ASTM A106 Grade B bututun ƙarfe ne mara nauyi wanda ya dogara da ma'aunin ASTM A106 kuma an tsara shi don jure yanayin zafi da matsa lamba.

Ana amfani da shi musamman a masana'antar mai, gas, da sinadarai don gina tsarin bututu da kayan aiki masu alaƙa.

Maɓallan kewayawa

Saukewa: ASTM A106

ASTM A106 ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun iskar carbon ƙarfe ne don aikace-aikacen zafi mai zafi wanda ASTM International ta haɓaka. Ƙididdigar ta bayyana maki uku na bututun ƙarfe maras sumul, Grade A, Grade B, da Grade C. Daga cikin waɗannan, Grade B shine mafi yawan amfani.

Darajojin "B" yana wakiltar ƙayyadaddun abun da ke tattare da sinadarai da matakin kayan aikin injiniya na kayan aiki a wasu yanayin zafi da matsi.

Idan kana son ƙarin sani game da ASTM A106 zaka iya danna:Menene Ma'anar ASTM A106?

Mabuɗin Siffofin

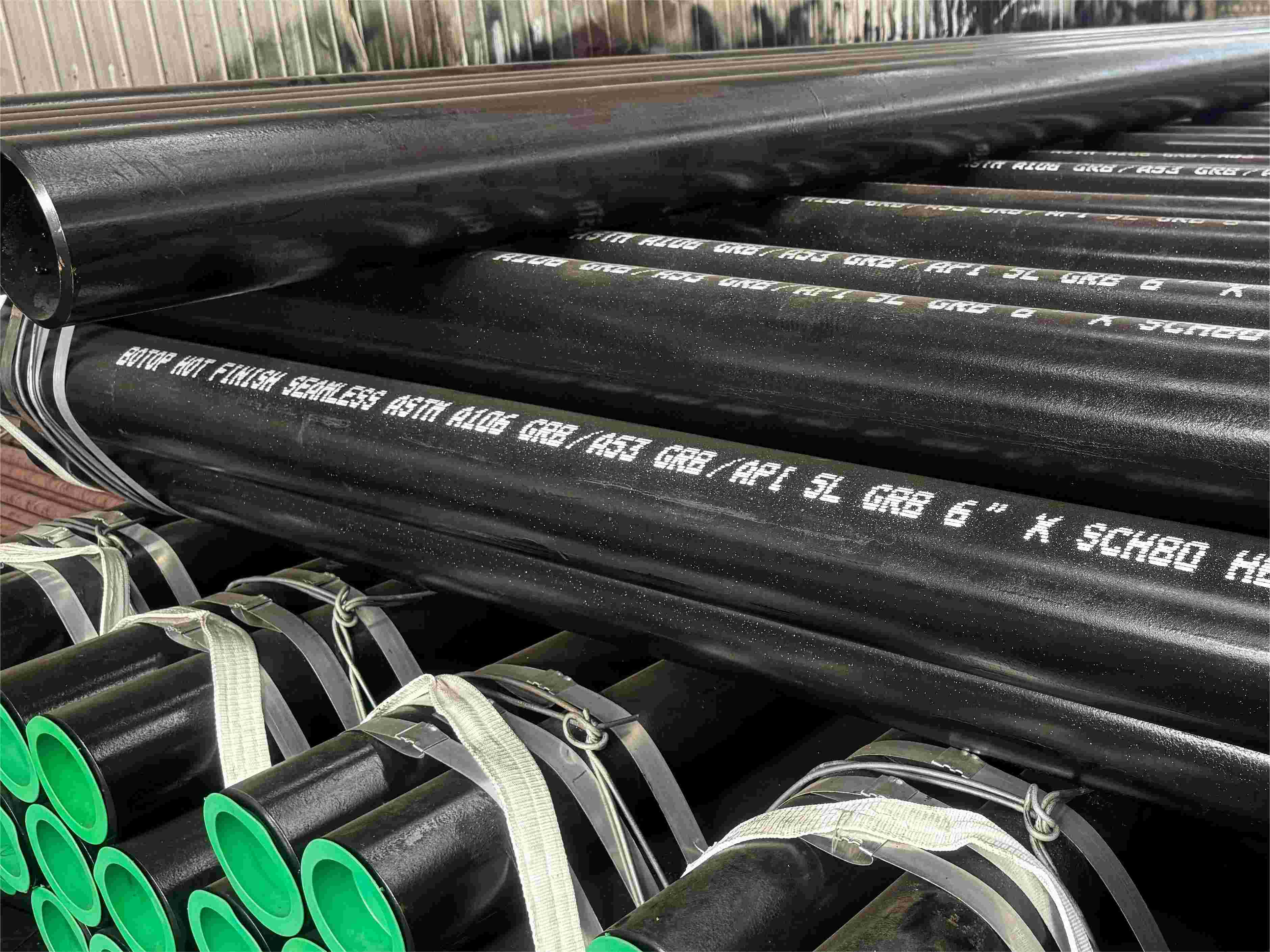

Manufacturing mara kyau

ASTM A106 Grade B bututu ana samar da shi ta hanyar masana'anta mara kyau wanda ke tabbatar da daidaito da ƙarfi don amfani a cikin mahallin da ke fuskantar babban damuwa.

Ayyukan Zazzabi mai girma

Wannan bututu ya dace musamman don aiki a cikin yanayin zafi mai zafi, kamar a cikin tsarin bututu a tashoshin wutar lantarki, matatun mai, da tsire-tsire masu sinadarai.

Haɗin Sinadari

Abubuwan da ke tattare da sinadarai na Grade B an ƙera shi don ba shi juriya mai kyau da ƙarfin aiki. Yawanci ya ƙunshi ƙananan abun ciki na carbon da matsakaicin adadin manganese, phosphorus, sulfur, da silicon.

Kayayyakin Injini

ASTM A106 Grade B karfe bututu yana ba da kyakkyawan ƙarfi mai ƙarfi da ƙarfin yawan amfanin ƙasa don aikace-aikacen da ke buƙatar kyawawan kaddarorin inji.

Faɗin Aikace-aikace

Saboda juriyar zafi da kaddarorin inji, ana amfani da bututun ASTM A106 Grade B a cikin aikace-aikace da yawa kamar mai da gas, petrochemicals, tukunyar jirgi, da masu musayar zafi.

Haɗin Sinadari

| Abun ciki | C (Carbon) | Mn (Manganese) | P (Phosphorus) | S (sulfur) | Si (Silikon) | Cr (Chromium) | Cu (Copper) | Mo (Molybdenum) | Ni (Nickel) | V (Vanadium) |

| max | - | max | max | min | max | max | max | max | max | |

| yawa kunshe | 0.30% | 0.29 - 1.06% | 0.035% | 0.035% | 0.10% | 0.40% | 0.40% | 0.15% | 0.40% | 0.08% |

Sai dai in ba haka ba wanda mai siye ya ayyana, ga kowane raguwar 0.01% ƙasa da ƙayyadaddun iyakar carbon, za a ba da izinin haɓaka 0.06% na manganese sama da ƙayyadaddun iyakar har zuwa matsakaicin 1.65%.

Cr, Cu, Mo, Ni, da V: jimlar waɗannan abubuwa biyar ba za su wuce 1% ba.

Kayayyakin Injini

| Jerin | Ƙarfin ɗaure, min | Ƙarfin bayarwa, min | ||

| rarrabawa | psi | MPa | psi | MPa |

| ASTM A106 B | 60,000 | 415 | 35,000 | 240 |

Hakuri Mai Girma

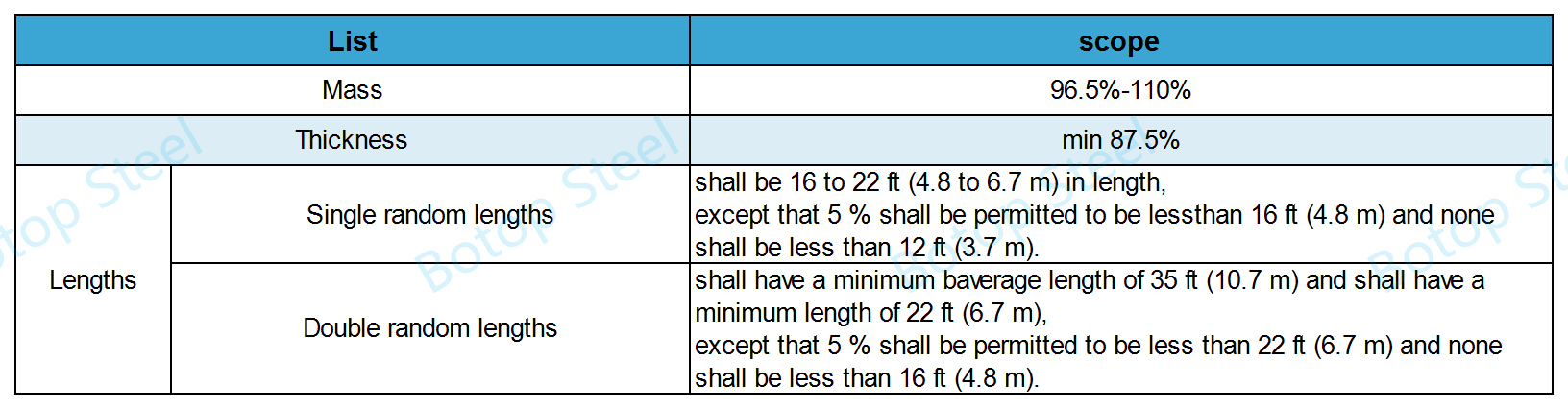

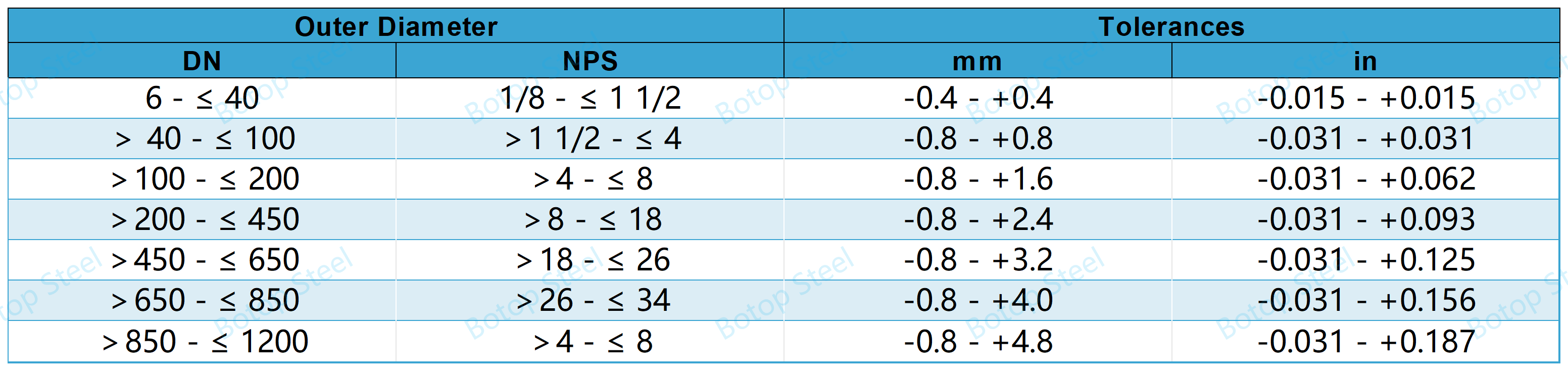

Taro, Kauri, da Tsawon Su

Diamita na waje

Gwaji da Takaddun shaida

Binciken Haɗin Halitta

Ƙayyade nau'ikan sinadarai na bututu, gami da carbon, manganese, phosphorus, sulfur, da silicon don tabbatar da cewa kayan sun cika buƙatun sinadarai da aka ƙayyade a cikin ma'auni.

Gwajin tensile

Auna ƙarfin juzu'i, ƙarfin samarwa, da haɓaka bututun ƙarfe. Waɗannan gwaje-gwajen suna taimakawa kimanta aikin kayan da tauri ƙarƙashin damuwa mai ƙarfi.

Lankwasawa Gwajin

Ana yin gwaje-gwajen lankwasawa akan bututun walda da maras sumul don kimanta ƙarfin nakasar sa na filastik da amincin haɗin gwiwa na walda.

Gwajin Lalacewa

Ana yin gwaje-gwajen ƙwanƙwasa akan bututu don kimanta nakasu da halayen fashewar su a ƙarƙashin matsin lamba.

Gwajin Tauri

Ana kimanta taurin abu ta hanyar gwajin taurin Brinell ko Rockwell. Wannan gwajin yana da mahimmanci wajen ƙayyade aiki da halayen aikace-aikacen kayan.

Hydrotesting

Dole ne a gwada kowane bututu ta hanyar ruwa don tabbatar da cewa ba shi da ɗigowa a ƙayyadadden matsa lamba don tabbatar da ƙarfi da amincin tsarin bututun.

Gwajin mara lalacewa

Ya haɗa da Gwajin Ultrasonic (UT), Gwajin Barbashi na Magnetic (MT) da/ko Gwajin Radiyo (RT) don gano lahani na ciki da na sama kamar fasa, haɗawa da porosity.

Gwajin Tasiri (bisa bukata)

A wasu lokuta, ana iya buƙatar gwajin tasiri (misali, gwaji na V-notch) don kimanta taurin karayar kayan a ƙananan yanayin zafi.

Babban Aikace-aikace na ASTM A106 Grade B

sufurin mai da iskar gas: don matsa lamba da yanayin zafi mai zafi.

sarrafa sinadaran: don lalata da kuma tsarin bututun da ke jure zafin jiki.

Tashoshin wutar lantarki: don layin tururi da kantunan tukunyar jirgi.

Masana'antu masana'antu: don bututun matsa lamba da kayan aiki mai ƙarfi.

Gina da ginin jirgi: don gina tsarin dumama da sanyaya da tsarin tukunyar jirgi da tururi don jiragen ruwa.

Masana'antar kera motoci: don kera sassan motoci masu jure yanayin zafi da matsi.

Madadin ASTM A106 GR.B

Lokacin zabar madadin kayan, ya kamata a yi la'akari da kaddarorin injiniyoyi, juriya na zafin jiki, juriya na matsa lamba, da juriya na lalata kayan don tabbatar da bin ƙayyadaddun buƙatun aikace-aikacen da ƙa'idodi da ƙa'idodi masu dacewa.

| Standard Name | Iyakar aikace-aikace |

| ASTM A53 Babban darajar B | Ƙarƙashin Matsi da Aikace-aikacen Tsarin Injini |

| API 5L Daraja B | Bututun mai da iskar gas |

| Bayani na ASTM A333 | Don sabis na ƙarancin zafin jiki |

| ASTM A335 P11 P22 | Don yanayin zafi mai zafi kamar tukunyar jirgi a tashoshin wutar lantarki |

| ASTM A312 TP304 da TP316 | Aikace-aikacen da ke buƙatar babban juriya na lalata |

| ASME SA106 | Yanayin zafi mai zafi da matsa lamba |

| AS/NZS 1163 C350L0 | Tsarin tsari da dalilai na inji |

| GB3087 | Bututun ƙarfe mara nauyi don ƙananan tukunyar jirgi da matsakaicin matsa lamba |

| GB 5310 | Bututun ƙarfe maras nauyi don manyan tukunyar jirgi |

| GB 9948 | Bututun ƙarfe mara nauyi don fashewar mai |

Rufin Kariya don ASTM A106 GR.B

Galvanized

Galvanizing wata hanya ce ta samar da kariya ta lalata ta hanyar yin amfani da murfin zinc zuwa saman karfe.

Mafi yawan fasaha na galvanizing shine zafi tsoma galvanizing, inda aka tsoma bututun ƙarfe a cikin narkakkar zinc don samar da tudun tutiya mai yawa a samansa.

Wannan Layer na Zinc ba wai kawai ya keɓance ma'aunin ƙarfe daga iska da ruwa ba, yana hana oxidation, amma kuma yana rage saurin lalata ƙarfe ta hanyar kariya ta anodic ta hadaya (zinc ya fi ƙarfin ƙarfe).

Bututun ƙarfe mai zafi-tsoma galvanized da aka yi da shi ya dace don amfani a waje ko a cikin yanayin rigar, kamar wuraren kula da ruwa da tsarin ginin waje.

Tufafi

Rufewa hanya ce ta hana lalata ta hanyar shafa ɗaya ko fiye da yadudduka na takamaiman abin da ke hana lalata a saman bututun ƙarfe.

Wadannan sutura na iya zama epoxy, polyurethane, polyethylene, ko wasu kayan aikin roba.

Ana amfani da suturar Epoxy a ko'ina a cikin bututun masana'antu saboda kyakkyawan kwanciyar hankalinsu da mannewa.

Babban aikin rufin shine toshe danshi da sinadarai masu lalata, yana hana su shiga kai tsaye tare da karfe. Maganin shafawa ya dace da wurare masu yawa kamar tsire-tsire masu sinadaran, yanayin ruwa da hanyoyin sadarwa na bututu na birni.

Rufin Rufi

Maganin rufi shine a yi amfani da Layer na kayan da ba su da lahani, kamar resin epoxy, yumbu, ko roba, a cikin bututun ƙarfe don hana lalata matsakaicin isarwa a bangon ciki na bututun ƙarfe.

Wannan hanya ta dace musamman don isar da ruwa mai lalacewa (misali acid, alkalis, mafita na gishiri, da sauransu).

Rufin guduro na Epoxy yana ba da wani kakkarfan Layer na hana lalata wanda zai iya jure wani mataki na harin sinadari da shanyewar jiki.

Rufin ba kawai yana kara tsawon rayuwar bututu ba amma yana kula da tsabtar ruwa kuma yana hana kamuwa da cuta.

Kayayyakinmu masu alaƙa

Mu ne daya daga cikin manyan welded carbon karfe bututu da sumul karfe bututu masana'antun da kuma masu kaya daga kasar Sin, tare da fadi da kewayon high quality-bututu bututu a stock, mun himma zuwa samar muku da cikakken kewayon karfe bututu mafita. Don ƙarin cikakkun bayanai na samfur, don Allah jin daɗin tuntuɓar mu, muna sa ido don taimaka muku samun mafi kyawun zaɓin bututun ƙarfe don bukatun ku!

tags:a106 aji b, A106, sumul, masu kaya, masana'antun, masana'antu, hannun jari, kamfanoni, wholesale, saya, farashin, zance, girma, na siyarwa, farashi.

Lokacin aikawa: Maris-01-2024