AS/NZS 1163Ƙayyadaddun tsarin sanyi-kafa, juriya-welded, sassan sassan bututun ƙarfe na tsari don tsarin tsarin gabaɗaya da aikace-aikacen injiniya ba tare da maganin zafi na gaba ba.

Daidaitaccen tsarin aiki ga Ostiraliya da New Zealand.

Maɓallan kewayawa

Rabewa ta Siffar Sashe na Giciye

AS/NZS 1163 Rarraba Matsakaici Matsayi

Albarkatun kasa

Tsarin Masana'antu

AS/NZS 1163 Haɗin Sinadari

Gwajin Tensile AS/NZS 1163

Gwajin Tasirin AS/NZS 1163

Gwajin Ciwon Sanyi

Jarabawa mara lalacewa

Haƙuri don Siffai da Mass

Hakuri na Tsawon

AS/NZS 1163 SSHS Jerin Girman Bututu da Teburin Nauyi Haɗe

Gyare-gyare na waje da na kwaskwarima

Galvanized

AS/NZS 1163 Alama

Aikace-aikace na AS/NZS 1163

Kayayyakinmu masu alaƙa

Rabewa ta Siffar Sashe na Giciye

Nau'o'i uku a cikin AS/NZS 1163 za a iya rarraba su bisa ga siffar sashin giciye, waɗanda su ne:

Sassan da'ira (CHS)

Sassan ramukan rectangular (RHS)

Sassan Ƙwararren Ƙwararren Ƙwararru (SHS)

Manufar wannan labarin shine taƙaita abubuwan buƙatun bututun ƙarfe tare da sassan madauwari mara kyau.

AS/NZS 1163 Rarraba Matsakaici Matsayi

Maki uku a cikin AS/NZS 1163 dangane da mafi ƙarancin ƙarfin yawan amfanin ƙasa (MPA) na ƙãre samfurin:

C250, C350 da C450.

Daidai da 0 ℃ low-zazzabi tasiri gwajin sa cewa karfe bututu iya saduwa:

C250L0, C350L0 da C450L0.

Har ila yau, mizanin ya nuna cewa madaidaicin hanyar bayyana darajar bututun ƙarfe ita ce:

AS/NZS 1163-C250 or AS/NZS 1163-C250L0

Albarkatun kasa

nada mai zafi ko mai sanyi

Nada mai sanyi shine mai zafi mai zafi wanda aka yi wa raguwar sanyi fiye da 15%.Ƙunƙarar za ta kasance tana da zagayowar ɓoyayyen ɓoyayyiyar ɓarna wanda zai sake sake fasalin tsarin kuma ya samar da sabbin hatsi na ferrite.Abubuwan da aka samu sun yi kama da naɗaɗɗen zafi.

An ƙayyade ƙarfe mai ƙyalƙyali a matsayin albarkatun ƙasa don coils na karfe.Karfe waɗanda ke da girman hatsi na austenitic na lamba 6 ko mafi kyau lokacin da aka gwada su daidai da AS 1733.

Ana samar da wannan ƙarfe ta hanyar Basic Oxygen Method (BOS) ko Electric Arc Furnace (EAF) kuma ana iya tace shi ta hanyar Vacuum Arc Remelting (VAR), Electroslag Remelting (ESR), ko ta hanyoyin yin ƙarfe na biyu kamar Vacuum Degassing ko Calcium Injection. .

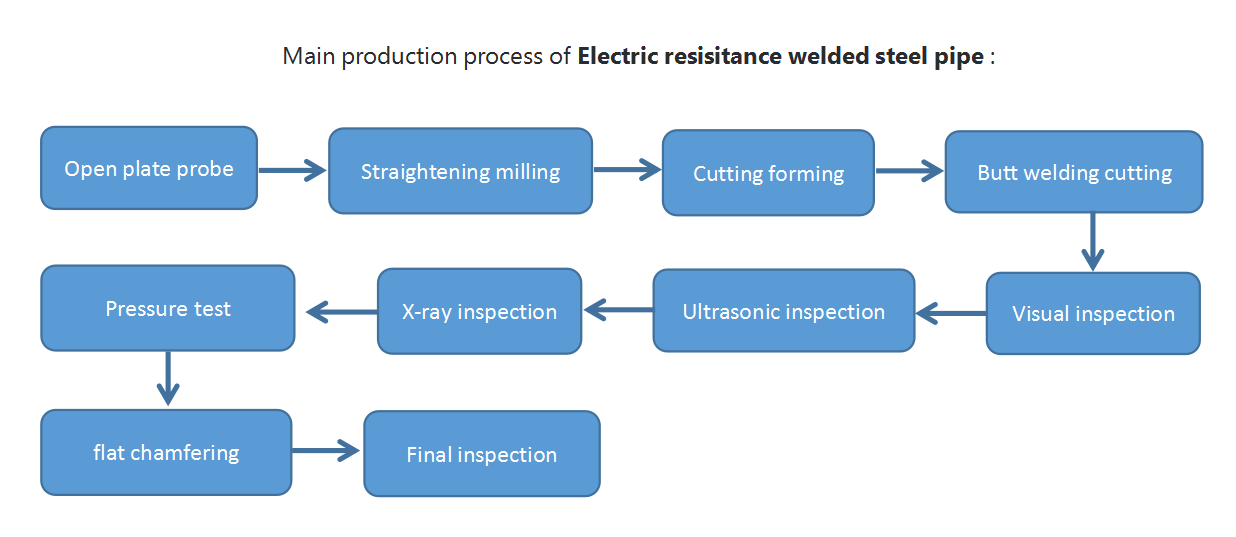

Tsarin Masana'antu

Samfurin da aka gama fashe ya zama kerarre ta hanyar tsarin sanyi da amfaniJuriya-welding (ERW)dabaru don shiga gefuna tsiri.

Kabu mai walda zai kasance mai tsayi kuma za a cire bacin rai na waje.

Ba za a sami cikakken jiyya na zafi na gaba akan samfurin da aka gama ba.

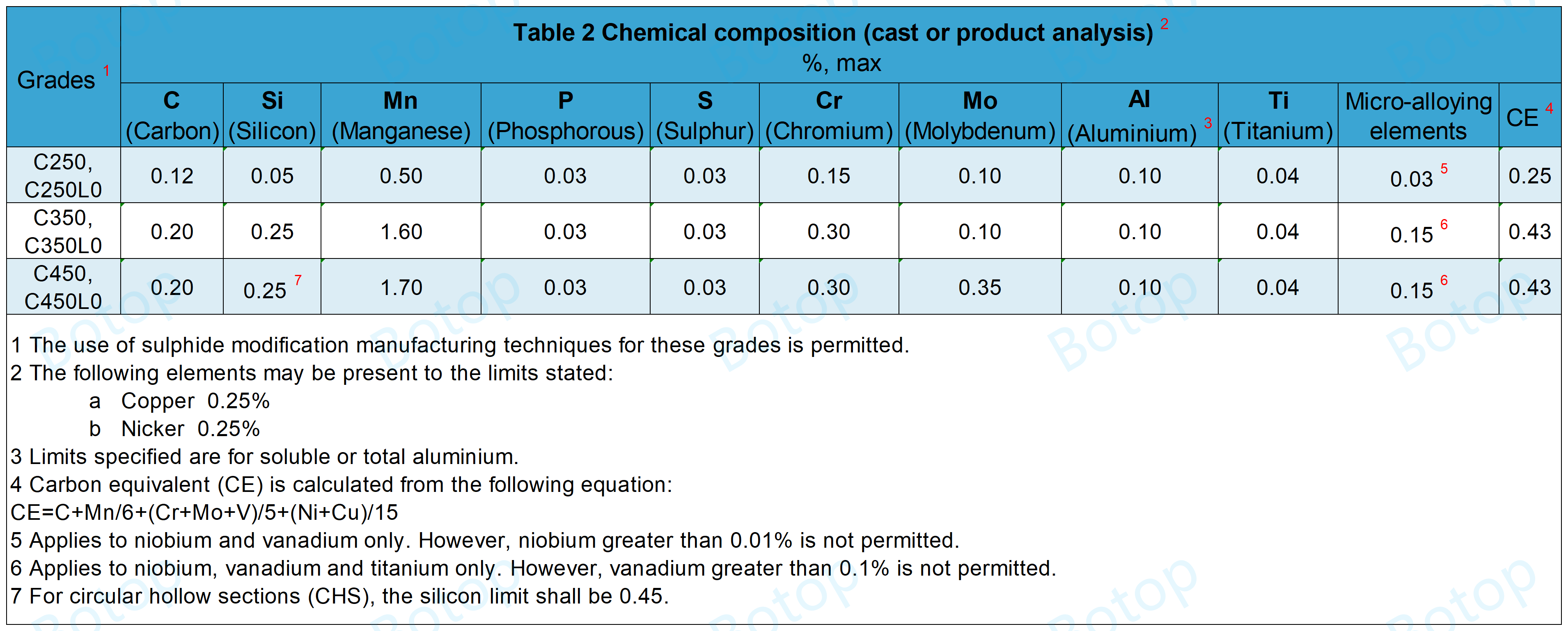

AS/NZS 1163 Haɗin Sinadari

AS/NZS 1163 a cikin gwajin abun da ke tattare da sinadaran ya kasu kashi biyu:

Ɗaya daga cikin shari'ar shine albarkatun ƙasa don gwajin abun da ke ciki,

ɗayan kuma shine aikin duba bututun ƙarfe da aka gama.

Yin nazari akan Karfe

Za a yi simintin simintin simintin ƙarfe na ƙarfe daga kowane zafi don ƙayyade adadin abubuwan da aka ƙayyade.

A cikin lokuta inda ba zai yiwu ba don samun samfurori daga ƙarfe na ruwa, ana iya ba da rahoton bincike kan samfuran gwajin da aka ɗauka daidai da AS/NZS 1050.1 ko ISO 14284 azaman ƙididdigar simintin.

Binciken simintin gyare-gyare na karfe zai bi iyakoki don ƙimar da ta dace da aka bayar a cikiTable 2.

Binciken Sinadarai na Samfurin da Ya Ƙare

AS/NZS 1163baya wajabta gwajin haɗakar sinadarai na samfurin ƙarshe.

Idan an yi gwaji, ya kamata a bi iyakokin da aka bayar a cikiTable 2da kuma hakurin da aka yi a cikiTable 3.

| TABLE 3 Hakuri na nazarin samfur don maki da aka bayar a Tebur 2 | |

| Abun ciki | Haƙuri akan iyakar iyaka |

| C(Carbon) | 0.02 |

| Si(Silikon) | 0.05 |

| Mn(Manganese) | 0.1 |

| P(phosphorous) | 0.005 |

| S(sulfur) | 0.005 |

| Cr(Chromium) | 0.05 |

| Ni(Nickel) | 0.05 |

| Mo(Molybdenum) | 0.03 |

| Cu(Copper) | 0.04 |

| AI(Aluminium) (duka) | -0.005 |

| Micro-alloying abubuwa (niobium da vanadium kawai) donMakin C250, C250L0 | 0.06 tare da niobium wanda bai wuce 0.020 ba |

| Ƙananan abubuwa masu haɗaka (niobium, vanadium, da titanium kawai) don makiC350, C350L0, C450, C450L0 | 0.19 tare da vanadium ba fiye da 0.12 |

Gwajin Tensile AS/NZS 1163

Hanyar gwaji: AS 1391.

Kafin gwajin tensile, samfurin za a yi zafi zuwa zafin da bai ƙasa da minti 15 ba ta dumama zuwa zafin jiki tsakanin 150 ° C da 200 ° C.

| Daraja | Mafi ƙarancin yawa ƙarfi | Mafi ƙarancin tensile ƙarfi | Ƙananan elongation a matsayin rabo na tsawon ma'aunin 5.65√S0 | ||

| yi/t | |||||

| ≤ 15 | 15 ≤30 | :30 | |||

| MPA | MPA | % | |||

| C250, C250L0 | 250 | 320 | 18 | 20 | 22 |

| C350, C350L0 | 350 | 430 | 16 | 18 | 20 |

| C450, C450L0 | 450 | 500 | 12 | 14 | 16 |

Gwajin Tasirin AS/NZS 1163

Hanyar gwaji: a 0°C bisa ga AS 1544.2.

Kafin gwajin tasirin, samfurin za a yi zafi ta hanyar dumama tsakanin 150 ° C da 200 ° C na ƙasa da minti 15.

| Daraja | Gwajin zafin jiki | Mafi ƙarancin kuzari, J | |||||

| Girman yanki na gwaji | |||||||

| 10mm × 10mm | 10mm × 7.5mm | 10mm × 5mm | |||||

| Matsakaicin na 3 gwaje-gwaje | Mutum gwadawa | Matsakaicin na 3 gwaje-gwaje | Mutum gwadawa | Matsakaicin na 3 gwaje-gwaje | Mutum gwadawa | ||

| C250L0 C350L0 C450L0 | 0 ℃ | 27 | 20 | 22 | 16 | 18 | 13 |

Gwajin Ciwon Sanyi

Za a daidaita yanki na gwajin har sai nisa tsakanin saman ya zama 0.75 yi ko ƙasa da haka.

Kada ya nuna alamun tsaga ko lahani.

Jarabawa mara lalacewa

A matsayin abin da ba na tilas ba, walda a cikin sassan sassa na welded na iya fuskantar gwajin mara lalacewa (NDE).

Haƙuri don Siffai da Mass

| Nau'in | Rage | Hakuri |

| Halaye | - | Sassan madauwari mara kyau |

| Girman waje (yi) | - | ± 1%, tare da mafi ƙarancin ± 0.5 mm kuma matsakaicin ± 10 mm |

| Kauri (t) | ku ≤406,4 mm | 10% |

| ku: 406.4 mm | ± 10% tare da max na ± 2 mm | |

| Rashin zagaye (o) | Diamita na waje(bo)/kaurin bango(t)≤100 | ± 2% |

| Madaidaici | tsayin duka | 0.20% |

| Mass (m) | kayyade nauyi | ≥96% |

Kauri:

Za a auna kauri (t) a matsayin wanda bai gaza 2t ba (Ma'anar kaurin bango 2x) ko 25 mm, ko wacce ta fi ƙasa, daga kabun walda.

fita daga zagaye:

An ba da rashin zagaye (o) ta: o = (yimax- yimin)/da×100

Hakuri na Tsawon

| Nau'in tsayi | Rage m | Hakuri |

| Tsawon bazuwar | 4m zuwa 16m da tsayin 2m a kowace oda abu | Kashi 10% na sassan da aka kawo na iya zama ƙasa da mafi ƙanƙanta don kewayon oda amma ba ƙasa da 75% na mafi ƙarancin |

| tsayin da ba a bayyana ba | DUKA | 0-+100mm |

| Madaidaicin tsayi | ≤6m ku | 0-+5mm |

| 6m≤10m | 0-+15mm | |

| · 10m | 0-+(5+1mm/m) mm |

AS/NZS 1163 SSHS Jerin Girman Bututu da Teburin Nauyi Haɗe

A cikin AS/NZS 1163, an ba da jerin sunayen sassa na gama-gari na sanyi da aka kafa (SSHS) a Ostiraliya da New Zealand.

Waɗannan jerin sunayen suna ba da sunaye na sashe, masu girma dabam dabam, halayen sashe, da halaye.

| Waje Diamita | Kauri | Tsawon Massperunit | Na waje shimfidar wuri | Rabo | |

| do | t | tsawon raka'a | kowace naúrar taro | ||

| mm | mm | kg/m | m²/m | m²/t | yi/t |

| 610.0 | 12.7CHS | 187 | 1.92 | 10.2 | 48.0 |

| 610.0 | 9.5CHS | 141 | 1.92 | 13.6 | 64.2 |

| 610.0 | 6.4CHS | 95.3 | 1.92 | 20.1 | 95.3 |

| 508.0 | 12.7CHS | 155 | 1.60 | 10.3 | 40.0 |

| 508.0 | 9.5CHS | 117 | 1.60 | 13.7 | 53.5 |

| 508.0 | 6.4CHS | 79.2 | 1.60 | 20.2 | 79.4 |

| 457.0 | 12.7CHS | 139 | 1.44 | 10.3 | 36.0 |

| 457.0 | 9.5CHS | 105 | 1.44 | 13.7 | 48.1 |

| 457.0 | 6.4CHS | 71.1 | 1.44 | 20.2 | 71.4 |

| 406.4 | 12.7CHS | 123 | 1.28 | 10.4 | 32.0 |

| 406.4 | 9.5CHS | 93.0 | 1.28 | 13.7 | 42.8 |

| 406.4 | 6.4CHS | 63.1 | 1.28 | 20.2 | 63.5 |

| 355.6 | 12.7CHS | 107 | 1.12 | 10.4 | 28.0 |

| 355.6 | 9.5CHS | 81.1 | 1.12 | 13.8 | 37.4 |

| 355.6 | 6.4CHS | 55.1 | 1.12 | 20.3 | 55.6 |

| 323.9 | 2.7CHS | 97.5 | 1.02 | 10.4 | 25.5 |

| 323.9 | 9.5CHS | 73.7 | 1.02 | 13.8 | 34.1 |

| 323.9 | 6.4CHS | 50.1 | 1.02 | 20.3 | 50.6 |

| 273.1 | 9.3 CHS | 60.5 | 0.858 | 14.2 | 29.4 |

| 273.1 | 6.4CHS | 42.1 | 0.858 | 20.4 | 42.7 |

| 273.1 | 4.8 CHS | 31.8 | 0.858 | 27.0 | 56.9 |

| 219.1 | 8.2 CHS | 42.6 | 0.688 | 16.1 | 26.7 |

| 219.1 | 6.4CHS | 33.6 | 0.688 | 20.5 | 34.2 |

| 219.1 | 4.8 CHS | 25.4 | 0.688 | 27.1 | 45.6 |

| 168.3 | 71 CHS | 28.2 | 0.529 | 18.7 | 23.7 |

| 168.3 | 6.4CHS | 25.6 | 0.529 | 20.7 | 26.3 |

| 168.3 | 4.8 CHS | 19.4 | 0.529 | 27.3 | 35.1 |

| 165.1 | 5.4CHS | 21.3 | 0.519 | 24.4 | 30.6 |

| 165.1 | 5.0 CHS | 19.7 | 0.519 | 26.3 | 33.0 |

| 165.1 | 3.5CHS | 13.9 | 0.519 | 37.2 | 47.2 |

| 165.1 | 3.0 CHS | 12.0 | 0.519 | 43.2 | 55.0 |

| 139.7 | 5.4CHS | 17.9 | 0.439 | 24.5 | 25.9 |

| 139.7 | 5.0 CHS | 16.6 | 0.439 | 26.4 | 27.9 |

| 139.7 | 3.5CHS | 11.8 | 0.439 | 37.3 | 39.9 |

| 139.7 | 3.0 CHS | 10.1 | 0.439 | 43.4 | 46.6 |

| 114.3 | 6.0 CHS | 16.0 | 0.359 | 22.4 | 19.1 |

| 114.3 | 5.4CHS | 14.5 | 0.359 | 24.8 | 21.2 |

| 114.3 | 4.8 CHS | 13.0 | 0.359 | 27.7 | 23.8 |

| 114.3 | 4.5CHS | 12.2 | 0.359 | 29.5 | 25.4 |

| 114.3 | 3.6 CHS | 9.83 | 0.359 | 36.5 | 31.8 |

| 114.3 | 3.2 CHS | 8.77 | 0.359 | 41.0 | 35.7 |

| 101.6 | 5.0 CHS | 11.9 | 0.319 | 26.8 | 20.3 |

| 101.6 | 4.0 CHS | 9.63 | 0.319 | 33.2 | 25.4 |

| 101.6 | 3.2 CHS | 7.77 | 0.319 | 41.1 | 31.8 |

| 101.6 | 2.6 CHS | 6.35 | 0.319 | 50.3 | 39.1 |

| 88.9 | 5.9CHS | 12.1 | 0.279 | 23.1 | 15.1 |

| 88.9 | 5.0 CHS | 10.3 | 0.279 | 27.0 | 17.8 |

| 88.9 | 5.5CHS | 11.3 | 0.279 | 24.7 | 16.2 |

| 88.9 | 4.8 CHS | 9.96 | 0.279 | 28.1 | 18.5 |

| 88.9 | 4.0 CHS | 8.38 | 0.279 | 33.3 | 22.2 |

| 88.9 | 3.2 CHS | 6.76 | 0.279 | 41.3 | 27.8 |

| 88.9 | 2.6 CHS | 5.53 | 0.279 | 50.5 | 34.2 |

| 76.1 | 5.9CHS | 10.2 | 0.239 | 23.4 | 12.9 |

| 76.1 | 4.5CHS | 7.95 | 0.239 | 30.1 | 16.9 |

| 76.1 | 3.6 CHS | 6.44 | 0.239 | 37.1 | 21.1 |

| 76.1 | 3.2 CHS | 5.75 | 0.239 | 41.6 | 23.8 |

| 76.1 | 2.3 CHS | 4.19 | 0.239 | 57.1 | 33.1 |

| 60.3 | 5.4CHS | 7.31 | 0.189 | 25.9 | 11.2 |

| 60.3 | 4.5CHS | 6.19 | 0.189 | 30.6 | 13.4 |

| 60.3 | 3.6 CHS | 5.03 | 0.189 | 37.6 | 16.8 |

| 48.3 | 5.4CHS | 5.71 | 0.152 | 26.6 | 8.9 |

| 48.3 | 4.0 CHS | 4.37 | 0.152 | 34.7 | 12.1 |

| 48.3 | 3.2 CHS | 3.56 | 0.152 | 42.6 | 15.1 |

| 42.4 | 4.9CHS | 4.53 | 0.133 | 29.4 | 8.7 |

| 42.4 | 4.0 CHS | 3.79 | 0.133 | 35.2 | 10.6 |

| 42.4 | 3.2 CHS | 3.09 | 0.133 | 43.1 | 13.3 |

Gyare-gyare na waje da na kwaskwarima

Bayyanar

Ƙarshen samfurin ba shi da lahani mai lahani ga ingancin tsarin kayan.

Cire Lalacewar Sama

Lokacin da aka cire lahani ta hanyar yashi, yanki mai yashi zai sami canji mai kyau.

Ragowar kaurin bango a cikin yanki mai yashi ba zai zama ƙasa da 90% na kauri ba.

Weld Gyaran Lalacewar Sama

Welds za su kasance da kyau, weld ɗin ya kasance mai haɗawa sosai ba tare da raguwa ko zoba ba.

Ƙarfin walda zai yi aikin aƙalla 1.5 mm sama da saman da aka yi birgima kuma za a cire ƙarfen da ake yi ta hanyar niƙa tare da birgima.

Galvanized

Galvanized zagaye m sassan tare da waje diamita na ≤ 60.3 mm da sauran siffa m sassa na daidai girma za su iya jure 90 ° lankwasa a kusa da tsagi mandrel.

Rufin galvanized ba zai nuna alamun fashe ko lahani ba bayan aikin lanƙwasawa.

AS/NZS 1163 Alama

Mai zuwa yana bayyana aƙalla sau ɗaya a cikin alamar bututun ƙarfe.

(a) Sunan masana'anta ko alamar, ko duka biyun.

(b) Shafukan masana'anta ko tantancewar niƙa, ko duka biyun.

(c) Na musamman, gano rubutun rubutu, wanda zai kasance cikin ɗaya ko duka biyun na waɗannan siffofi:

(i) Lokaci da ranar da aka yi samfurin.

(ii) Serialed lambar tantancewa don ingantaccen iko/tabbaci da dalilai na ganowa.

Misali:

BOTOP CHINA AS/NZS 1163-C350L0 457×12.7CHS×12000MM PIPE NO.001 ZAFI NO.000001

Aikace-aikace na AS/NZS 1163

Tsarin Gine-gine da Injiniya: Ana amfani da su a cikin tsarin tallafi na gine-gine, kamar manyan gine-gine da filayen wasa.

Kayayyakin sufuri: Ana amfani da su wajen gina gadoji, tunnels, da abubuwan more rayuwa na layin dogo.

Mai, iskar gas, da hakar ma'adinai: ana amfani da su wajen gina rijiyoyin mai, kayan aikin hakar ma'adinai, da tsarin jigilar kayayyaki masu alaƙa.

Sauran manyan masana'antu: gami da tsarin firam don masana'antar masana'anta da injuna masu nauyi.

Kayayyakinmu masu alaƙa

Mu ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun masana'anta ce kuma masu siyarwa daga China, har ila yau, ƙwararrun ƙwararrun bututun ƙarfe mara nauyi, suna ba ku nau'ikan mafita na bututun ƙarfe!

Tags: as/nzs 1163,chs, tsarin, erw, masu kaya, masana'antun, masana'antu, hannun jari, kamfanoni, wholesale, saya, farashin, zance, girma, na siyarwa, farashi.

Lokacin aikawa: Afrilu-21-2024