ASTM A500 karfeshi ne mai sanyi-kafa welded kuma maras sumul carbon karfe tsarin tubing for welded, riveted, ko bolted gadoji da gine-gine da kuma janar tsarin dalilai.

Maɓallan kewayawa

Siffar Sashe mai zurfi

Rarraba Darajoji

Girman Rage

Raw Materials

Hanyoyin Masana'antu

Nau'in Ƙarshen Tube

Maganin zafi

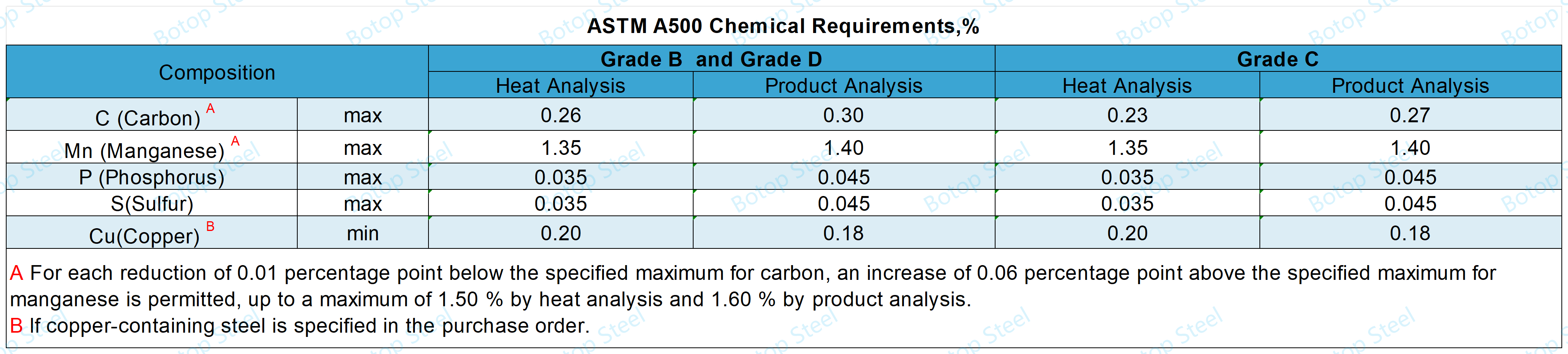

Chemical Haɗin gwiwar ASTM A500

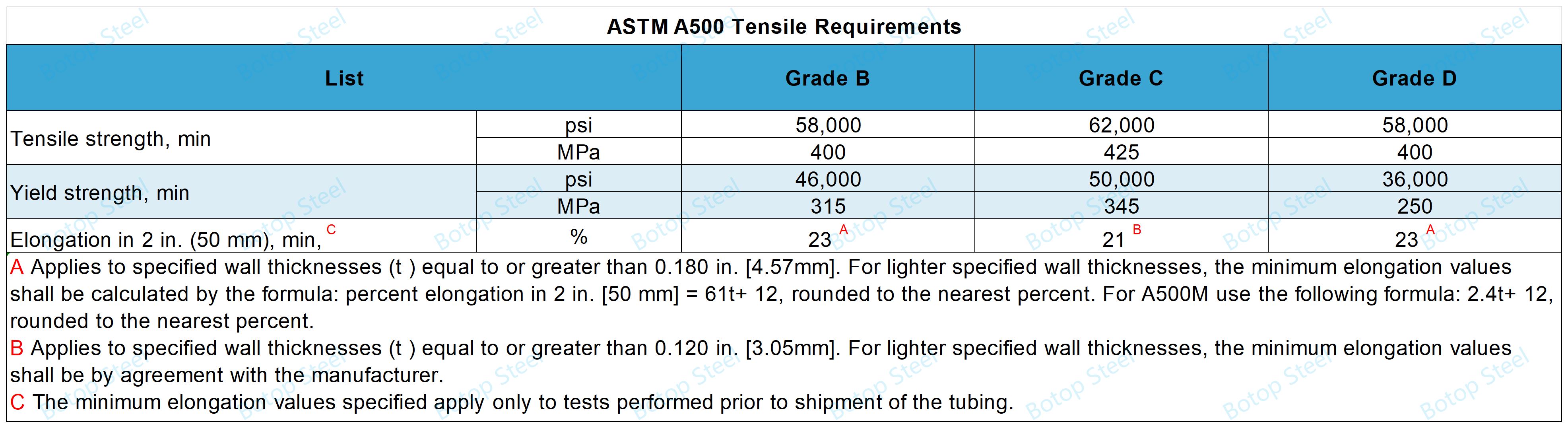

Bukatun Tensile na ASTM A500

Gwajin Lalacewa

Gwajin Walƙiya

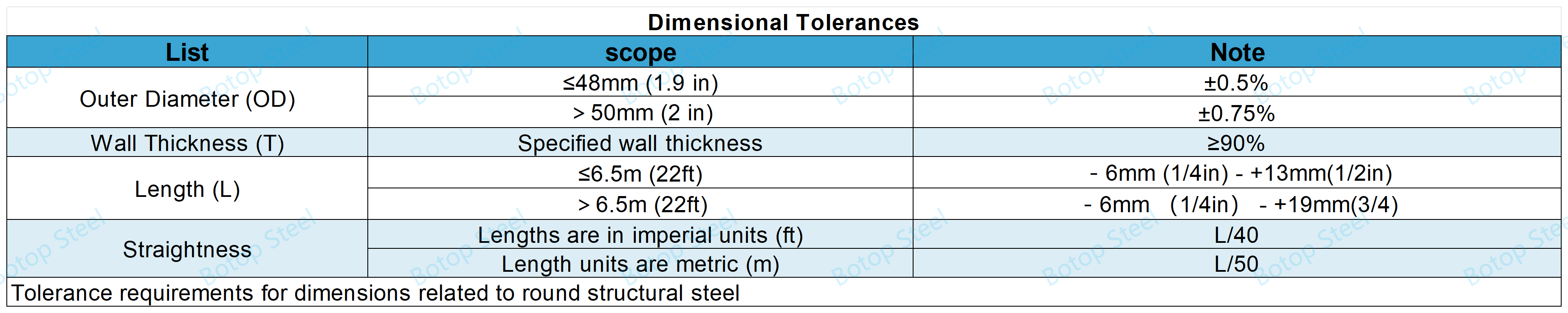

Haƙuri na Girma na ASTM A500

Alamar Tube

Abubuwan da suka dace don ASTM A500

Alternative Materials na ASTM A500

Kayayyakinmu masu alaƙa

Siffar Sashe mai zurfi

Yana iya zamazagaye, murabba'i, rectangular, ko wasu siffofi na musamman na musamman.

Wannan labarin yana mai da hankali kan buƙatun ASTM A500 don ƙirar ƙirar zagaye.

Rarraba Darajoji

ASTM A500 yana rarraba bututun ƙarfe zuwa maki uku,digiri na B, C, da D.

Yana da kyau a lura cewa nau'ikan ASTM A500 na baya kuma suna da Grade A, wanda aka cire a cikin sabuwar sigar 2023.

Girman Rage

Don bututu masu diamita na waje ≤ 2235mm [88in] da kaurin bango ≤ 25.4mm [1in].

Raw Materials

Za a yi ƙarfe ɗaya ko fiye daga cikin matakai masu zuwa:asali oxygen ko wutar lantarki.

Basic Oxygen Process: Wannan hanya ce ta zamani mai sauri na samar da ƙarfe, wanda ke rage abubuwan da ke cikin carbon ta hanyar hura iskar oxygen a cikin narkakken ƙarfen alade, tare da cire sauran abubuwan da ba a so kamar su sulfur da phosphorus. Ya dace da saurin samar da ƙarfe mai yawa.

Tsarin Tanderun Lantarki: Tsarin wutar lantarki yana amfani da baka mai zafin jiki na lantarki don narkewa da rage baƙin ƙarfe kai tsaye, kuma yana da amfani musamman don samar da maki na musamman da sarrafa abubuwan haɗin gwal, da kuma samar da ƙaramin tsari.

Hanyoyin Masana'antu

tsari mara kyau ko walda.

Za a yi bututun da aka yi wa ƙera daga ƙarfe mai birgima ta hanyar aikin walƙiya-juriya (ERW). Ya kamata a dunƙule kabu ɗin walda don tabbatar da ƙarfin bututun.

Bututun da aka samar ta hanyar walda yawanci ba sa cire walda na ciki.

Nau'in Ƙarshen Tube

Idan ba a buƙata ta musamman ba, ya kamata tubes tsarin su kasancemkuma mai tsabta daga burrs.

Maganin zafi

Darasi B da C

Ana iya shafewa ko rage damuwa.

Ana cim ma gyaran bututun ta hanyar dumama bututu zuwa babban zafin jiki sannan a sanyaya shi a hankali. Annealing yana sake tsara ƙananan kayan don inganta taurinsa da daidaito.

Ana samun kawar da damuwa gabaɗaya ta dumama kayan zuwa ƙananan zafin jiki (yawanci ƙasa da na annealing) sannan a riƙe shi na ɗan lokaci sannan a sanyaya shi. Wannan yana taimakawa hana ɓarna ko fashewar kayan yayin ayyuka na gaba kamar walda ko yanke.

Darasi D

Ana buƙatar maganin zafi.

Ya kamata a yi shi a zafin jiki na akalla1100°F (590°C) na awa 1 cikin kaurin bango 25 mm.

Chemical Haɗin gwiwar ASTM A500

Hanyar gwaji: ASTM A751.

Bukatun Tensile na ASTM A500

Samfuran za su cika buƙatun da suka dace na ASTM A370, Shafi A2.

Gwajin Lalacewa

Welded Zagaye Tsarin Bututu

Welddamfanitest: Yin amfani da samfurin aƙalla inci 4 (100 mm) tsayi, daidaita samfurin tare da walda a 90 ° zuwa hanyar lodi har sai nisa tsakanin faranti bai wuce 2/3 na diamita na waje na bututu ba. samfurin ba za a tsage ko karya a ciki ko waje yayin wannan tsari ba.

Gwajin ductility na bututu: ci gaba da daidaita samfurin har sai nisa tsakanin faranti bai wuce 1/2 na diamita na waje ba. a wannan lokacin, bututun bai kamata ya sami tsagewa ko karaya a saman ciki da waje ba.

Mutuncitest: Ci gaba da daidaita samfurin har sai an sami karaya ko har sai an cika buƙatun kauri na bango. Idan an sami shaidar kwasfa, kayan da ba su da ƙarfi, ko walda waɗanda ba su cika ba a lokacin gwajin baƙaƙe, za a yi la'akari da samfurin bai gamsu ba.

Bututun Tsarin Zagaye Mara Sumul

Tsawon Samfura: Tsawon samfurin da ake amfani da shi don gwaji bazai zama ƙasa da 2 1/2 a (65 mm).

Gwajin gwaji: Ba tare da tsagewa ko karaya ba, samfurin yana daidaitawa tsakanin faranti iri ɗaya har sai nisa tsakanin faranti bai kai darajar "H" da aka ƙididdige su ta hanyar wannan tsari:

H=(1+e)t/(e+t/D)

H = nisa tsakanin faranti masu lanƙwasa, a cikin. [mm],

e= nakasawa kowane tsayin raka'a (tsayawa don ƙimar ƙarfe da aka bayar, 0.07 don Grade B, da 0.06 don Grade C),

t= ƙayyadadden kauri na bangon bututu, a cikin. [mm],

D = ƙayyadaddun diamita na tubing, a cikin. [mm].

Mutuncitest: Ci gaba da daidaita samfurin har sai samfurin ya karye ko kuma sabanin bangon samfurin ya hadu.

Kasawactsarin mulki: Bawon laminar ko raunin abu da aka samu a duk lokacin gwajin lallashi zai zama dalilin ƙin yarda.

Gwajin Walƙiya

Ana samun gwajin walƙiya don bututu mai zagaye ≤ 254 mm (inci 10) a diamita, amma ba dole ba ne.

Haƙuri na Girma na ASTM A500

Alamar Tube

Ya kamata a haɗa waɗannan bayanai masu zuwa:

Sunan masana'anta: Wannan na iya zama cikakken sunan masana'anta ko gajarta.

Alamar kasuwanci ko Alamar kasuwanci: Sunan tambari ko alamar kasuwanci da masana'anta ke amfani da su don bambanta samfuran ta.

Ƙididdigar Ƙira: ASTM A500, wanda baya buƙatar haɗa da shekarar bugawa.

Wasikar Daraja: B, C ko D.

Don bututun tsari ≤ 100mm (4in) a diamita, ana iya amfani da takalmi don yiwa bayanin ganowa alama a sarari.

Abubuwan da suka dace don ASTM A500

Saboda kyawawan kaddarorin inji da walƙiya, ana amfani da bututun ƙarfe na ASTM A500 a cikin sassa iri-iri inda ake buƙatar karko da ƙarfi.

Gina: An yi amfani da shi don tallafawa tsarin gine-gine kamar tsarin tsarawa, tsarin rufin, abubuwan ƙirar baka, da ginshiƙan zagaye.

Gina gada: Don abubuwan tsarin gadoji, kamar ginshiƙai masu ɗaukar nauyin madauwari da trusses don gadoji.

Kayan aikin masana'antu: A cikin manyan gine-ginen masana'antu irin su man fetur da iskar gas, masana'antun sinadarai, da masana'antun karfe, ana amfani da bututun ƙarfe zagaye don gina gine-ginen tallafi da watsa bututu.

Tsarin sufuri: Don ginshiƙan alamar zirga-zirga, sandunan haske, da matakan tsaro.

Masana'antar injuna: A matsayin wani ɓangare na injuna da kayan aiki masu nauyi, kamar injinan noma, kayan aikin hakar ma'adinai, da injinan gini.

Abubuwan amfani: Ana amfani da shi a cikin bututun ruwa, gas, man fetur, da dai sauransu, kuma a matsayin bututun kariya na waya da na USB.

Wuraren wasanni: A cikin ginin wuraren wasanni, ana amfani da bututun ƙarfe zagaye don yin bleachers, hasumiya mai haske, da sauran kayan tallafi.

Furniture da kayan ado: Ana amfani da bututun ƙarfe na tsarin zagaye zagaye don yin kayan ƙarfe, kamar ƙafafu don tebur da kujeru, da kuma abubuwan ado don ƙirar ciki na zamani.

Tsarin shinge da layin dogo: Ana amfani da shi azaman ginshiƙai don tsarin shinge da layin dogo, musamman inda ake buƙatar ƙarfin tsari da dorewa.

Alternative Materials na ASTM A500

ASTM A501: Wannan ƙayyadaddun ƙayyadaddun ƙayyadaddun bututun ƙarfe ne na carbon karfe mai zafi, mai kama da ASTM A500, amma ya dace da tsarin masana'anta mai zafi.

ASTM A252: Standard for karfe bututu tara don amfani a tushe da kuma aikin tarawa.

ASTM A106: Bututun ƙarfe na carbon mara ƙarfi, yawanci ana amfani dashi a cikin yanayin zafi mai zafi.

ASTM A53: Wani nau'in bututun ƙarfe na carbon don matsa lamba da aikace-aikacen injiniya, ana amfani da su sosai a cikin tsarin canja wurin ruwa.

EN 10210: A Turai, ma'aunin EN 10210 yana ƙayyadaddun yanayin isar da fasaha don sassan fashe-fashe masu zafi, waɗanda ke da wuraren aikace-aikacen iri ɗaya zuwa ASTM A500.

CSA G40.21: Ma'auni na Kanada wanda ke ba da nau'i na nau'i na nau'i mai kyau na kayan aiki a cikin nau'o'in ƙarfin ƙarfin da za a iya amfani da su don aikace-aikace iri ɗaya.

Saukewa: G3466: Matsayin Masana'antu na Jafananci don murabba'i da bututu na rectangular na carbon karfe don amfanin tsarin gaba ɗaya.

Farashin 4923: Ƙimar Indiya don sassauƙan sassauƙan sassauƙa na welded ko maras sumul.

AS/NZS 1163: Matsayin Australiya da New Zealand don bututun ƙarfe na tsari da sassan fashe.

Kayayyakinmu masu alaƙa

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun carbon karfe a Arewacin kasar Sin, wanda aka sani da kyakkyawan sabis, samfuran inganci, da cikakkun mafita. Babban kewayon samfuran kamfanin sun haɗa da bututun ƙarfe mara ƙarfi, ERW, LSAW, da SSAW, da kayan aikin bututu, flanges, da ƙarfe na musamman.

Tare da ƙaƙƙarfan sadaukarwa ga inganci, Botop Karfe yana aiwatar da tsauraran sarrafawa da gwaje-gwaje don tabbatar da amincin samfuran sa. Ƙwararrun ƙungiyar ta tana ba da mafita na musamman da goyan bayan ƙwararru, tare da mai da hankali kan gamsuwar abokin ciniki.

Tags: astm a500, astm a500 digiri b, astm a500 digiri c, astm a500 digiri d.

Lokacin aikawa: Mayu-04-2024