Bututun ƙarfe mara nauyi isbututun karfe da aka yi da karfen zagaye gaba daya wanda aka ratsa ba tare da wani dunkule mai walda a saman ba.

Rabewa: Dangane da siffar sashe, an raba bututun ƙarfe mara nauyi zuwa nau'i biyu: zagaye da siffa.

Kaurin bango kewayon: 0.25-200mm.

Kewayon diamita: 4-900mm.

Tsarin samarwa: Samar da bututun ƙarfe maras sumul yafi ɗaukar hanyar mirgina mai zafi ko sanyi.

Amfani: mafi kyawun ƙarfin matsa lamba, ƙarin tsari iri ɗaya, ƙarfi mafi girma, kuma mafi kyawun zagaye.

Rashin amfani: farashi mafi girma da ƙananan zaɓuɓɓukan girman iyaka

Amfani: An fi amfani da shi azaman bututun hakowa na ƙasa, petrochemical fasa bututu, bututun tukunyar jirgi, bututu mai ɗaukar nauyi, da kuma ingantaccen bututun ƙarfe na ƙarfe don mota, tarakta, da jirgin sama.

Maɓallan kewayawa

samar da tsari na zafi mirgina

Shirye-shiryen albarkatun kasa → Dumama → Perforation → Mirgina → Tsawaitawa → Girman girma da rage bango → Maganin zafi → Gyaran madaidaici → Bincika da gwaji → Yankewa da Ƙarshe Binciken Samfur → Maganin rigakafin lalata

Shirye-shiryen albarkatun kasa: Billet ɗin suna buƙatar tsaftace saman sama don cire duk wani abu na oxides ko wasu ƙazanta kafin kerawa.

Dumama: Ana ciyar da billet a cikin tanderun dumama don dumama zuwa yanayin da ya dace, wanda yawanci sama da 1200 ℃.

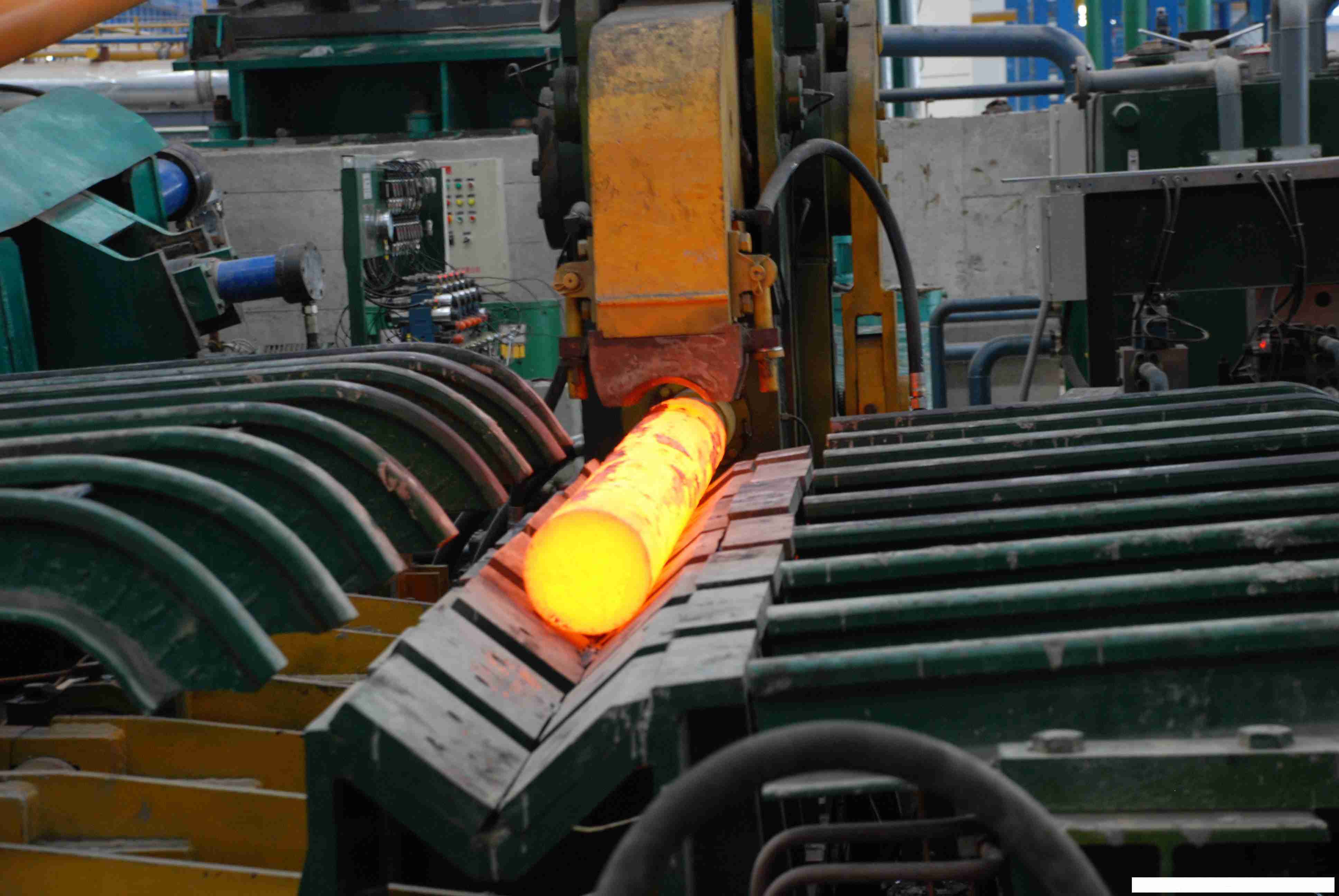

Perforation: Ana ciyar da billet ɗin mai zafi a cikin na'ura mai raɗaɗi, wanda ya huda shi ya zama babban billet.

Mirgina: Bayan an huda, billet ɗin ya shiga injin niƙa. Billet ɗin yana wucewa ta nau'i-nau'i na nau'i-nau'i masu yawa waɗanda ke ci gaba da rage diamita na waje kuma suna ƙara tsawon billet.

Tsawaitawa: Ana ƙara shimfiɗa billet ɗin ta hanyar elongator don cimma ƙarin ƙayyadaddun ƙira.

Girma da raguwar bango: Girma da raguwar bangon billet a cikin injin ƙira don cimma ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun bango da kauri.

Maganin zafi: bututu yana buƙatar magani mai zafi don daidaita tsarin ƙarfensa da inganta kayan aikin injiniya na kayan aiki, ciki har da matakan daidaitawa da haɓakawa.

Gyaran daidai: Ana gyara bututu ta hanyar daidaitawa na'ura don tabbatar da madaidaiciyar bututu.

Dubawa da gwaji: Ana gudanar da gwaje-gwaje iri-iri da gwaje-gwaje akan bututun ƙarfe da aka kammala, kamar su hydrotest, gwajin ultrasonic, gwajin eddy na yanzu, da sauransu.

Yanke da Ƙarshen Binciken Samfur: Yanke bututun cikin ƙayyadaddun tsayi bisa ga buƙatun abokin ciniki kuma yin binciken gani na ƙarshe da girma.

Maganin rigakafin lalata: Idan ya cancanta, an lulluɓe bututun ƙarfe maras nauyi tare da mai hana lalata ko wasu magunguna masu lalata, kamar galvanized; 3LPE, FBE da sauransu.

Tsarin samarwa na sanyi-jawo

Shirye-shiryen bututun billet →Maganin cirewa →Zaɓi da man shafawa → Zane mai sanyi →Maganin zafi → Gyaran madaidaici → Bincika da gwaji → Yankewa da Kammala Binciken Samfuri → Maganin hana lalata

Shirye-shiryen bututun Billet: Zaɓin bututun ƙarfe mara nauyi mai zafi wanda ya dace kamar kayan albarkatun ƙasa, watau bututun billet na farko.

Maganin annealing: Domin kawar da matsalolin da ke haifarwa a lokacin zafi mai zafi na aikin bututun billet, bututun billet yawanci suna buƙatar anneal.

Pickling da Lubrication: Bayan annealing, da bututu bukatar pickled don cire surface oxidized fata da tsatsa. Bayan haka, ana shafa wani abu mai mai a saman bututu don rage juzu'i da lalacewa yayin aikin zane mai sanyi.

Zane Mai sanyi: Ana sanya bututun billet akan injin zane mai sanyi kuma an shimfiɗa ta ta hanyar mutuwa, tsarin da ke rage diamita na bututun tare da inganta yanayin ƙasa da daidaiton girman.

Bayan haka, maganin zafi da sauran hanyoyin samarwa iri ɗaya ne da mirgina mai zafi, kuma ba za a sake maimaita su anan ba.

Yadda za a bambanta tsakanin zafi birgima da sanyi zana sumul karfe bututu, za ka iya mayar da hankali a kan wadannan sauki fasali:

| Jerin | zafi mirgina | zane mai sanyi |

| Bayyanuwa | Filayen ya fi ƙanƙara kuma yana iya samun fata mai oxidized da ƙarin lahani na saman kamar su karce, alamomi, da alamun birgima. | Kyakkyawan gamawa, yawanci santsi da haske fiye da bututun ƙarfe mai birgima |

| Diamita na Wuta (OD) | OD≥33.9 | OD | 33.9 |

| Kaurin bango | 2.5-200 mm | 0.25-12 mm |

| Hakuri | Mai yiwuwa ga kaurin bango mara daidaituwa da ovalization | kauri bangon diamita na waje tare da ƙananan haƙuri |

| Farashin | Ƙananan farashi don yanayi iri ɗaya | Farashin mafi girma don yanayi iri ɗaya |

Ka'idojin aiwatar da bututu mara ƙarfi

Matsayin Duniya

TS EN ISO 3183 bututun ƙarfe don masana'antar mai da iskar gas

American Standard

ASTM A106: Bututun ƙarfe mara nauyi don sabis na zafin jiki mai girma

ASTM A53: Baƙi mara kyau da Welded Baƙar fata da Bututun Karfe na Galvanized mai zafi

API 5L: Bututun layi don jigilar mai, gas da ruwa

API 5CT: Rukunin rijiyar mai da tubing

ASTM A335: Bututun ƙarfe na ƙarfe mara nauyi da bututu don sabis na zafin jiki

ASTM A312: Bututun Karfe Bakin Karfe da Bututu maras Sumul, Welded and Heavy Duty Cold

Matsayin Turai

EN 10210: Bututun ƙarfe da bututu marasa ƙarfi da welded don sifofi masu zafi

TS EN 10216 Bututun ƙarfe da bututu marasa ƙarfi (don aikace-aikacen matsa lamba)

TS EN 10297 Bututun ƙarfe na ƙarfe da bututu marasa ƙarfi don dalilai na injiniya da na gaba ɗaya

DIN 2448: Girma da ingancin bututun ƙarfe mara nauyi

DIN 17175: Bututun ƙarfe mai jure zafi mara ƙarfi

TS EN 10216-2 Bututun ƙarfe mara ƙarfi da gami

TS EN 10255 Bututun ƙarfe mara ƙarfi da bututu don haɗin welded da threaded

Matsayin Jafananci

Saukewa: G3454: Carbon karfe bututu don matsa lamba bututu

JIS G3455: Carbon karfe bututu don babban matsin sabis

JIS G3461: Carbon karfe bututu don tukunyar jirgi da zafi musayar

JIS G3463: tukunyar jirgi da bututun musayar zafi na bakin karfe

Matsayin Rasha

GOST 8732-78: Bututun ƙarfe da bututu masu zafi marasa ƙarfi da bututu bisa ga Matsayin Rasha

Matsayin Australiya

AS/NZS 1163: Standard for Structural Karfe tubes da bututu rufe zagaye, murabba'i da rectangular tubes da bututu kayayyakin.

Farashin AS1074: Bututun ƙarfe da kayan aikin ruwa, gas da bututun jirgin sama.

Quality iko na m karfe bututu

1. Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Kayayyakin Hulɗa: Don bincika ingancin saman, gami da lahani irin su fashe, tarkace, tsatsa da lalata, da daidaiton girman, gami da tsayi, diamita, da kauri na bango.

2. Binciken Haɗin Sinadarai: Tabbatar da cewa sinadarin ƙarfe na ƙarfe ya dace da daidaitattun buƙatun ta hanyar bincike na gani da sauran hanyoyin.

3. Gwajin kayan aikin jiki: ciki har da ƙarfin ƙarfi, ƙarfin samar da ƙarfi, haɓakawa, gwajin gwagwarmaya, da dai sauransu don tabbatar da kayan aikin injiniya na kayan.

4. Gwajin mara lalacewa (NDT):

- Gwajin Ultrasonic (UT): don lahani na ciki, kamar haɗawa da fasa.

- Gwajin ƙwayar magnetic (MT): galibi ana amfani da su don nemo lahani kamar fashe-fashe a saman saman bututun ƙarfe.

-Gwajin rediyo (RT): yana gano lahani na ciki ta hanyar X-ray ko γ-ray, wanda ya dace da gano lahani na ciki a cikin gaɓoɓin welded da jikin bututu.

-Eddy halin yanzu dubawa (ET): dace don gano saman da lahani na ƙasa, galibi ana amfani da su don kayan sirara.

5.Hydrostatic gwajin: Ta hanyar cika bututun ƙarfe da ruwa da kuma yin amfani da takamaiman matsa lamba, ana duba shi don yawo don tabbatar da ƙarfin ƙarfinsa.

6.Impact gwajin: Musamman ga aikace-aikace tare da ƙananan yanayin zafi ko wasu buƙatu na musamman, gwajin tasiri yana kimanta ƙarfin abu lokacin da aka yi tasiri na kwatsam.

7.Metallographic bincike: Yana nazarin microstructure na kayan don tabbatar da cewa ƙungiyar ƙarfe na bututun ƙarfe mara nauyi ya dace da bukatun.

Kariya don siyan bututun ƙarfe mara nauyi

Manyan Al'amura:

-Bayyana ƙayyadaddun ƙayyadaddun bayanai: tabbatar da samar da ingantattun bayanai dalla-dalla kamar diamita na waje, kaurin bango, tsayi, da sauransu.

-Zaɓi abu: Zaɓi ƙimar ƙarfe da ta dace da kayan aiki bisa ga yanayin aikace-aikacen, kamar ƙarfe na carbon, gami karfe, bakin karfe, da dai sauransu.

-Ma'auni da takaddun shaida: Ƙayyade ƙa'idodin da za a bi (misali ASTM, API, DIN, da sauransu) da takaddun ingancin da ake buƙata ko rahotannin gwaji.

-Yawai: Samar da ingantattun ƙididdiga, la'akari da yuwuwar ɓarna da abubuwan buƙatun.

Ƙarin al'amura:

-Maganin saman: dangane da buƙatun aikace-aikacen, yanke shawara ko bututun ƙarfe yana buƙatar a yi masa magani, kamar galvanized ko fenti.

-Ƙarshen magani: Nuna ko ƙarshen bututu yana buƙatar magani na musamman, kamar lebur, beveled, threaded, da dai sauransu.

— Bayanin amfani: Samar da yanayi da amfani da bututun ƙarfe domin mai siyarwa ya ba da shawarar samfuran da suka dace.

- Abubuwan buƙatun buƙatun: Ƙayyade buƙatun na musamman don marufi don tabbatar da aminci yayin sufuri.

—Lokacin bayarwa: Tabbatar da ranar bayarwa na odar don tabbatar da ya dace da jadawalin aikin ku.

—Sharuɗɗan farashi: Tattaunawa da kammala sharuddan farashin, gami da farashin jigilar kaya, haraji, da sauransu.

-Bayan-sabis: fahimci sabis na bayan-tallace-tallace na mai kaya, kamar yadda ake tafiyar da lamuran inganci.

-Tallafin fasaha: Tabbatar da samun goyan bayan fasaha, musamman don aikace-aikace na musamman ko shigarwa.

Game da Mu

Botop Karfe ƙwararren ƙwararren Welded Carbon Karfe Bututun masana'anta ne kuma mai siyarwa, Mai sarrafa bututun Karfe mara ƙarfi a China. Tare da fiye da shekaru 16 na tarihi, muna adana fiye da tan 8,000 na bututun layi mara nauyi a hannun jari kowane wata. Idan kuna son ƙarin sani game da samfuran bututun ƙarfe namu, zaku iya tuntuɓar mu don samar muku da samfuran da ayyuka masu inganci!

tags: bututun ƙarfe mara nauyi; ma'anar bututu maras sumul; misali; Masu kaya, masana'antun, masana'anta, Stockist, kamfanoni, wholesale, saya, farashin, zance, girma, na siyarwa, farashi.

Lokacin aikawa: Afrilu-04-2024