JIS G 3456 karfe Bututusu ne carbon karfe shambura ne da farko dace don amfani a sabis muhallin tare da waje diamita tsakanin 10.5 mm da 660.4 mm a yanayin zafi fiye da 350 ℃.

Maɓallan kewayawa

JIS G 3456 Rarraba Darajoji

Raw Materials

JIS G 3456 Hanyoyin Ƙirƙira

Ƙarshen bututu

Magani Zafi

Abubuwan sinadaran JIS G 3456

Gwajin Tensile na JIS G 3456

Gwajin Lalacewa

Gwajin Lantarki

Gwajin Hydraulic ko Gwajin Nodestructive (NDT)

Chart Nauyin Bututu da Jadawalin Bututu na JIS G 3456

Hakuri Mai Girma

Bayyanar

Saukewa: JIS G3456

JIS G 3456 Aikace-aikacen Bututu Karfe

Ma'auni masu alaƙa da JIS G 3456

Kayayyakinmu masu alaƙa

JIS G 3456 Rarraba Darajoji

Ma'auni na JIS G 3456 yana da maki uku bisa ga ƙarfin ƙarfi na bututu.

STPT370, STPT410 da STPT480

Suna wakiltar bututu mai ƙaramin ƙarfi na 370, 410, da 480 N/mm² (MPa) bi da bi.

Raw Materials

Za a kera bututun daga karfen da aka kashe.

Ƙarfe da aka kashe wani nau'i ne na musamman na ƙarfe wanda ke da alaƙa da ƙari na musamman, irin su aluminum da silicon, yayin aikin narkewa don sha da ɗaure iskar oxygen da sauran abubuwa masu cutarwa a cikin karfe.

Wannan tsari yana kawar da iskar gas da ƙazanta yadda ya kamata, ta yadda zai inganta tsabta da daidaituwar ƙarfe.

JIS G 3456 Hanyoyin Ƙirƙira

Samar da ta amfani da dacewa hade da tube masana'antu matakai da karewa hanyoyin.

| Alamar daraja | Alamar tsarin masana'anta | ||

| Tsarin kera bututu | Hanyar gamawa | Alama | |

| Saukewa: STPT370 Saukewa: STPT410 Saukewa: STPT480 | M:S | An gama zafi:H An gama sanyi:C | Kamar yadda ya zo a cikin 13 b). |

| Juriya na lantarki:E Butt welded:B | An gama zafi:H An gama sanyi:C Kamar yadda juriyar wutar lantarki ta walda:G | ||

DominSTPT 480bututu mai daraja, bututun ƙarfe maras sumul kawai za a yi amfani da shi.

Idan aka yi amfani da walda mai juriya, za a cire waldan da ke saman ciki da na waje na bututun don samun walƙiya mai santsi.

Ƙarshen bututu

Ya kamata bututu ya kasancem karshen.

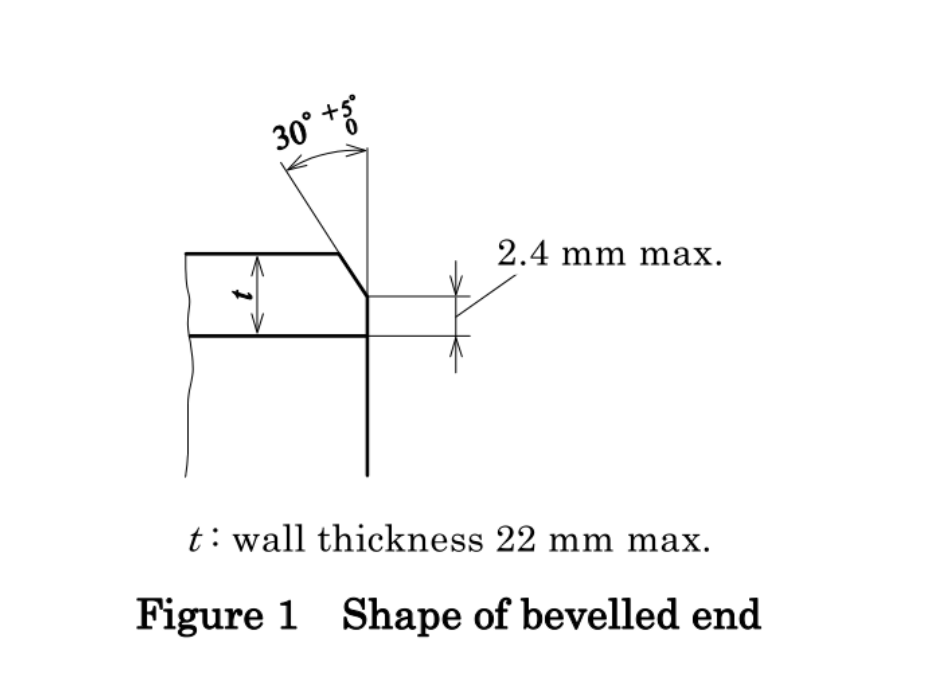

Idan ana buƙatar bututun da za a sarrafa shi zuwa ƙarshen beveled, don kauri bango ≤ 22mm karfe bututu, kusurwar bevel shine 30-35 °, nisa nisa na bakin bututun ƙarfe: shine max 2.4mm.

Wall kauri fiye da 22mm karfe bututu sloping karshen, gabaɗaya sarrafa a matsayin m bevel, aiwatar da nagartacce na iya koma zuwa dacewa bukatun na ASME B36.19.

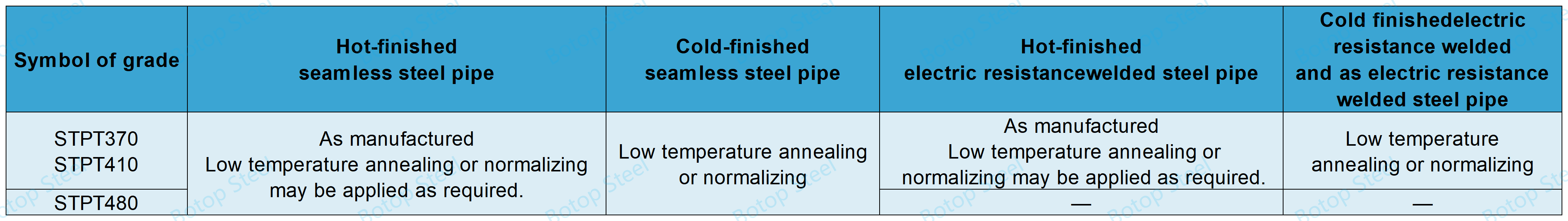

Magani Zafi

Zaɓi tsarin kula da zafi mai dacewa bisa ga ƙima da tsarin masana'antu.

Abubuwan sinadaran JIS G 3456

Gwajin Haɗin Sinadari

Hanyar nazarin zafi za ta kasance daidai da JIS G 0320.

Hanyar nazarin samfurin za ta kasance daidai da JIS G 0321.

| Alamar daraja | C(Carbon) | Si(Silikon) | Mn(Manganese) | P(Phosphorus) | S(sulfur) |

| max | max | max | |||

| Saukewa: STPT370 | 0.25% | 0.10-0.35% | 0.30-0.90% | 0.035% | 0.035% |

| Saukewa: STPT410 | 0.30% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

| Saukewa: STPT480 | 0.33% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

Haƙuri don Haɗin Sinadarai

Bututun ƙarfe mara ƙarfi za su kasance ƙarƙashin juriya a cikin Table 3 na JIS G 0321.

Bututun ƙarfe masu juriya-welded za su kasance ƙarƙashin juriya a cikin Tebur 2 na JIS G 0321.

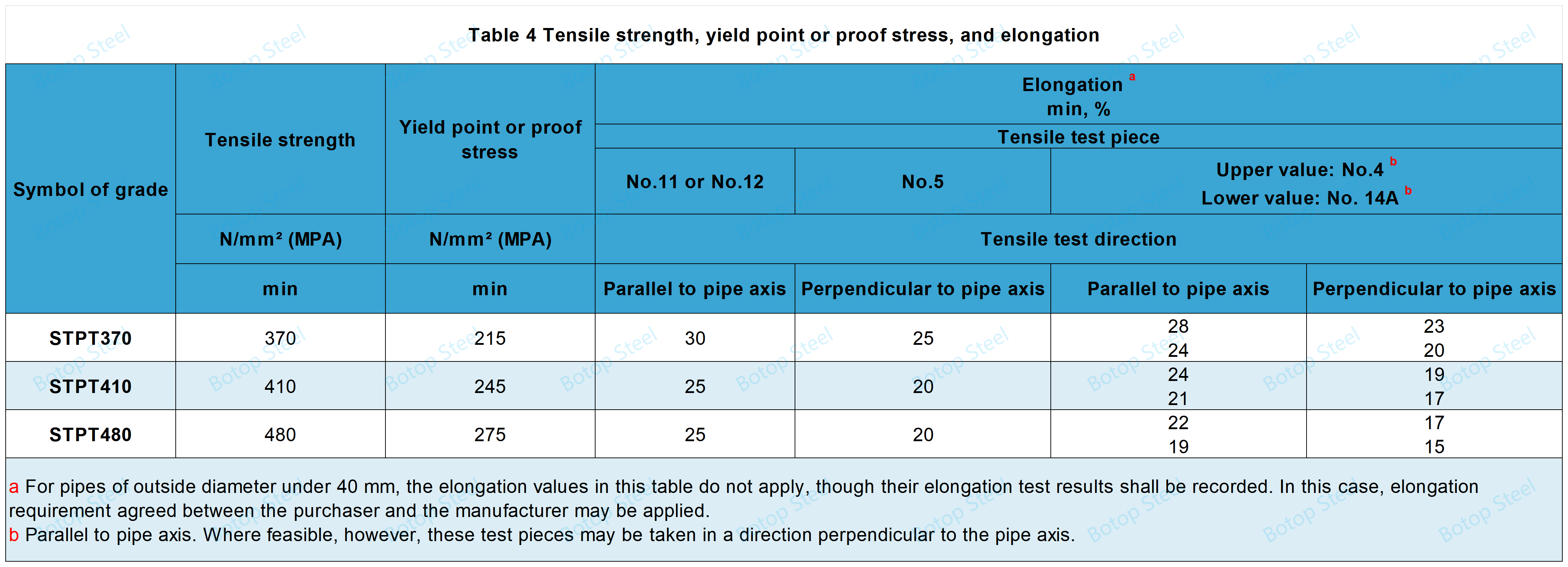

Gwajin Tensile na JIS G 3456

Hanyoyin Gwaji: Hanyoyin gwajin za su dace da ma'auni a JIS Z.2241.

Bututun zai cika buƙatun da aka bayar a cikin Teburin 4 don ƙarfin ƙarfi, ƙarfin haɓaka, da haɓakawa.

Gwajin gwajin da aka yi amfani da shi zai kasance na lamba 11, No. 12 (No. 12A, No. 12B, ko No. 12C), No. 14A, No. 4 or No. 5 kayyade a JIS Z 2241.

Matsakaicin yanki na Gwaji No. 4 zai zama 14 mm (tsawon ma'auni 50 mm).

Gwajin guda No. 11 da No. 12 za a dauka a layi daya zuwa bututu axis,

Gwaji guda No. 14A da No. 4, ko dai a layi daya ko perpendicular zuwa bututu axis,

da Gwajin yanki No. 5, a perpendicular zuwa bututu axis.

Gwajin yanki na 12 ko na 5 da aka ɗauka daga bututun ƙarfe na juriya na lantarki ba zai ƙunshi walda ba.

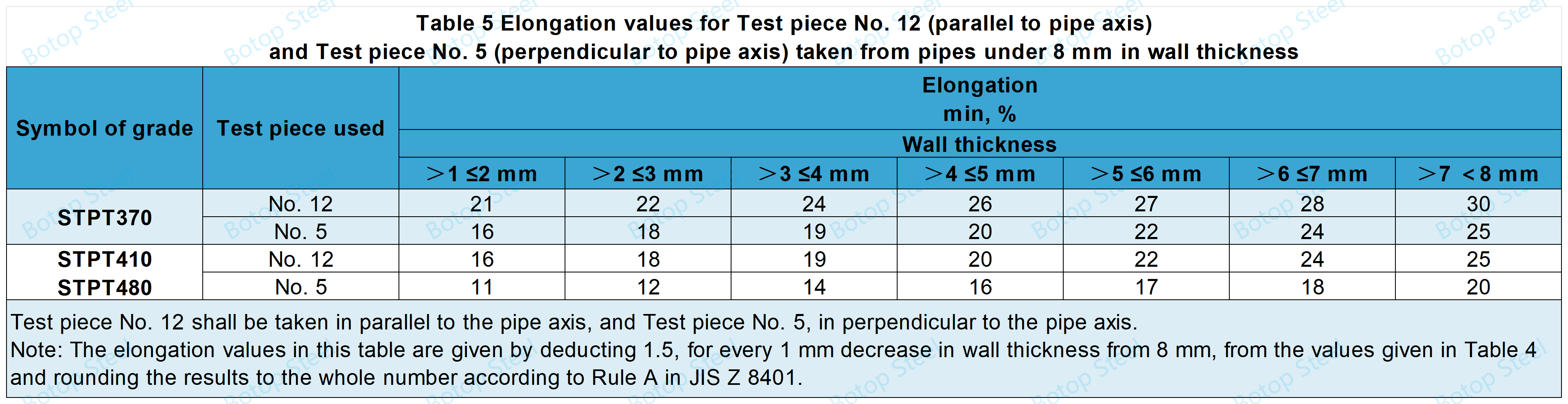

Don gwajin gwaji na bututu a ƙarƙashin 8 mm a cikin kauri da aka yi ta amfani da Gwajin Gwaji No. 12 ko Gwajin Gwaji A'a. 5, buƙatar elongation da aka bayar a cikin Tebur 5 zai yi amfani.

Gwajin Lalacewa

A dakin da zafin jiki (5 ° C - 35 ° C), karkatar da samfurin tsakanin dandamali guda biyu har sai ya zama.nisa (H) tsakanin su ya kai ƙayyadaddun ƙima sannan a duba tsaga.

H=(1+e)t/(e+t/D)

н: nisa tsakanin faranti (mm)

t: kaurin bangon bututu (mm)

D: waje diamita na bututu (mm)

е: akai-akai da aka ƙayyade ga kowane nau'i na bututu:

0.08 don STPT370,

0.07 don STPT410 da STPT480

Gwajin Lantarki

Bendability yana da amfani ga bututu tare da diamita na waje na 60.5 mm ko ƙasa da haka.

Hanyar gwaji A dakin da zafin jiki (5°C zuwa 35°C), lanƙwasa yanki na gwajin a kusa da mandrel har sai radius na ciki ya ninka diamita na waje sau 6 na bututun kuma bincika fashe. A cikin wannan gwajin, weld ɗin ya kamata a kasance a kusan 90° daga ƙarshen ɓangaren lanƙwasa.

Hakanan ana iya yin gwajin Bendability daidai da buƙatun cewa radius na ciki ya ninka diamita na waje sau huɗu kuma kusurwar lanƙwasa shine 180 °.

Gwajin Hydraulic ko Gwajin Nodestructive (NDT)

Za a yi gwajin ruwa ko gwaji mara lahani akan kowane bututu.

Gwajin Ruwan Ruwa

Rike bututun aƙalla a ƙaramin gwajin hydraulic da aka ƙayyade na aƙalla daƙiƙa 5 kuma lura cewa bututun yana iya jure matsi ba tare da yayyo ba.

An ƙayyade lokacin na'ura mai aiki da karfin ruwa bisa ga Jadawalin bututun ƙarfe.

| Tebura 6 Mafi ƙarancin gwajin gwaji na hydraulic | ||||||||||

| Kaurin bango mara kyau | Lambar jadawalin: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Matsakaicin gwajin hydraulic, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Gwajin mara lalacewa

Idan an yi amfani da duban ultrasonic, sigina daga samfurori masu ɗauke da ka'idodin nau'in UD, kamar yadda aka ƙayyade a JIS G 0582, za a yi amfani da su azaman matakan ƙararrawa; duk wani sigina daga bututu daidai ko mafi girma fiye da matakin ƙararrawa za a ƙi. Bugu da kari, mafi ƙarancin zurfin murabba'ai don gwajin bututu, ban da ƙarewar sanyi, zai zama 0.3 mm.

Idan an yi amfani da binciken eddy na yanzu, sigina daga ma'auni na nau'in EY kamar yadda aka ƙayyade a JIS G 0583 za a yi amfani da shi azaman matakin ƙararrawa; duk wani sigina daga bututu daidai ko mafi girma fiye da matakin ƙararrawa zai zama dalilin ƙin yarda.

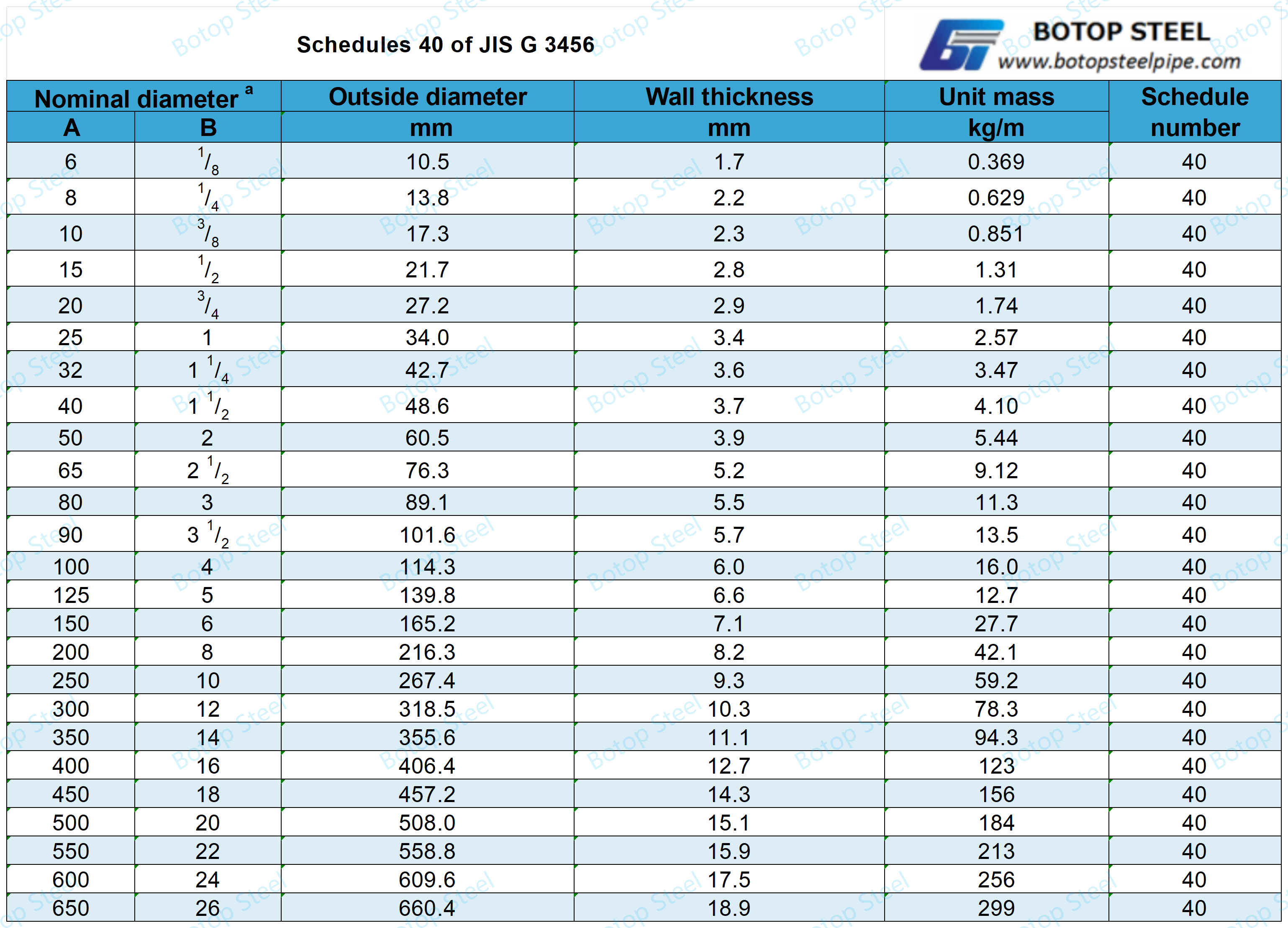

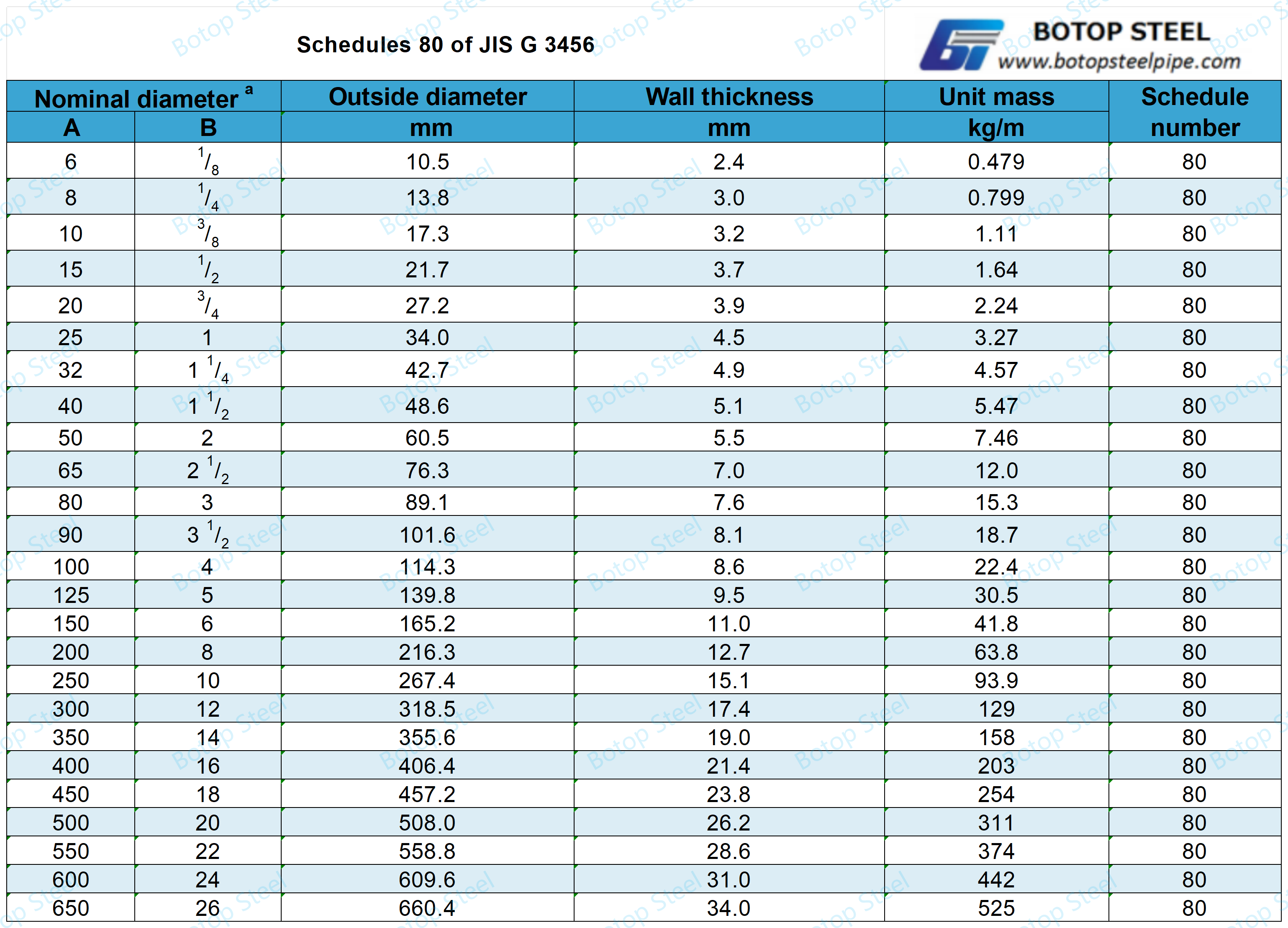

Chart Nauyin Bututu da Jadawalin Bututu na JIS G 3456

Formula Nauyin Ƙarfe Na Ƙarfe

Ɗauki nauyin 7.85 g/cm³ don bututun ƙarfe kuma a zagaye sakamakon zuwa mahimman lambobi uku.

W=0.02466t(Dt)

W: girman naúrar bututu (kg/m)

t: kaurin bango na bututu (mm)

D: waje diamita na bututu (mm)

0.02466: juzu'i don samun W

Jadawalin Nauyin Bututu

Tebur masu nauyi da jadawalin bututu sune mahimman bayanai waɗanda aka saba amfani da su a aikin injiniyan bututun mai.

Jadawalin Bututu

Jadawalin ƙayyadaddun ƙayyadaddun haɗe-haɗe na kaurin bango da diamita na bututu.

Jadawalin 40 da Jadawalin 80 bututun ƙarfe ana amfani da su sosai a masana'antu da gini. Girman bututu ne na gama-gari tare da kauri daban-daban na bango da iya aiki don yanayin aikace-aikacen daban-daban.

Idan kuna son ƙarin sani game dabututu nauyi tebur da bututu jadawalina cikin ma'auni, zaku iya danna don duba shi!

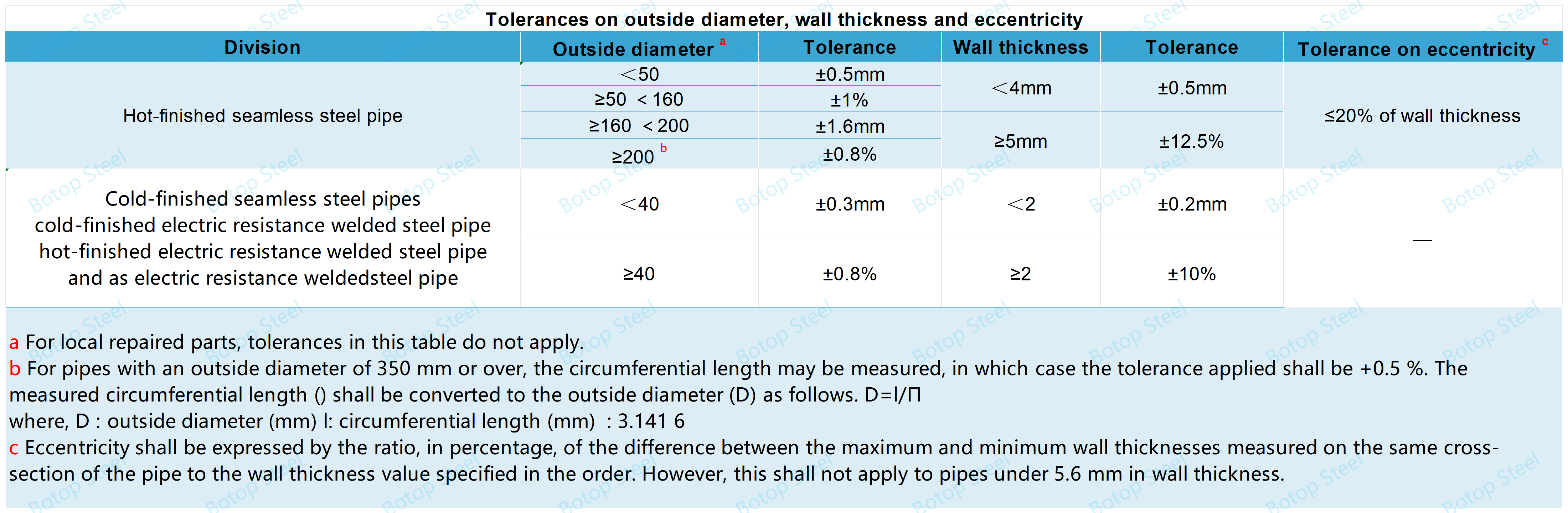

Hakuri Mai Girma

Bayyanar

Filayen ciki da na waje na bututu za su kasance santsi kuma ba su da lahani mara amfani.

Bututun zai zama madaidaiciya, tare da iyakar a kusurwoyi masu dacewa zuwa ga ma'aunin bututu.

Ana iya gyara bututu ta hanyar niƙa, injina ko wasu hanyoyin, amma kaurin bangon da aka gyara zai kasance cikin ƙayyadaddun haƙuri kuma saman da aka gyara zai zama santsi a cikin bayanan martaba.

Dole ne a kiyaye kauri na bangon bututun da aka gyara a cikin ƙayyadaddun haƙuri kuma saman bututun da aka gyara ya zama santsi a cikin bayanin martaba.

Saukewa: JIS G3456

Kowane bututun da ya wuce dubawa yakamata a yi masa lakabi da bayanin da ke gaba. Ana iya amfani da tambari akan daure don ƙananan bututun diamita.

a) Alamar daraja

b) Alamar tsarin masana'anta

Alamar tsarin masana'anta zai kasance kamar haka. Za a iya maye gurbin dashes tare da ɓangarorin.

Bututun ƙarfe mara nauyi mai zafi:-SH

Sanyi-ƙare sumul karfe bututu:-SC

Kamar yadda lantarki juriya welded karfe bututu:-EG

Hot-ƙare lantarki juriya welded karfe bututu: -EH

Cold-ƙare lantarki juriya welded karfe bututu:-EC

c) Girma, wanda aka bayyana da diamita na ƙididdigewa × kauri mara kyau na bango, ko diamita na waje × kaurin bango.

d) Sunan masana'anta ko alamar ganowa

Misali:BOTOP JIS G 3456 SH STPT370 50A×SHC40 ZAFI NO.00001

JIS G 3456 Aikace-aikacen Bututu Karfe

JIS G 3456 bututun karfe yawanci ana amfani dashi don kayan aiki da tsarin bututu a cikin yanayin zafi mai zafi da matsa lamba, kamar a cikin tukunyar jirgi, masu musayar zafi, bututun tururi mai matsa lamba, tsire-tsire masu ƙarfi, tsire-tsire masu sinadarai, da injin takarda.

Ma'auni masu alaƙa da JIS G 3456

Ma'auni masu zuwa duk sun dace da bututu a cikin yanayin zafi mai zafi da matsananciyar yanayi kuma ana iya amfani da su azaman madadin JIS G 3456.

ASTM A335/A335M: dacewa da bututun ƙarfe na gami

DIN 17175: don bututun ƙarfe mara nauyi

TS EN 10216-2 bututun ƙarfe mara nauyi

GB 5310: zartar da bututun ƙarfe mara nauyi

ASTM A106/A106M: Bututun ƙarfe na ƙarfe mara nauyi

ASTM A213 / A213M Bututu da bututu na gami karfe da bakin karfe

TS EN 10217-2: Ya dace da bututun walda da bututu

TS EN ISO 9329-2 Carbon mara kyau da bututun ƙarfe da bututu

NFA 49-211: don bututun ƙarfe da bututu marasa ƙarfi

BS 3602-2: don bututun ƙarfe na ƙarfe mara nauyi da kayan aiki

Kayayyakinmu masu alaƙa

Mu ne babban ingancin welded carbon karfe bututu masana'anta da kuma maroki daga kasar Sin, da kuma wani m karfe bututu stockist, ba ku da fadi da kewayon karfe bututu mafita! Idan kuna son ƙarin sani game da samfuran bututun ƙarfe, zaku iya tuntuɓar mu.

Tags: JIS G 3456, SPTP370, STPT410, STPT480, STPT, kaya, masana'antun, masana'antu, hannun jari, kamfanoni, wholesale, saya, farashin, zance, girma, don sayarwa, farashi.

Lokacin aikawa: Afrilu-29-2024