AS 1074 Bututun ƙarfe da tubulars don sabis na yau da kullun

Maɓallan kewayawa

AS 1074 Daidaitaccen Bayani

| Iyakar | Yana ƙayyadaddun buƙatun don bututun ƙarfe mai zare da tubular, da bututun ƙarfe na ƙarshen-ƙarshen da suka dace da screwing kamar yadda aka ƙayyade a AS 1722.1 |

| Rabe-rabe | Kaurin bango guda uku na bututu: wanda aka zaɓa Haske, Matsakaici, da Nauyi |

| Tube | Za a iya welded da sumul tubes: tsawon uniform madauwari m sashe |

| Screw Threads | Abubuwan da aka zana za su bi AS 1722.1 |

| Waje Diamita | DN 8 zuwa DN 150 wanda ya haɗa (girman ƙima) |

| Kaurin bango | 1.8mm-5.4mm |

| shafi | Varnish shafi, galvanized, 3 yadudduka PE, FBE, da dai sauransu. |

| Ka'idoji masu alaƙa | ISO 65; ISO 3183; ASTM A53, ASTM A106; BS EN 10255; BS 1387; DIN 2440; DIN 2448; JIS G 3452; JIS G 3454; CSA Z245.1; GOST 10704-62-10704-91; ; EN 10217-1; da dai sauransu. |

AS 1074 Haɗin Sinadaran

| sinadaran abun da ke ciki | iyaka |

| CE(Mai daidai da Carbon) | ≤0.4 |

| P(Phosphorus) | max 0.045% |

| S(sulfur) | max 0.045% |

CE(madaidaicin carbon) =C+Mn/6

Phosphorus (P)kumaSulfur (S):Wadannan abubuwa guda biyu suna rage tauri da waldar karfe.Babban matakan phosphorus da sulfur na iya haifar da ƙarfe ya yi karye, musamman a ƙananan zafin jiki.

Daidaiton Carbon (CE):Wannan ma'auni ne na waldawar karfe wanda ke yin la'akari da adadin carbon da ke cikin karfen da kuma sauran abubuwan da ake hadawa da su (misali, manganese, chromium, molybdenum, da sauransu) wadanda ke shafar waldarsa.Mafi girman daidai da carbon, ƙarancin walda da ƙarfe shine kuma ana buƙatar ƙarin preheating da matakan jiyya don walda.

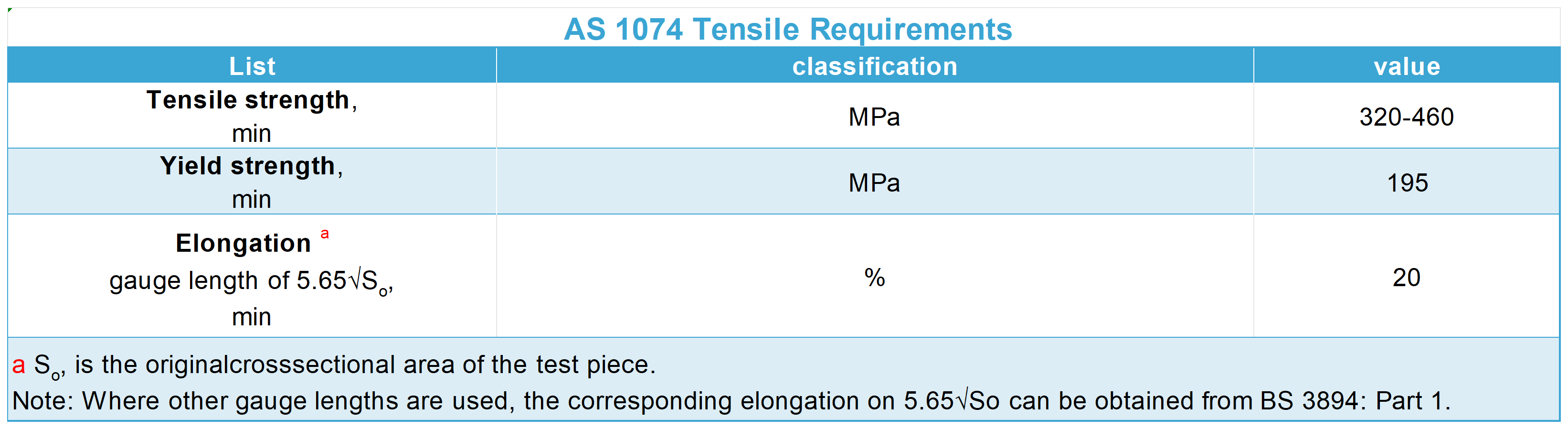

Abubuwan Bukatun Tensile AS 1074

AS 1074 girma

| Tebur 2.1 GIRMAN KARFE TUBE-HASKE | |||||

| Girman mara kyau | Waje Diamita mm | Kauri mm | Mass na baki tube kg/m | ||

| min | max | A fili ko dunƙule ƙare | Cire kuma socketed | ||

| DN 8 | 13.2 | 13.6 | 1.8 | 0.515 | 0.519 |

| DN 10 | 16.7 | 17.1 | 1.8 | 0.67 | 0.676 |

| DN 15 | 21.0 | 21.4 | 2.0 | 0.947 | 0.956 |

| DN 20 | 26.4 | 26.9 | 2.3 | 1.38 | 1.39 |

| DN 25 | 33.2 | 33.8 | 2.6 | 1.98 | 2.00 |

| DN 32 | 41.9 | 42.5 | 2.6 | 2.54 | 2.57 |

| DN 40 | 47.8 | 48.4 | 2.9 | 3.23 | 3.27 |

| DN 50 | 59.6 | 60.2 | 2.9 | 4.08 | 4.15 |

| DN 65 | 75.2 | 76.0 | 3.2 | 5.71 | 5.83 |

| DN 80 | 87.9 | 88.7 | 3.2 | 6.72 | 6.89 |

| Farashin DN100 | 113.0 | 113.9 | 3.6 | 9.75 | 10.0 |

| SHAFIN 2.2 GIRMAN KARFE TUBES-MATSAKI | |||||

| Girman mara kyau | Waje Diamita mm | Kauri mm | Mass na baki tube kg/m | ||

| min | max | A fili ko dunƙule ƙare | Cire da soket | ||

| DN 8 | 13.3 | 13.9 | 2.3 | 0.641 | 0.645 |

| DN 10 | 16.8 | 17.4 | 2.3 | 0.839 | 0.845 |

| DN 15 | 21.1 | 21.7 | 2.6 | 1.21 | 1.22 |

| DN 20 | 26.6 | 27.2 | 2.6 | 1.56 | 1.57 |

| DN 25 | 33.4 | 34.2 | 3.2 | 2.41 | 2.43 |

| DN 32 | 42.1 | 42.9 | 3.2 | 3.10 | 3.13 |

| DN 40 | 48 | 48.8 | 3.2 | 3.57 | 3.61 |

| DN 50 | 59.8 | 60.8 | 3.6 | 5.03 | 5.10 |

| DN 65 | 75.4 | 76.6 | 3.6 | 6.43 | 6.55 |

| DN 80 | 88.1 | 89.5 | 4.0 | 8.37 | 8.54 |

| Farashin DN100 | 113.3 | 114.9 | 4.5 | 12.2 | 12.5 |

| Farashin DN125 | 138.7 | 140.6 | 5.0 | 16.6 | 17.1 |

| Farashin DN150 | 164.1 | 166.1 | 5.0 | 19.7 | 20.3 |

| SHAFIN 2.3 GIRMAN TUSHEN KARFE-NA KYAU | |||||

| Girman mara kyau | Waje Diamita mm | Kauri mm | Mass na baki tube kg/m | ||

| min | max | A fili ko dunƙule ƙare | Cire da soket | ||

| DN 8 | 13.3 | 13.9 | 2.9 | 0.765 | 0.769 |

| DN 10 | 16.8 | 17.4 | 2.9 | 1.02 | 1.03 |

| DN 15 | 21.1 | 21.7 | 3.2 | 1.44 | 1.45 |

| DN 20 | 26.6 | 27.2 | 3.2 | 1.87 | 1.88 |

| DN 25 | 33.4 | 34.2 | 4.0 | 2.94 | 2.96 |

| DN 32 | 42.1 | 42.9 | 4.0 | 3.80 | 3.83 |

| DN 40 | 48.0 | 48.8 | 4.0 | 4.38 | 4.42 |

| DN 50 | 59.8 | 60.8 | 4.5 | 6.19 | 6.26 |

| DN 65 | 75.4 | 76.6 | 4.5 | 7.93 | 8.05 |

| DN 80 | 88.1 | 89.5 | 5.0 | 10.3 | 10.5 |

| Farashin DN100 | 113.3 | 114.9 | 5.4 | 14.5 | 14.8 |

| Farashin DN125 | 138.7 | 140.6 | 5.4 | 17.9 | 18.4 |

| Farashin DN150 | 164.1 | 166.1 | 5.4 | 21.3 | 21.9 |

| NOTE: Girma da taro suna daidai da ISO 65. | |||||

Idan kuna son ƙarin koyo game dajadawalin nauyin bututu da jadawalina cikin Standard,don Allah danna nan!

Hakuri Mai Girma

| Jurewar girma | ||

| Jerin | Nau'in | tsinke |

| Kauri (T) | Haske waldadden bututu | min 92% |

| Matsakaici da nauyi welded bututu | min 90% | |

| Matsakaici da nauyi bututu marasa sumul | min 87.5% | |

| Waje Diamita(OD) | Haske waldadden bututu | Tebur 2.1 |

| Matsakaicin bututu | Tebur 2.2 | |

| Bututu masu nauyi | Table 2.3 | |

| Mass | jimlar tsawon≥150m | ± 4% |

| Bututun karfe daya | 92% ~ 110% | |

| Tsawon tsayi | Daidaitaccen tsayi | 6.50± 0.08 m |

| Daidai tsayi Inda aka ƙayyade tsayin daka, ko dai don bututun zaren ko don bututun ƙarshen ƙarshen | 0 ~ +8 mm | |

Galvanized

| Jerin | Abun ciki | |

| Daidaitawa | Tubes da aka ba da umarnin galvanized za su bi AS 1650. | |

| Bayyanuwa | Fuskar bututun galvanized zai kasance mai ci gaba, mai santsi da rarrabawa daidai gwargwado, kuma ba tare da lahani wanda zai shafi aikin ko aikin bututun da ake amfani da shi ba. | |

| Ciki Diamita | Bututun DN 8 zuwa DN 25 masu haɗawa zasu, bayan galvanizing, su sami damar samun sanda mai tsayin mm 230, na diamita mai dacewa kamar yadda aka bayar a bayanin kula A, ta hanyar su don tabbatar da diamita na ciki kyauta. | |

| Lura | Bututu | Bututun da za a yi zaren za a yi amfani da su kafin zaren. |

| Sockets | Za a sanya kwasfa da zaren zare kafin a yi zaren. | |

| Tubular | Tubular da za a yi zaren za a yi ta galvanized kafin zaren. | |

| Bayanin A: Bututu Diamita: DN 8 Diamita na sanda: 4.4mm Bututu Diamita: DN 10 Diamita na sanda: 7.1mm Diamita Bututu: DN 15 Diamita na sanda: 9.5mm Bututu Diamita: DN 20 Diamita na sanda: 14.3mm Diamita Bututu: DN 25 Diamita na sanda: 20.6mm | ||

Alama

Za a bambanta tubes da launi a gefe ɗaya kamar haka:

| Tube | Launi |

| Bututu mai haske | Brown |

| Matsakaici bututu | Blue |

| Tubu mai nauyi | Ja |

Za a yi amfani da alamun kafin bututun su bar aikin masana'anta.

Kariya

Zaren duk bututu za a kiyaye su da kyau daga lalata.Kowane bututu wanda ya fi DN 80 girma zai kasance yana da zoben kariya wanda aka maƙala a ƙarshen da aka zare.

Ma'auni masu dangantaka AS 1074

TS EN ISO 65: Bututun ƙarfe na carbon wanda ya dace da dunƙulewa daidai da TS EN ISO 7-1

TS EN ISO 3183 Masana'antar mai da iskar gas - bututun ƙarfe don tsarin jigilar bututu

ASTM A53Matsakaicin Ƙirar Ƙarfe don Bututu, Karfe, Baƙar fata da Zazzaɓi, Mai Rufe Zinc, Welded da mara kyau

ASTM A106: Madaidaicin Ƙimar Ƙarfe don Bututun Karfe na Karfe don Babban Sabis na Zazzabi

TS EN 10255 Bututun ƙarfe mara ƙarfi wanda ya dace da walda da zaren

BS 1387: Bututun ƙarfe don amfani da ruwa, gas, iska, da tururi

DIN 2440: Bututun ƙarfe matsakaici nauyi dace da dunƙulewa

DIN 2448: Bututun ƙarfe mara ƙarfi da girman bututu, yawan jama'a na kowane tsayin raka'a

JIS G 3452: Carbon karfe bututu don talakawa bututu

JIS G 3454: Carbon karfe bututu don matsa lamba sabis

CSA Z245.1: Karfe bututu

GOST 10704-91: Layin Ƙarfe na Ƙarfe da Lantarki

SANS 62-1: Bututun Karfe don Ruwa da Ruwan Sharar gida

API 5L: Ƙididdiga don Bututun Layi

TS EN 10217-1 Bututun ƙarfe da aka weld don dalilai na matsa lamba - Bututun ƙarfe mara ƙarfi tare da ƙayyadaddun kaddarorin zafin daki

Iyakar Aikace-aikacen

Gina: Ana amfani da shi a cikin gine-gine a matsayin wani muhimmin sashi na aikin famfo, bututun iskar gas, da tsarin dumama.

Masana'antu da masana'antu: azaman tsarin bututu don jigilar kayayyaki, sharar gida, da ƙãre kayayyakin.

Masana'antar mai da iskar gas: a matsayin bututu don jigilar mai da iskar gas, musamman a tsarin tarawa da rarrabawa.

Noma: don jigilar ruwa a cikin tsarin ban ruwa.

Masana'antar hakar ma'adinai: isar da ma'adanai da sauran kayan aiki, da tsarin magudanar ruwa.

Injiniyan birni: bututun ruwa a cikin birane da tsarin magudanar ruwa, da kuma tsarin kashe gobara.

Injiniyoyi da ababen hawa: don jigilar ruwa da iskar gas a zaman wani ɓangare na kayan aikin injiniya da ababen hawa.

Kayayyakin mu

Game da Mu

BotopSteel ƙwararren ƙwararren ƙwararren ƙwararren ƙwararren Carbon Karfe ne wanda ke kera bututun Karfe & Masu samarwa Sama da Shekaru 16 tare da tan 8000+ na bututun Layi mara kyau a cikin Hannun jari kowane wata.Samar da ku da ingancin bututun ƙarfe mai inganci da ƙarancin farashi, idan kuna buƙatar don Allah a tuntuɓe mu, za mu samar muku da samfuran bututun ƙarfe da yawa.

tags: kamar yadda 1074, Karfe shambura, welded shambura, sumul shambura,masu kaya, masana'antun, masana'antu, masu hannun jari, kamfanoni, masu siyarwa, siyayya, farashi, zance, girma, siyarwa, farashi.

Lokacin aikawa: Maris 29-2024