X52,X56,X60,X65,X70,X80,X90,X100,X120.

Kuma grade A da B.Darasi A=L210 B=L 2459

Jihohin bayarwa masu karbuwa

Lura: L415/X60 ko mafi girma maki bai kamata a yi amfani da shi a madadin L360/X52 ko ƙananan maki ba tare da yarjejeniyar mai siye ba.

Raw Materials for Karfe Bututu

Ingot, billet, billet, tsiri (naɗa) ko faranti.

Lura:

1. The albarkatun kasa donAPI 5L PSL2karfe bututu zai zama lafiya-hatsi sedimented karfe.

2. Karfe tsiri (naɗa) ko farantin da aka yi amfani da shi don kera bututun ƙarfe na API 5L PSL2 ba zai ɗauki kowane walda ba.

Nau'o'in Bututun Karfe da Ƙarshen Tube An Rufe ta API 5L

Welded Karfe bututu

CW Pipe:Tsari na samar da dinki ta dumama tsiri a cikin tanderu da kuma latsa gefuna da aka kafa tare da inji, inda aka haɗa coils na tsiri tare don samar da ci gaba da kwararar tsiri don injin walda.

COWHPkira:Samfurin Tubular yana da kabu mai helical guda ɗaya da aka samar ta hanyar haɗakar baka na ƙarfe na iskar gas da waldawar baka mai nutsewa, wanda ba a cire gaba ɗaya ba a cire ƙwanƙolin ƙarfen iskar gas ta hanyar waldawar baka.

COWL bututu:Samfurin Tubular yana da kabu ɗaya ko biyu na tsayin daka da aka samar ta hanyar haɗakar baka na ƙarfe na gas da waldawar baka mai nutsewa, inda ba a cire gabaɗayan katakon gas ɗin baƙar walda ta hanyar waldawar baka.

EW Pipe:Samfurin Tubular yana da kabu mai tsayi ɗaya wanda aka samar ta hanyar walƙiya mai ƙaranci ko babba mai ƙarfi.

HFW Pipe:EWpipe ya samar' tare da mitar walda na yanzu daidai ko fiye da 70 kHz.

LFW Pipe:Ana samar da bututun EW tare da mitar walda na yanzu wanda bai wuce 70 kHz ba.

LW Pipe:Tubular samfurin yana da kabu ɗaya mai tsayi wanda aka samar ta hanyar walƙiya ta Laser.

SAWH Pipe:Samfurin Tubular yana da kabu mai helical guda ɗaya wanda tsarin waldawar baka mai zurfi ya samar.

SAWbututu:Samfurin Tubular yana da kabu ɗaya ko biyu na tsayin daka wanda aka samar ta hanyar waldawar baka.

Bututu Karfe mara sumul

SMLS bututu:Hot birgima sumul karfe bututu da sanyi birgima sumul karfe bututu, akwai wasu sauran hanyoyin sarrafa, kamar sanyi zane, sanyi zane, ƙirƙira, da dai sauransu.

API 5L PSL2 nau'ikan bututu don aikace-aikace na musamman

Juriya ga Yada Karya (G)

Bututun Sabis Mai tsami (S)

Bututun Sabis na Ƙasashen waje (O)

Ana buƙatar layin filastik na kwana

Nau'in Ƙarshen Bututu

Ƙarshen Socket, Ƙarshen Flat, Ƙarshen Ƙarshen Ƙarshen Ƙarshen Ƙarshen Ƙarshen Ƙarshen Zare.

Lura:

1. Ƙarshen soket, ƙarshen bututu don ƙugiya na musamman, da kuma ƙarshen bututun da aka zana don API 5L PSL1 kawai.

2. L175 P/A25 P karfe sa API 5L PSL1 karfe bututu za a machined tare da threaded iyakar, da API 5L PSL1 karfe bututu na sauran karfe maki za a machined da lebur iyakar.

3. API 5L PSL 2 tubes za a tsĩrar da lebur iyakar.

Tsare-tsaren Ƙirƙirar Ƙarfafa don PSL2 Tubin Karfe

| Tebur 3-Hanyoyin Ƙirƙira Karɓar Don Bututun PSL 2 | ||||

| Nau'in Bututu | Farkon Materia | Samar da bututu | Bututu Heat Magani | Bayarwa Sharadi |

| SMLS | Ingot, Bloom, ko billet | Kamar yadda aka yi birgima | - | R |

| Normalizing forming | - | N | ||

| Zafafan kafa | Daidaitawa | N | ||

| Quenching da tempering | Q | |||

| Hot forming da sanyi gamawa | Daidaitawa | N | ||

| Quenching da tempering | Q | |||

| HFW | Nada mai naɗaɗɗen al'ada | Sanyi kafa | Maganin zafia na yankin walda kawai | N |

| Thermomechanical-birgima nade | Sanyi kafa | Maganin zafia na yankin walda kawai | M | |

| Maganin zafia na yankin walda da kuma kawar da damuwa gabaɗayan bututu | M | |||

| Kamar birgima ko thermomechanical-birgima nada | Sanyi kafa | Daidaitawa | N | |

| Quenching da fushi | Q | |||

| Ciwon sanyi ya biyo baya da zafi ragewa a ƙarƙashin sarrafawa zafin jiki sakamakon yanayin da aka daidaita | - | N | ||

| Ciwon sanyi ya biyo baya thermomechanical forming na bututu | - | M | ||

| SAW ko SANNU | Al'ada ko na al'ada- birgima ko faranti | Sanyi kafa | - | N |

| Kamar yadda aka yi birgima thermomechanical-birgima normalizing-birgima, ko al'ada | Sanyi kafa | Daidaitawa | N | |

| Thermomechanical-birgima nada ko faranti | Sanyi kafa | - | M | |

| An kashe da fushi farantin karfe | Sanyi kafa | - | Q | |

| Kamar yadda aka yi birgima thermomechanical-birgima normalizing-birgima, ko nada al'ada ko faranti | Sanyi kafa | Quenching da fushi | Q | |

| Kamar yadda aka yi birgima thermomechanical-birgima normalizing-birgima, ko nada al'ada ko faranti | Normalizing forming | - | N | |

| aDuba ISO 5L 8.8 don aikace-aikacen jiyya na zafi | ||||

Binciken bayyanar da lahani na kowa na API 5L

Bayyanuwa

Wurin waje na bututu zai zama santsi kuma ba shi da lahani wanda zai iya shafar ƙarfi da abubuwan rufewa na bututu.

Manyan Laifuka

Gefuna masu kauri:Za a iya samun mafi kyawun gefuna ta hanyar dubawa ta gani.

Arc yana ƙonewa:Za a yi hukunci da konewar Arc a matsayin mai lahani.

Arc konewa wasu lahani ne da aka samu ta hanyar narkewar saman ƙarfen da ke haifar da baka tsakanin lantarki ko ƙasa da kuma saman bututun ƙarfe.

Wuraren tuntuɓar tabo ne na tsaka-tsaki kusa da layin walda na bututun EW, wanda ke haifar da tuntuɓar wutar lantarki da ke ba da walƙiyar halin yanzu da saman bututun.

Delamination:Duk wani keɓancewa ko haɗawa wanda ya shimfiɗa saman bututu ko fuska mai murɗa kuma yana> 6.4 mm (0.250 in) a tsayin dawafi akan dubawa na gani za a ɗauki aibi.

Matsalolin Geometric:Bambance-bambancen lissafi (misali, toshe mai lebur ko pout, da sauransu), ban da ramin digo, wanda aka haifar ta hanyar samar da bututu ko aikin masana'anta.Nisa tsakanin matsananci batu da tsawo na al'ada kwane-kwane na bututu, watau, zurfin fiye da 3.2 mm (0.125 in), za a yi la'akari da lahani.

Ramin da aka sauke zai zama ≤ 0.5 D a kowace hanya.

Tauri: Lokacin da duban gani ya nuna taurin da ake zargi, za a yi amfani da na'urar gwajin tauri mai ɗaukuwa don gudanar da gwajin taurin, kuma ƙima guda ɗaya tare da ƙimar taurin fiye da 35 HRC, 345 HV10, ko 327 HBW za a yi la'akari da lahani idan girman girman. na ciki ya fi 50 mm (2.0 in) a kowace hanya.

Kulawa mara kyau

Da fatan za a koma zuwa abubuwan da suka dace a cikin API 5L Shafi C don sarrafawa.

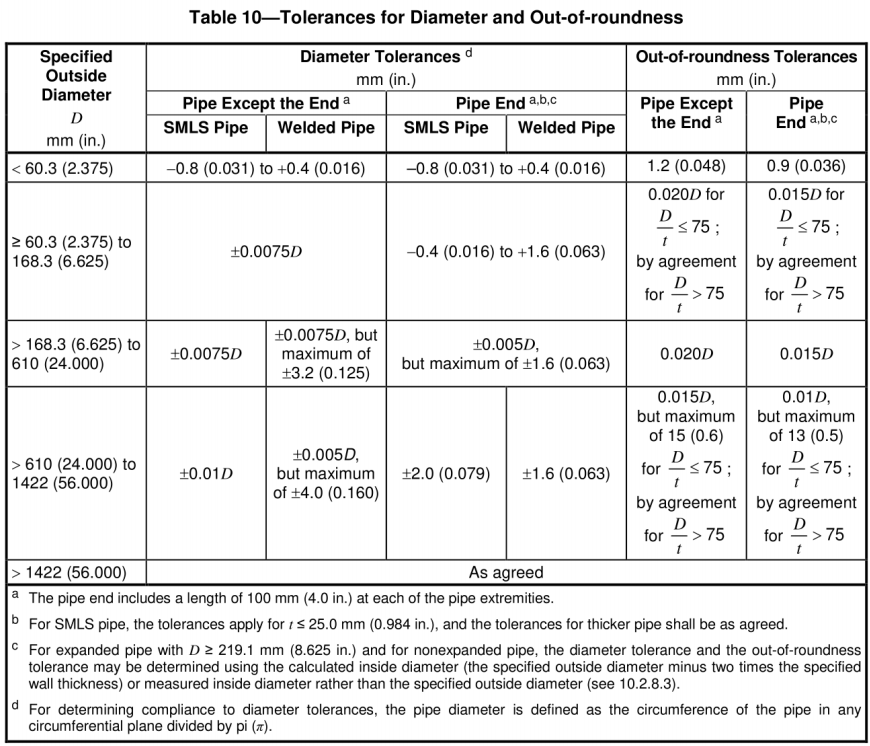

Duban Girma (Bambancin Girma)

Jadawalin Nauyin Bututu da Rage nauyi

Tsarin Nauyi

M=(DT)×T×C

M shine yawan adadin kowane tsawon raka'a;

D shine ƙayyadadden diamita na waje, wanda aka bayyana a cikin millimeters (inci);

T shine ƙayyadadden kauri na bango, wanda aka bayyana a cikin millimeters (inci);

C shine 0.02466 don ƙididdigewa a cikin raka'a SI da 10.69 don ƙididdigewa a cikin raka'o'in USC.

TSARI DA TSARI NA NAUYIN PIPE

Teburan nauyi na bututu a cikin API 5L ana nufin suISO 4200kumaSaukewa: ASME B36.10M, wanda ke ba da daidaitattun ƙididdiga don bututu tare da ƙayyadadden diamita na waje da ƙayyadadden kauri na bango.

Jadawalin 40 da Jadawalin 80an haɗe a ƙasa, idan kuna son ganin cikakken jadawalin bututu,don Allah danna nan!

Rage nauyi

Ingancin kowane bututu dangane da ka'idar: nauyi: 95% ≤ ka'idar nauyi ≤ 110;

Juyawa da ƙananan bututu ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa: 5% ≤ 110% na nauyin ka'idar;

L175, L175P, A25, da A25P karfe maki: 95% ≤ 110% na ka'idar nauyi.

Diamita na Waje da Tsawon Kaurin bango

| Tebur 9-An Halatta Ƙayyadaddun Ƙayyadaddun Diamita na Waje da Ƙayyadaddun Kaurin bango | ||

| Ƙayyadaddun Diamita na Waje D mm (in.) | Ƙaunar bangon Ƙayyadaddun t mm (in.) | |

| Girman Haske na Musammana | Girman Girma na yau da kullun | |

| ≥10.3 (0.405) zuwa <13.7 (0.540) | - | ≥1.7 (0.068) zuwa 2.4 (0.094) |

| ≥13.7 (0.540) zuwa <17.1 (0.675) | - | ≥2.2 (0.088) zuwa 3.0 (0.118) |

| ≥17.1 (0.675) zuwa <21.3 (0.840) | - | ≥2.3 (0.091) zuwa≤3.2 (0.125 |

| ≥21.3 (0.840) zuwa <26.7 (1.050) | - | ≥2.1 (0.083) zuwa ≤7.5 (0.294) |

| ≥26.7 (1.050) zuwa <33.4 (1.315) | - | ≥2.1 (0.083) zuwa ≤7.8 (0.308) |

| ≥33.4 (1311}5) zuwa <48.3 (1.900) | - | ≥2.1 (0.083) zuwa ≤10.0 (0.394) |

| ≥48.3 (1.900) zuwa <60.3 (2.375) | - | ≥2.1 (0.083) zuwa ≤12.5 (0.492) |

| ≥60.3 (2.375) zuwa <73.0 (2.875) | ≥2.1 (0.083) zuwa 3.6 (0.141) | > 3.6 (0.141) zuwa ≤14.2 (0.559) |

| ≥73.0 (2.875) zuwa <88.9 (3.500) | ≥2.1 (0.083) zuwa 3.6 (0.141) | > 3.6 (0.141) zuwa ≤20.0 (0.787) |

| ≥88.9 (3.500) zuwa <101.6 (4.000) | ≥2.1 (0.083) zuwa 4.0 (0.156) | > 4.0 (0.156) zuwa ≤22.0 (0.866) |

| ≥101.6 (4.000) zuwa <168.3 (6.625) | ≥2.1 (0.083) zuwa 4.0 (0.156) | > 4.0 (0.156) zuwa ≤25.0 (0.984) |

| ≥168.3 (6.625) zuwa <219.1 (8.625) | ≥2.1 (0.083) zuwa 4.0 (0.156 | > 4.0 (0.156) zuwa ≤40.0 (1.575) |

| ≥219.1 (8.625) zuwa <273.1 (10.750) | ≥3.2 (0.125) zuwa 4.0 (0.156 | > 4.0 (0.156) zuwa ≤40.0 (1.575 |

| ≥273.1 (10.750) zuwa <323.9 (12.750) | ≥3.6 (0.141) zuwa 5.2 (0.203) | > 5.2 (0.203) zuwa ≤45.0 (1.771) |

| ≥323.9 (12.750) zuwa <355.6 (14.000) | ≥4.0 (0.156) zuwa ≤5.6 (0.219) | > 5.6 (0.219) zuwa ≤45.0 (1.771 |

| ≥355.6 (14.000) zuwa <457 (18.000) | ≥4.5 (0.177) zuwa ≤7.1 (0.281) | > 7.1 (0.281) zuwa ≤45.0 (1.771 |

| ≥457 (18.000) zuwa <559 (22.000) | ≥4.8 (0.188) zuwa ≤7.1 (0.281) | > 7.1 (0.281) zuwa ≤45.0 (1.771) |

| ≥559 (22.000) zuwa <711 (28.000) | ≥5.6 (0.219) zuwa ≤7.1 (0.281) | > 7.1 (0.281) zuwa ≤45.0 (1.771) |

| ≥711 (28.000) zuwa <864 (34.000) | ≥5.6 (0.219) zuwa≤7.1 (0.281) | > 7.1 (0.281) zuwa ≤52.0 (2.050) |

| ≥864 (34.000) zuwa <965 (38.000) | - | ≥5.6 (0.219) zuwa ≤52.0 (2.050) |

| ≥965 (38.000) zuwa <1422 (56.000) | - | ≥6.4 (0.250) zuwa ≤52.0 (2.050) |

| ≥1422 (56.000) zuwa <1829 (72.000) | - | ≥9.5 (0.375) zuwa ≤52.0 (2.050) |

| ≥1829 (72.000) zuwa <2134 (84.000) | - | ≥10.3 (0.406) zuwa ≤52.0 (2.050) |

| aBututu mai haɗuwa da ƙayyadaddun diamita na waje da ƙayyadadden kauri na bango an ayyana shi azaman bututu mai girman haske na musamman;sauran haɗe-haɗe da aka bayar a cikin wannan tebur an ayyana su azaman bututu mai girma na yau da kullun. | ||

Diamita da Roundness Deviation

Rage Kaurin bango

| Tebur 11-Haƙuri don Kaurin bango | |

| Kaurin bango t mm (in.) | Haƙuria mm (in.) |

| Farashin SMLSb | |

| ≤4.0 (0.157) | +0.6 (0.024) -0.5 (0.020) |

| > 4.0 (0.157) zuwa <25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146) ko +0.1t, duk wanda ya fi girma -3.0 (0.120) ko-0.1t, duk wanda ya fi girma |

| Welded Pipecd | |

| ≤5.0 (0.197) | ± 0.5 (0.020) |

| > 5.0 (0.197) zuwa <15.0 (0.591) | ± 0.1t |

| ≥15.0 (0.591) | ± 1.5 (0.060) |

| aIdan odar siyan ya ƙididdige ƙarancin haƙuri don kaurin bango ƙasa da ƙimar da ake buƙata da aka bayar a cikin wannan tebur, ƙarin juriya na kauri na bango za a ƙaru da adadin da ya isa don kula da iyakar haƙurin da ya dace. bDon bututu tare da D2 355.6 mm (14.000 in.) da 1 2 25.0 mm (0.984 in.), haƙurin kaurin bango a gida na iya wuce ƙarin juriya don kauri na bango ta ƙarin 0.05t, muddin ƙarin juriya ga taro (duba) 9.14) ba a wuce ba. cƘarin haƙuri don kauri na bango baya shafi yankin walda. dDuba 9.13.2 don ƙarin hani. | |

Tsawon Tsawon

Kafaffen-tsawon jurewar bututu: Tsawon tsayi yakamata ya zama mm 500 (inci 20).

Haƙurin bututu mai tsayi bazuwar:

| Tebur 12-Haƙuri don Bututu Tsawon Bazuwar | |||

| Tsawon Random Nadi m (ft) | Mafi qarancin Tsawon m (ft) | Matsakaicin Tsawon Matsakaici Ga kowane Abun oda m (ft) | Matsakaicin Tsayin m (ft) |

| Bututu mai zare-da-haɗe-haɗe | |||

| 6 (20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72 (45.0 |

| Bututun Ƙarshe | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72 (45.0) |

| 15(50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

Madaidaiciya

Jimlar ƙetare daga madaidaiciyar layi a kan dukan tsawon bututu zai zama <0.2% na tsawon bututu;

Maɓallin yanki daga madaidaiciyar layi zai zama <3.2 mm (0.125 in) sama da tsayin 1.5 m (5.0 ft) na kowane ƙarshen bututu.

Maɓallin kusurwar Bevel

Tube tare da t> 3.2 mm (0.125 in) lebur iyakar za a yi amfani da shi tare da belun walda tare da kusurwar bevel na 30 ° -35 °.

Faɗin Tushen Tushen Tushen

1.6 mm (0.063 in) tare da karkatacciyar ± 0.8 mm (0.031 in).

Range of Inner Cone Angle (kawai don bututu maras sumul)

| Tebur 13-Mafi girman kusurwar Taper na ciki don bututun SMLS | |

| Ƙaunar bangon Ƙayyadaddun t mm (in.) | Matsakaicin kusurwar Taper digiri |

| <10.5 (0.413) | 7.0 |

| 10.5 (0.413) zuwa <14.0 (0.551) | 9.5 |

| 14.0 (0.551) zuwa <17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

Ƙarshen Ƙarshen Ƙarshen Ƙarshen Ƙarshe (ba tare da square)

Ana auna ma'auni na waje a matsayin rata tsakanin ƙarshen bututu da ƙafar ƙarshen bututu, wanda zai zama 1.6 mm (0.063 in.).

Welding Seam Deviation

Kuskuren Tsari/Sheet:

Don bututu mai walƙiya (EW) da Laser-welded (LW), rashin daidaituwa bai kamata ya haifar da ragowar kaurin bango a walda wanda bai kai mafi ƙarancin kaurin bangon da aka yarda ba.

Ga Submerged Arc Welded (SAW) da Bututun Haɗuwa (COW), kuskuren bai kamata ya wuce daidaitattun ƙimar da aka bayar a cikin Tebu 14 na API 5L ba.

Burs (Electro-welded (EW) da Laser-welded (LW) tubes):

Za a cire burbushin waje zuwa yanayin daɗaɗɗa (tare da kayan tushe).

Burs na ciki ba zai wuce mm 1.5 (0.060 in) sama da kwandon bututun ba, kuma kaurin bango a wurin cire burar ba zai zama ƙasa da ƙaramin ƙaurin bangon da aka yarda ba.

Weld Height(Submerged Arc Welding (SAW) and Combination Welding (COW) Pipe):

Cire sauran tsayin walda na ciki a cikin mafi ƙarancin 100 mm (4.0 in) na ƙarshen bututun a kowane ƙarshen bututun, sannan a niƙa waldar don kada ya tashi sama da 0.5 mm (0.020 in) sama da saman saman. na kusa da bututu.

API 5L Abubuwan Gwajin

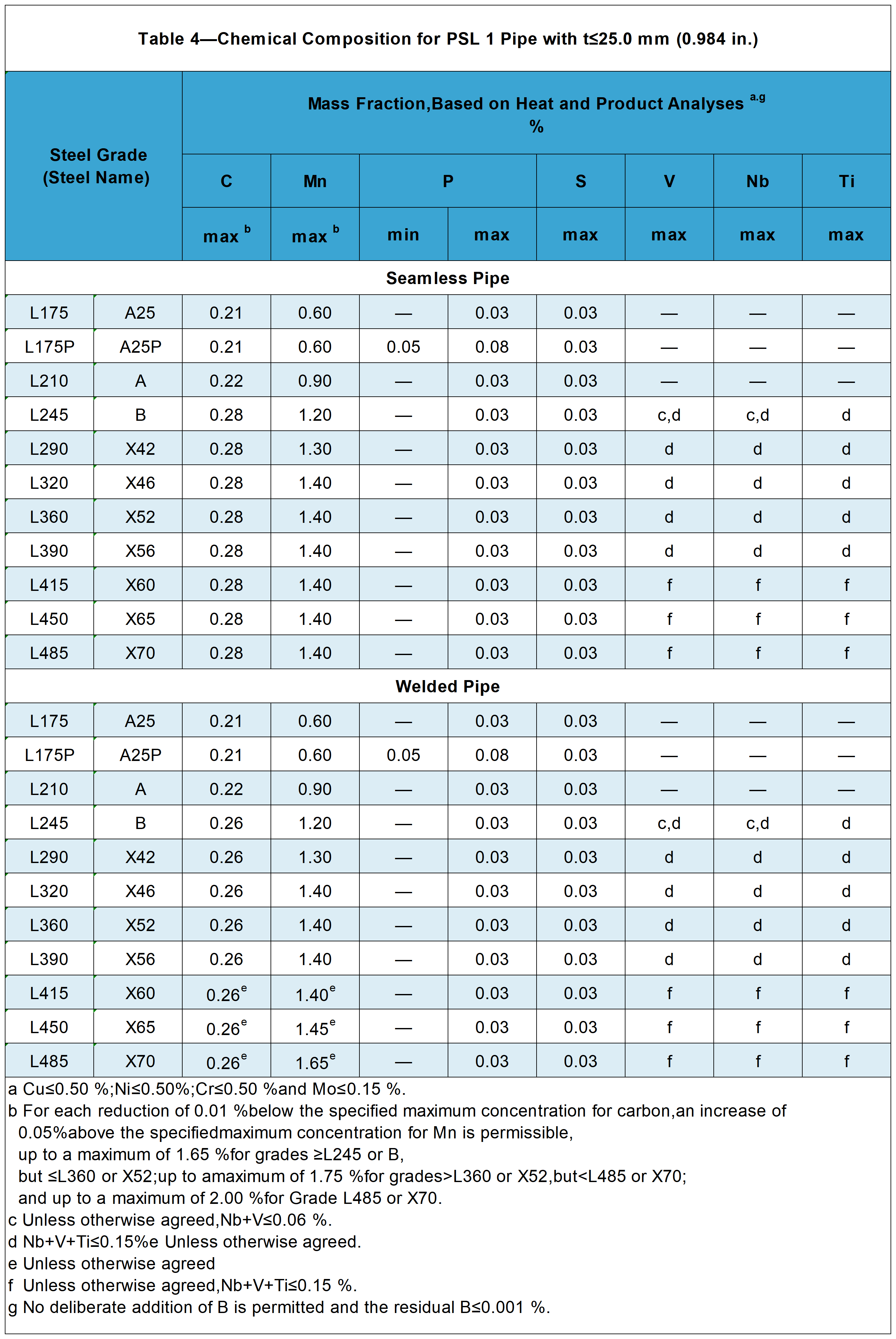

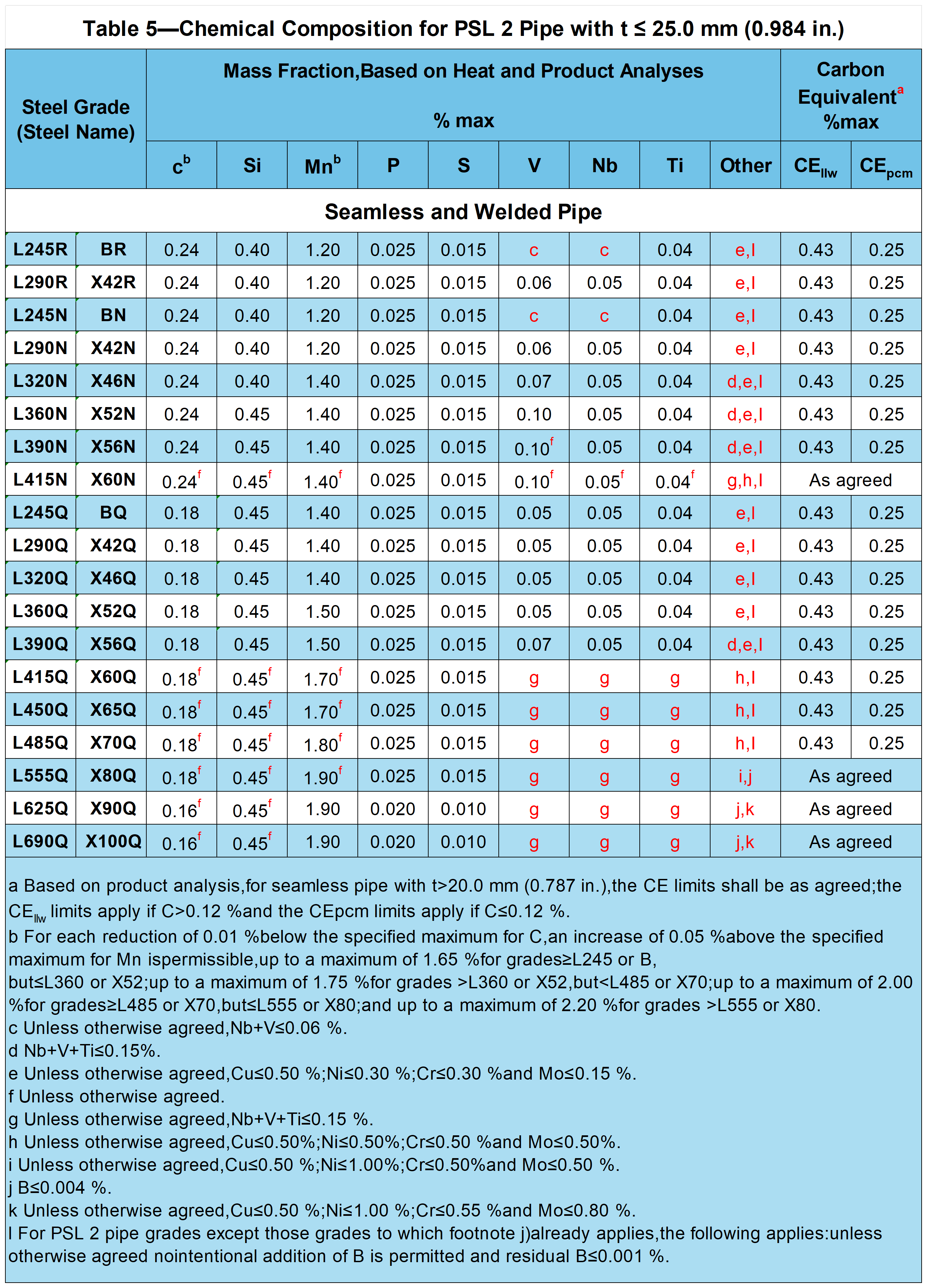

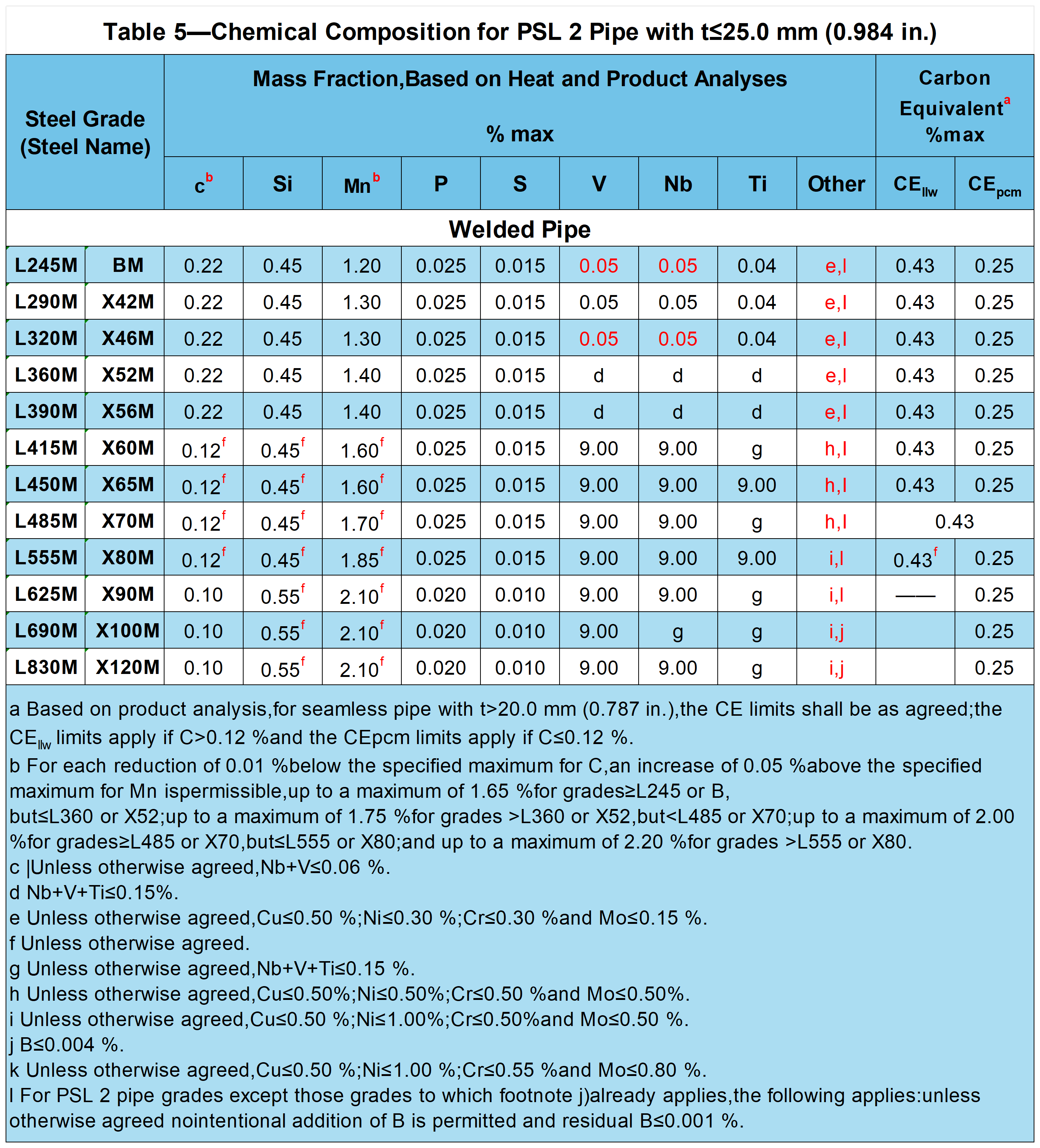

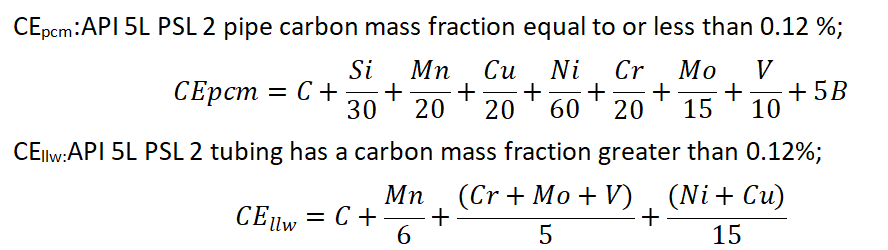

Haɗin Sinadari

Hanyar Gwaji: Koma zuwa ISO 9769 ko ASTM A751.

Abubuwan sinadaran API 5L PSL1 da API 5L PSL2 karfe bututu t> 25.0 mm (0.984 in) za a ƙaddara ta hanyar shawarwari dangane da abubuwan da ke tattare da sinadarai a cikin tebur masu dacewa.

Haɗin Kemikal don PSL 1 Bututu tare da t≤25.0 mm (0.984 in.)

Haɗin Kemikal don PSL 2 Bututu tare da t≤25.0 mm (0.984 in.)

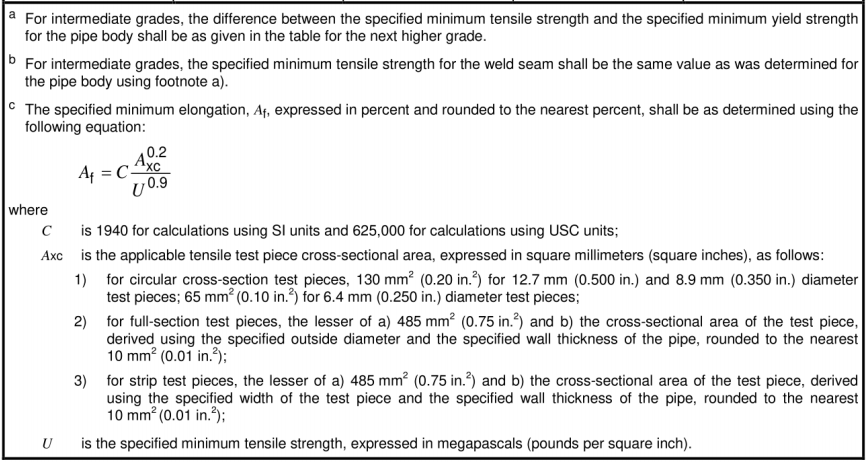

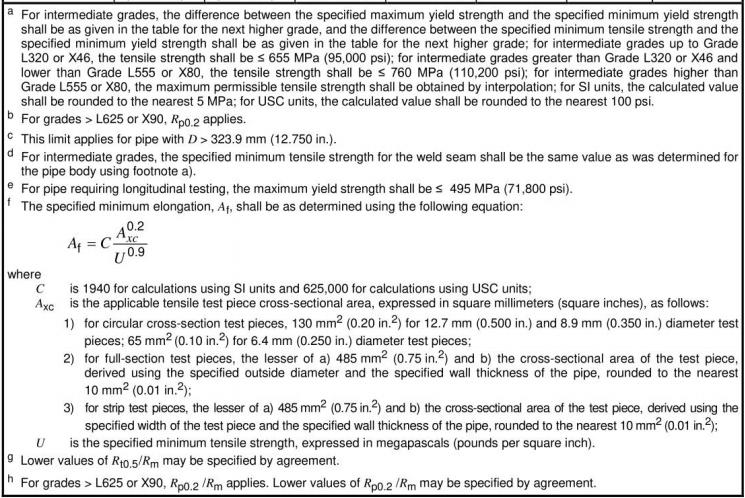

Tensile Properties

Hanyoyin Gwaji: Za a yi daidai da ISO 6892-1 ko ASTM A370.

Abubuwan Bukatu don Sakamakon Gwajin Tensile na PSL 1 Pipe

| Table 6-Bukatun don sakamakon Sakamakon Tasun da Tenes na PSL 1 | ||||

| Bututu Grade | Jikin Bututu na Bututu mara sumul da Welded | Weld Seam na EW, LW, SAW, da bututun COW | ||

| Ƙarfin Haɓakaa Rku.5 MPa (psi) | Ƙarfin Ƙarfin Ƙarfia Rm MPa (psi) | Tsawaitawa (a kan 50 mm ko 2 in.) Af % | Ƙarfin Ƙarfin Ƙarfib Rm MPa (psi) | |

| min | min | min | min | |

| L175 ya da A25 | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L175P ya da A25P | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L210 ya da A | 210 (30,500) | 335 (48,600) | c | 335 (48,600) |

| L245 ya da B | 245 (35,500) | 415 (60,200) | c | 415 (60,200) |

| L290 ya da X42 | 290 (42,100) | 415 (60,200) | c | 415 (60,200) |

| L320 ya da X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 ya da X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) |

| L390 ya da X56 | 390 (56,600) | 490 (71,100) | c | 490 (71,100) |

| L415 ya da X60 | 415 (60,200) | 520 (75,400) | c | 520 (75,400) |

| L450 ya da X65 | 450 (65,300) | 535(77,600) | c | 535(77,600) |

| L485 ya da X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Abubuwan Bukatu don Sakamakon Gwajin Tensile na PSL 2 Pipe

| Tebur 7-bukatun sakamakon sakamakon gwajin Tenes ga PSL 2 PIPE | |||||||

| Bututu Grade | Jikin Bututu na Bututu mara sumul da Welded | Weld Seam da HFW SAW kuma CoW Pipe | |||||

| Ƙarfin Haɓakaa Rto.5 MPa (psi) | Ƙarfin Ƙarfin Ƙarfia Rm MPa (psi) | Raboac Rt0.5/Rm | Tsawaitawa (na 50 mm ko 2 in.) Af % | Tashin hankali Ƙarfid Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R ya da BR L245N ya da BN L245Q ya da BQ L245M ya da BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R ya da X42R L290N ya da X42N L290Q ya da X42Q L290M ya da X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N ya da X46N L320Q ya da X46Q L320M ya da X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N ya da X52N L360Q ya da X52Q L360M ya da X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N ya da X56N L390Q ya da X56Q L390M ya da X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N ya da X56N L390Q ya da X56Q L390M ya da X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N ya da X60N L415Q ya da X60Q L415M ya da X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q ya da X65Q L450M ya da X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q ya da X70Q L485M ya da X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q ya da X80Q L555 ya da X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M ya da X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q ya da X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M ya da X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q ya da X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M ya da X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Za a ba da rahoton haɓakar kashi dari a lokacin hutu don samfurori tare da tsayin ma'auni na 50 mm (2 in).

Don samfuran da ke da tsayin ma'aunin ƙasa da 50 mm (2 inci), haɓakawa a lokacin hutu za a canza shi zuwa haɓakawa a 50 mm (2 in) daidai da ISO 2566-1 ko ASTM A370.

Gwajin Matsi na Hydrostatic

Hanyar gwaji: API 5L 10.2.6.

Duk girman bututu maras sumul (SMLS) da bututu mai walda tare da D ≤ 457 mm (18.000 in) za su sami lokacin daidaitawa na bai wuce daƙiƙa 5 ba.bututu mai walda tare da D> 457 mm (18.000 in) zai sami lokacin daidaitawa na bai gaza 10 seconds ba.

Lanƙwasa Gwajin

Hanyoyin Gwaji: Gwajin lanƙwasawa zai dace da buƙatun ISO 8491 ko ASTM A370.

Babu wani ɓangare na samfurin da zai tsage kuma walda ba zai tsage ba.

Matsayin L175P/A25P shine ƙarfe mai haɓaka phosphorus wanda ke ba da mafi kyawun aikin zaren fiye da L175/A25 ƙarfe amma ya fi wuya a lanƙwasa.

Gwajin Lalacewa

Hanyoyin Gwaji: Gwajin matsawa zai dace da buƙatun ISO 8492 ko ASTM A370.

Nisa tsakanin faranti biyu zai zama kamar yadda ba za a fasa walda ba har sai an kai ƙayyadadden nisa.

Gwajin Lankwasawa Mai Jagora

Hanyoyin Gwaji: Gwajin lanƙwasawa mai jagora zai dace da buƙatun ISO 5173 ko ASTM A370.

Gwajin Tauri

Hanyar gwaji: Gwajin taurin gwargwadon ISO 6506, ISO 6507, ISO 6508, ko ASTM A370.

Lokacin da aka sami kullutu masu tsauri a cikin duban bayyanar, ya kamata a yi amfani da ma'aunin taurin wuyan hannu don gwajin taurin.

Gwajin Tasirin CVN don API 5L PSL2 Karfe Bututu

Hanyoyin Gwaji: Gwajin tasirin charpy zai dace da buƙatun ASTM A370.

Gwajin DWT don API 5L PSL2 Welded Pipe

Hanyar gwaji: Gwajin DWT zai kasance daidai da API5L3.

Macro-Inspection da Metallographic Test

Za a bincika karkatar da walda ta ciki da ta waje na bakar welded (SAW) da bututu mai walda (COW) ta hanyar duban ma'auni.

Don bututun da ke buƙatar maganin zafi na walda, za a yi gwajin ƙarfe don tabbatar da cewa an yi wa HAZ ɗin gabaɗayan zafi da kyau a cikin cikakken kaurin bango.

Don bututun da ba sa buƙatar maganin zafi na walda, za a yi gwajin ƙarfe don tabbatar da cewa babu ragowar martensite mara ƙarfi.

Gwajin Mara lalacewa (kawai don bututun API 5L PSL2 na musamman guda uku)

Hanyar gwaji: API 5L Annex E.

Alamar Bututu da Wuri

Abubuwan alama gama gari don bututun ƙarfe:

Sunan mai kera bututu ko alama;

Alama "API Spec 5L".(Gaba ɗaya an taƙaita zuwa API 5L.) Samfuran da suka dace da ma'auni masu jituwa fiye da ɗaya ana iya yiwa alama da sunan kowane ma'auni.

Ƙayyadaddun Diamita na Waje

Ƙayyadadden kauri na bango

Matsayin bututu (sunan karfe)

Nau'in bututu

Tsawon (tsawon bututu a m zuwa mafi kusa 0.01 m (a cikin ft zuwa mafi kusa goma na ƙafa))

Wurin alamar bututun ƙarfe

D ≤ 48.3 mm (1.900 in) bututun ƙarfe: Shafukan da ake ci gaba da ƙirƙira tare da tsayin bututun ƙarfe ko waɗanda za a iya amintar da su zuwa bututun ƙarfe.

Bututu mai D> 48.3 mm (1.900 in):

Filayen waje: Farawa daga wani wuri a saman waje na bututu tsakanin 450 mm da 760 mm (1.5 ft da 2.5 ft) daga ƙarshen bututun.

Ciki: Fara yin alama akan saman ciki na bututu aƙalla 150 mm (6.0 in) daga ƙarshen bututun.

Daidaiton Daidaitawa

Bututu na ƙasa da ƙasa da ƙa'idodin bututu wanda API 5L yayi daidai ko, a wasu yanayi, zaɓin madadin, da kuma ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun aikace-aikace:

Matsayin duniya da na yanki

1. ISO 3183 - Matsayin bututun mai na duniya don masana'antar mai da iskar gas ta Ƙungiyar Ƙididdiga ta Duniya ta buga kuma tana da alaƙa da API 5L.

TS EN 10208 - Matsayin Turai don bututun ƙarfe don jigilar iskar gas da ruwa.

3. GB / T 9711 - Ma'auni na kasar Sin don tsarin sufuri na bututu a cikin masana'antar man fetur da iskar gas.

4. CSA Z245.1 - Kanadiya Standard rufe layin bututu don sufuri na man fetur da gas.

5. GOST 20295 - Matsayin Rasha don bututun layin karfe don jigilar kayan mai da mai.

6. IPS (Iran Petroleum Standards) - Ka'idodin Man Fetur na Iran don bututun layin don masana'antar mai da iskar gas.

7. JIS G3454, G3455, G3456 - Jafananci Masana'antu Standards don watsa bututu na daban-daban matsa lamba azuzuwan.

8. DIN EN ISO 3183 - Matsayin Masana'antu na Jamus dangane da ISO 3183 don bututun layi.

9. AS 2885 - Matsayin Australiya don tsarin bututun layi don jigilar mai da iskar gas.

Ƙimar ƙayyadaddun aikace-aikace

1. API 5CT - Ma'aunin Cibiyar Man Fetur na Amurka don yin rijiyar mai da tubing, wanda, ko da yake ana amfani da shi da farko a rijiyoyin mai, yana da mahimmanci a masana'antar mai da iskar gas.

2. ASTM A106 - American Society for Testing and Materials Standard for m da welded carbon karfe bututu don high-zazzabi sabis.

3. ASTM A53 - Cibiyar Gwaji da Kayan Aiki ta ƙasa don ƙayyadaddun bututun ƙarfe na carbon maras sumul da walda, yawanci ana amfani da su don jigilar ruwa a cikin ɗaki ko ƙananan yanayin zafi.

4. TS EN ISO 3834 - Ƙungiya ta ƙasa da ƙasa don daidaitattun buƙatun, mai da hankali kan tsarin tabbatar da ingancin ƙarfe na walda.

5. dnv-os-f101 - Ma'aunin rarrabuwar jama'a ta Norwegian don tsarin bututun da ke karkashin ruwa don bututun watsa mai da iskar gas.

6. MSS SP-75 - Manufacturers Standards Society misali mayar da hankali a kan high ƙarfi, manyan diamita madauwari welded karfe bututu kayan aiki.

Gudanar da Inganci da Matsayin Dacewar Muhalli

1. NACE MR0175 / ISO 15156 - Abubuwan buƙatun kayan da aka yi amfani da su a cikin man fetur da iskar gas a cikin mahallin sulfur-dauke da hydrocarbon, wanda, yayin da yake damuwa da zaɓin kayan abu, yana da mahimmanci don tabbatar da juriya na kayan da aka yi amfani da su a cikin masana'antar mai da gas.

Kayayyakinmu masu alaƙa

API 5L PSL1&PSL2 GR.B Bututu mai Welded Submerged-Arc

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Carbon Karfe Bututu

API 5L GR.B Babban Kauri Mai Kauri Ba Tare Da Sulun Bututu Don Sarrafa Injini

API 5L Gr.X52N PSL 2 Bututun Karfe Mara Sumul ACC.Zuwa IPS-M-PI-190(3) & NACE MR-01-75 don sabis na tsami

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Mai da Gas Carbon Karfe Bututu

API 5L GR.B Bututun Layi Mara Sumul don Matsawa da Tsari

API 5L/ASTM A106/ASTM A53

BotopSteel kwararre ne na kasar SinWelded Carbon Karfe Bututu Manufacturer & SuppliersSama da Shekaru 16 tare da 8000+ Ton na Bututun Layi mara kyau a cikin Hannun jari kowane wata.Mun shirya don ba ku amsa a cikin sa'o'i 24 da yawa ba da daɗewa ba bayan karɓar buƙatu ɗaya kuma don haɓaka fa'idodi marasa iyaka da tsari na juna tare da yuwuwar yuwuwar.

tags: API 56 46th, Dimensional Deviations, PSL1, PSL2,masu kaya, masana'antun, masana'antu, masu hannun jari, kamfanoni, masu siyarwa, siyayya, farashi, zance, girma, siyarwa, farashi.

Lokacin aikawa: Maris 22-2024