ASTM A513 karfebututu ne na carbon da gami da ƙarfe da bututu da aka yi daga ƙarfe mai zafi ko sanyi mai birgima azaman albarkatun ƙasa ta hanyar walƙiya juriya ta lantarki (ERW), wanda aka yi amfani da shi sosai a kowane nau'in tsarin injina.

Maɓallan kewayawa

Nau'i da Yanayin thermal na ASTM A513

Rarraba Darajoji

ASTM A513 Size Range

Siffar Sashe mai zurfi

Raw Materials

ASTM A513 Tsarin Masana'antu

Magani Zafi

Welding Seam Handling

Abubuwan Kemikal na ASTM A513

Bayanan Bayani na ASTM A513

Gwajin Tauri

Gwajin Lalacewa

Gwajin Walƙiya

Gwajin Zagaye Mai Ruwa na Hydrostatic

Gwajin Lantarki mara lalacewa

Hakuri don Girman Bututun Zagaye

Hakuri na Ma'auni da Girman Tube Rectangular

Bayyanuwa

Tufafi

Alama

ASTM A513 aikace-aikace

Amfaninmu

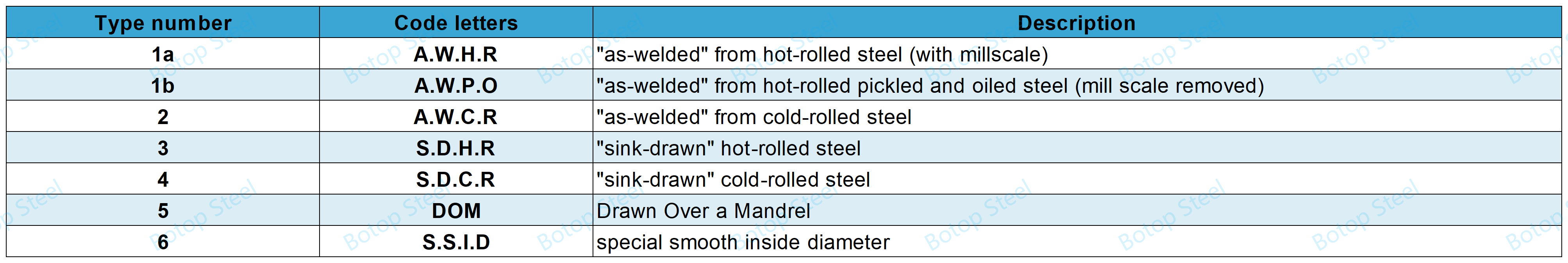

Nau'i da Yanayin thermal na ASTM A513

Rarraba yana dogara ne akan yanayi daban-daban ko matakai na bututun ƙarfe.

Rarraba Darajoji

ASTM A513 na iya zama ko dai carbon ko alloy karfe, dangane da ainihin aikace-aikacen.

Karfe Karfe

MT 1010, MT 1015, MT X 1015, MT 1020, MT X 1020.

1006, 1008, 1009, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1023, 1024, 10265, 3, 1026 1033, 1035, 1040, 1050, 1060, 1524.

Alloys Karfe

1340, 4118, 4130, 4140, 5130, 8620, 8630.

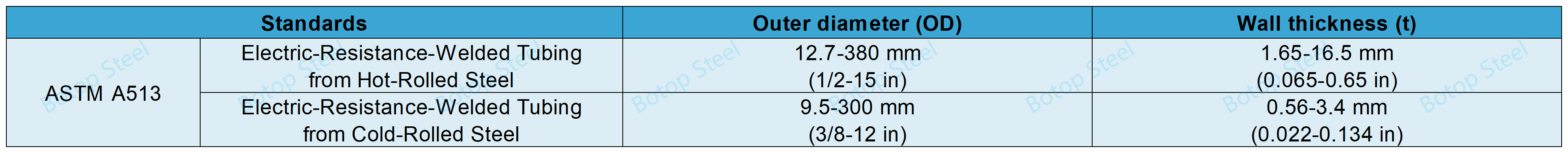

ASTM A513 Size Range

Siffar Sashe mai zurfi

Zagaye

Square ko rectangular

Sauran siffofi

kamar streamlined, hexagonal, octagonal, zagaye ciki da hexagonal ko octagonal waje, ribbed ciki ko waje, triangular, zagaye rectangular da siffofi D.

Raw Materials

Ana iya yin ƙarfe ta kowane tsari.

Narkewar farko na iya haɗawa da keɓancewa ko tacewa kuma ana iya biye da shi ta hanyar narkewa ta biyu, irin su electro slag ko vacuum-arc remelting.

Ana iya yin jifa da ƙarfe a cikin ingots ko ƙila a yi jifa.

ASTM A513 Tsarin Masana'antu

Tubes za a yi talantarki-juriya-welded (ERW)tsari kuma za a yi shi daga karfe mai zafi ko sanyi kamar yadda aka ƙayyade.

ERW bututu shine tsari na ƙirƙirar walda ta hanyar murɗa wani ƙarfe a cikin silinda da yin juriya da matsa lamba tare da tsawonsa.

Karfe Mai Zafi: A cikin tsarin samarwa, karfe mai zafi yana fara zafi a yanayin zafi mai zafi, yana ba da damar yin jujjuya karfe a cikin yanayin filastik, wanda ya sauƙaƙa canza siffar da girman karfe. A ƙarshen aikin mirgina mai zafi, kayan yawanci ana ƙididdige su kuma sun lalace.

Karfe Mai Sanyi: Ƙarfe mai sanyi yana ƙara karawa bayan kayan ya sanyaya don cimma girman girman da siffar da ake so. Yawancin lokaci ana yin wannan tsari ne a cikin ɗaki kuma yana haifar da ƙarfe tare da ingantaccen ingancin ƙasa da madaidaicin ma'auni.

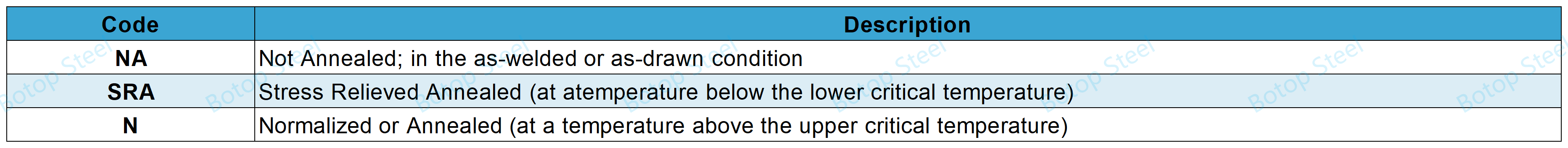

Magani Zafi

Lokacin da ba a ƙayyade yanayin zafi ba, ana iya ba da bututun a yanayin NA.

Lokacin da aka ƙayyade jiyya na thermal na ƙarshe, matsatsin oxide na al'ada ne.

Lokacin da aka ayyana saman da ba shi da oxide, bututun na iya zama mai haske a goge ko tsinke a zaɓin masana'anta.

Welding Seam Handling

Dole ne a tsaftace walda na waje

Welds na ciki zasu sami buƙatun tsayi daban-daban dangane da Nau'in.

Ana iya samun takamaiman buƙatu a cikin ASTM A513, sashe na 12.3.

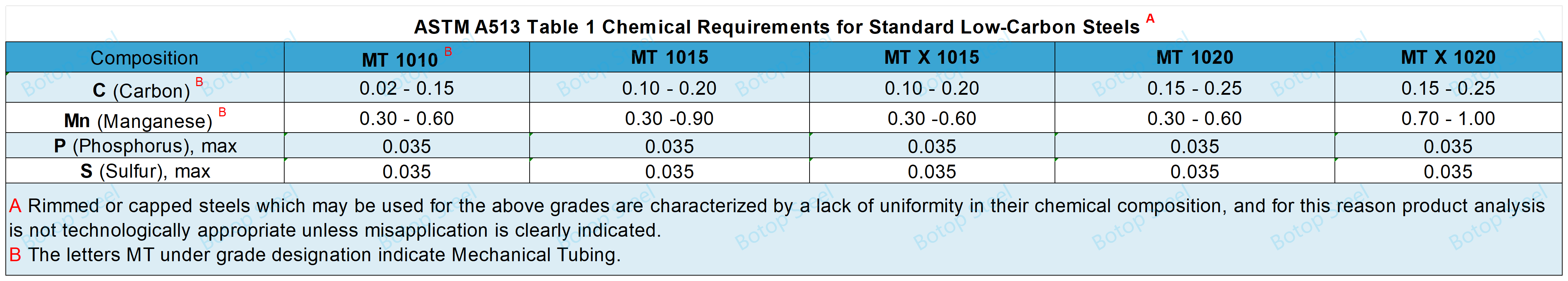

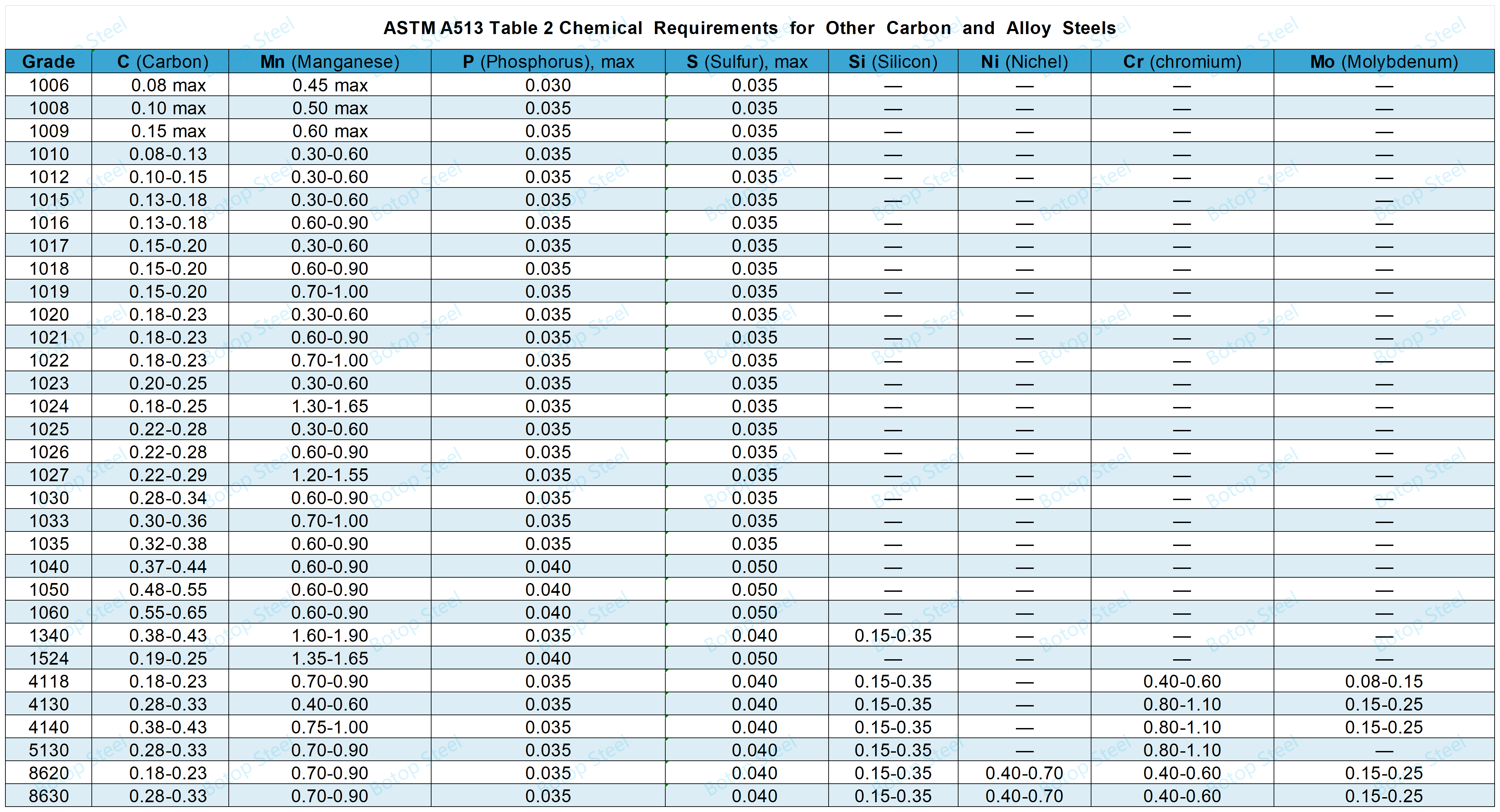

Abubuwan Kemikal na ASTM A513

Karfe zai yi daidai da buƙatun sinadaran da aka ƙayyade a cikin Tebu 1 ko Tebu 2.

Lokacin da aka ba da odar ma'aunin ƙarfe na carbon daga ma'auni, baya halatta a samar da ma'aunin alloy waɗanda ke kira musamman don ƙari na kowane nau'in ban da waɗanda aka jera a cikin Tables I da 2.

Idan ba a ƙayyade maki ba, ana samun maki MT 1010 zuwa MT 1020.

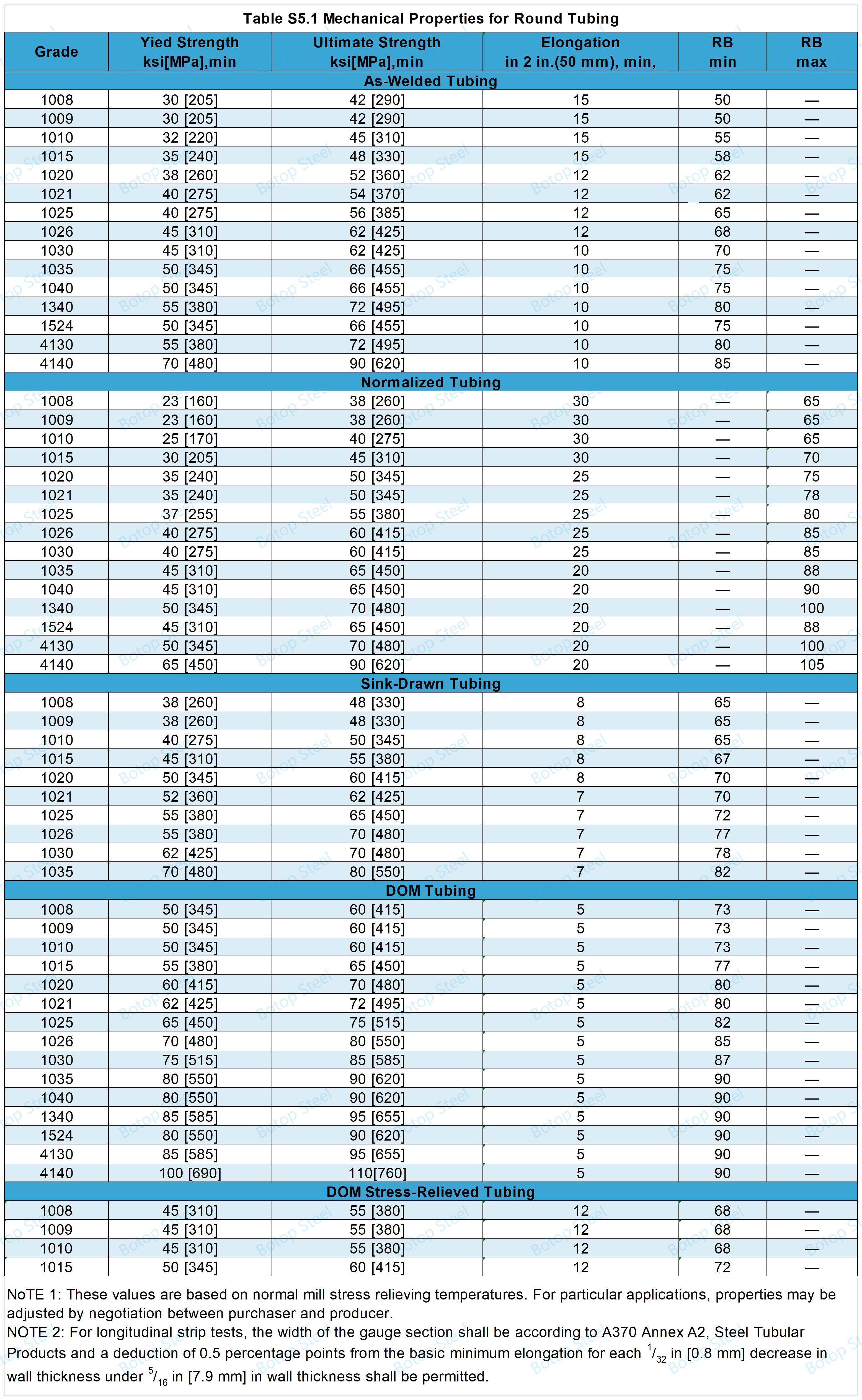

Bayanan Bayani na ASTM A513

Za a yi gwajin jinkiri sau ɗaya a kowace kuri'a.

Lokacin da aka ƙayyade "Ayyukan Tensile da ake buƙata" a cikin odar siyayya, tubing zagaye zai dace da buƙatun tensile kuma ba lallai ba ne ga iyakokin taurin da aka nuna a cikin Tebura 5.

Gwajin Tauri

1% na duk bututu a kowace kuri'a kuma ba kasa da bututu 5 ba.

Gwajin Lalacewa

Bututun zagaye da bututun da ke samar da wasu sifofi lokacin da suke zagaye suna da amfani.

Ba za a buɗe a cikin walda ba har sai nisa tsakanin faranti bai wuce kashi biyu cikin uku na ainihin diamita na waje na bututun ba.

Babu tsaga ko karaya a cikin ƙarfen tushe ba zai faru har sai nisa tsakanin faranti bai wuce kashi ɗaya bisa uku na ainihin diamita na waje na tubing ba amma a cikin kowane hali ƙasa da kaurin bangon tubing sau biyar.

Shaidar lamination ko kayan da aka ƙone ba za su haɓaka ba yayin aikin shimfidawa, kuma walda ba zai nuna lahani mai rauni ba.

Lura: Lokacin da aka gwada ƙananan tubing rabo na D-to-t, saboda nau'in da aka sanya saboda lissafin lissafi ba shi da ma'ana a saman ciki a wurare shida da goma sha biyu na rana, fasa a waɗannan wuraren ba zai zama dalilin ƙin yarda ba idan rabon D-to-t bai wuce 10 ba.

Gwajin Walƙiya

Bututun zagaye da bututun da ke samar da wasu sifofi lokacin da suke zagaye suna da amfani.

Wani sashe na bututu kamar inci 4 [100] tsayin zai tsaya yana walƙiya tare da kayan aiki mai kusurwar 60° har sai an faɗaɗa bututun da ke bakin walƙiya 15% na diamita na ciki, ba tare da tsagewa ko nuna lahani ba.

Gwajin Zagaye Mai Ruwa na Hydrostatic

Duk tubing za a yi gwajin hydrostatic.

Kula da mafi ƙarancin matsi na gwajin ruwa na ƙasa da 5s.

Ana ƙididdige matsi kamar:

P=2St/D

P= mafi ƙarancin gwajin gwajin hydrostatic, psi ko MPa,

S= damuwa fiber da aka yarda na 14,000 psi ko 96.5 MPa,

t= ƙayyadadden kauri na bango, ciki ko mm,

D= ƙayyadaddun diamita na waje, a cikin. ko mm.

Gwajin Lantarki mara lalacewa

Manufar wannan gwajin ita ce ƙin yarda da bututu masu ɗauke da lahani.

Kowane bututu za a gwada shi da gwajin lantarki mara lalacewa daidai da Practice E213, Practice E273, Practice E309, ko Practice E570.

Hakuri don Girman Bututun Zagaye

Don ƙarin bayani, da fatan za a duba tebur mai dacewa a cikin ma'auni.

Diamita na waje

Table 4Hakuri na Diamita don Nau'in I (AWHR) Zagaye Tubing

Table 5Hakuri na Diamita don Nau'in 3, 4, 5, da 6 (SDHR, SDCR, DOM, da SSID) Zagaye Tubing

Table 10Hakuri na Diamita don Nau'in 2 (AWCR) Zagaye Tubing

Kaurin bango

Table 6Hakurin Hakurin bango don Nau'in I (AWHR) Rukunin Zagaye (Raka'a Inch)

Table 7Hakurin Hakurin bango don Nau'in I (AWHR) Zagaye Tubing (Raka'a SI)

Table 8Hakurin Kaurin bango na Nau'o'in 5 da 6 (DOM da SSID) Rukunin Zagaye (Raka'a Inch)

TAMBAYA 9Hakurin Hakurin Kaurin bango Na Nau'in 5 da 6 (DOM da SSID) Rukunin Zagaye (Raka'a SI)

Table 11Hakurin Kaurin bango don Nau'in 2 (AWCR) Rukunin Zagaye (Raka'a Inch)

Table 12Hakurin Hakurin Kaurin bango don Nau'in 2 (AWCR) Rukunin Zagaye (Raka'a SI)

Tsawon

Table 13Haƙuri na Yanke-Tsawon Don Rukunin Zagaye-Yanke

Table 14Haƙuri Tsawon Tsawon Juyi, Saw-, ko Yanke Fayil ɗin Zagaye

Bakar fata

Table 15Haƙuri (Inci) don Girman Yanke (Kowanne Ƙarshe) Lokacin da Aka Ƙayyadad da Shi don Zagaye

Hakuri na Ma'auni da Girman Tube Rectangular

Don ƙarin bayani, da fatan za a duba tebur mai dacewa a cikin ma'auni.

Diamita na waje

Table 16Haƙuri, Wuraren Maɗaukaki na Waje da Tub ɗin Rectangular

Radi na Corners

Table 17Radi na Kusurwoyin Wurin Juriya-Lantarki-Welded da Tubing Rectangular

Tsawon

Table 18Haƙuri Tsawon-Square da Tubing Rectangular

Juyawa Juriya

Table 19Juriya-juriya na Lantarki-Waɗanda aka ƙera don Faɗakarwa da Bututun Injini Rectangular

Bayyanuwa

Bututun ba zai zama mara lahani da lahani ba kuma ya kasance yana da ƙarewa kamar mai aiki.

Tufafi

Za a shafe tubing tare da fim ɗin mai kafin jigilar kaya don jinkirta tsatsa.

Yana hana tsatsa faruwa cikin kankanin lokaci.

Idan odar ta fayyace cewa za a jigilar bututun ba tare da tsatsa mai hana tsatsa ba, fim ɗin mai da ya faru zai kasance a saman.

Alama

Ana yiwa saman karfen alama ta amfani da hanya mai dacewa kuma ya ƙunshi bayanai masu zuwa:

Sunan masana'anta koiri

Ƙayyadadden girman

Nau'in

lambar odar mai siye,

Standard lamba, ASTM A513.

Hakanan za'a iya amfani da lambobi azaman hanyar tantancewa na ƙarin.

ASTM A513 aikace-aikace

Masana'antar kera motociAn yi amfani da shi a cikin firam ɗin wurin zama na mota, abubuwan dakatarwa, ginshiƙan tutiya, maƙallan, da sauran kayan aikin abin hawa.

Masana'antar gine-gine: a matsayin kayan tallafi don gine-ginen gine-gine, irin su bututun da aka yi amfani da su, shingen tsaro, dogo, da dai sauransu.

Injiniyoyimkerawa: Ana amfani da shi wajen samar da kayan aikin injiniya daban-daban, irin su silinda na tsarin hydraulic, sassa masu juyawa, bearings, da sauransu.

Kayan aikin noma: A cikin masana'antar injinan noma, ana amfani da su don yin sassa na kayan aikin gona, tsarin watsawa, da sauransu.

Masana'antar Kayan Aiki: Ana amfani da shi wajen kera kayan karafa daban-daban, kamar rumbun littattafai, firam ɗin kujera, firam ɗin gado, da sauransu.

Kayan wasanni: a cikin wuraren wasanni da masana'antun kayan aiki, ana amfani da su azaman sassa na ƙarfe, kamar kayan aikin motsa jiki, burin kwando, burin ƙwallon ƙafa, da dai sauransu.

Kayayyakin masana'antu: ana amfani da shi wajen kera bel na jigilar kaya, rollers, tankuna, da sauran kayan aikin masana'antu.

Amfaninmu

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun carbon karfe a Arewacin kasar Sin, wanda aka sani da kyakkyawan sabis, samfuran inganci, da cikakkun mafita. Babban kewayon samfuran kamfanin sun haɗa da bututun ƙarfe mara ƙarfi, ERW, LSAW, da SSAW, da kayan aikin bututu, flanges, da ƙarfe na musamman.

Tare da ƙaƙƙarfan sadaukarwa ga inganci, Botop Karfe yana aiwatar da tsauraran sarrafawa da gwaje-gwaje don tabbatar da amincin samfuran sa. Ƙwararrun ƙungiyar ta tana ba da mafita na musamman da goyan bayan ƙwararru, tare da mai da hankali kan gamsuwar abokin ciniki.

Tags: ASTM A513, carbon karfe, nau'in 5, nau'in 1, dom.

Lokacin aikawa: Mayu-07-2024