Nau'in E karfe bututuana kera shi daidai daASTM A53kuma ana samarwa ta amfani da Electric-Resistance-welding (ERW) tsari.

Ana amfani da wannan bututu da farko don aikace-aikacen inji da matsa lamba amma kuma ya dace da amfani dashi azaman bututun gabaɗaya don jigilar tururi, ruwa, iskar gas, da iska.

Girman kewayonASYM A53 shine DN 6-650.

A samar kewayonNau'in E shine DN 20-650 DN.

Diamita na bututu da ke ƙasa da DN 20 suna da ƙanƙanta don Nau'in E. Don dalilai na fasaha babu hanyar samar da su, don haka Type S, wanda shinem masana'antu tsari, ana yawan amfani da shi.

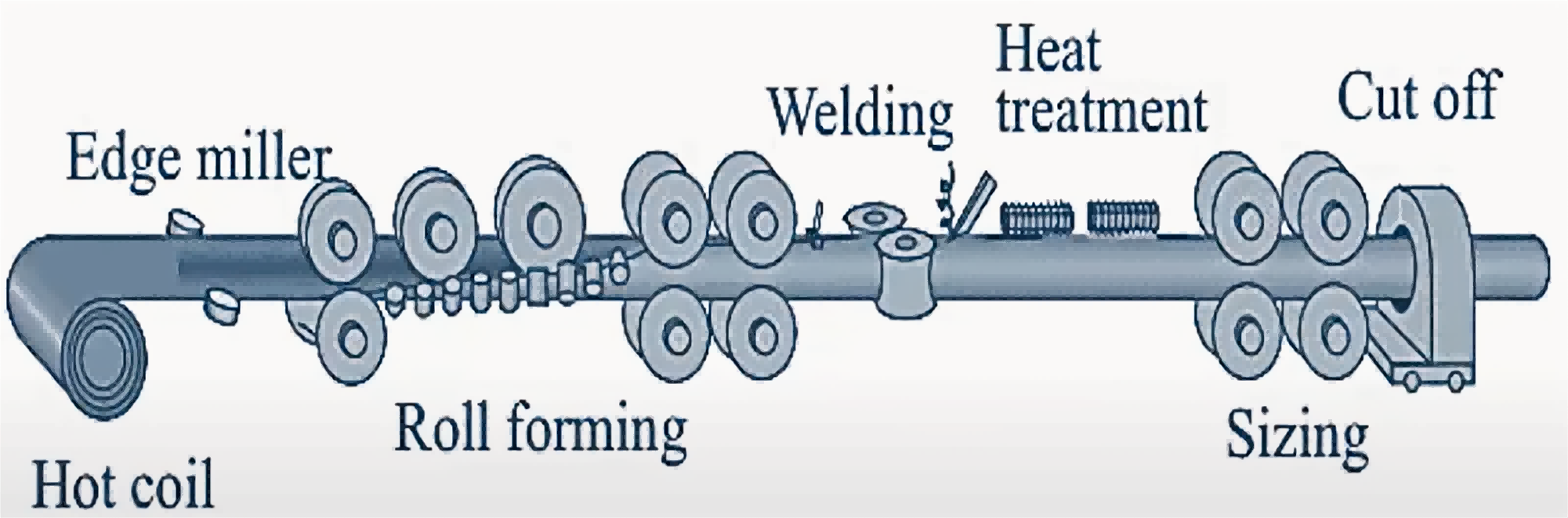

Tsarin kera don ASTM A53 Nau'in E

Tsarin samarwa ya haɗa da samar da coils na karfe ta hanyar rolls, gefuna walda ta juriya dumama, deburring welds, da girma da daidaitawa don yin bututu.

Halayen ASTM A53 Nau'in E Karfe Bututu

Yana da weld ɗin gindi guda biyu masu tsayi a ciki da waje.Gefuna na faranti na karfe suna welded a ciki da waje na bututu yayin aikin samarwa don tabbatar da ƙarfi da rufewa.

Ba a ganin walda ta ciki da ta waje.A ciki da kuma na waje welds ana tsabtace zuwa game da tsayi tsawo kamar yadda bututu surface a lokacin samarwa, wanda ke taimakawa ga overall bayyanar da yiwuwar hydrodynamic Properties na bututu.

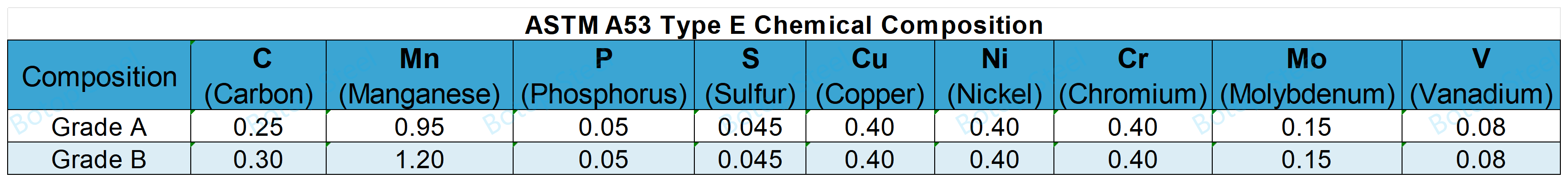

ASTM A53 Nau'in Kayan Kayan Kifi na E

Ga kowane raguwa na 0.01 % ƙasa da ƙayyadadden iyakar carbon, haɓakar 0.06 % na manganese sama da iyakar ƙayyadaddun za a ba da izini har zuwa iyakar 1.65 %.

Cu, Ni, Cr, Mo, da V, su ne abubuwa biyar tare ba su wuce 1.00%.

ASTM A53 Nau'in E Kayayyakin Injini

Gwajin tashin hankali

Juriya welded bututu DN ≥ 200 za a gwada ta amfani da biyu transverse samfurori, daya a fadin weld da sauran a gaban walda.

| Jerin | rarrabawa | Darasi A | Darasi B |

| Ƙarfin ɗaure, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Ƙarfin bayarwa, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Tsawaitawa cikin mm 50 (2 in) | Lura | A, B | A, B |

Note A: Matsakaicin tsayin daka a cikin 2 a [50 mm] za a ƙaddara ta hanyar ma'auni mai zuwa:

e = 625000 [1940] A0.2/U0.9

e = ƙaramar haɓakawa a cikin 2 a cikin ko 50 mm a cikin kashi, taso zuwa kashi mafi kusa

A = mafi ƙarancin 0.75 in2[500 mm2] da yankin giciye na samfurin gwajin tashin hankali, ana ƙididdige su ta amfani da ƙayyadaddun diamita na waje na bututu, ko faɗin ƙima na samfurin gwajin tashin hankali da ƙayyadadden kauri na bangon bututu, tare da ƙididdige ƙimar zuwa mafi kusa 0.01 in2 [1 mm2].

U= ƙayyadaddun ƙayyadaddun ƙarfin ƙarfi, psi [MPa].

Bayanin B: Duba Tebu X4.1 ko Tebu X4.2, duk abin da ya dace, don ƙananan ƙimar haɓakawa waɗanda ake buƙata don haɗuwa daban-daban na girman samfurin gwajin tashin hankali da ƙayyadaddun ƙarancin ƙarfi.

Lanƙwasa Gwajin

Don bututu, DN ≤50, isasshen tsayin bututu zai iya zama mai lanƙwasa sanyi ta hanyar 90 ° a kusa da mandrel cylindrical, diamita wanda shine sau goma sha biyu ƙayyadaddun diamita na waje na bututu, ba tare da haɓaka fashe a kowane yanki ba kuma ba tare da buɗe weld ba.

Bututu mai ƙarfi sau biyu akan DN 32 baya buƙatar yin gwajin lanƙwasa.

"Biyu-karin-karfi", galibi ana kiransa XXSbututu ne da ke da kaurin bango na musamman mai ƙarfi, wanda aka saba amfani da shi a aikace-aikacen masana'antu don jure matsi mai ƙarfi da yanayi mai tsauri. Kaurin bangon wannan bututu yana da kauri fiye da bututu na yau da kullun, don haka yana ba da ƙarin ƙarfi da ƙarfi.

Gwajin Lalacewa

Za a yi gwajin ƙwanƙwasa akan bututun walda sama da DN 50 a cikin ƙarin nauyi mai ƙarfi (XS) ko mai sauƙi.

Hanyar gwaji mai zuwa ta shafi Nau'in E, maki A da B.

Lokacin latsa lebur, weld ɗin yakamata a sanya shi a 0 ° ko 90 ° zuwa layin ƙarfin ƙarfi, dangane da takamaiman buƙatun.

Mataki na 1: Gwada ductility na weld. Kada a sami tsaga ko karyewa a cikin ciki ko na waje na walda har sai nisa tsakanin faranti bai wuce kashi biyu cikin uku na diamita na waje na bututu ba.

Mataki na 2: Ci gaba da danna lebur da gwada ductility a cikin yankin wajen walda. Kada a sami tsagewa ko karyewa a ciki ko waje na bututun da ya wuce walda har sai nisa tsakanin faranti bai wuce kashi ɗaya bisa uku na diamita na bututun ba, amma bai wuce kaurin bangon bututun ba.

Mataki na 3: Gwada amincin kayan ta ci gaba da danna lebur har sai samfurin gwajin ya karye ko bangon bututu ya shiga cikin hulɗa. Ana amfani da wannan don gwada kayan don matsaloli kamar fashe yadudduka, rashin jin daɗi, ko weld ɗin da bai cika ba.

Gwajin Hydrostatic

Za a yi amfani da gwajin hydrostatic, ba tare da yayyo ba ta cikin kabu ko jikin bututu.

Za a gwada bututun ƙarshen-ƙarshen ta hanyar hydrostatically zuwa matsi mai dacewa da aka bayar a cikin Tebur X2.2,

bututu mai zare-da-haɗe-haɗe za a gwada ta hanyar ruwa zuwa matsi mai dacewa da aka bayar a cikin Tebur X2.3.

Don bututun ƙarfe tare da DN ≤ 80, gwajin gwajin ba zai wuce 17.2MPa ba;

Don bututun ƙarfe tare da DN · 80, gwajin gwajin ba zai wuce 19.3MPa ba;

Gwajin Lantarki mara lalacewa

Don Nau'in E da Nau'in F Class B bututu DN ≥ 50, welds dole ne a fuskanci gwajin lantarki mara lalacewa.

Za a yi gwajin lantarki mara lalacewa daidai da ƙayyadaddun bayanai E213, E273, E309 ko E570.

Idan an yi gwajin lantarki mara lalacewa, za a yiwa bututun alama "NDE".

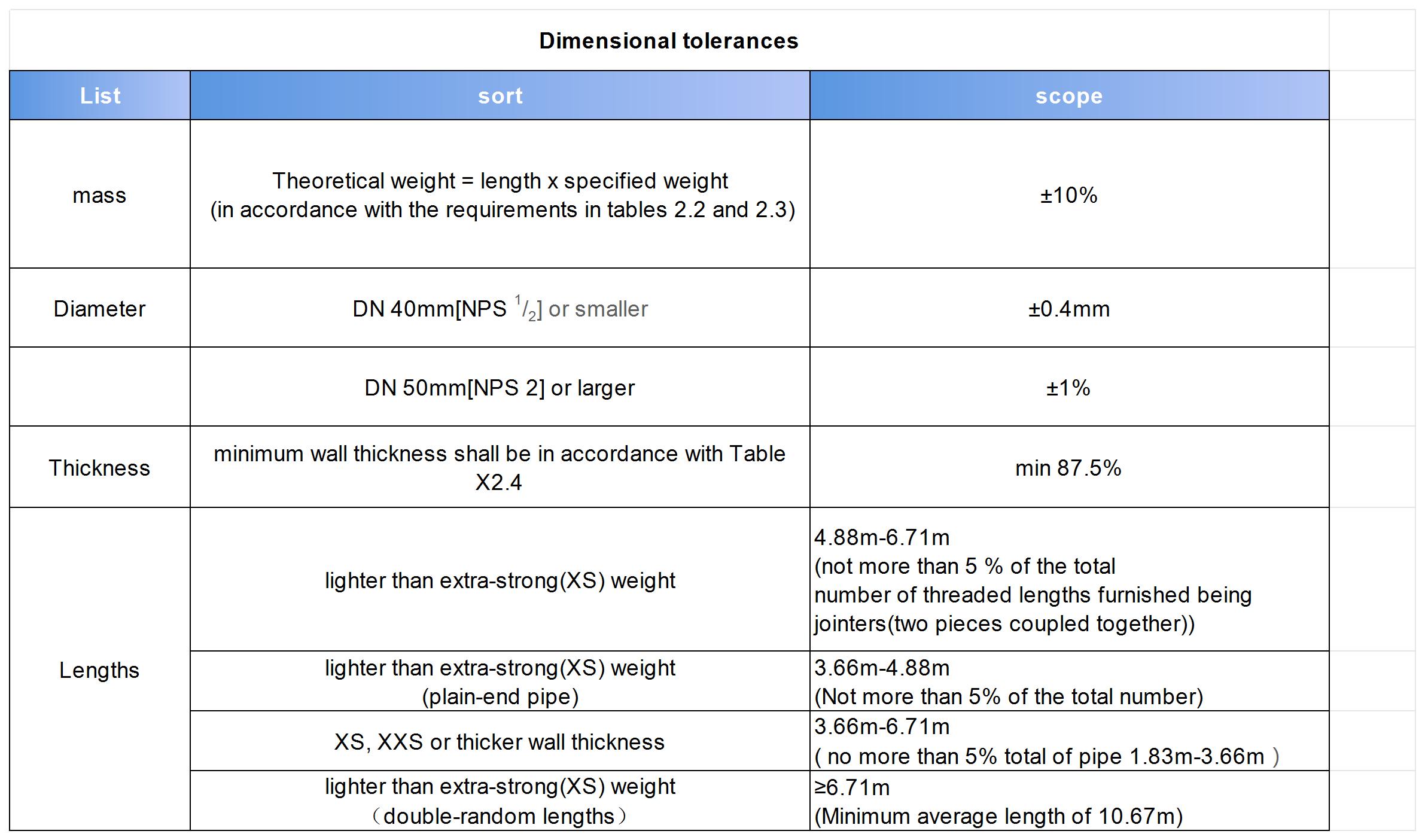

ASTM A53 Hakuri Masu Girma

Charts Nauyin Bututu da Jadawalin Bututu

Amfanin ASTM A53 Type E Pipe

Waldawar juriya hanya ce ta walƙiya mai rahusa, wanda ke sa bututun Nau'in E ba su da tsada don samarwa kuma sun dace da samarwa da yawa.

Tsarin waldawar juriya yana da sauri kuma ana iya samar da shi gabaɗaya, wanda ke ƙara yawan aiki kuma yana rage lokutan gubar.

Saboda kyawawan kaddarorinsa na inji da juriya na lalata, ana amfani da irin wannan nau'in bututu sosai a aikace-aikace iri-iri don jigilar ruwa, kamar ruwa, gas, da tururi.

Za a iya yin kusan ganuwa da walda ta hanyar kyakkyawan kula da walda, wanda ba wai yana inganta bayyanar bututun ba har ma yana iya rage juriya ga kwararar ruwa ta hanyar walda..

Aikace-aikace na ASTM A53 Type E Karfe bututu

Amfanin tsari: A cikin ginin, ana amfani da bututun ƙarfe na A53 Nau'in E azaman kayan haɗin ginin kamar goyan bayan gini da tsarin truss.

Bututun ruwa: Ana amfani da shi a cikin tsarin samar da ruwa don gine-gine, ciki har da tsarin yayyafa wuta.

Tsarin tururi: A cikin wuraren masana'antu, ana amfani da wannan bututun ƙarfe a cikin tsarin isar da tururi, musamman ma a cikin aikace-aikacen ƙananan matsa lamba.

Watsawar iskar gas: Ana amfani da shi don jigilar iskar gas ko sauran iskar gas, musamman a tsarin samar da iskar gas na birni da na zama.

Sinadarai shuke-shuke: don isar da ƙananan tururi, ruwa, da sauran sinadarai.

Takarda da masana'antar sukari: don isar da albarkatun kasa da samfuran da aka gama, da kuma zubar da sharar gida.

Tsarin dumama da sanyaya: Ana amfani da shi sosai don bututu a tsarin dumama, iska, da kwandishan (HVAC).

Maganin sharar ruwa: Domin isar da ruwan sha ko ruwan da aka sarrafa.

Tsarin ban ruwa: Bututun ruwa da ake amfani da su don ban ruwa na ƙasar noma.

Ma'adinai: Ana amfani da shi don jigilar ruwa da iskar gas a cikin ma'adinai.

Kayayyakinmu masu alaƙa

Tun lokacin da aka kafa shi a cikin 2014, Botop Steel ya zama babban mai samar da bututun ƙarfe na carbon a Arewacin kasar Sin, wanda aka sani don kyakkyawan sabis, samfurori masu inganci, da cikakkun mafita.

Kamfanin yana ba da nau'ikan bututun ƙarfe na carbon da samfuran da ke da alaƙa,

ciki har da sumul, ERW, LSAW, da SSAW bututun ƙarfe, da kuma cikakken jeri na kayan aikin bututu da flanges.

Kayayyakin sa na musamman kuma sun haɗa da galoli masu daraja da austenitic bakin karafa, waɗanda aka keɓance don biyan buƙatun ayyukan bututun.

Tags: ASTM a53, nau'in e, daraja a, daraja b, erw.

Lokacin aikawa: Mayu-12-2024