ASTM A671 bututun karfe ne da aka yi daga farantin ingancin jirgin ruwa,Wutar Lantarki-Fusion-Welded (EFW)don matsanancin yanayi a yanayin yanayi da ƙananan yanayin zafi.

Ya dace musamman don aikace-aikacen da ke buƙatar kwanciyar hankali mai ƙarfi da ƙayyadaddun ƙarancin zafin jiki.

ASTM A671 Size Range

Shawarar da aka ba da shawarar: bututun ƙarfe tare da DN ≥ 400 mm [16 in] da WT ≥ 6 mm [1/4].

Hakanan za'a iya amfani da shi don wasu nau'ikan bututu, muddin ya dace da duk sauran buƙatun wannan ƙayyadaddun.

ASTM A671

Don ƙarin fahimtar ASTM A671, bari mu fara fahimtar abun cikin sa alama. Wannan yana taimakawa wajen fayyace iyakokin aikace-aikacen da halayen wannan ma'auni.

Misalin Fesa Alamar:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 ZAFI NO.4589716

BOTOP: Sunan masana'anta.

EFW: Karfe tube masana'antu tsari.

ASTM A671: Matsayin Gudanarwa don Tushen Karfe.

Saukewa: CC60-22: Taqaitaccen maki don cc60 da aji 22.

16" x SCH80: Diamita da Kaurin bango.

ZAFI A'A. 4589716: Zafi no. don samar da bututun ƙarfe.

Wannan shine tsarin gama gari na ASTM A671 mai lakabin feshi.

Ba shi da wahala a sami ASTM A671 a cikin aji da aji biyu, to waɗannan rabe-raben biyu suna wakiltar menene ma'anar.

Rarraba Darajoji

An rarraba bisa ga nau'in farantin da ake amfani da shi don kera bututun ƙarfe.

Daban-daban maki suna wakiltar nau'ikan sinadarai daban-daban da kaddarorin inji don matsi daban-daban da yanayin zafin jiki.

Misali, wasu maki na karafa ne na carbon, yayin da wasu karfen karfe ne da ke da wasu abubuwan hadewa, kamar karfen nickel.

| Bututu Grade | Nau'in Karfe | Bayanin ASTM | |

| A'a. | Daraja/aji/nau'i | ||

| CA 55 | carbon mai haske | A285/A285M | Gr C |

| Farashin 60 | carbon fili, ya mutu | A515/A515M | Gr 60 |

| Farashin 65 | carbon fili, ya mutu | A515/A515M | Gr 65 |

| Farashin 70 | carbon fili, ya mutu | A515/A515M | Gr 70 |

| Farashin CC60 | carbon fili, kashe, lafiyayyen hatsi | A516/A516M | Gr 60 |

| Bayani na CC65 | carbon fili, kashe, lafiyayyen hatsi | A516/A516M | Gr 65 |

| Farashin CC70 | carbon fili, kashe, lafiyayyen hatsi | A516/A516M | Gr 70 |

| CD70 | manganese-silicon, al'ada | A537/A537M | Cl 1 |

| CD80 | manganese-silicon, quenched da fushi | A537/A537M | Cl 2 |

| Farashin 65CFA | karfe nickel | A203/A203M | Gr A |

| Farashin 70 | karfe nickel | A203/A203M | Gr B |

| Farashin CFD65 | karfe nickel | A203/A203M | Gr D |

| Farashin CFE70 | karfe nickel | A203/A203M | Gr E |

| Farashin CG100 | 9% nickel | A353/A353M | |

| Farashin CH115 | 9% nickel | A553/A553M | Nau'i na 1 |

| CJA 115 | gami karfe, quenched da fushi | A517/A517M | Gr A |

| CJB 115 | gami karfe, quenched da fushi | A517/A517M | Gr B |

| Farashin 115 | gami karfe, quenched da fushi | A517/A517M | Gr E |

| Farashin CJF115 | gami karfe, quenched da fushi | A517/A517M | Gr F |

| CJH 115 | gami karfe, quenched da fushi | A517/A517M | Gr H |

| Farashin 115 | gami karfe, quenched da fushi | A517/A517M | Gr P |

| Farashin CK75 | carbon-manganese-silicon | A299/A299M | Gr A |

| Farashin CP85 | gami karfe, shekaru hardening, quenched da hazo zafi magani | A736/A736M | Gr A, Darasi 3 |

Rabewa

An rarraba tubes bisa ga nau'in maganin zafi da suke karɓa yayin aikin masana'antu da kuma ko an duba su ta hanyar rediyo da gwada matsa lamba.

Daban-daban nau'ikan suna nuna ƙayyadaddun ƙayyadaddun maganin zafi daban-daban don bututu.

Misalai sun haɗa da daidaitawa, rage damuwa, quenching, da fushi.

| Class | Maganin zafi akan bututu | Radiyo, duba bayanin kula: | Gwajin matsi, duba bayanin kula: |

| 10 | babu | babu | babu |

| 11 | babu | 9 | babu |

| 12 | babu | 9 | 8.3 |

| 13 | babu | babu | 8.3 |

| 20 | an kawar da damuwa, duba 5.3.1 | babu | babu |

| 21 | an kawar da damuwa, duba 5.3.1 | 9 | babu |

| 22 | an kawar da damuwa, duba 5.3.1 | 9 | 8.3 |

| 23 | an kawar da damuwa, duba 5.3.1 | babu | 8.3 |

| 30 | al'ada, duba 5.3.2 | babu | babu |

| 31 | al'ada, duba 5.3.2 | 9 | babu |

| 32 | al'ada, duba 5.3.2 | 9 | 8.3 |

| 33 | al'ada, duba 5.3.2 | babu | 8.3 |

| 40 | al'ada da fushi, duba 5.3.3 | babu | babu |

| 41 | al'ada da fushi, duba 5.3.3 | 9 | babu |

| 42 | al'ada da fushi, duba 5.3.3 | 9 | 8.3 |

| 43 | al'ada da fushi, duba 5.3.3 | babu | 8.3 |

| 50 | mai kashewa da fushi, duba 5.3.4 | babu | babu |

| 51 | mai kashewa da fushi, duba 5.3.4 | 9 | babu |

| 52 | mai kashewa da fushi, duba 5.3.4 | 9 | 8.3 |

| 53 | mai kashewa da fushi, duba 5.3.4 | babu | 8.3 |

| 70 | quenched da hazo zafi magani | babu | babu |

| 71 | quenched da hazo zafi magani | 9 | babu |

| 72 | quenched da hazo zafi magani | 9 | 8.3 |

| 73 | quenched da hazo zafi magani | babu | 8.3 |

Ya kamata a lura da zafin jiki na amfani lokacin zabar kayan. Ana iya yin la'akari da ƙayyadaddun ASTM A20/A20M.

Raw Materials

Ana iya samun faranti masu inganci don tasoshin matsa lamba, cikakkun bayanai na nau'ikan, da matakan aiwatarwa a cikin tebur a cikiRarraba Darajojia sama.

Mabuɗin Welding

Welding: Seams za a yi biyu-welded, cikakken shigar azzakari cikin farji.

Za a yi walda a daidai da hanyoyin da aka kayyade a Sashe na IX na ASME Boiler da Lambar Jirgin Ruwa.

Za a yi walda ko dai da hannu ko ta atomatik ta tsarin lantarki wanda ya haɗa da jigon ƙarfe na filler.

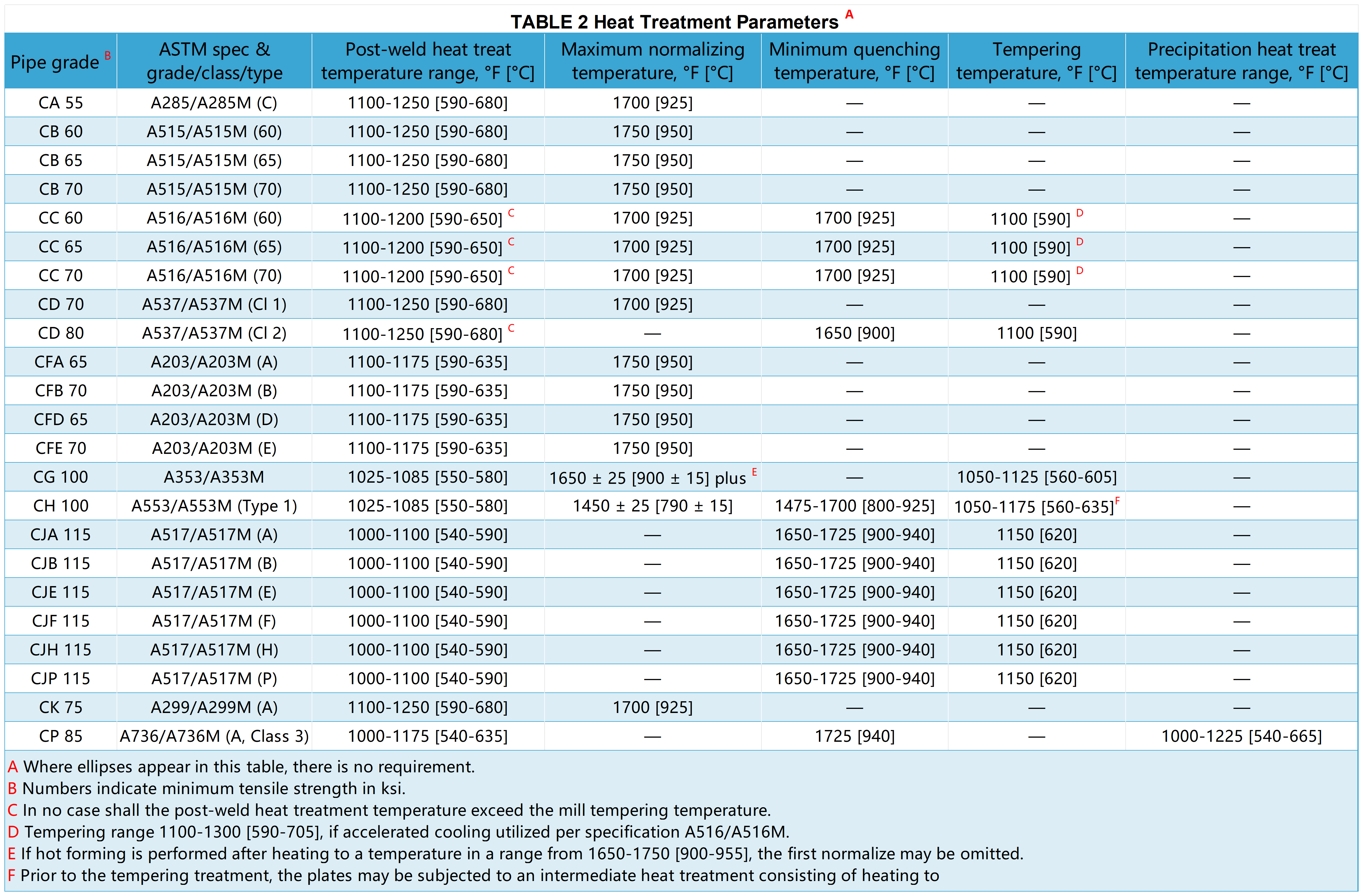

Maganin zafi don Azuzuwa Daban-daban

Duk azuzuwan ban da 10, 11, 12, da 13 za a yi maganin zafi a cikin tanderun da aka sarrafa zuwa ±25 °F[± 15°C].

Darasi na 20, 21, 22, da 23

Za a yi zafi iri ɗaya a cikin kewayon zafin jiyya mai zafi bayan walda wanda aka nuna a cikin Tebu 2 don aƙalla 1 h/in. [0.4 h/cm] na kauri ko na 1 h, duk wanda ya fi girma.

Darasi na 30, 31, 32, da 33

Za a yi zafi iri ɗaya zuwa zafin jiki a cikin kewayon austenitizing kuma kada ya wuce matsakaicin matsakaicin zafin jiki da aka nuna a cikin Tebu 2 kuma daga baya a sanyaya a cikin iska a zazzabi na ɗaki.

Darasi na 40, 41, 42, da 43

Za a daidaita bututun.

Dole ne a sake mayar da bututu zuwa yanayin zafin jiki wanda aka nuna a cikin Table 2 a matsayin mafi ƙanƙanta kuma a riƙe shi a zafin jiki na akalla 0.5 h / in. [0.2 h / cm] na kauri ko don 0.5 h, duk wanda ya fi girma, kuma a sanyaya iska.

Darasi na 50, 51, 52, da 53

Za a yi zafi da bututu iri ɗaya zuwa yanayin zafi a cikin kewayon austenitizing kuma kada ya wuce matsakaicin yanayin zafi da aka nuna a Tebur 2.

Daga baya, a kashe a cikin ruwa ko mai. Bayan quenching, bututu za a sake zafi zuwa mafi ƙarancin zafin jiki wanda aka nuna a cikin Tebu 2 kuma a riƙe shi a wancan.

zafin jiki mafi ƙanƙanta na 0.5 h/inch [0.2 h/cm] na kauri ko 0.5 h, duk wanda ya fi girma, da sanyaya iska.

Darasi na 70, 71, 72, da 73

Bututun zaia yi zafi iri ɗaya zuwa zafin jiki a cikin kewayon austenitizing, ba zai wuce matsakaicin zafin zafin da aka nuna a cikin Tebu 2 ba, sannan a kashe shi cikin ruwa ko mai.

Bayan quenching bututu za a sake yin zafi a cikin kewayon yanayin zafi na hazo da aka nuna a cikin Tebu 2 na wani lokaci da masana'anta za su ƙayyade.

ASTM A671 Gwajin Ayyuka

Haɗin Sinadari

Dangane da buƙatun daidaitattun ka'idodin aiwatar da albarkatun ƙasa, nazarin abubuwan da ke tattare da sinadarai, sakamakon gwajin don saduwa da daidaitattun buƙatun.

Gwajin tashin hankali

Duk bututun da aka ƙera zuwa wannan ƙayyadaddun dole ne su sami gwajin juzu'i na ƙetare bayan jiyya na zafi na ƙarshe, kuma dole ne sakamakon ya dace da buƙatun kayan tushe don ƙarfin juzu'i na ƙayyadaddun kayan farantin.

Bugu da ƙari, CD XX da CJ XXX, lokacin da waɗannan na Class 3x, 4x, ko 5x suke, kuma Grade CP na 6x da 7x za su sami gwajin juzu'i na ƙarfe na ƙarfe wanda aka yi akan samfuran da aka yanke daga bututu da aka gama. Sakamakon waɗannan gwaje-gwajen zai cika mafi ƙarancin buƙatun gwajin injina na ƙayyadaddun farantin.

Gwajin Lanƙwasawa Mai Wutar Wuta

Gwajin lanƙwasawa za a karɓa idan babu tsaga ko wasu lahani da suka wuce1/8in. [3 mm] a kowace hanya suna kasancewa a cikin ƙarfen walda ko tsakanin walda da ƙarfe na tushe bayan lanƙwasa.

Fashewar da ke tasowa tare da gefuna na samfurin yayin gwaji, kuma waɗanda ba su kai ba1/4in. [6 mm] da aka auna ta kowace hanya ba za a yi la'akari da shi ba.

Gwajin Matsi

Za a gwada bututun azuzuwan X2 da X3 daidai da ƙayyadaddun A530/A530M, Bukatun Gwajin Hydrostatic.

Gwajin Radiyo

Cikakken tsawon kowane weld na Azuzuwan X1 da X2 za a gwada su ta hanyar rediyo daidai da kuma biyan buƙatun ASME Boiler da Lambar Jirgin Ruwa, Sashe na VIII, Sakin layi na UW-51.

Ana iya yin gwajin rediyo kafin a yi maganin zafi.

Bayanin ASTM A671

Bututun da aka gama ba zai zama mara lahani ba kuma ya kasance yana da ƙarewa kamar mai aiki.

Bayar da izini a Girma

| Wasanni | Darajar Haƙuri | Lura |

| Waje Diamita | ± 0.5% | Dangane da ma'aunin kewaye |

| Fita-da-Roundness | 1%. | Bambanci tsakanin manya da ƙananan diamita na waje |

| Daidaitawa | 1/8 a cikin [3 mm] | Yin amfani da madaidaicin gefen kafa 10 (m3) wanda aka sanya shi ta yadda iyakar biyu su kasance cikin hulɗa da bututu |

| Kauri | 0.01 a cikin [0.3 mm] | Mafi ƙarancin kaurin bango ƙasa da ƙayyadadden kauri maras tushe |

| Tsawon tsayi | 0 - +0.5in [0 - +13mm] | ƙarewar da ba a sarrafa ba |

Aikace-aikace don ASTM A671 Karfe Tubing

Masana'antar Makamashi

An yi amfani da shi don jigilar ruwayen cryogenic a cikin masana'antar sarrafa iskar gas, matatun mai, da wuraren sarrafa sinadarai.

Tsarin Refrigeration na Masana'antu

Don amfani a cikin ɓangaren cryogenic na refrigeration da tsarin kwandishan don tabbatar da kwanciyar hankali da aminci.

Abubuwan amfani

Don ajiya da wuraren sufuri don iskar gas.

Gine-gine da Gine-gine

Aiwatar da ayyukan samar da ababen more rayuwa a ƙananan zafin jiki ko matsanancin yanayin muhalli, kamar ginin ajiyar sanyi.

Mu ne daya daga cikin manyan welded carbon karfe bututu da sumul karfe bututu masana'antun da kuma masu kaya daga kasar Sin, tare da fadi da kewayon high quality-bututu bututu a stock, mun himma zuwa samar muku da cikakken kewayon karfe bututu mafita. Don ƙarin cikakkun bayanai na samfur, don Allah jin daɗin tuntuɓar mu, muna sa ido don taimaka muku samun mafi kyawun zaɓin bututun ƙarfe don bukatun ku!

Tags: ASTM a671, efw, cc 60, aji 22, masu kaya, masana'antun, masana'antu, masu hannun jari, kamfanoni, wholesale, siye, farashin, zance, girma, na siyarwa, farashi.

Lokacin aikawa: Afrilu-19-2024